I cut a piece of baffle seal material to fit to the lower left cowl inlet and cut screw holes in it.

After attaching the baffle strip to the cowl inlet, I reinstalled the lower cowl to check the fit. The baffle seal is cut back through the middle to expose the entire air filter, but goes back a little farther around the baffles to provide a little more overlap.

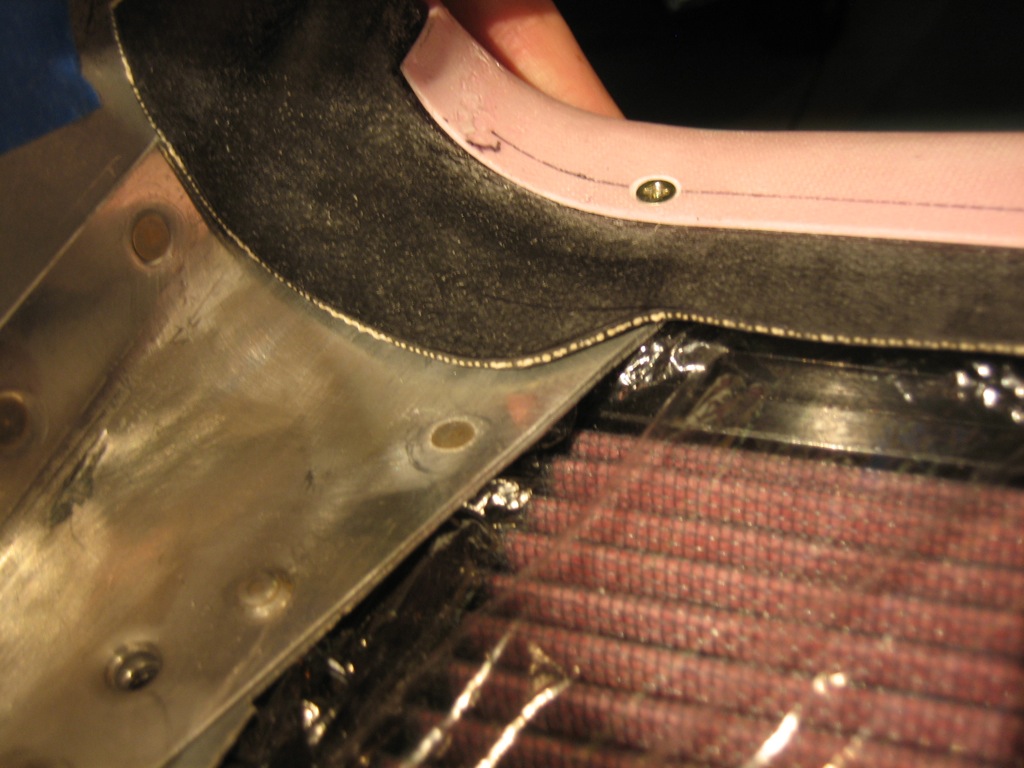

Here’s a shot of the outside edge of the inlet showing how the baffle seal material follows the conical gusset.

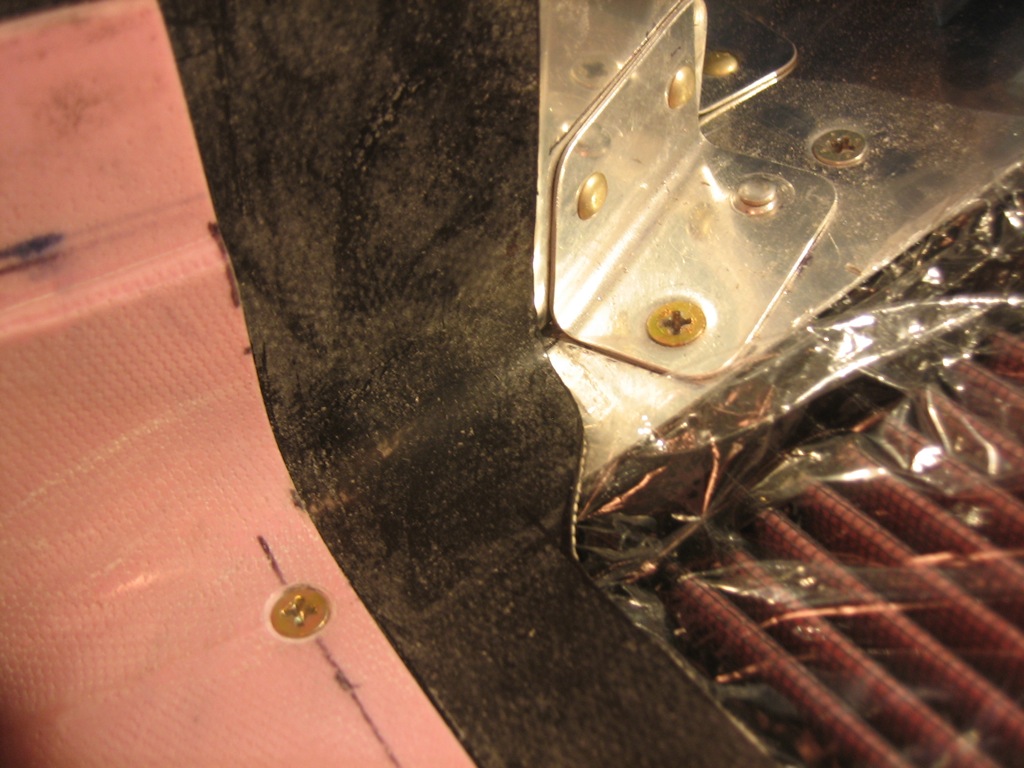

On the inside edge of the inlet, the baffle seal makes a sharp turn to tuck into the corner between the floor and wall of the baffles.

