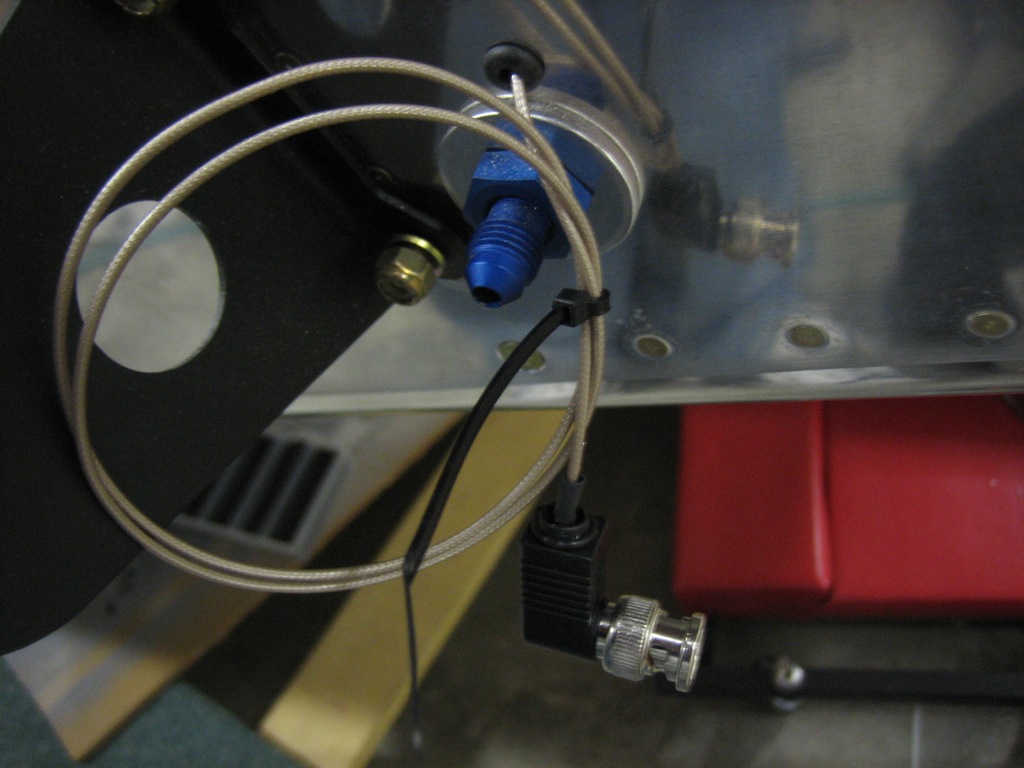

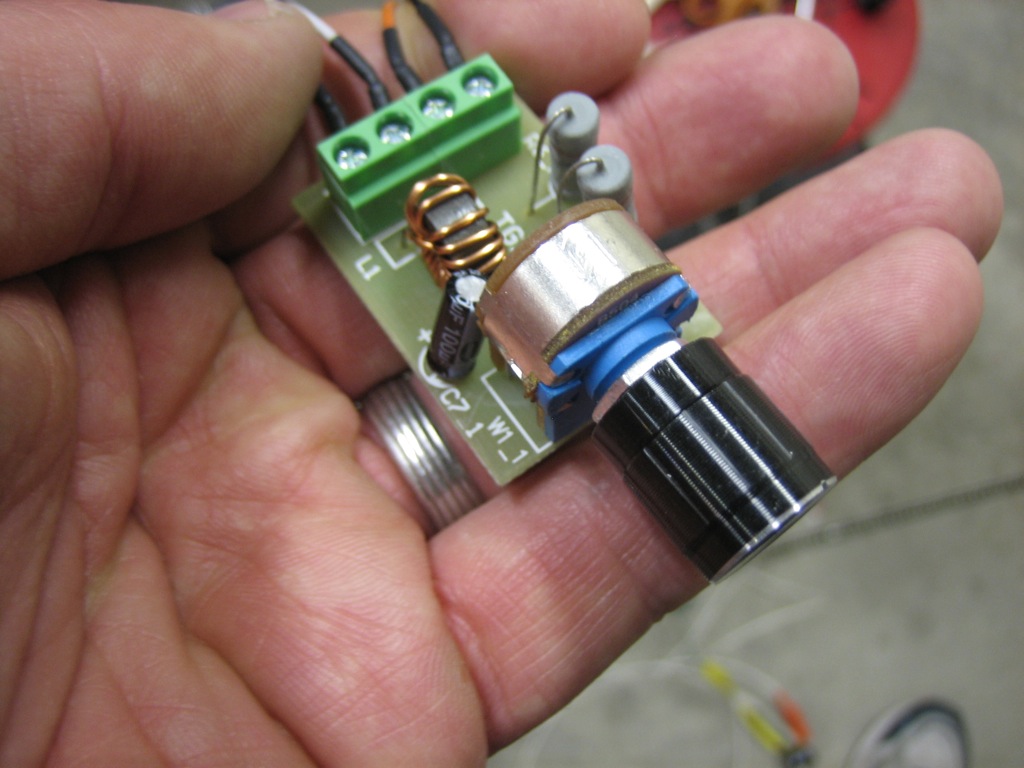

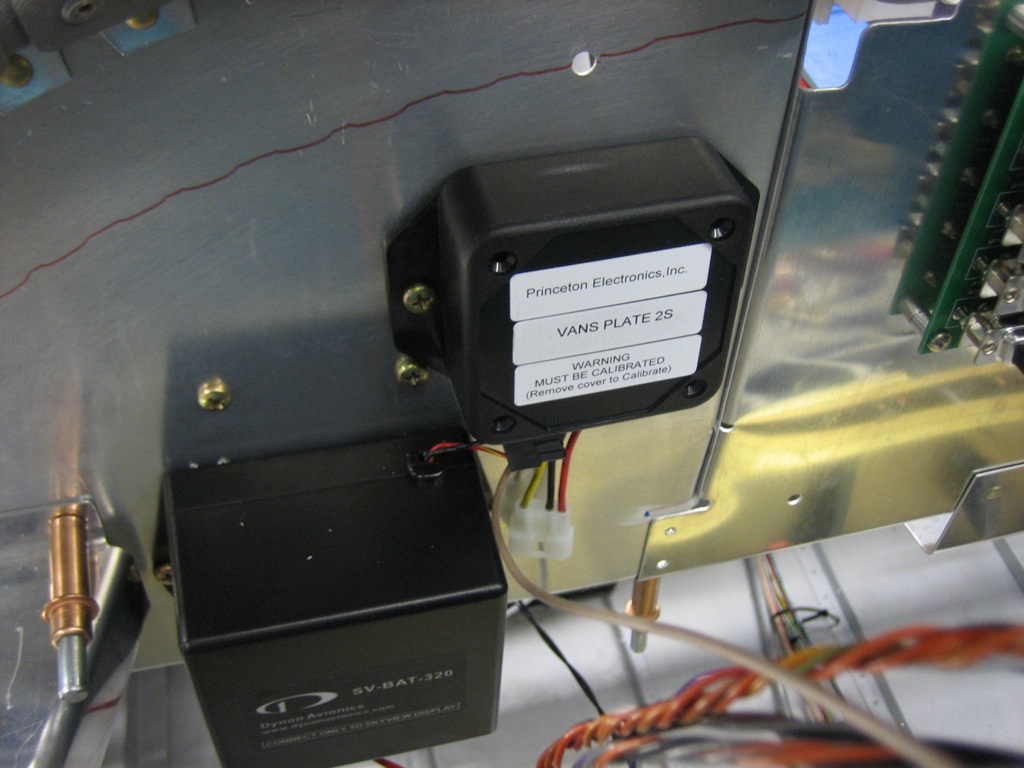

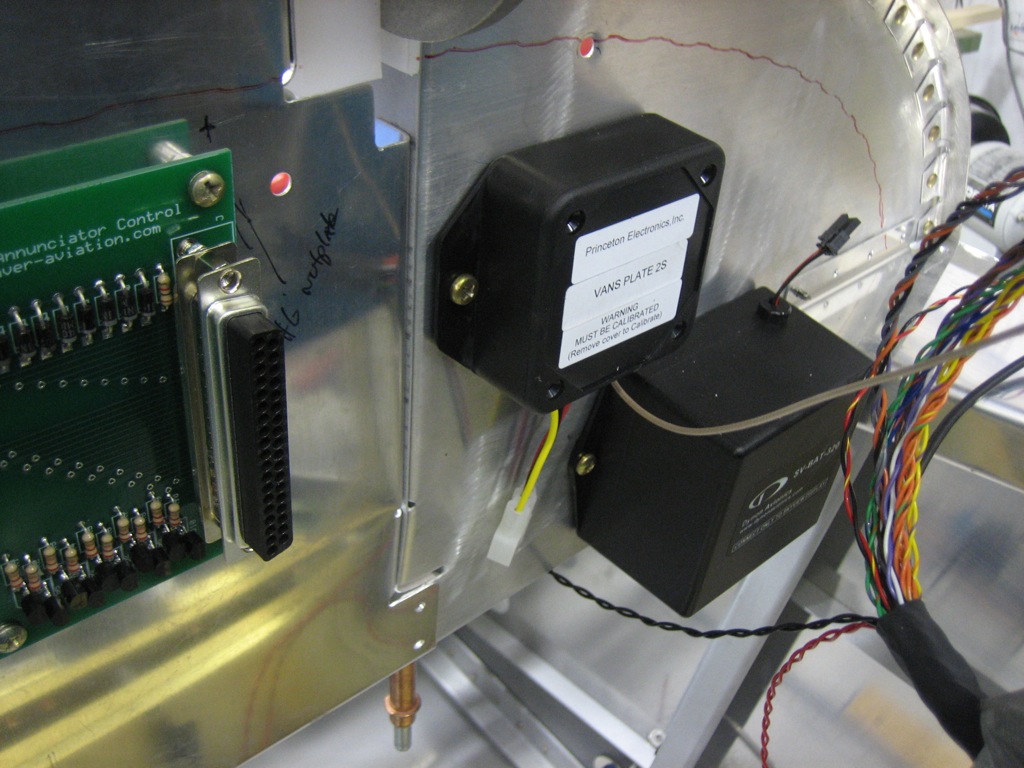

I received my capacitive fuel senders from Princeton Electronics. They don’t have a website, but you can reach them at (616) 243-8800. They have both 2 level and 5 level senders. Both convert the capacitance range from 0-5 volts, but the 2S model only has calibration points for empty and full. The 5S model has three intermediate points which is important if you want a linear movement on an analog gauge. Since I’m using the SkyView which has numerous intermediate calibration points, it doesn’t matter if the sender is linear or not, so I’m just using the 2S sender. I cut most of the wires off and installed some four position molex connectors on each sender so that they can be easily removed if necessary (well, except for the cable with the BNC connector).

