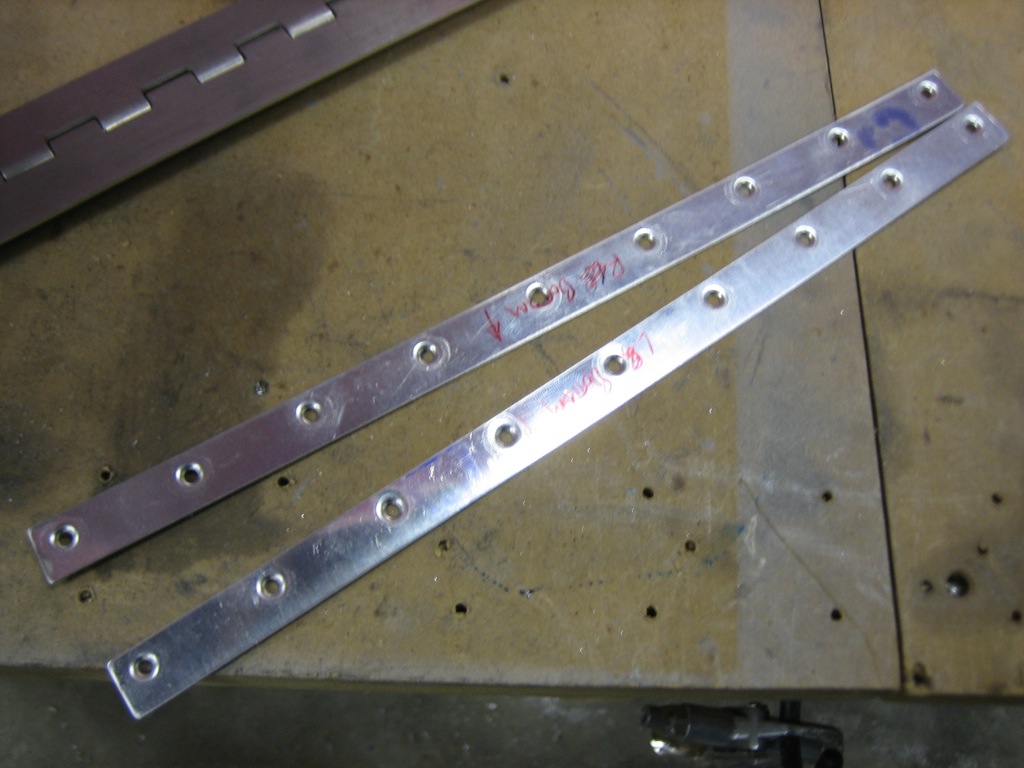

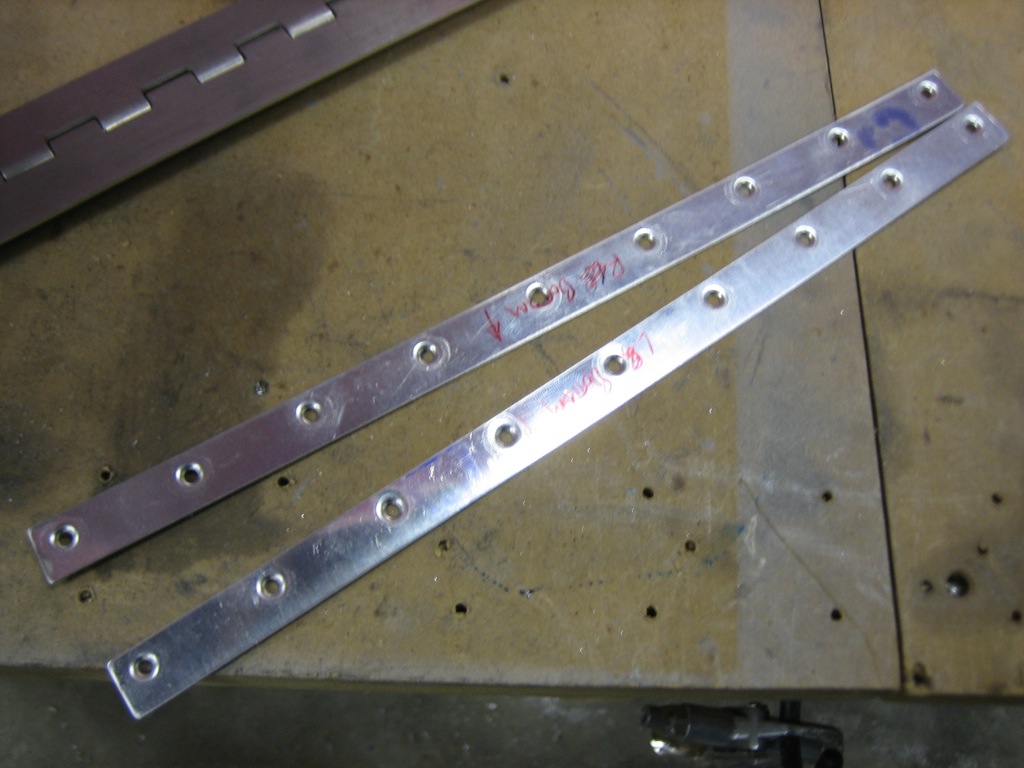

I fabricated the 0.020″ spacers for the hinges that attach the bottom of the cowl to the firewall.