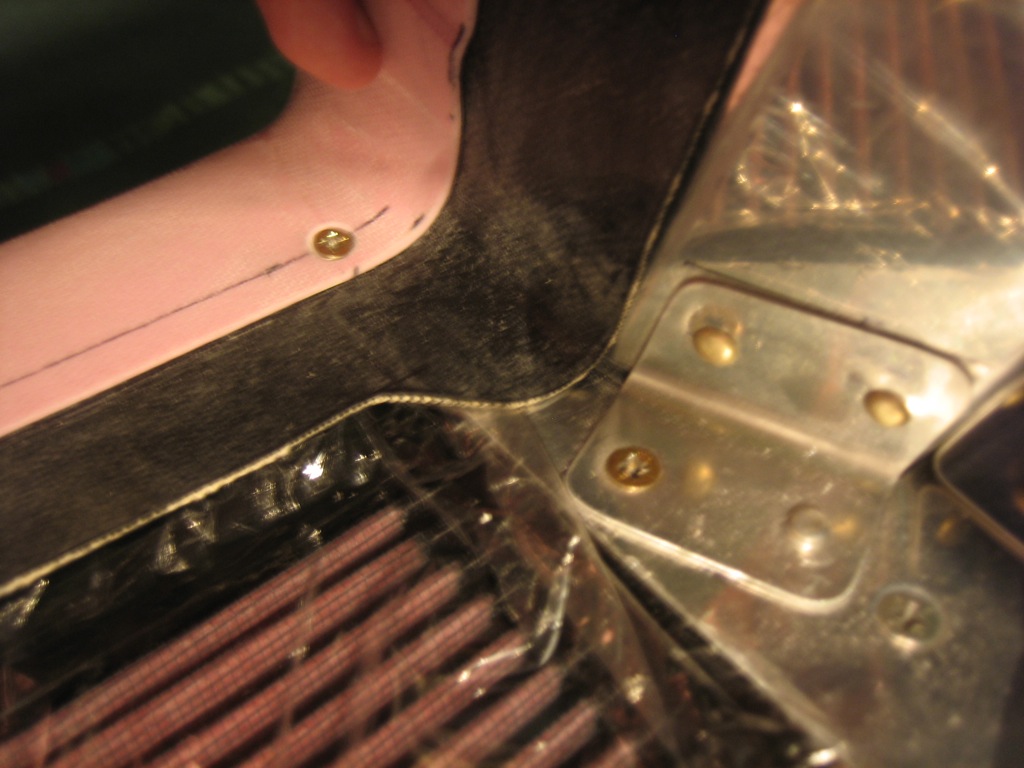

Here’s a shot looking forward showing how nicely the baffle seal material tucks into the corner. There will be some RTV silicone sealing the gaps between the floor and the wall, so I’ll probably make a little fillet here to prevent air from leaking through the gap. You might think I’m being anal about sealing every little gap (and I am), but any air that comes in the cowl inlets and isn’t used for cooling is unnecessary drag.

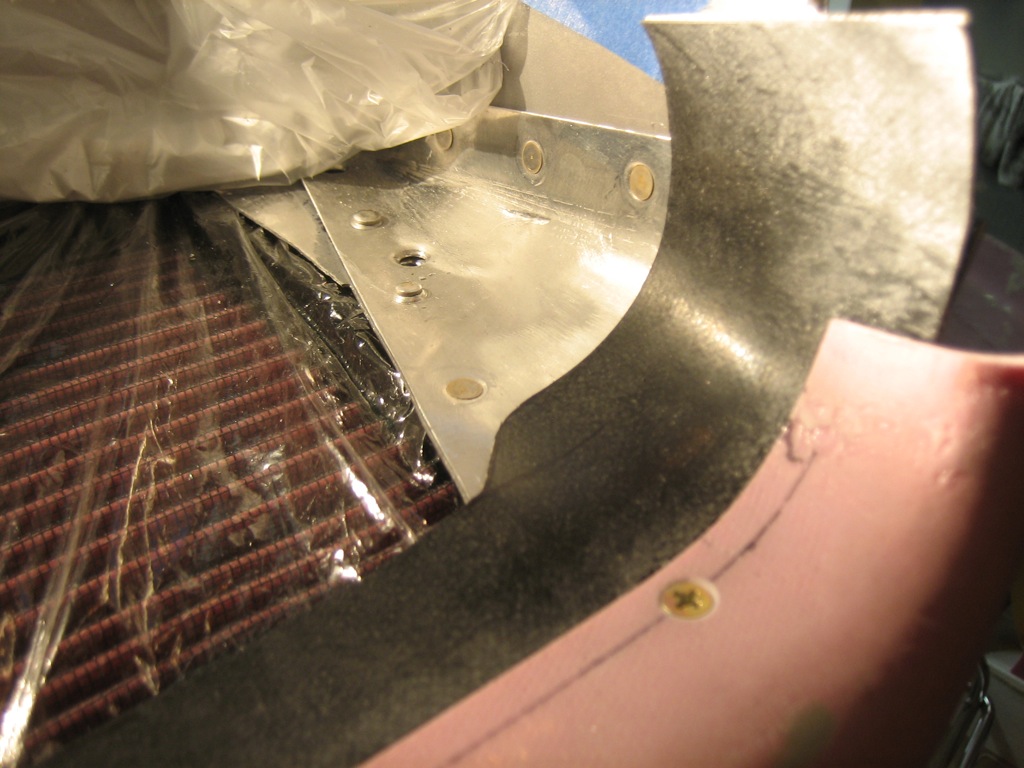

This is looking forward at the outer edge of the inlet at the conical gusset. You can see that the baffle seal material lays down fairly well against the gusset. Once the plane is flying and the engine heat warms this up, it will take a set and should lay down nice and tight.