I popped the cowl apart from my filler application last night and this worked beautifully to make the flanges a perfect fit.

You can see here that it also allowed me to slightly extend the flange on the upper cowl to match up with the lower cowl.

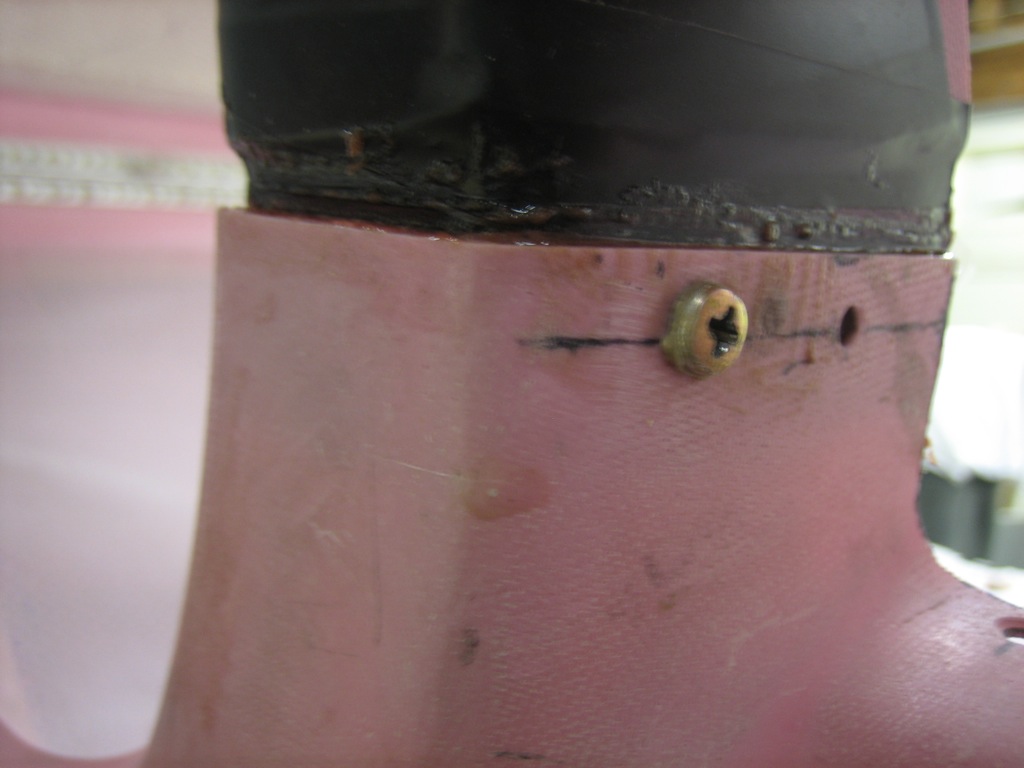

Next up, I trimmed the upper and lower cowl flanges a bit and then wrapped the lower cowl flange with tape. The electrical tape is there to define the line where the upper cowl flange should reach. The packing tape is there to keep the epoxy from sticking to the lower cowl flange.

After assembling the cowl halves, I cleaned out the screw holes and punched a hole in the packing tape for the screw that aligns the two halves. I waxed up the screw really well to keep the epoxy from sticking.

I then cleaned up the inside of the joint so there isn’t a bunch of excess epoxy here.