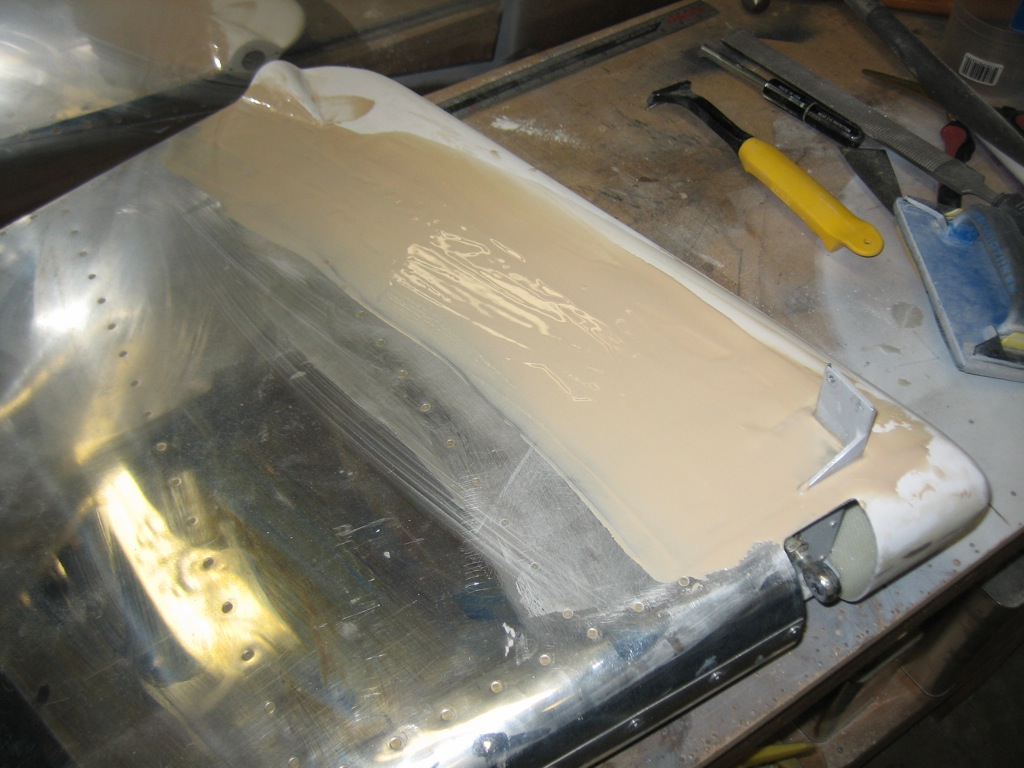

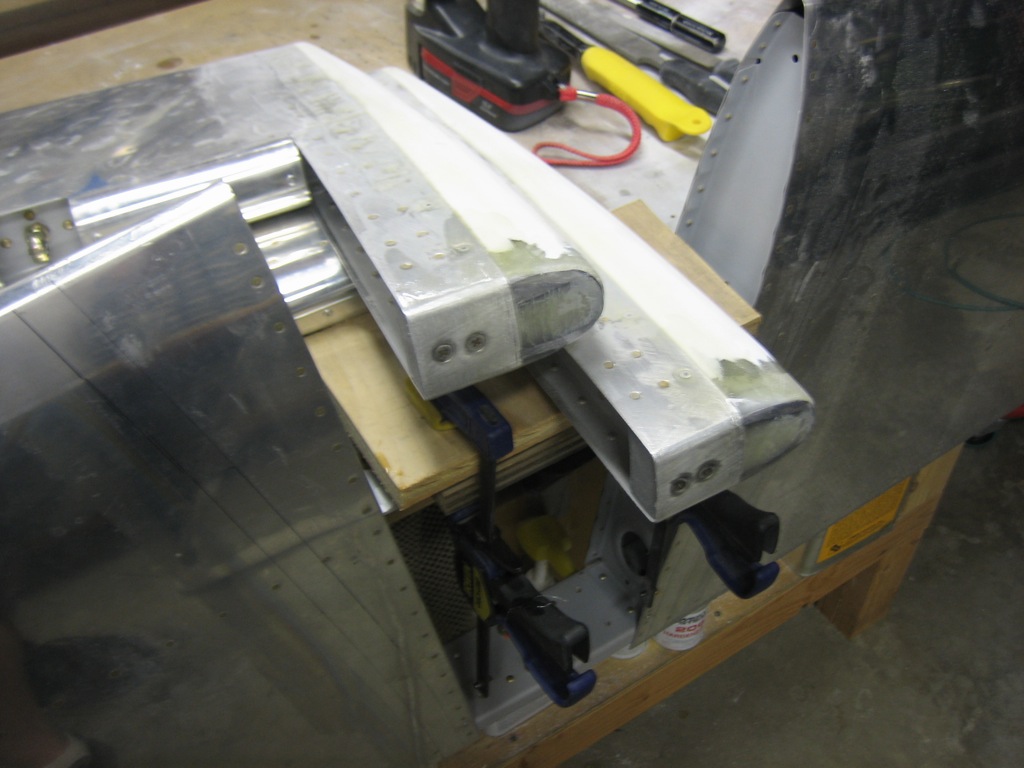

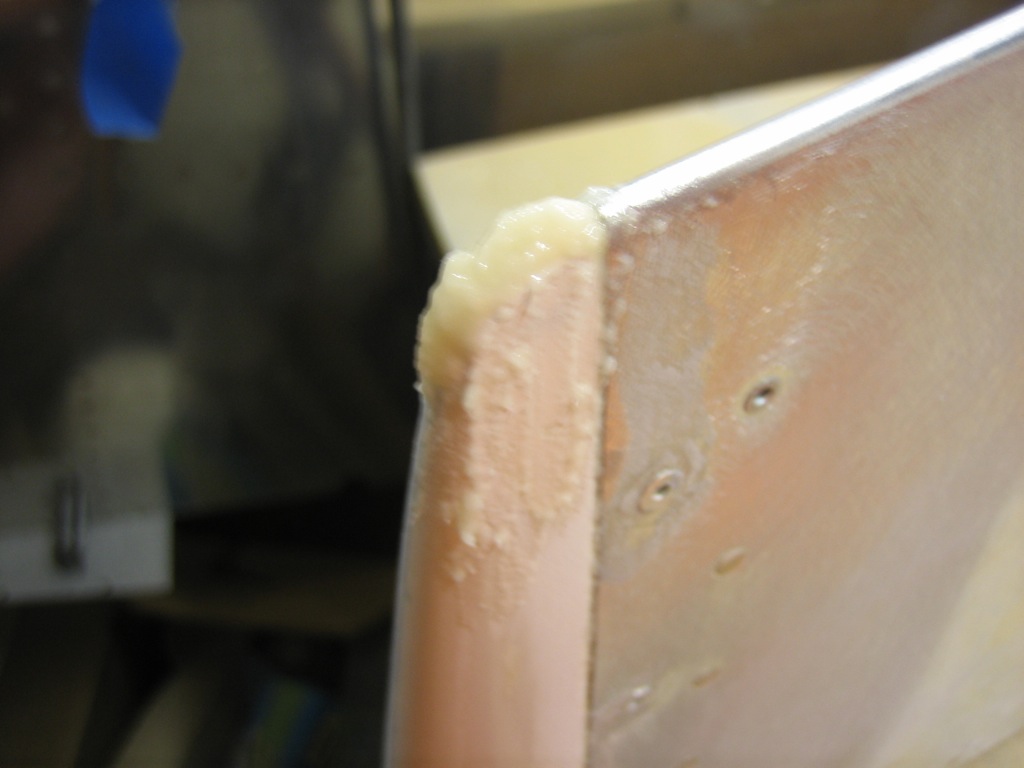

I decided to reinforce the wingtips by glassing in some foam rod. I mixed up some epoxy/microlight/flox and bonded the rod to the inside of the wingtip and formed a fillet along both sides. Afterward, I layed up a couple of layers of glass over each rod and then reinstalled the wingtip to put the right curvature in the skin.

I sanded down the filler on the left side of the rudder and then applied some filler to the right side. I also removed the foam from the fiberglass tip at the top of the vertical stabilizer. I need to reshape the tip a bit to fair it in with the rudder.