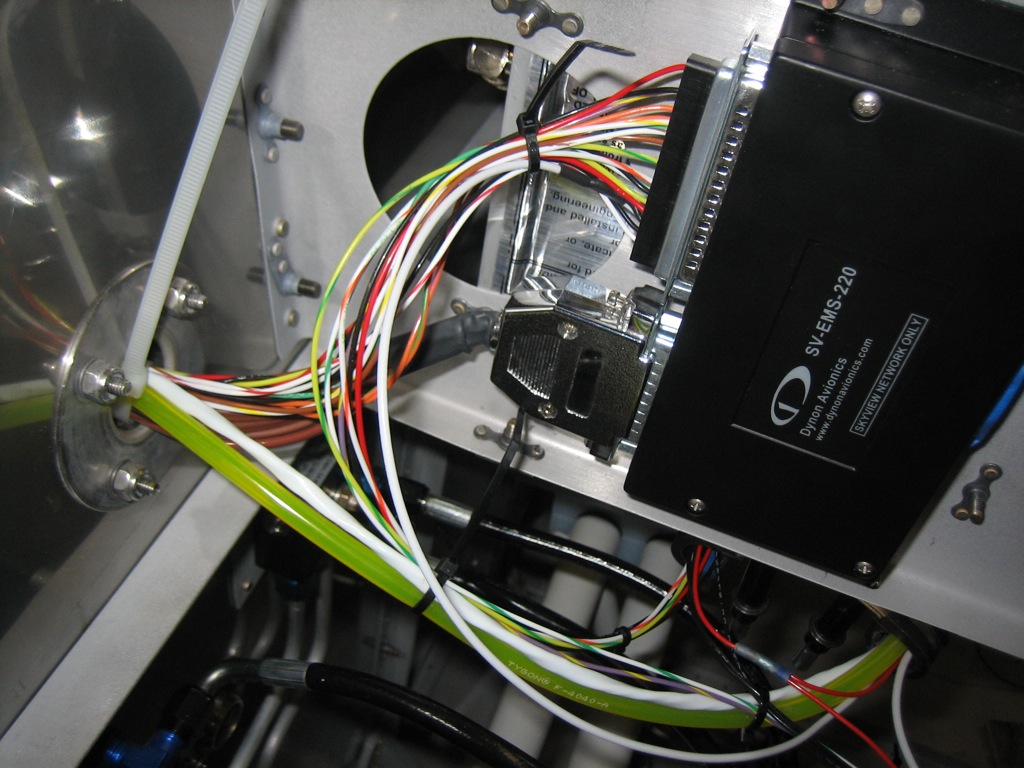

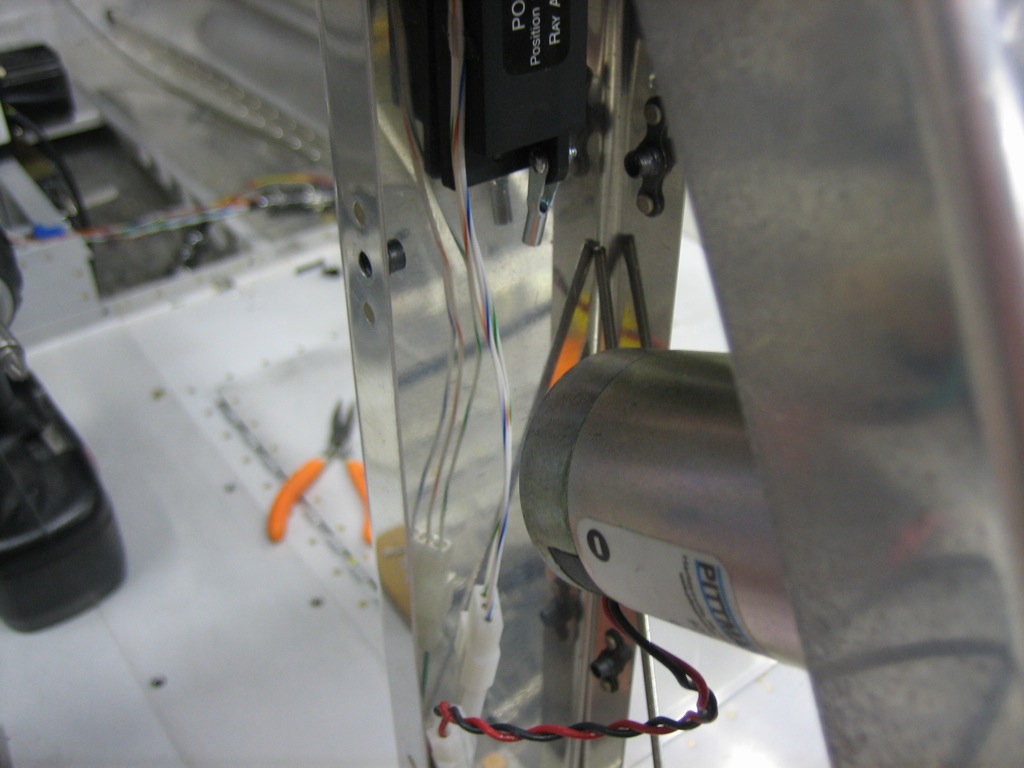

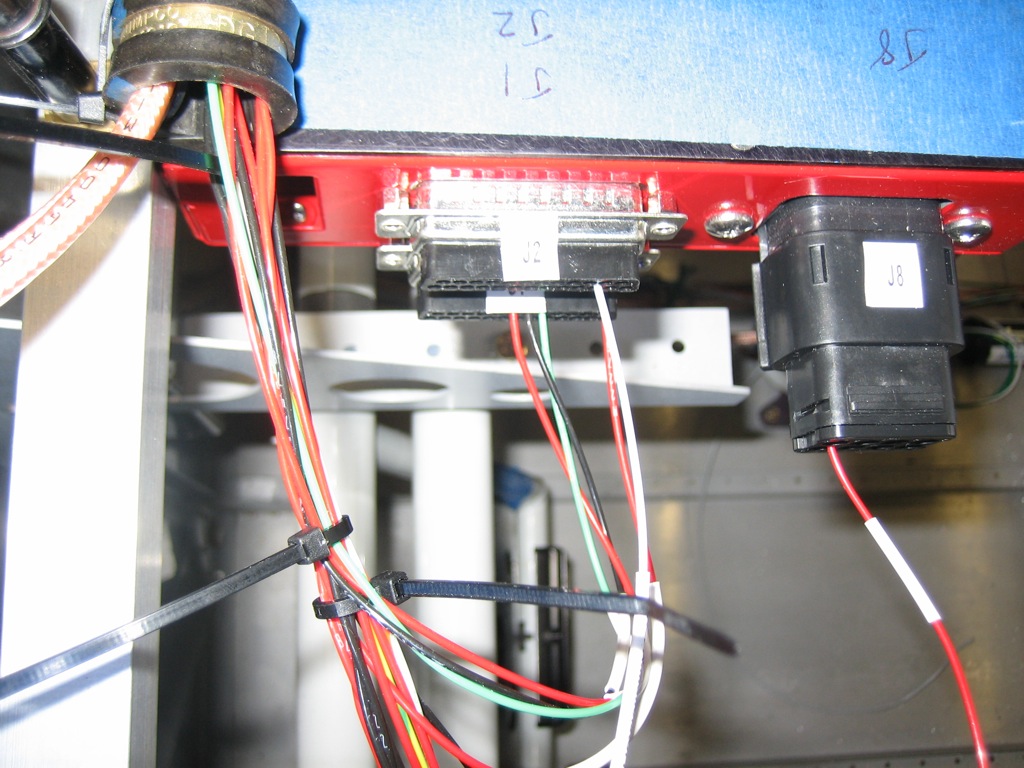

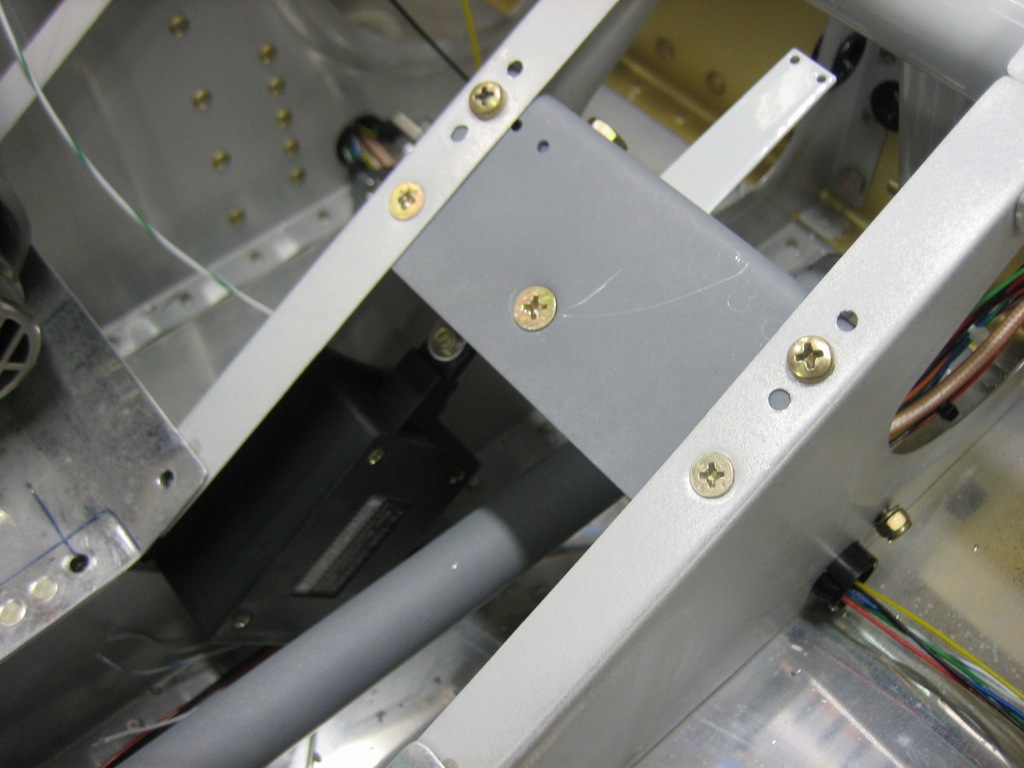

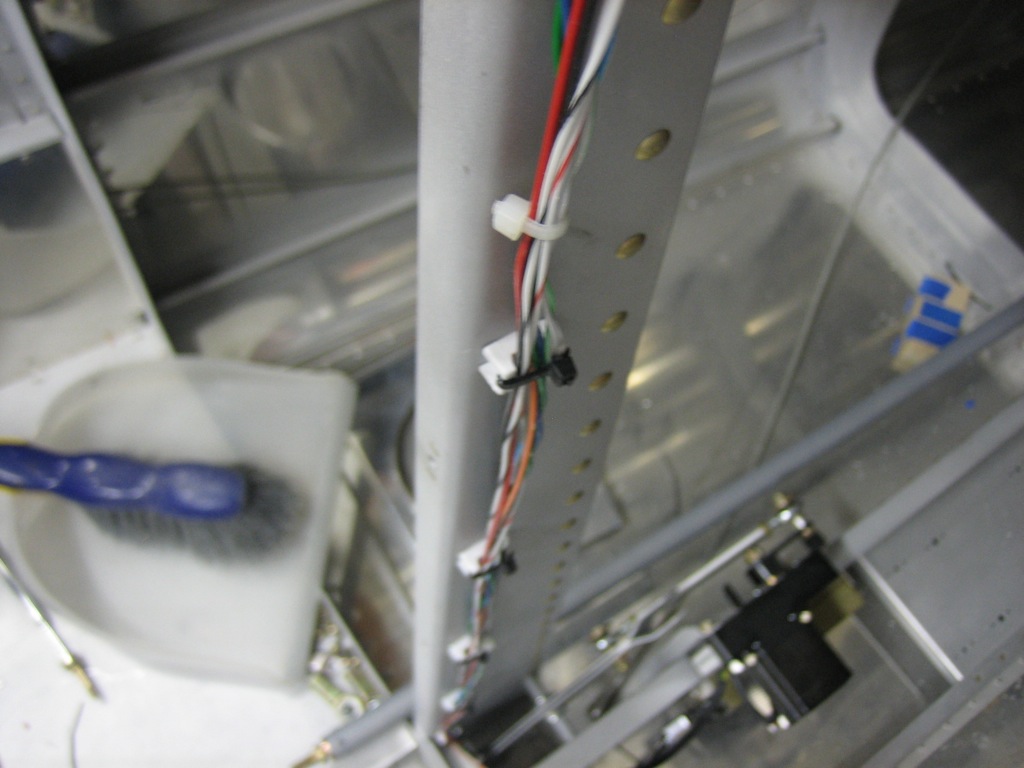

