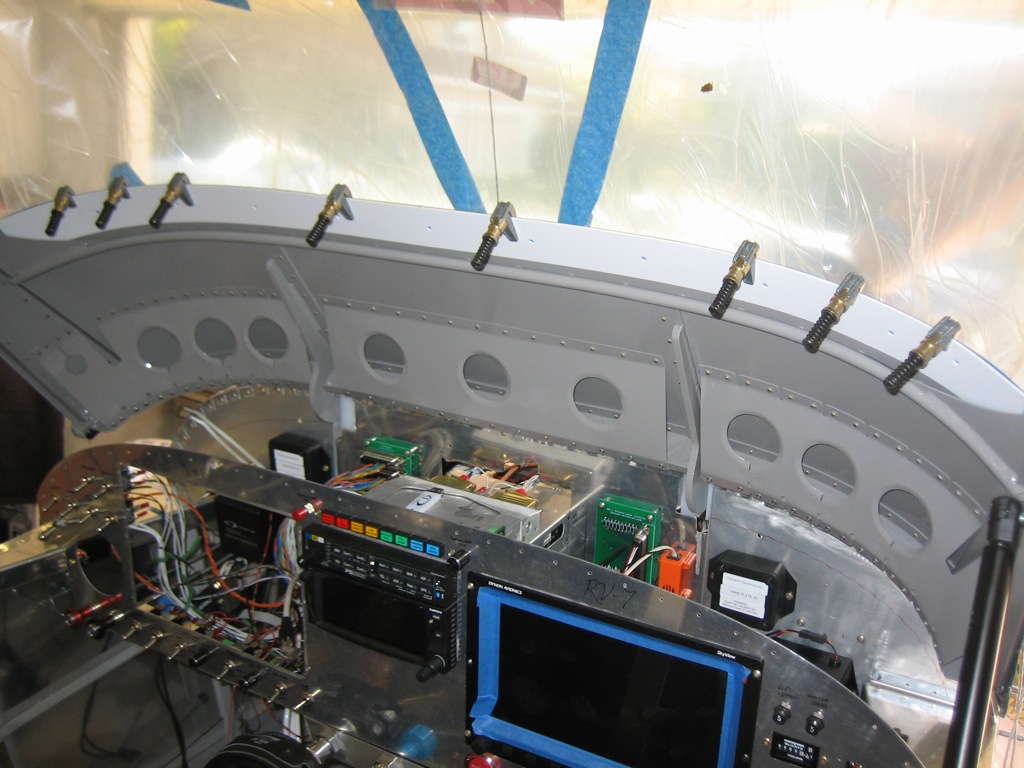

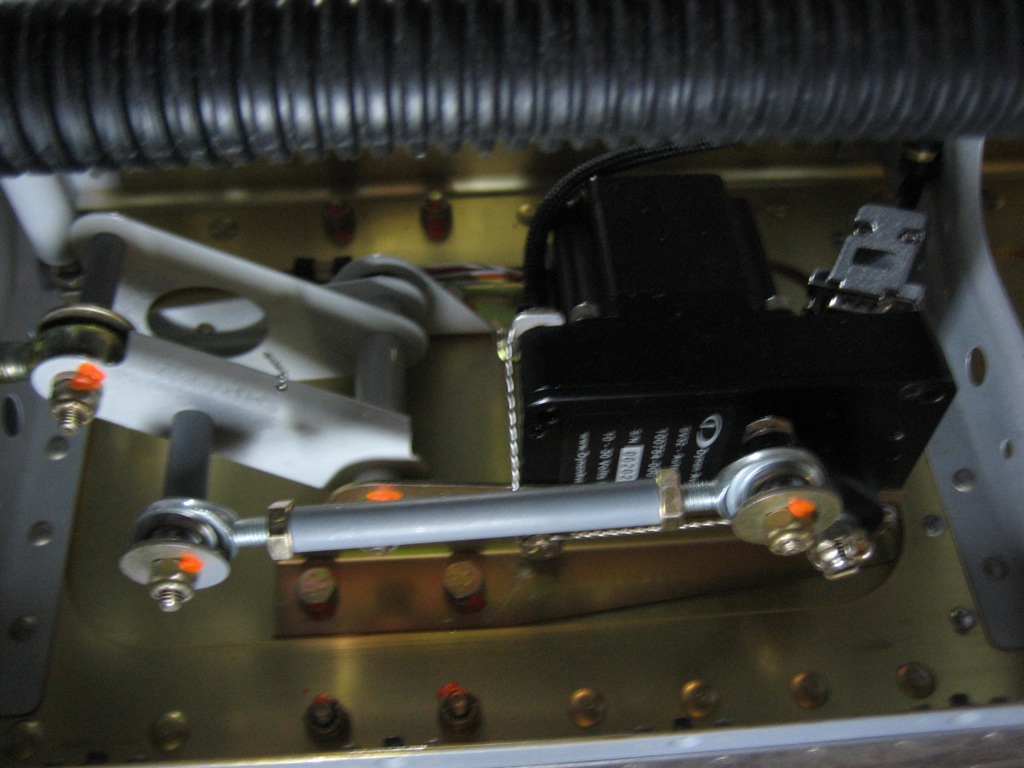

I spoke with Dynon this morning and they were already aware of the reverse trim issue. The fix will require software updates to both the Dynon SkyView and the VP-X, but those aren’t out yet. It’s not blocking anything for me right now, so I’ll just wait for the updates.

