I built a couple of the EAA Chapter 1000 workbenches. Ignore part of the tail kit on the far table, this picture was taken a few days later when it came. I still have a bit of shop prep to do as you can see.

I flew down to Riverside, CA with a couple of good friends of mine, Dan Zitter and Andre Boule, to attend the EAA SportAir sheet metal workshop. The flight down was beautiful with a nice 10-15 kt tailwind most of the way.

We flew right over the approach end of 16R at Van Nuys…

and landed at Riverside Municipal. The class was at Flabob, but RAL had rental cars.

I really like the terrain around Riverside.

The class started Saturday morning around 8am. I’m pretty sure my friends and I were the youngest people there.

Our teacher was Buck Greenlaw.

Andre doing some assembly.

Dan doing some drilling.

Andre squeezing some rivets.

Our “classroom”.

Me with our completed assembly.

Our class was held at the historic EAA chapter 1 hanger.

Leaving Riverside.

Lousy groundspeed on the way home. At one point, it dipped to around 80kts.

And a nice clear night arrival back at Reid-Hillview.

Overall, I was pretty disappointed with the SportAir class. I had heard great things about the class, so I had high expectations. The materials were complete shit though. The pieces didn’t remotely line up and edges of sheets weren’t even straight. On top of that, our instructor was pretty disappointing. Despite his impressive credentials, I think I would have learned a hell of a lot more from another RV builder.

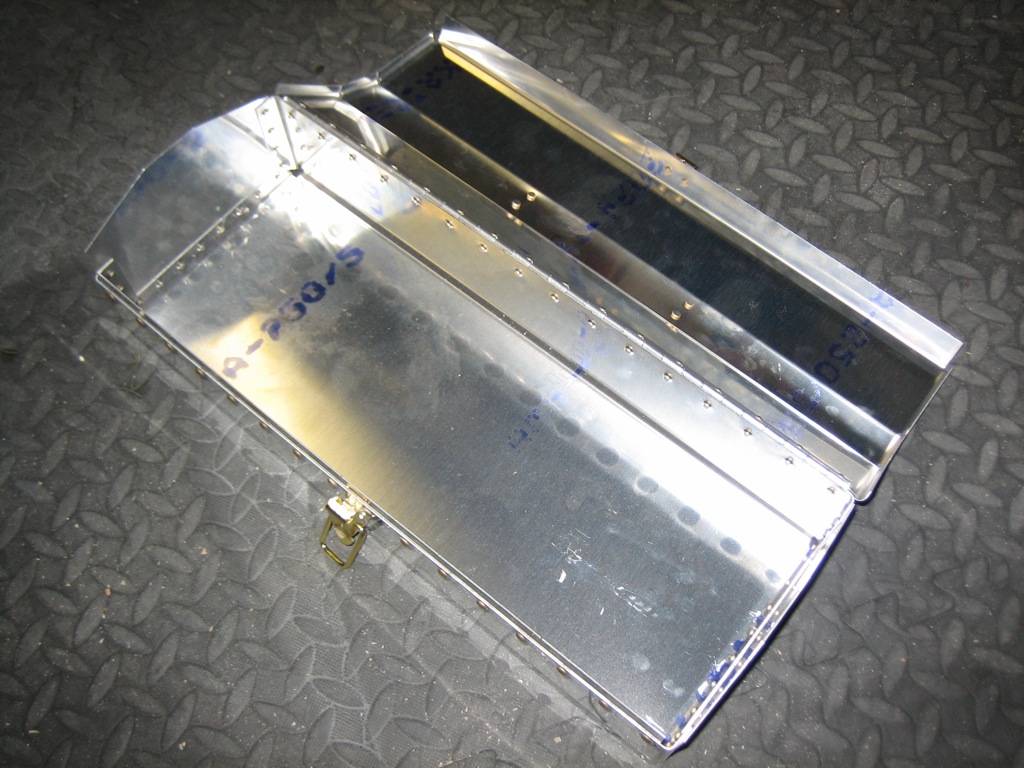

I also built Van’s RV Training Project practice kit which is similar to many of the control surface used on Van’s aircraft. This was a much more involved project than the toolbox, but still only took me about 6 hours (hey, I’m getting a little faster :-).

