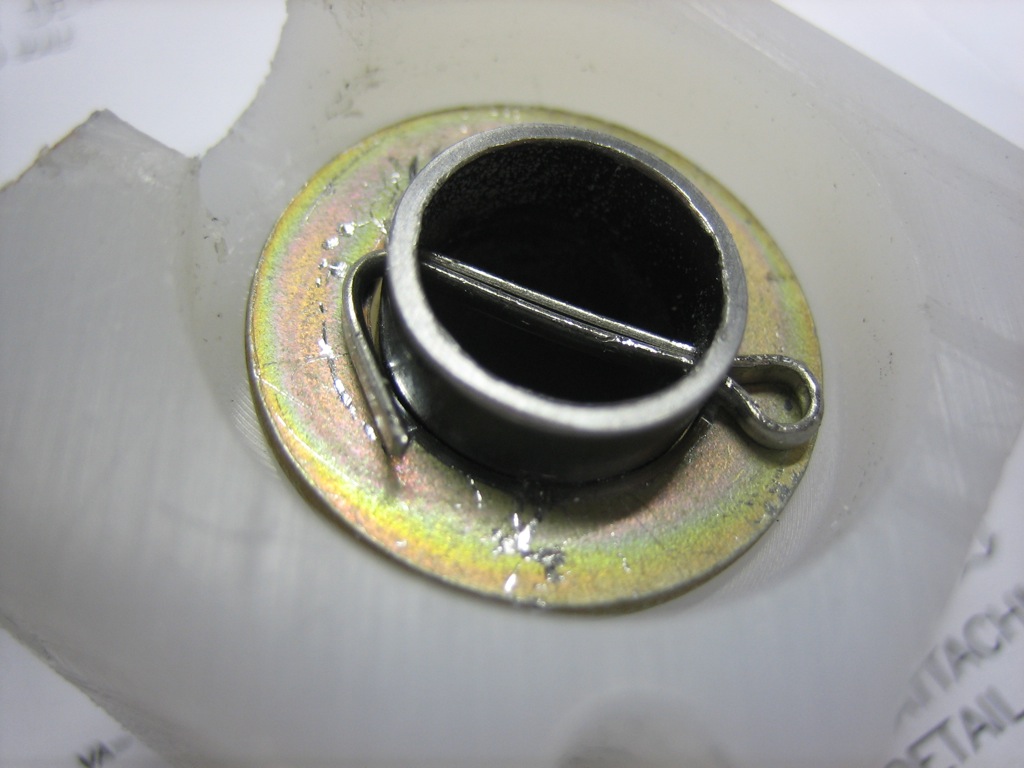

I drilled the bracket shaft with a #53 bit and installed the cotter pin. This is a snug fit, so there is zero slop in the bracket.