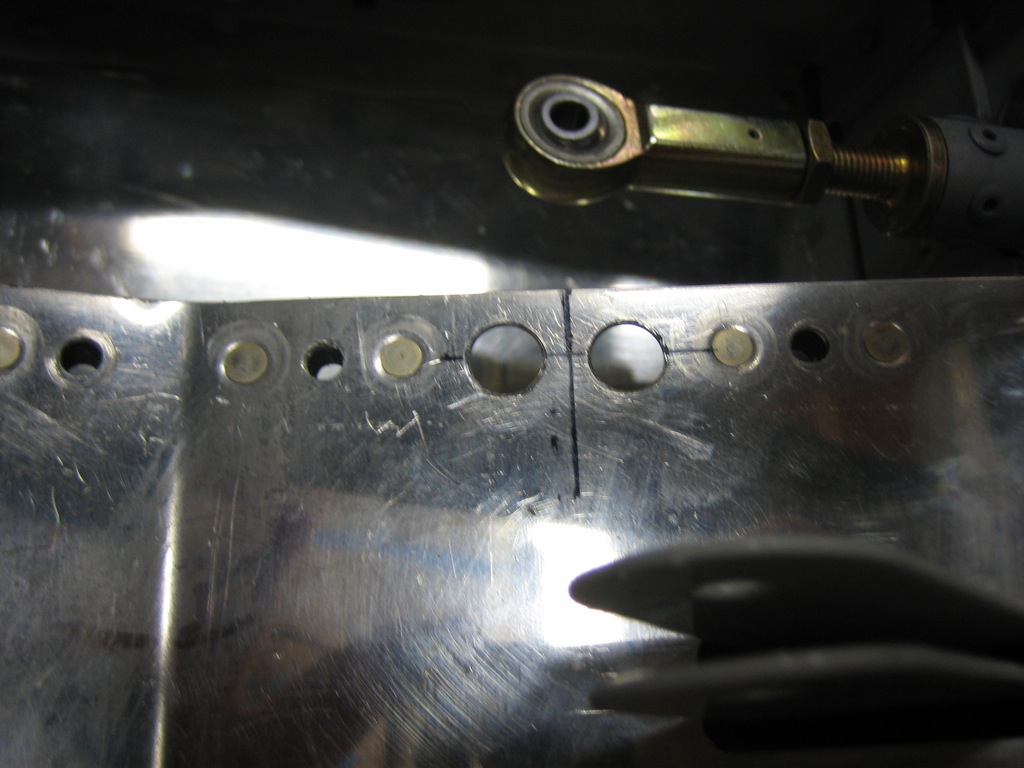

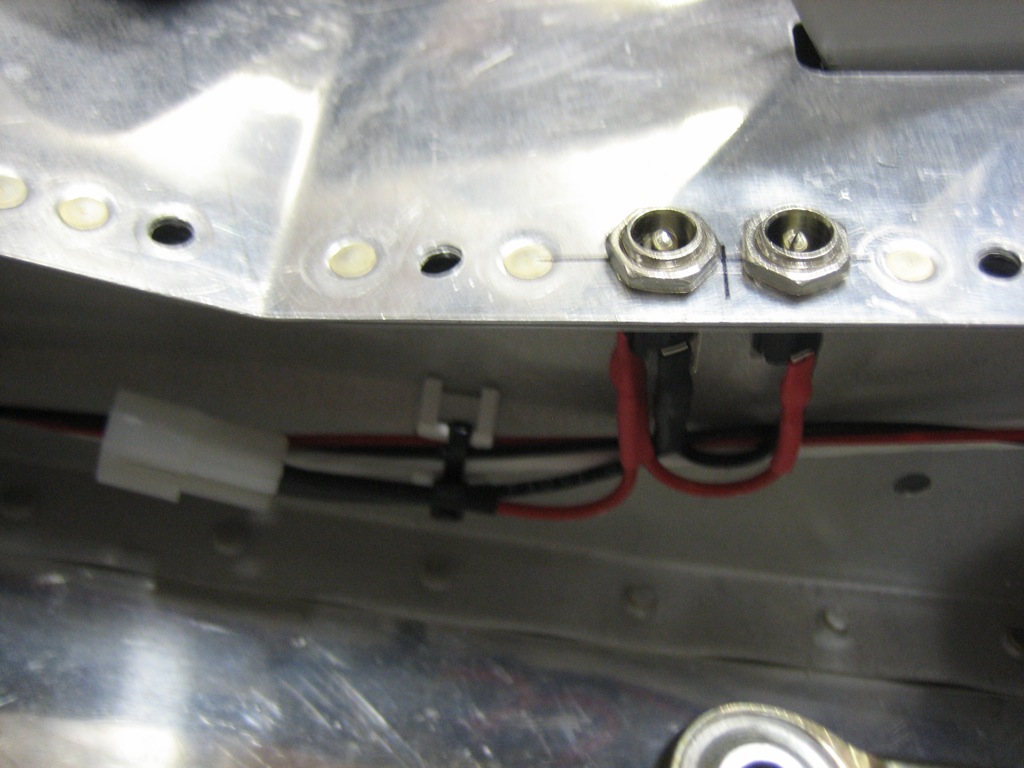

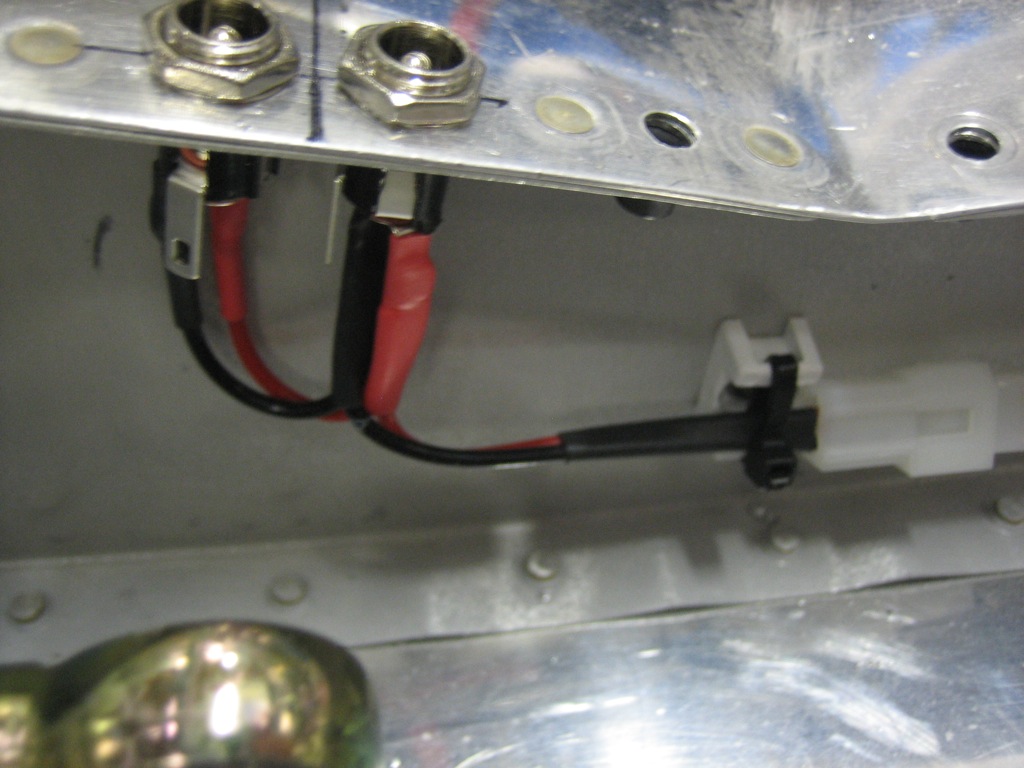

