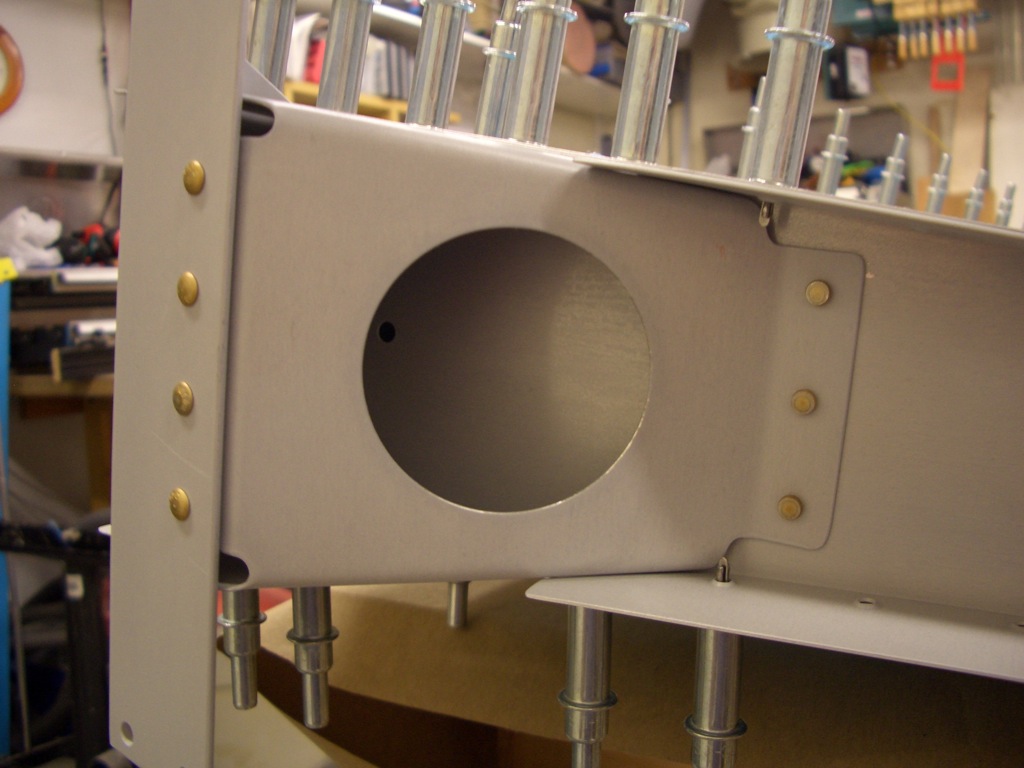

Jenn helped me shoot the last two rivets (seen here at the far left and right edged inside the rudder brace hole). Jenn had never riveted before, but she picked it up quickly and did a great job.

Here are the rest of the rivets that hold the rudder brace on. I managed to get all solid rivets in here without too much trouble. This would have been nearly impossible without the longeron yoke. A lot of people wait until the fuselage to order the longeron yoke, but it’s been invaluable on the empennage. There have already been a number of spots that couldn’t be squeezed any other way.