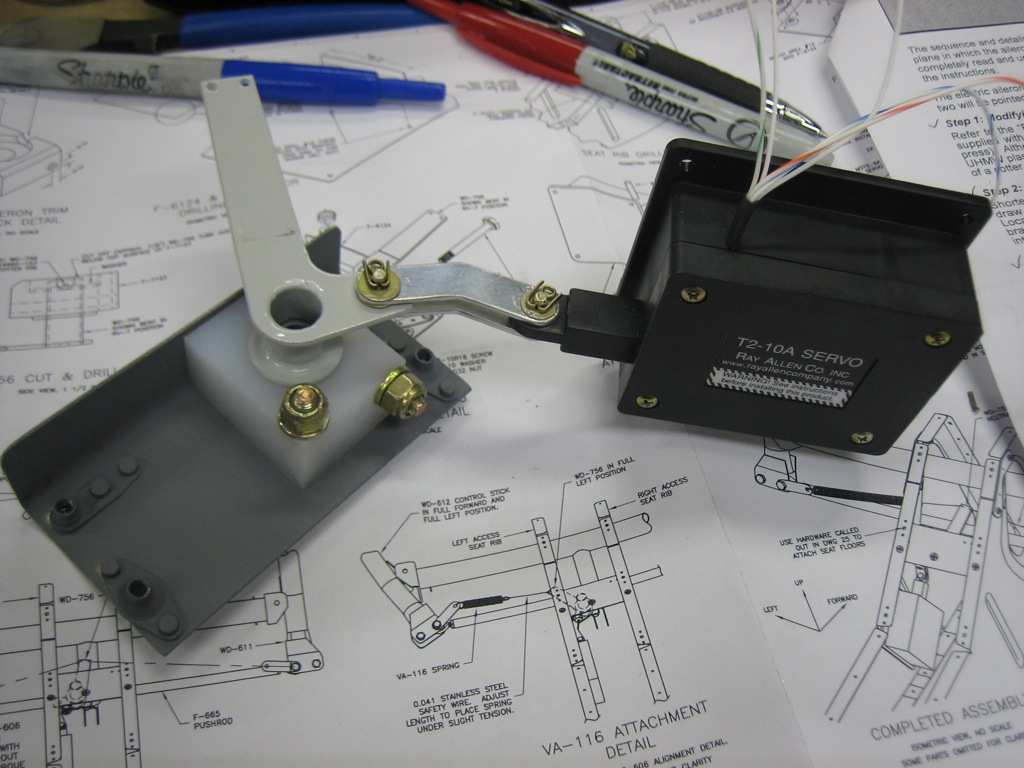

Here’s the whole mechanism assembled. The servo pushes on the bracket and will turn it around the shaft. Spring linkages will connect the other bracket arm to the control sticks to bias the neutral point.

Here’s a closeup of the linkage between the servo and the bracket.

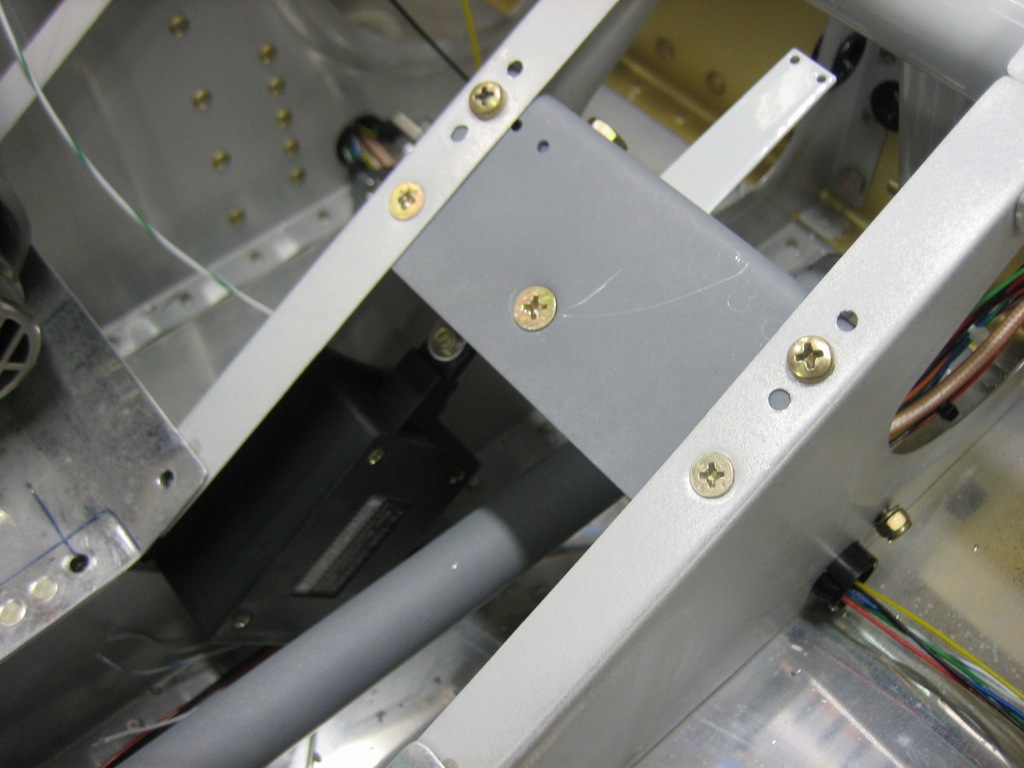

The bushing block is bolted to the mounting flange with one #10 screw and one AN3 bolt through the holes I drilled yesterday.

The hole for the #10 screw was dimpled in the mounting flange and the bushing was countersunk since the seat pan gets installed right above this and there wouldn’t be clearance for a bolt head. The other hole can just use a normal bolt since there are no space considerations.

Finally, I mounted the bracket between the seat ribs. I had to remove the elevator pushrod to get the angle drill in here to drill the servo to the skin.