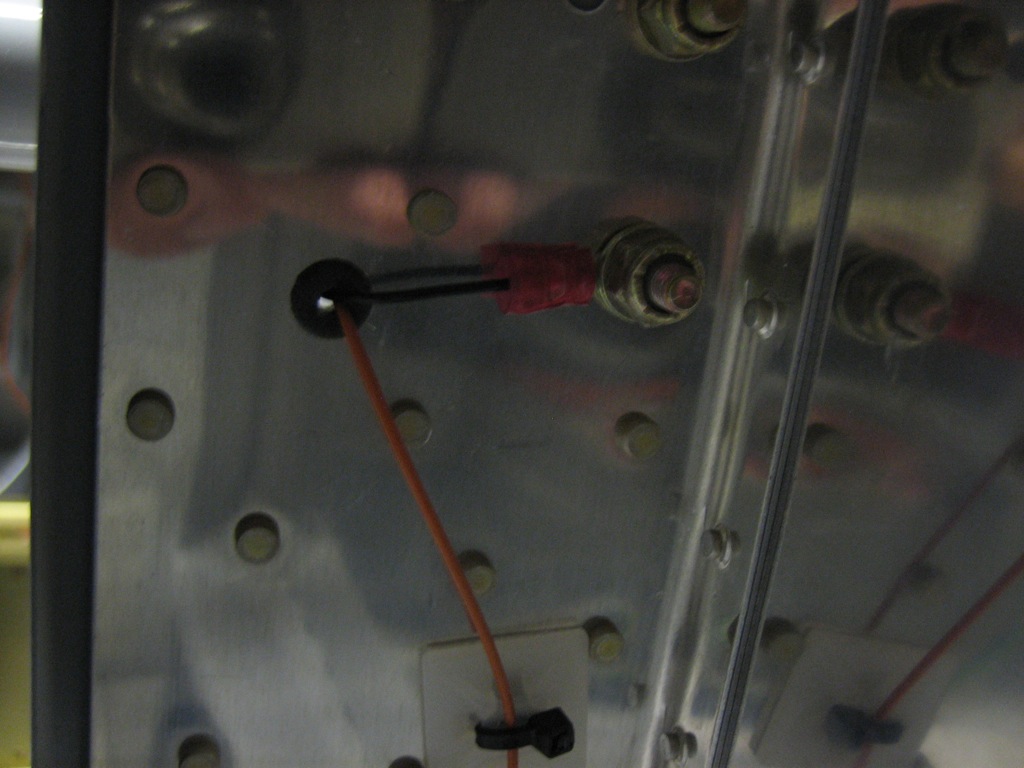

I moved ahead and finished the power and ground wires for the seat heaters. I *think* this will be the last ground wire that attaches to the firewall ground block.

