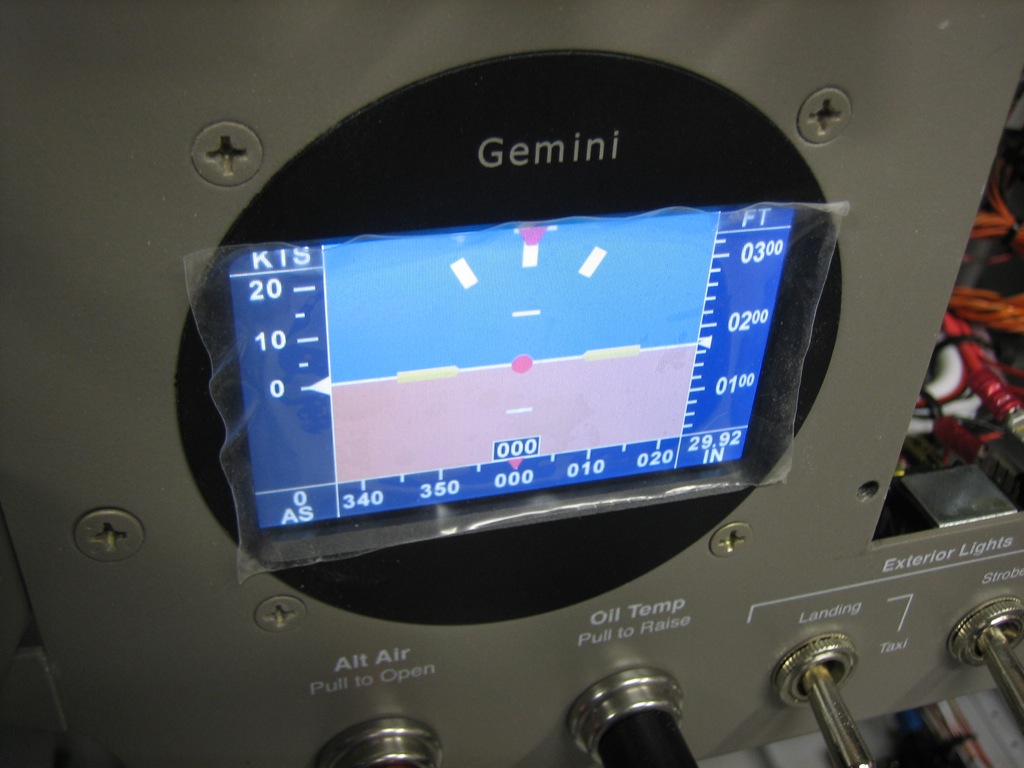

I’ve been planning on updating from my SkyView Touch displays to the SkyView HDX displays for quite awhile, but was holding off until Dynon offered a trade-in plan. They recently did that, but the trade-in offer was disappointing, so I decided to just buy the new displays and will sell these. Here’s the old pilot side display.

And here’s the old co-pilot’s side display. These displays have worked perfectly and will be a great addition to some other builder’s plane.

