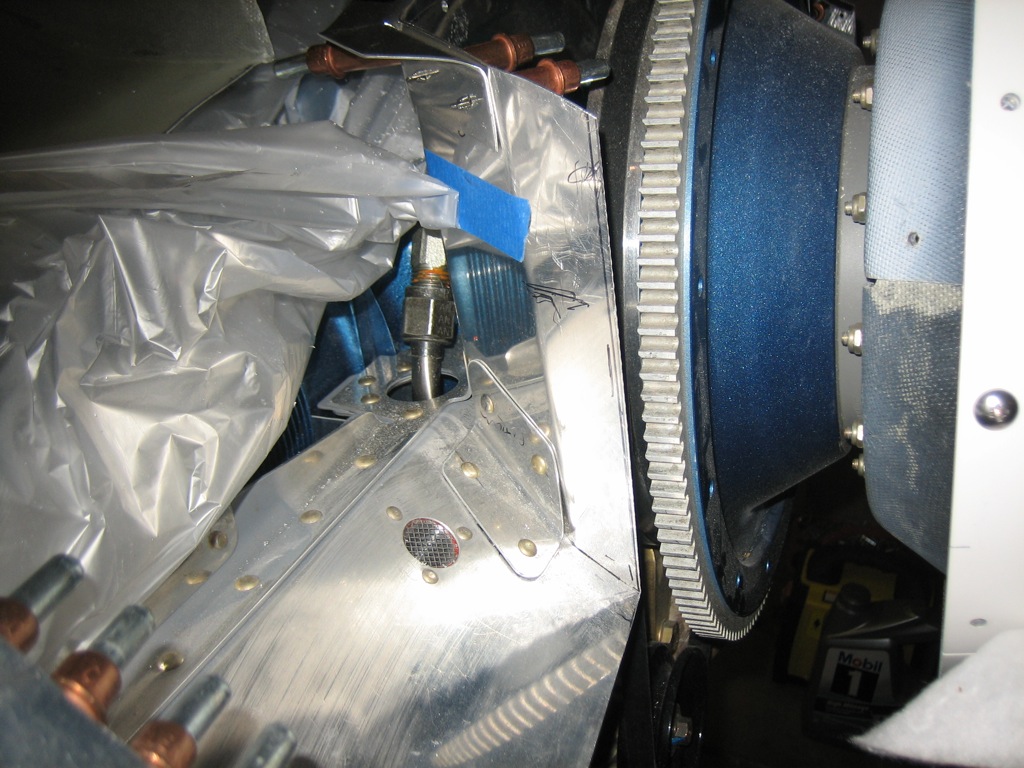

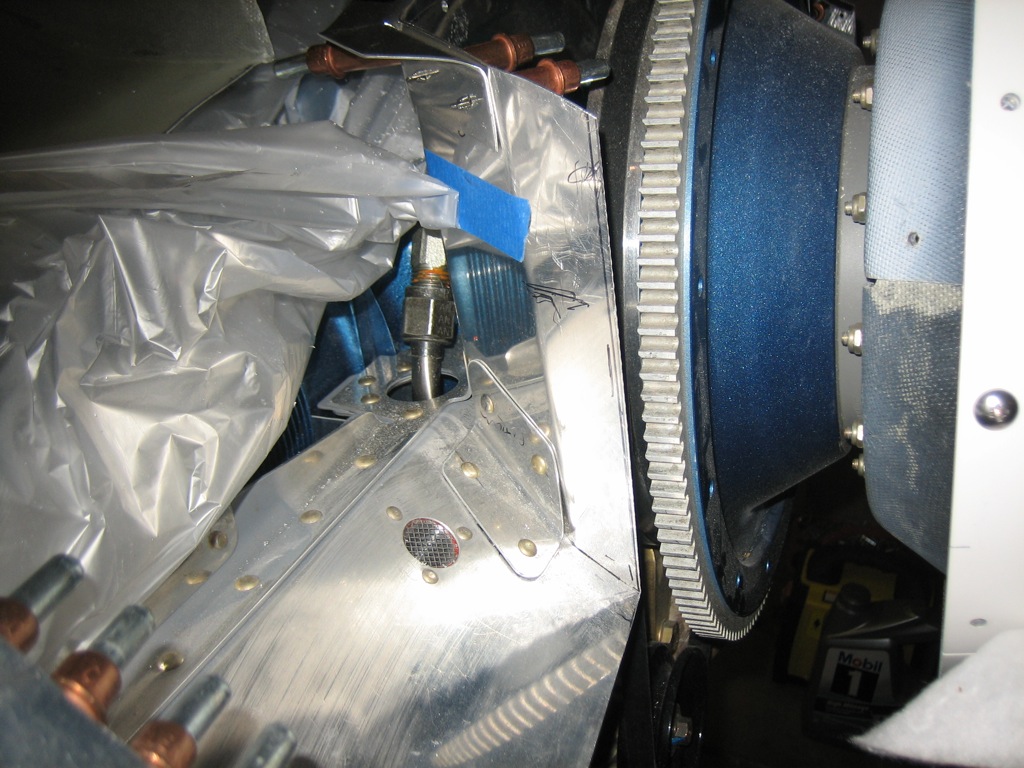

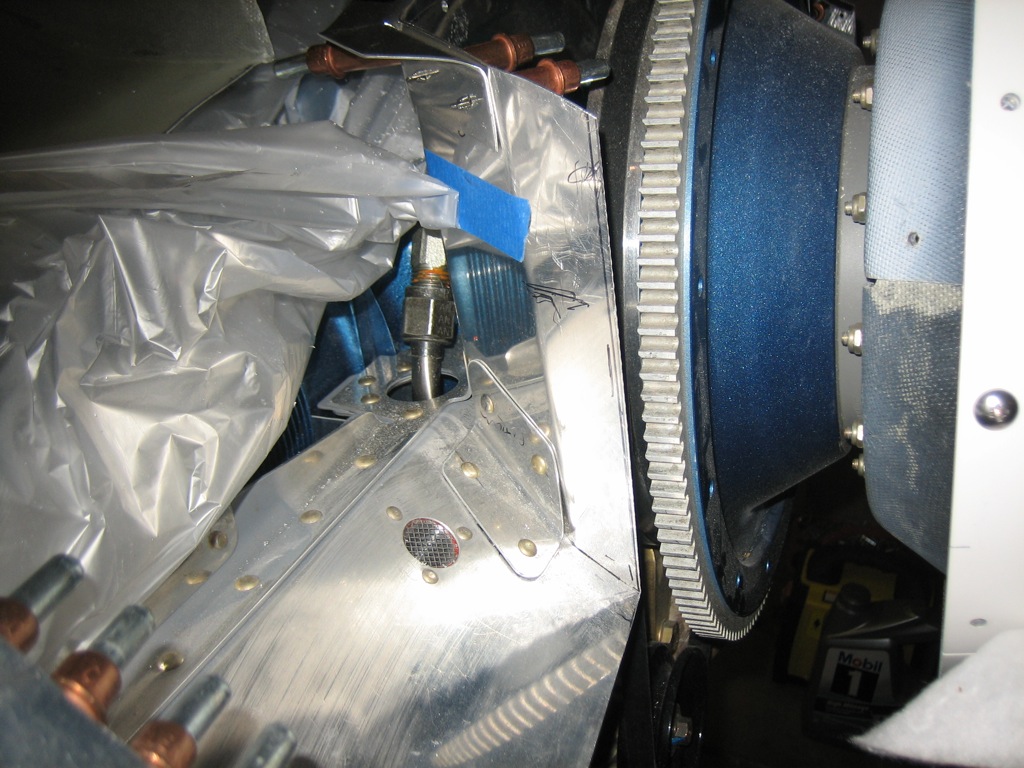

I trimmed back the vertical walls on the inner ends of the cowl inlets so that they line up with the front edge of the ramps. Here’s the right side.

And here’s the left side.

I trimmed the cowl inlets back so there is 3/8″ of clearance between the cowl and the ramps. This will provide room to slip the cowl in place while pulling the baffle seal material through the gap. The baffle seal material will span this gap to prevent cooling air from leaking through here. Here’s the right side.