I’m not getting to spend much time on preparing for the RV project since I’m trying to finish my kitchen remodel. I’m hoping to finish that in the next couple of months, take the SportAir Sheet Metal class in early October, get the shop ready in the fall and start the kit around the end of the year.

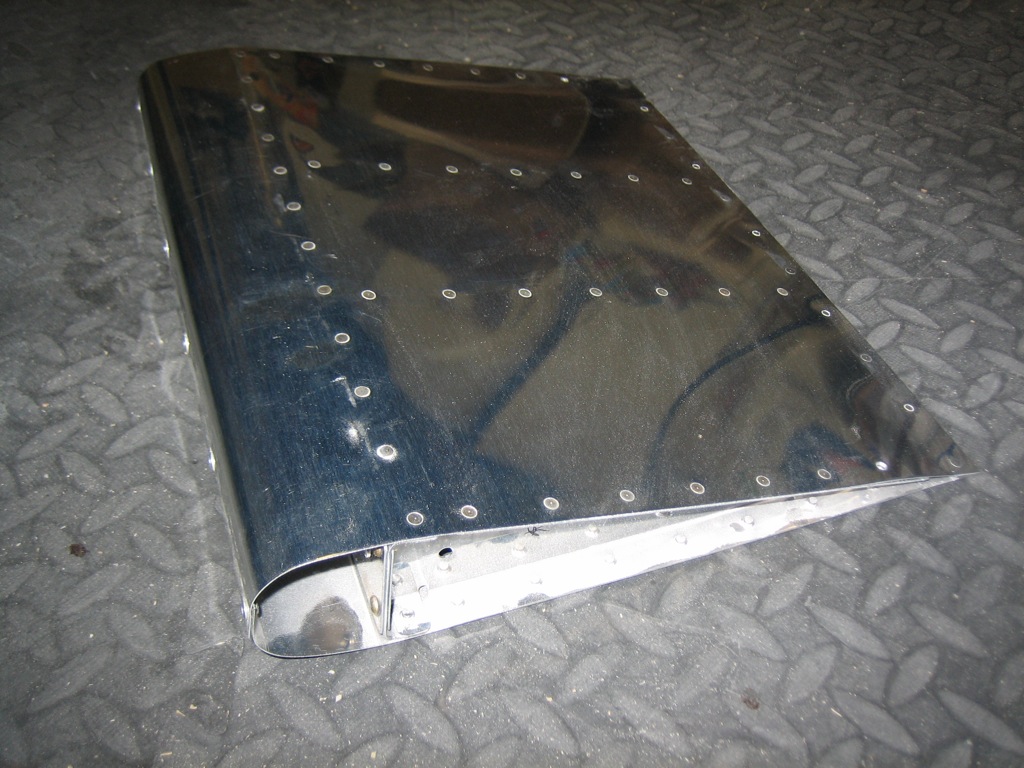

Before attending the SportAir Sheet Metal class, I thought I’d try building Van’s toolbox practice kit. My dad and I knocked this out in about six hours (which seems really slow, but aluminum construction was pretty new to both of us). It was a good introduction because it was fairly simple but had examples of several different skills that will be used to construct the actual plane.

The tool kit from Isham arrived minus the DRDT-2 dimpler which was back-ordered. Details can be seen on the tools page.

I picked up a new tool chest at Lowes. I’ll be able to roll the bottom portion around the shop and keep all my tools close to what I’m working on. I’ll also put an MDF top on it so I can use it as a small workbench.

I visited Van’s Aircraft today with a couple of friends and took demo rides in the RV-7A and the RV-10. I went there really to confirm that I wanted the RV-10. I currently own a 1/4 share of a nice Cessna Cardinal. It’s a great plane, but like many GA aircraft, it is really underpowered which translates into a poor useful load and rather anemic climb. I’d also love to have a little faster cruise speed and better range. The RV-10 has a much larger engine which results in a great useful load and great climb rate and is 30-40kts faster than the cardinal.

While I’d love to have an aerobatic aircraft (and hopefully will one day), I primarily need a fast IFR cross-country plane. I was fairly certain before the visit that the RV-10 was the plane I would choose, but I was even more impressed with the plane than I expected I would be.

Update 12/17/2008: Unfortunately, the collapse of the economy (and our net worth) made the RV-10 an unwise choice at this time. Instead, I’m going to build an RV-7 now and will hopefully build an RV-10 after I finish with the RV-7.