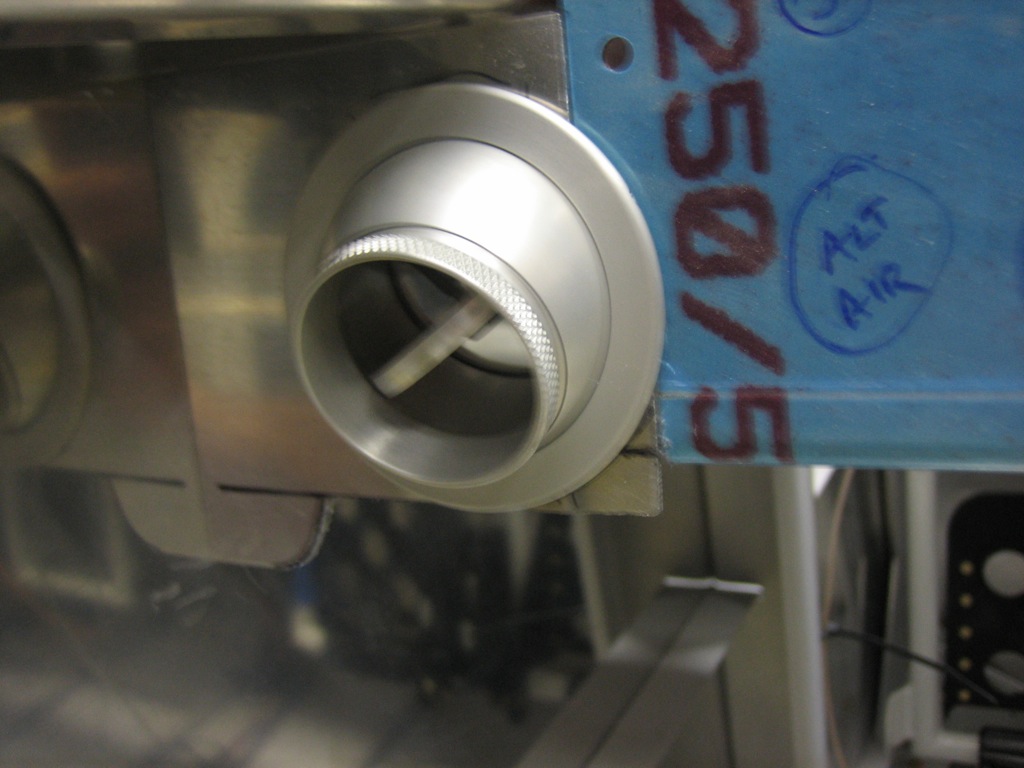

I installed the senders on the aft side of the subpanel since they need to be accessed during calibration. This is the left sender.