And here’s the left side.

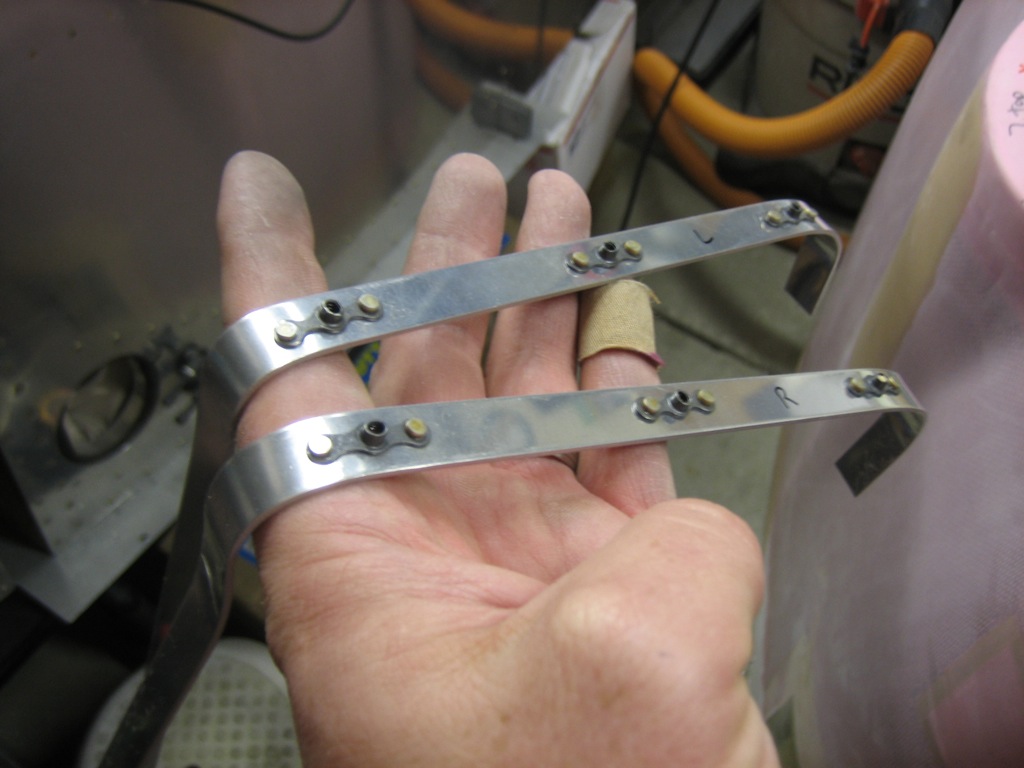

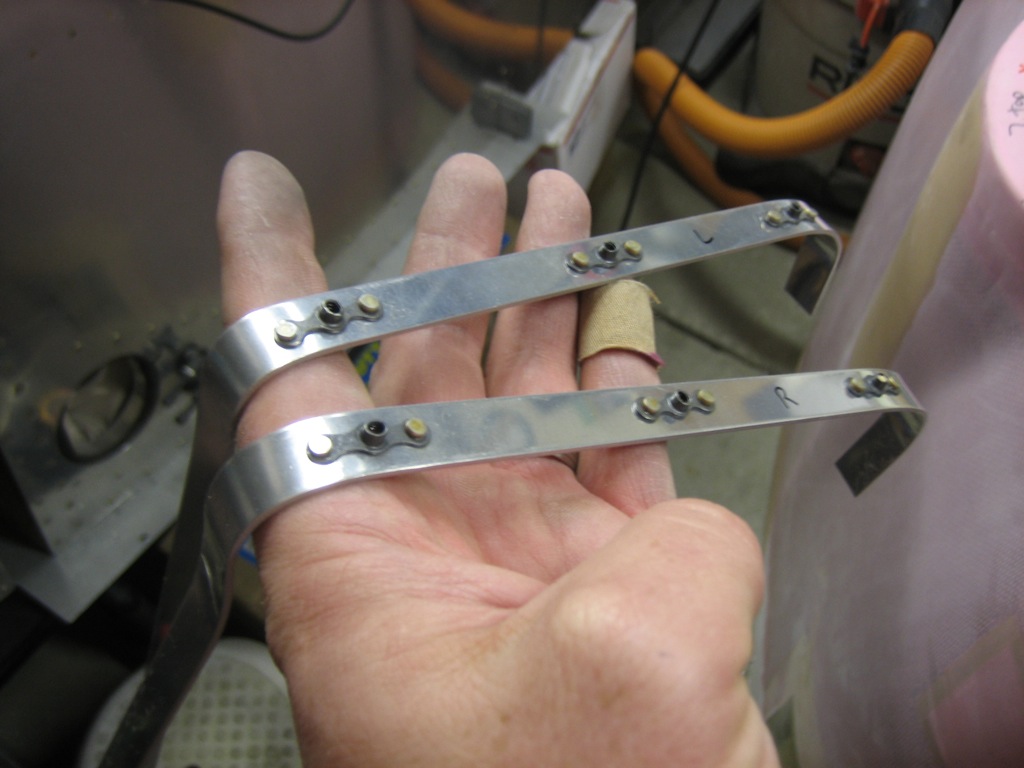

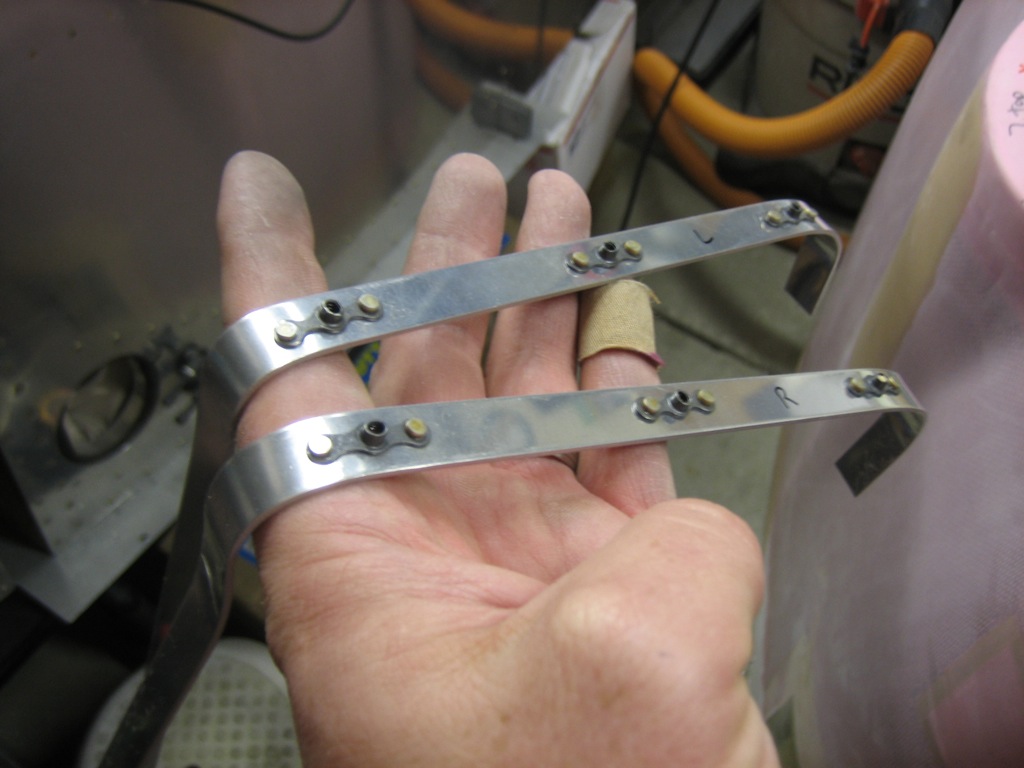

I then started fabricating the cowl inlet seal retaining strips for the lower cowl out of some 0.063″ strip stock. The baffle seal material will be sandwiched between the cowl and the retaining strip.

I laid out and drilled three holes through the cowl and retaining strip.

I did this to both strips and then installed some #6 nutplates.