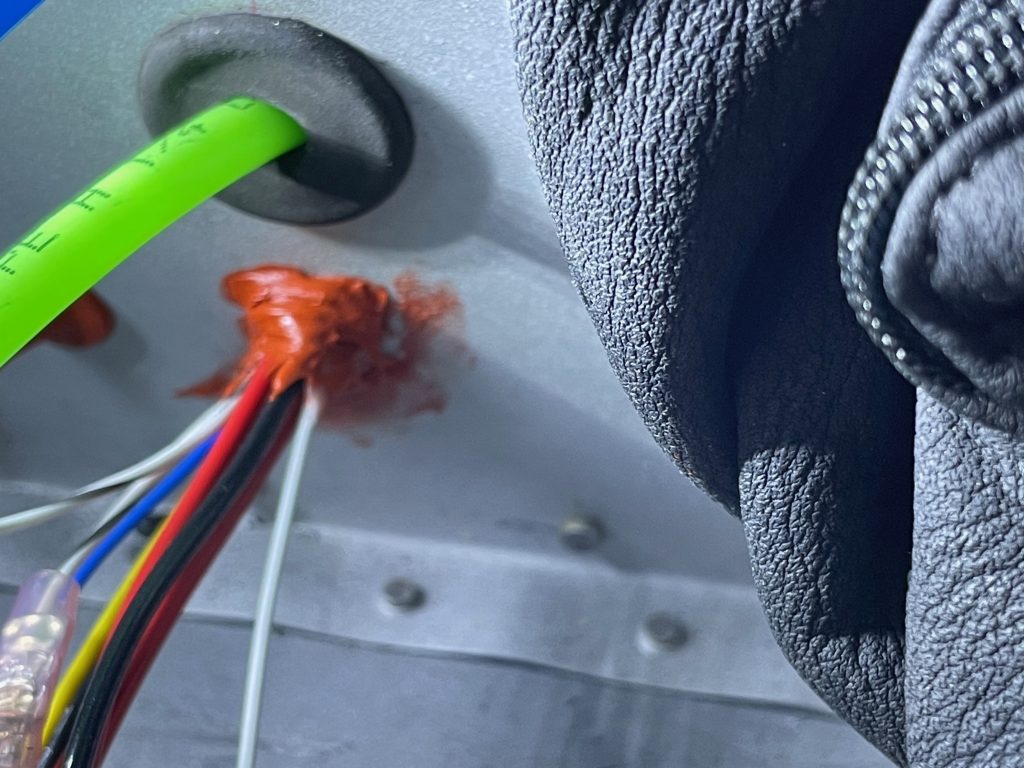

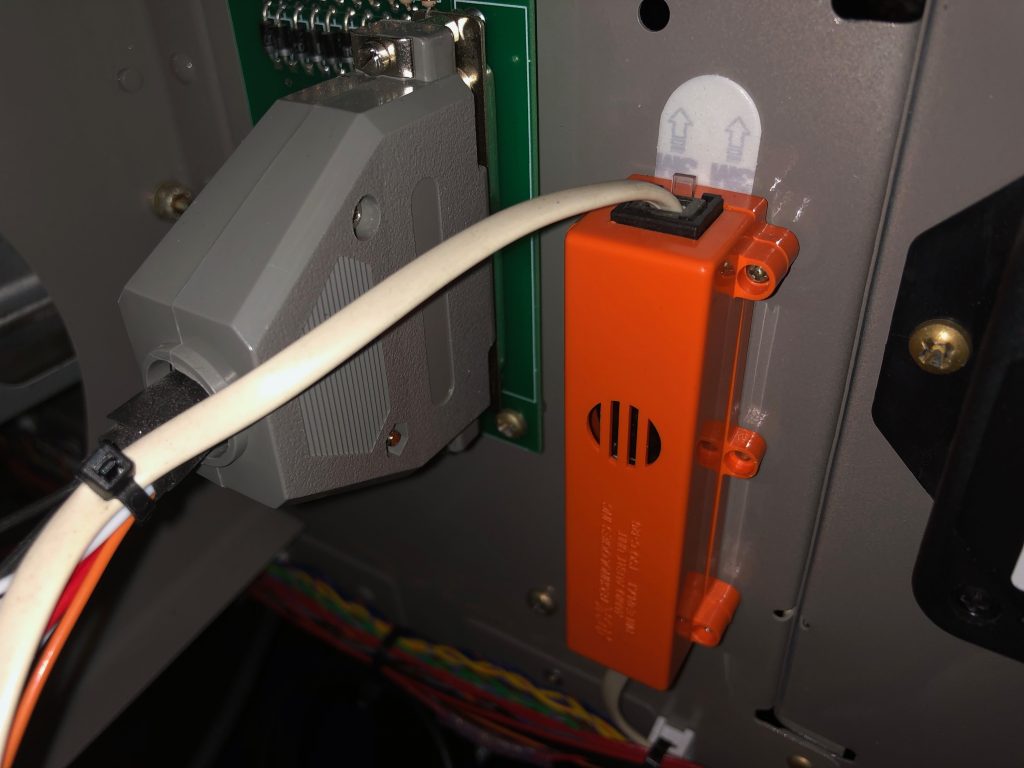

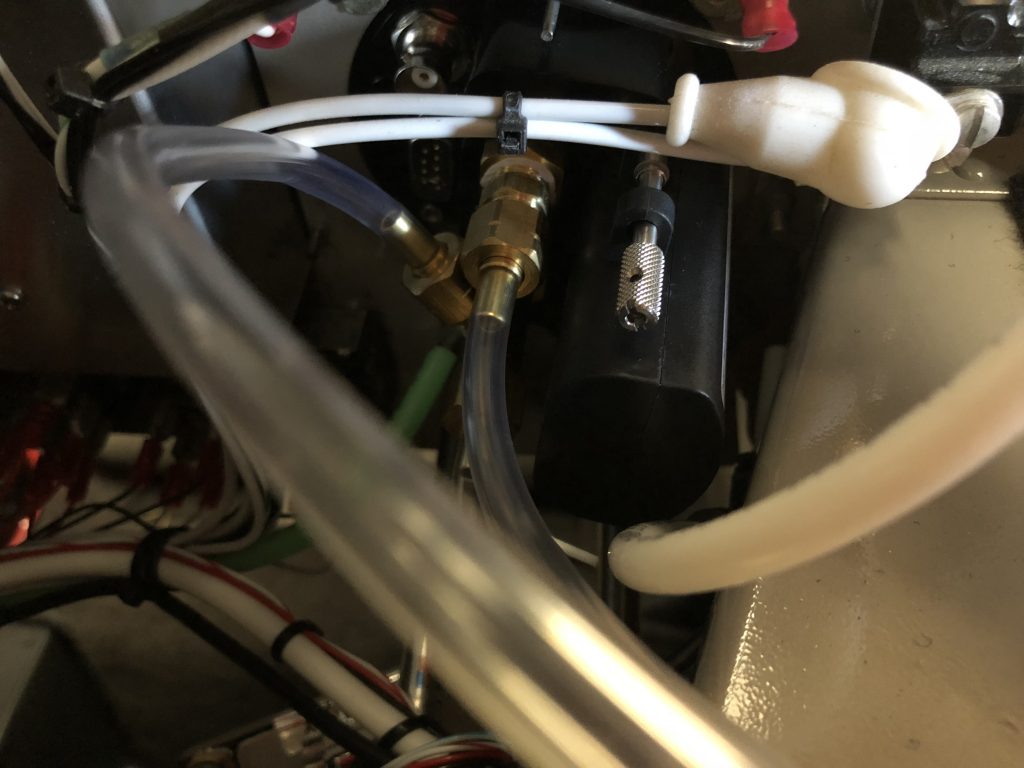

For some reason, Dynon no longer supports the USB pins in the DB-37 connector. I was using these for the panel mounted USB ports so that both of the USB ports on the rear of the SkyView were available. I replaced the panel mounted USB ports with ones that just plug into the back of the SkyView displays. With those and the WiFi dongles, both USB ports are now used on each display. The only concern I have with this is that I have considered adding the video dongle so that I can add a camera feed, but perhaps I can use a USB hub if I do that.

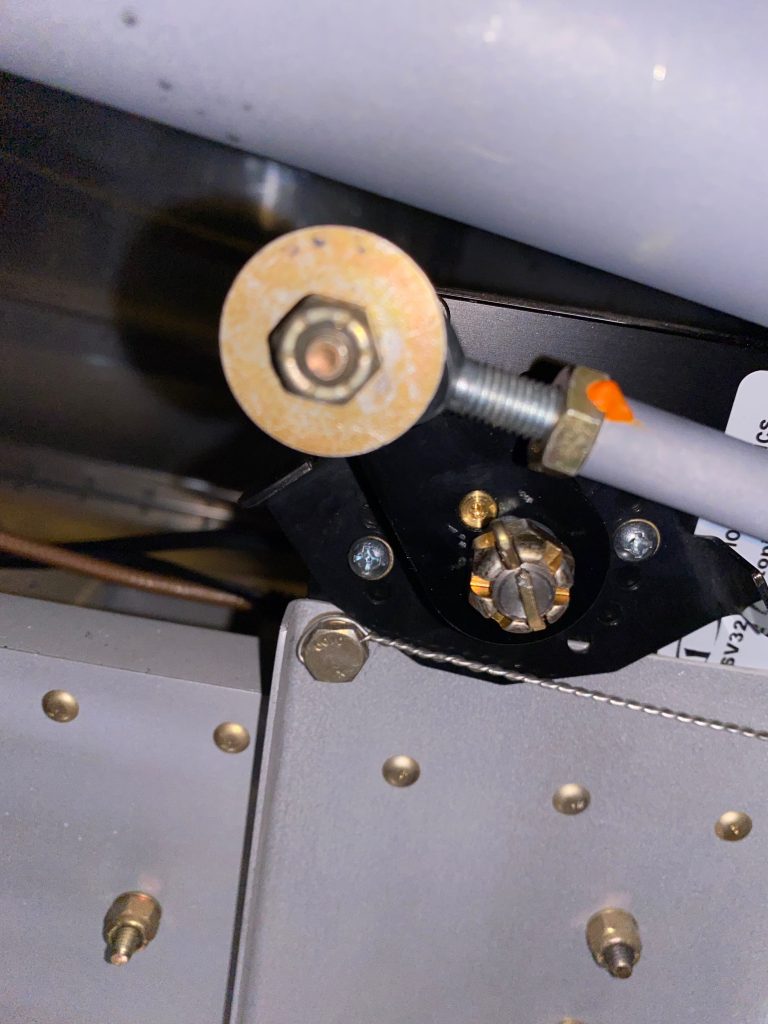

The new HDX displays only use two screws per side instead of three. The upper one is fortunately in the same location, but the lower screw doesn’t line up with the existing nut plate, so I needed to install new nut plates above them.

Here’s one of the new displays installed. These displays don’t completely fill the hole in the panel, so there’s a cover plate hidden behind the lower lip of the display to cover the rest of the hole. You can see in the upper right where the panel mount USB port goes. It’s removed because the new ports with USB connectors on the other end are on order and should be here soon.

You can also see that the lower lip of the display obscures part of the panel labels. It’s not too bad from where I sit, but it would have been nice if this wasn’t an issue.

Here are both displays installed and configured. They’re somewhat brighter than the old displays and support a horizontal engine strip (as shown on the left display) as well as better touch based menus and screens.