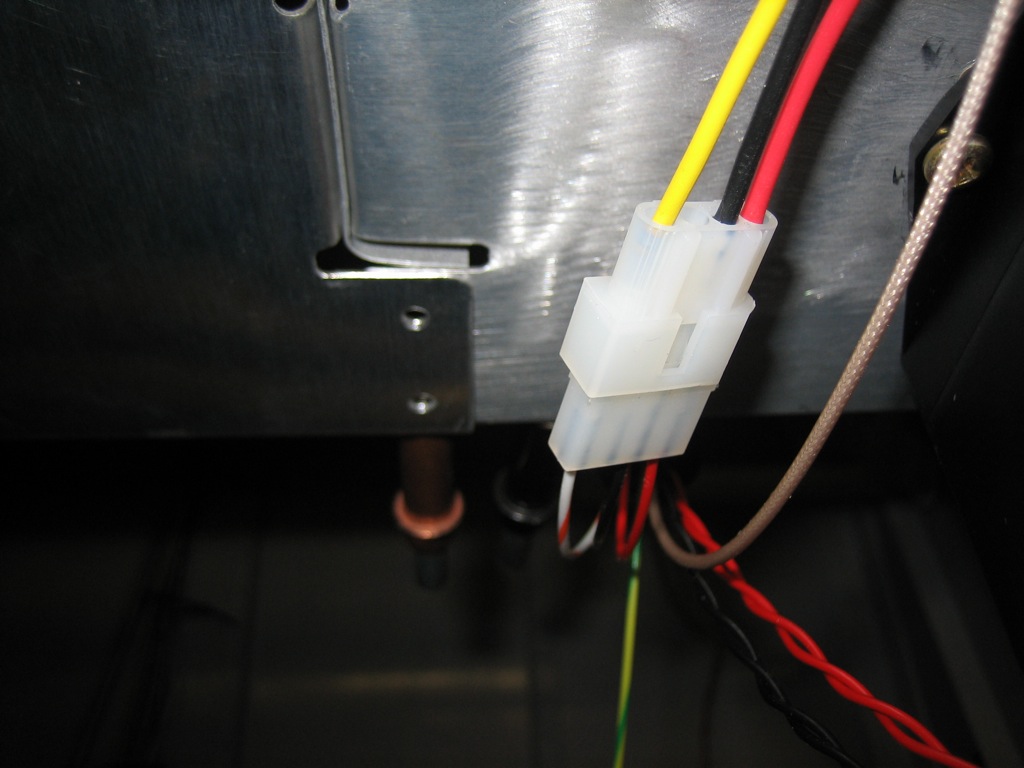

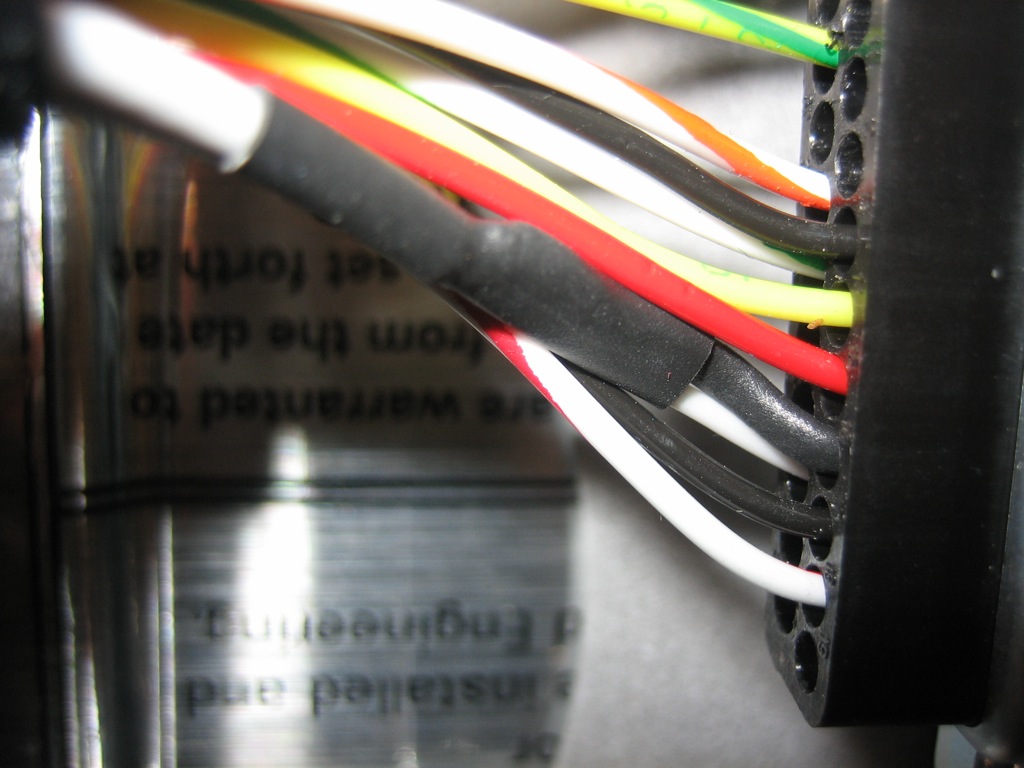

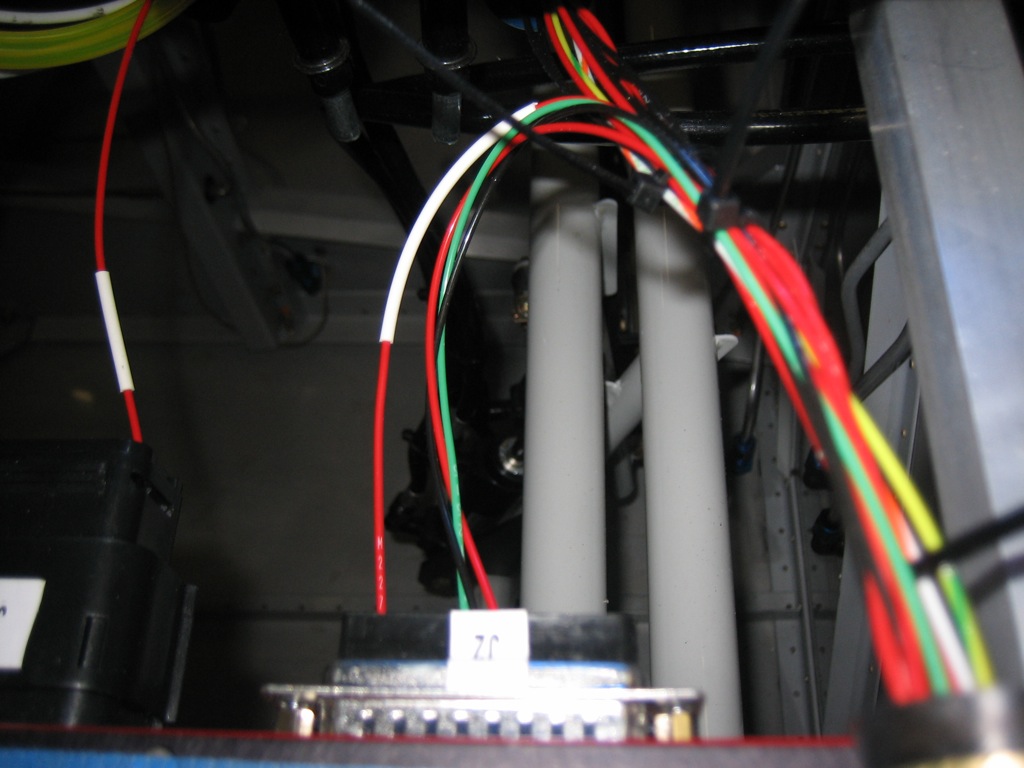

The right one is in the same relative position.