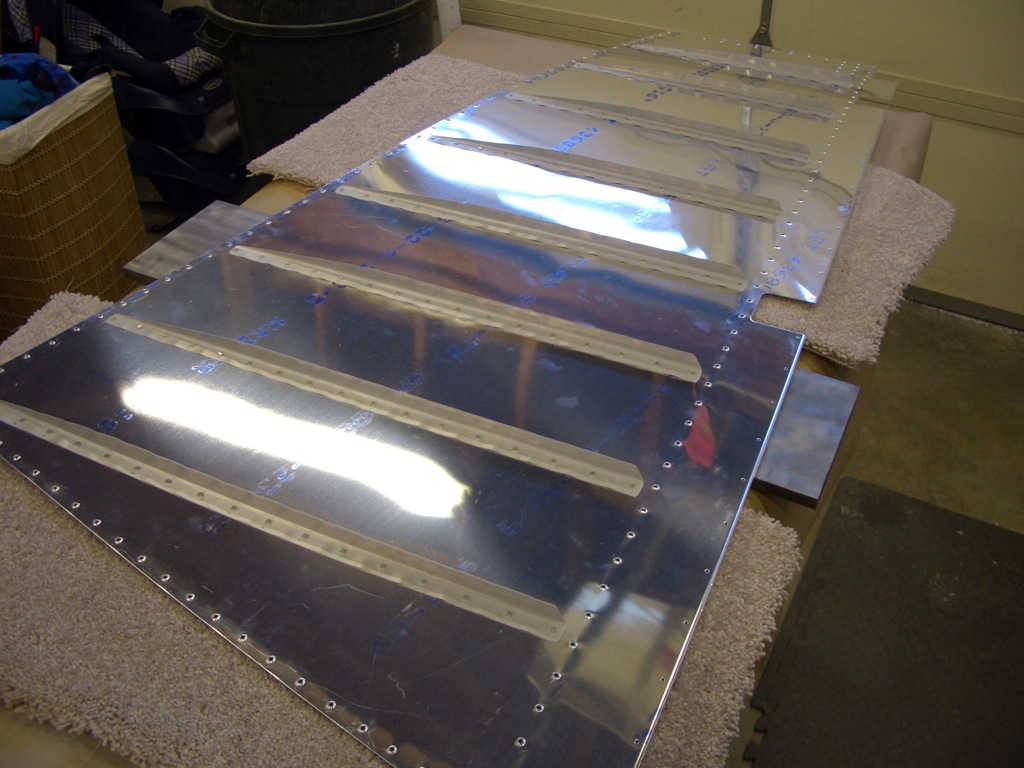

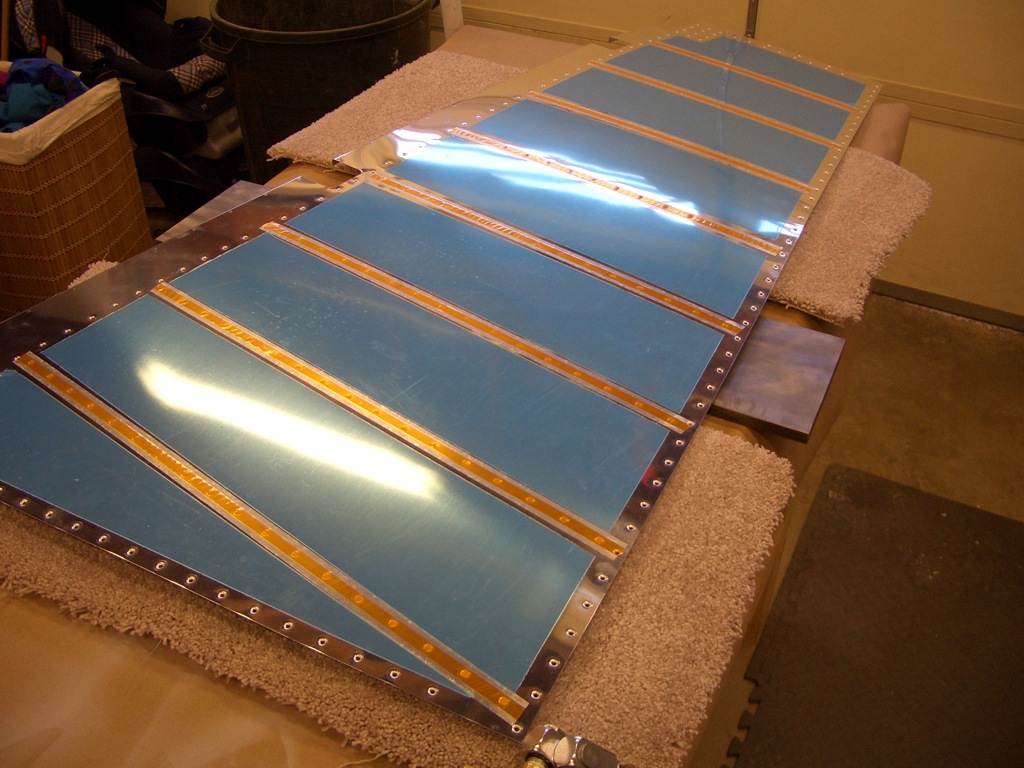

I riveted all of the rudder stiffeners on this morning before work since I’ve been getting home too late to do it before the kids go to bed.

These rivets are back-riveted which means the rivet gun forms the shop head while the manufactured head rests against a back-rivet place (in this case a large piece of cold rolled steel that I picked up at a local metal supply shop. Below, you can see the rivet tape that is used to hold the rivets in place until they’re driven. As everyone says, back-riveting rocks. The skin is amazingly smooth.

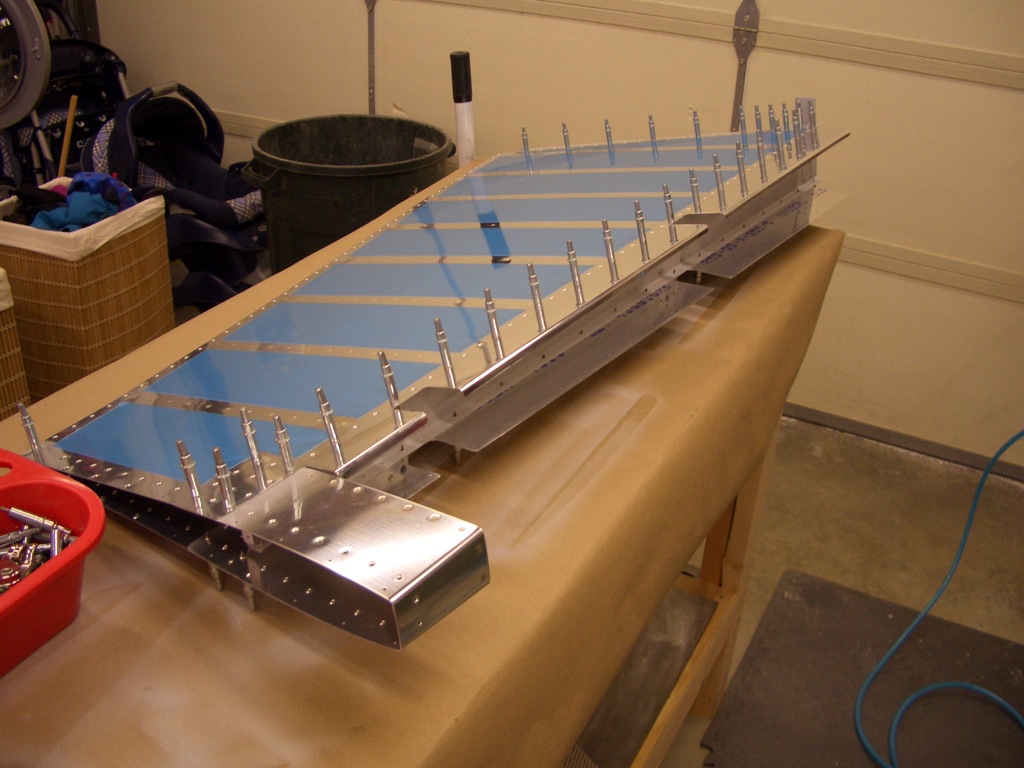

Here is the structure all clecoed together. Most if not all of the remaining rivets except the trailing edge can be squeezed. I’ll knock that out tomorrow and then get started on the trailing edge.