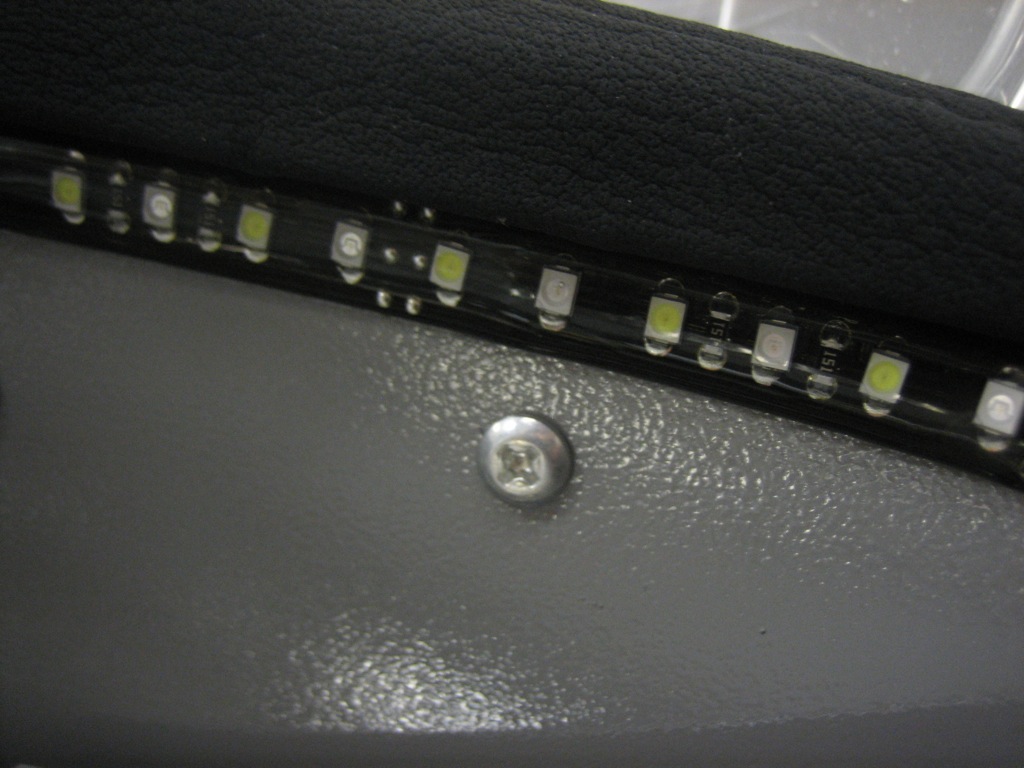

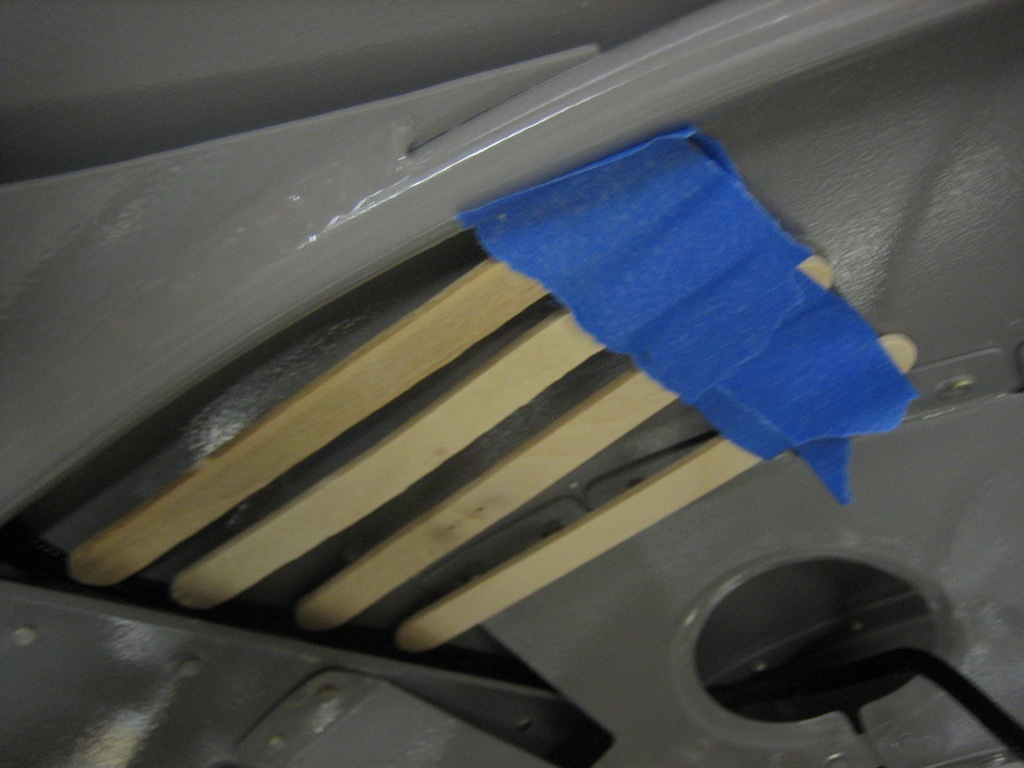

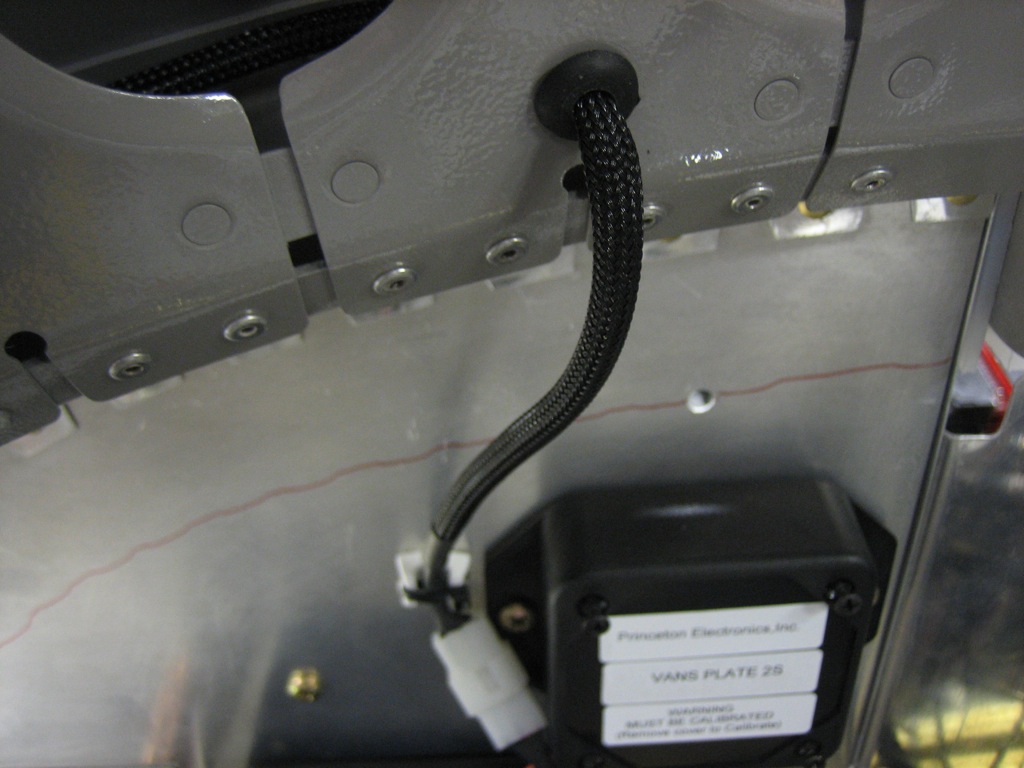

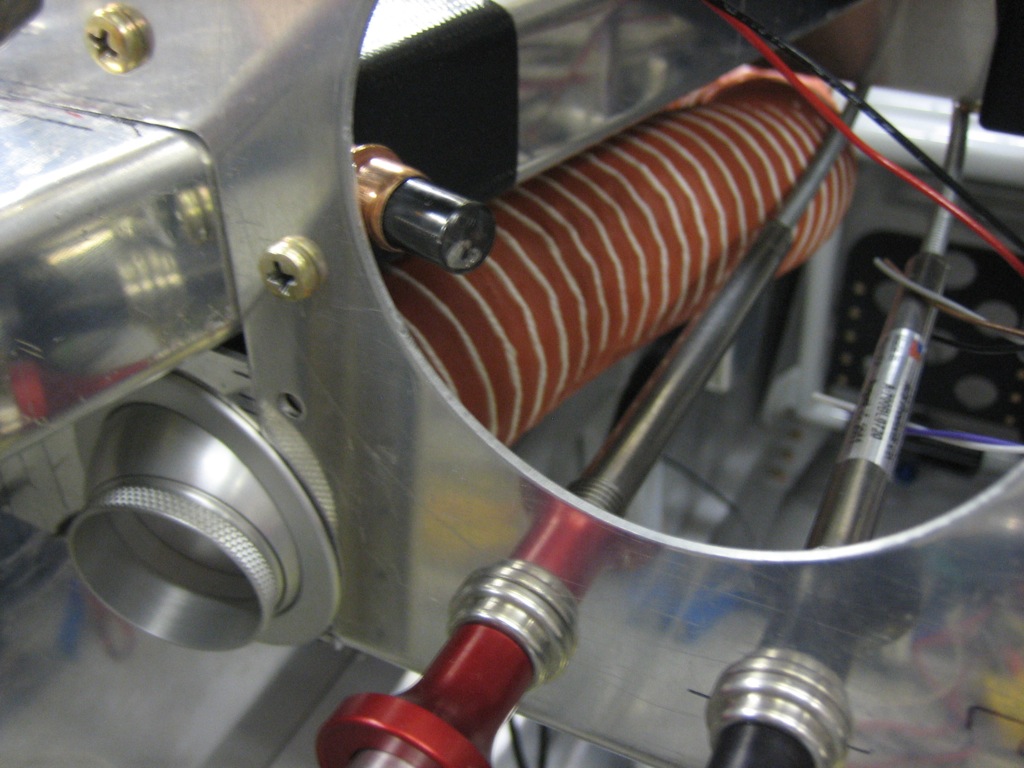

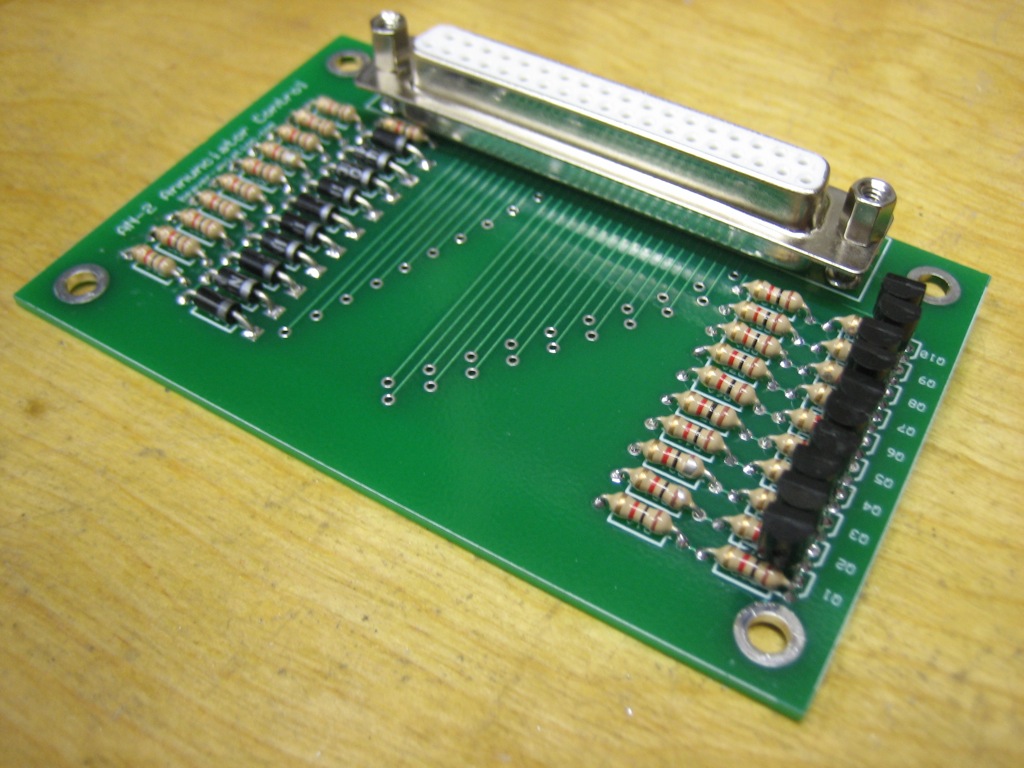

Next up, I started wiring the interior lights. I had been planning on wiring the cabin lights (in the roll bar support channel) directly to the battery bus so that I can turn them on without turning on the master switch. I originally ordered a linear dimmer module from Perihelion Design. This has the nice feature that when the knob is turned off, the dimmer draws absolutely no power. A while back though, I decided to switch to a PWM dimmer from pilotlights.net. The dimmer provides a much smoother and more linear brightness ramp, but unfortunately, it draws between 6 and 13 mA even when the output is open. At 13 mA, that would completely drain my battery in ~54 days, but it would drain enough power to affect starting in quite a bit less time. I don’t really see a way around this since the dimmer has to be connected prior to the switch that routes power to either the white or green cabin lights, so there’s no way to shut off power to the dimmer if it’s wired directly to the battery bus. I’ve decided to just move the cabin lights to the interior lights circuit on the VP-X. This will eliminate the current drain, but will unfortunately mean I will have to turn on the master switch to turn on the cabin lights.