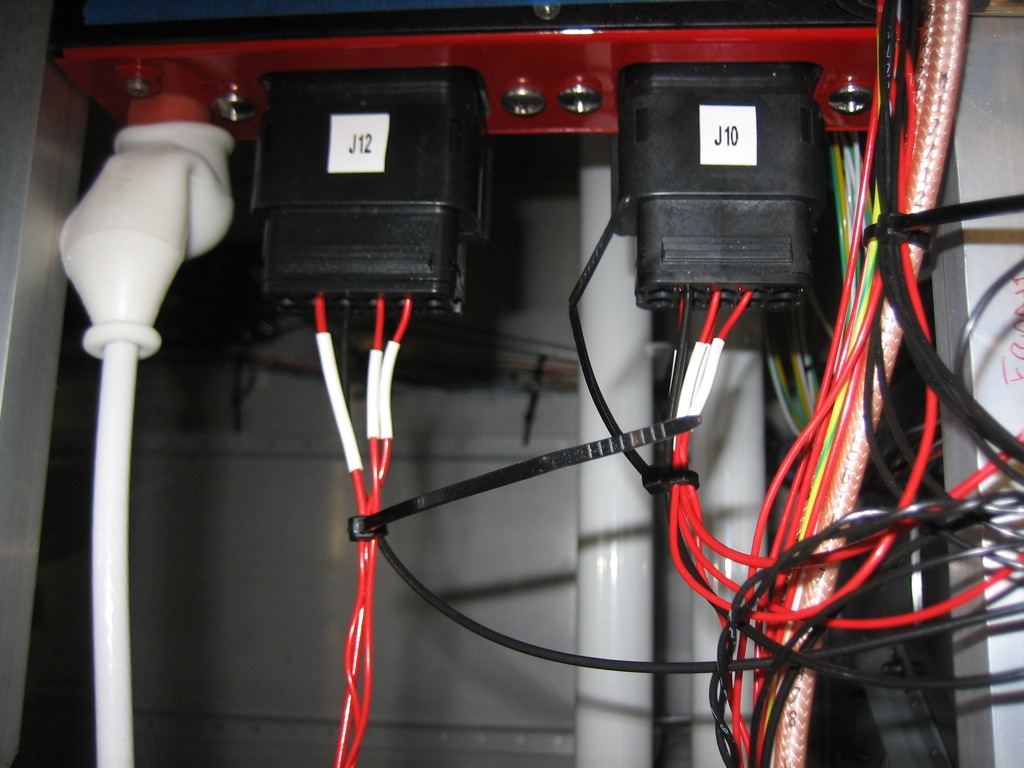

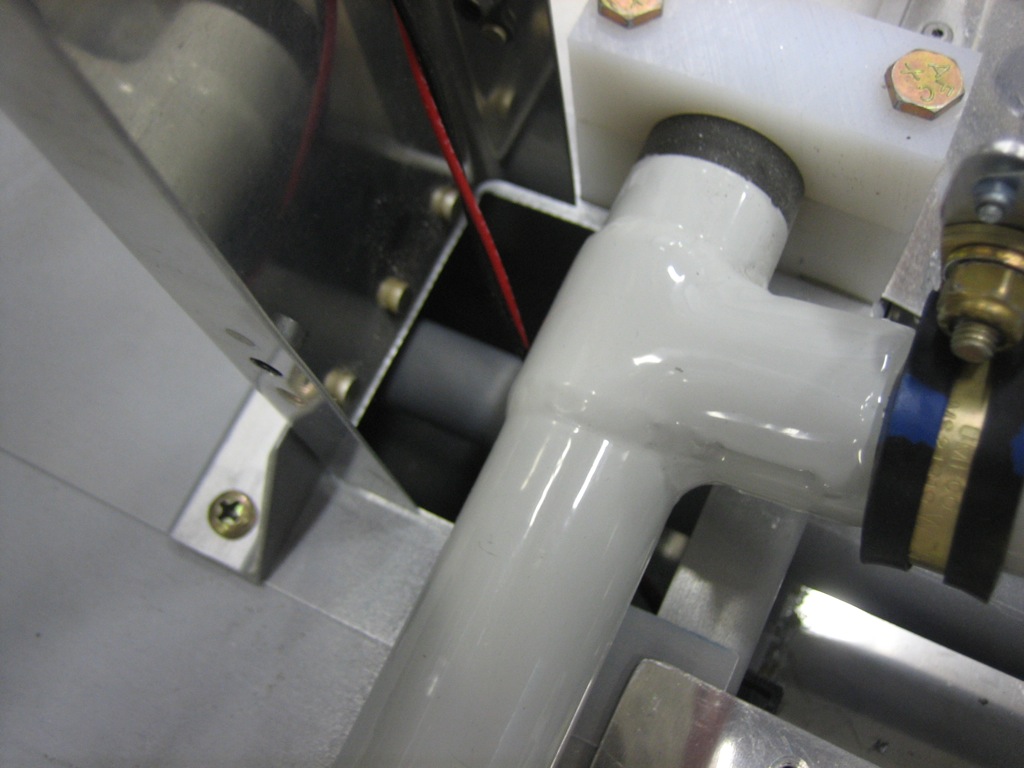

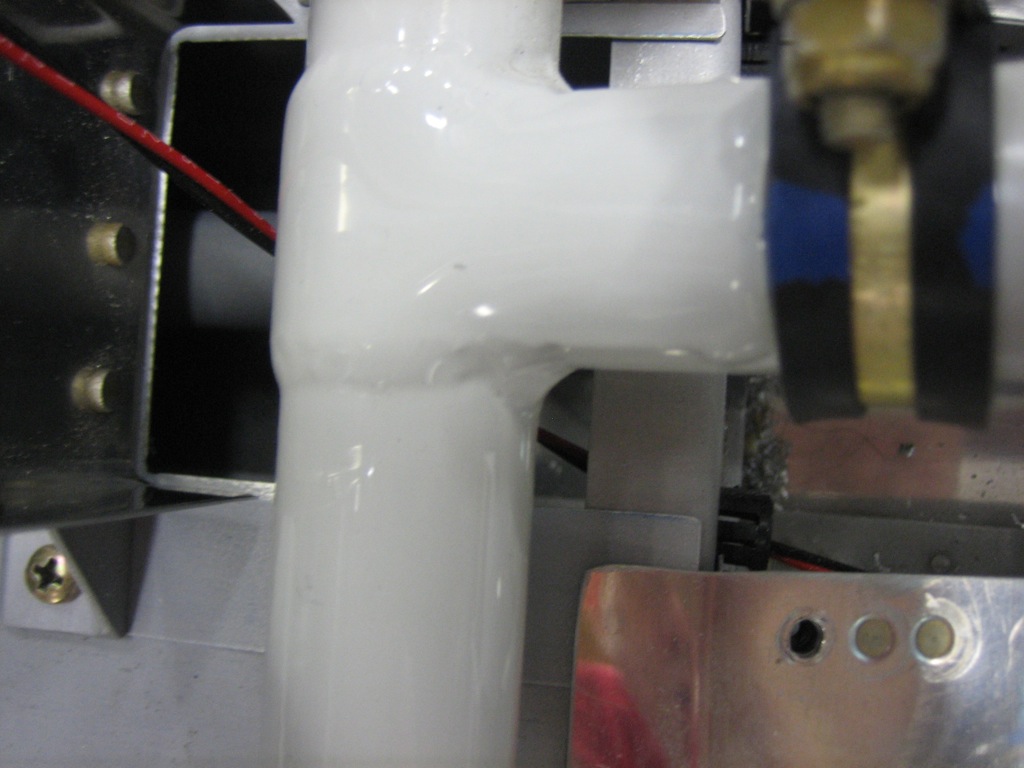

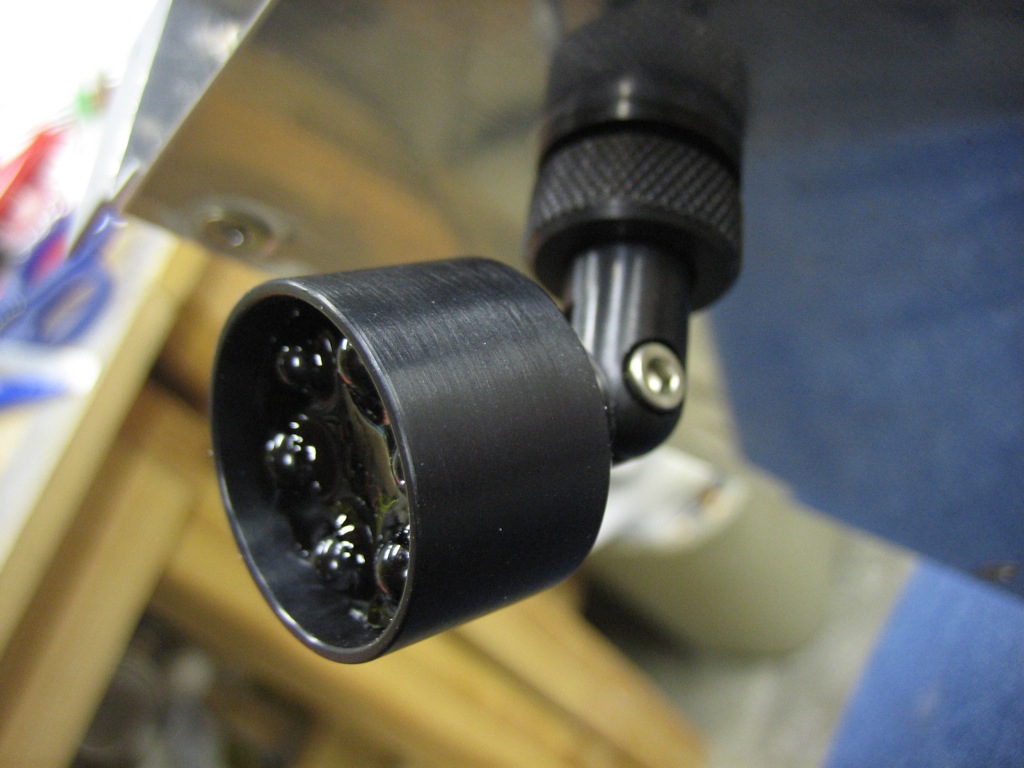

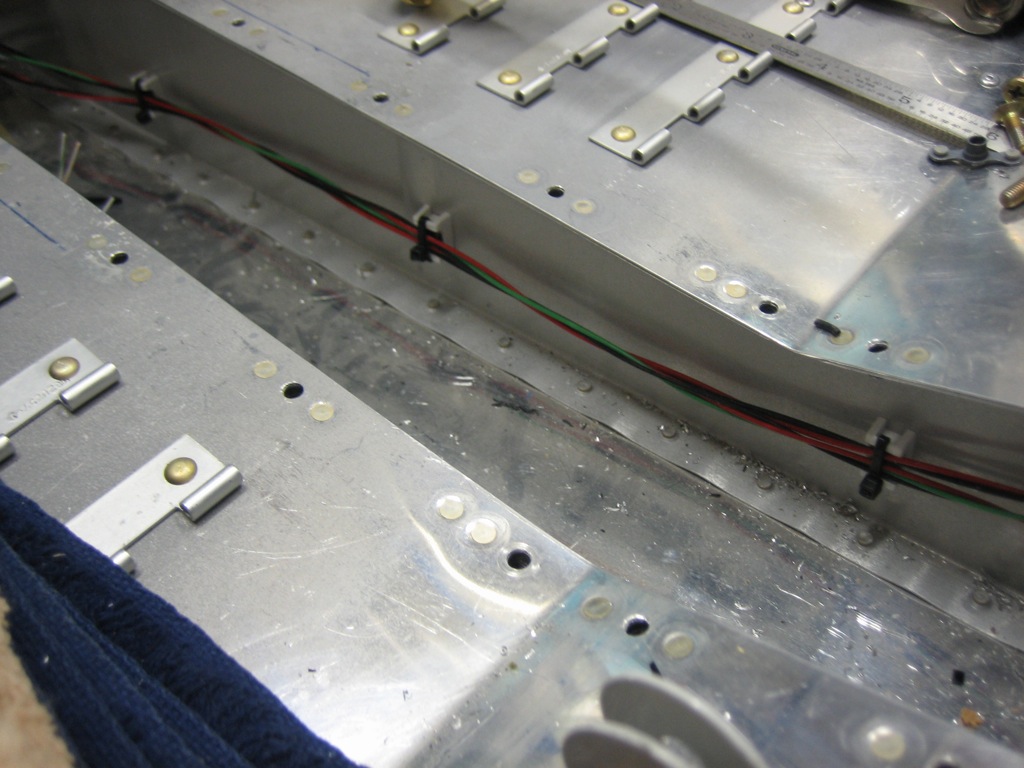

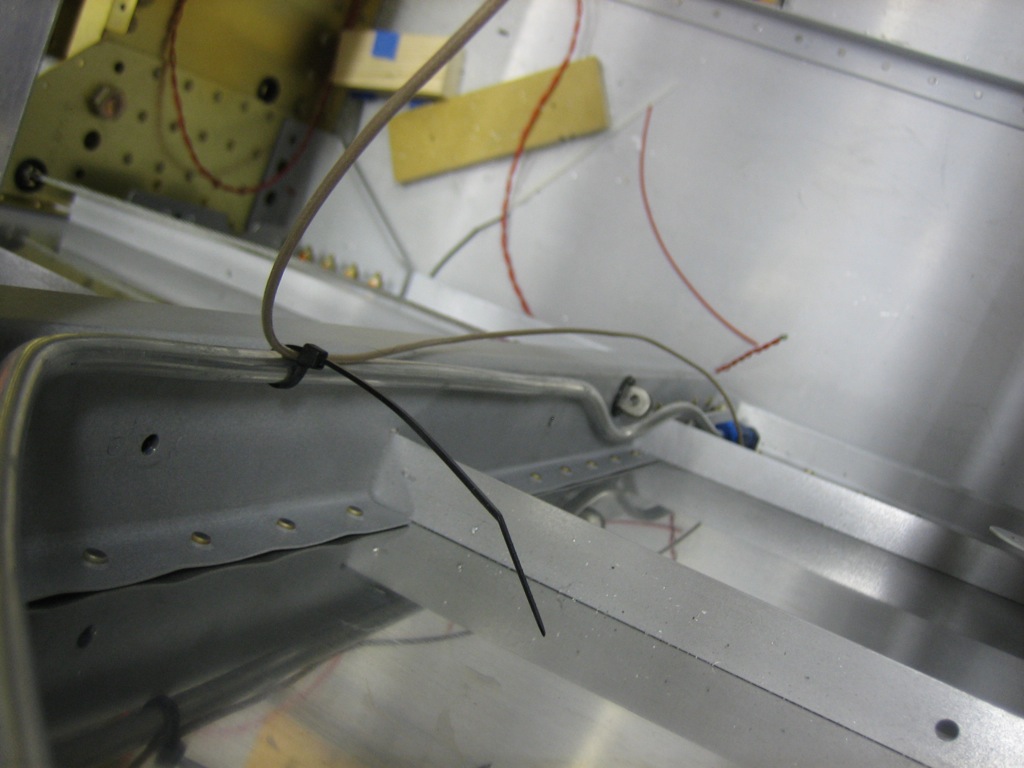

The cable to the fuel tank will get routed down the vent line, but I’m leaving it loose for now until I nail down the overall routing.

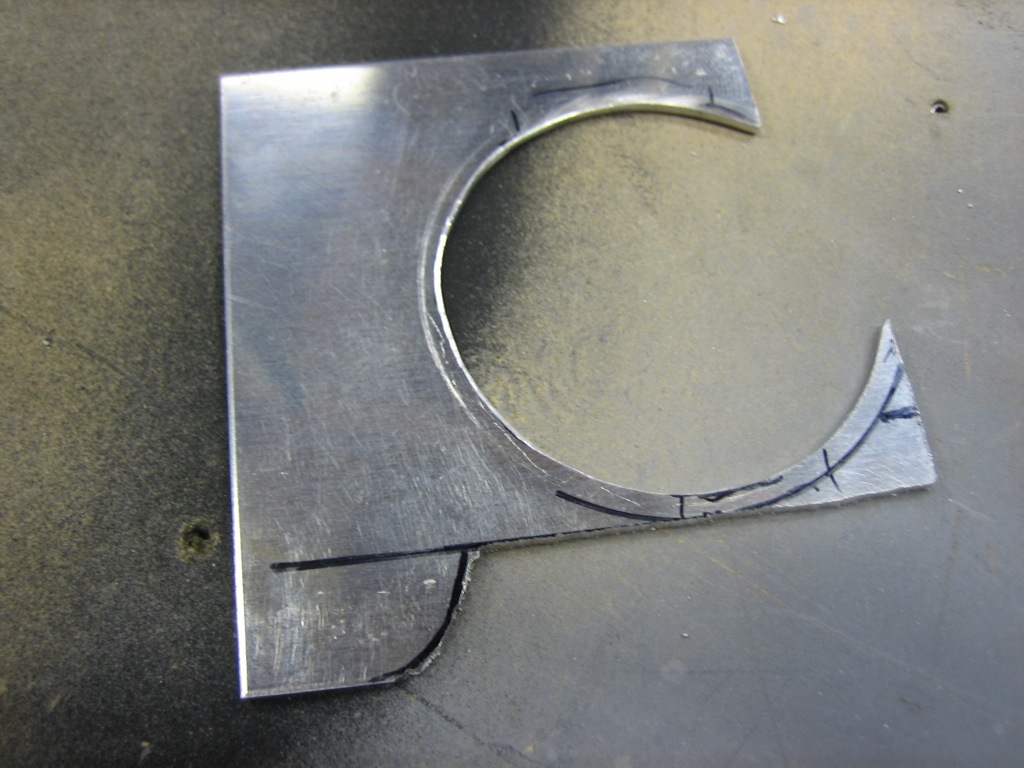

I drilled 1/4″ holes just above the vent bulkhead fitting and ran the cable with the BNC connector out through it. This will get connected to the BNC fitting on the fuel tank which is wired up to the capacitive plates inside the tank.