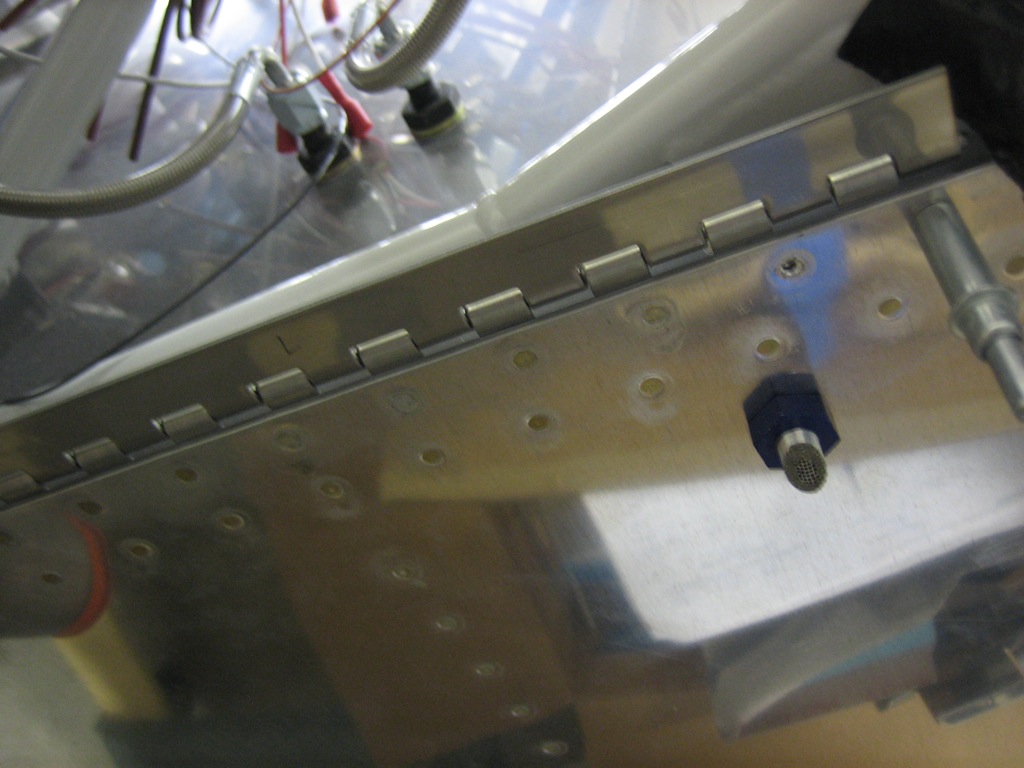

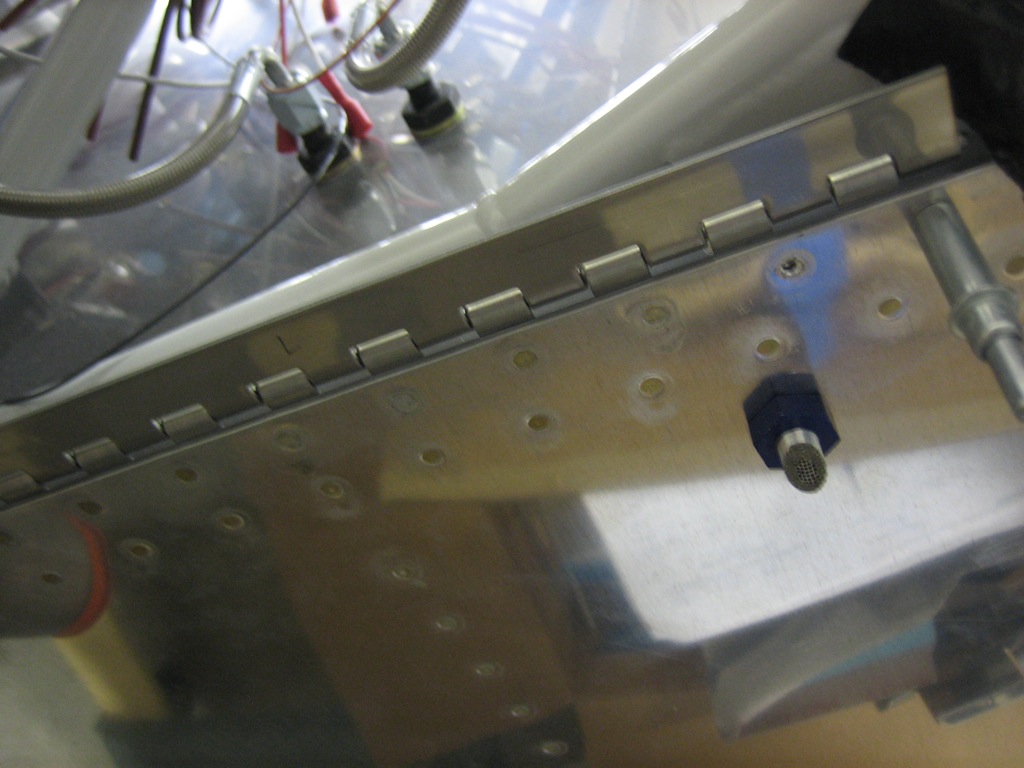

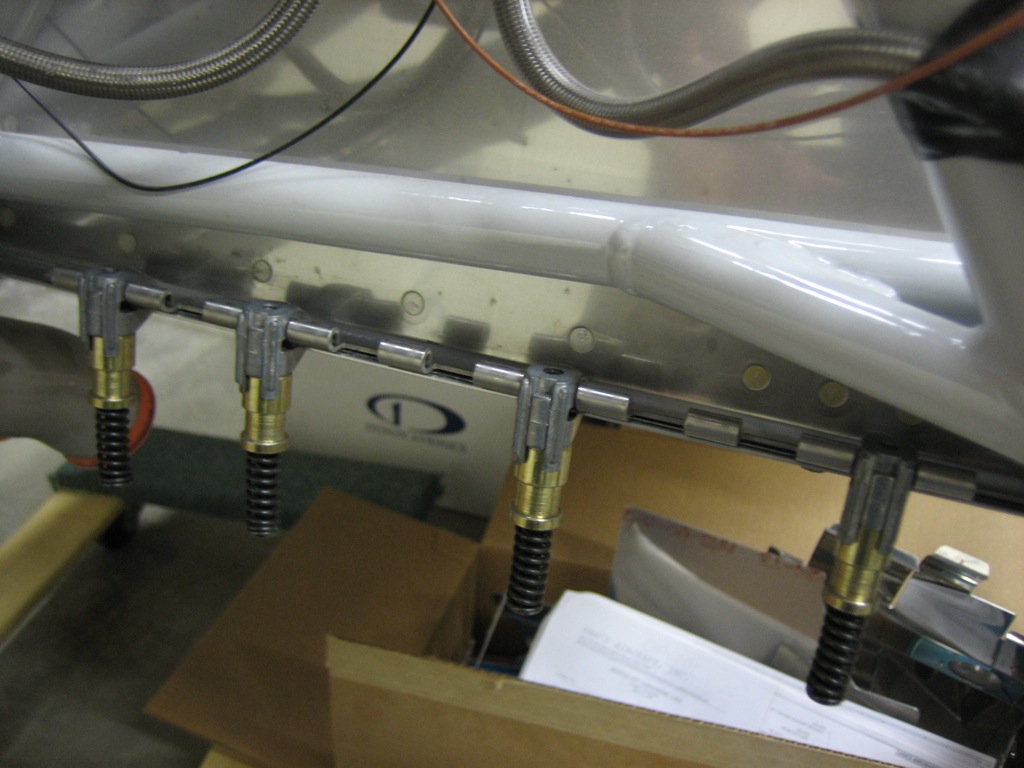

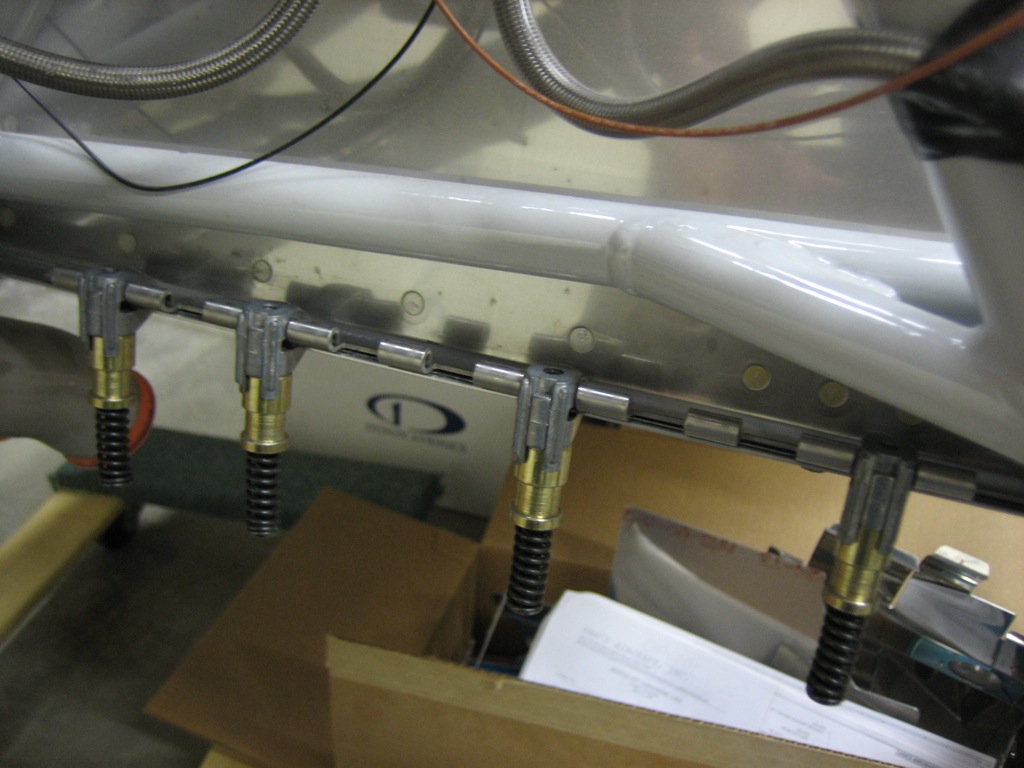

Next up, I cut and drilled the hinges to the firewall. The plans call for the same 1/8″ aluminum hinge stock that is used along the sides and top of the firewall, but this is an area that is subject to high vibration and it’s quite common for eyelets to break off of the aluminum hinges here. A number of builders have switched to stainless steel hinges and this appears to have cured all of the problems, so that’s what I’m using.

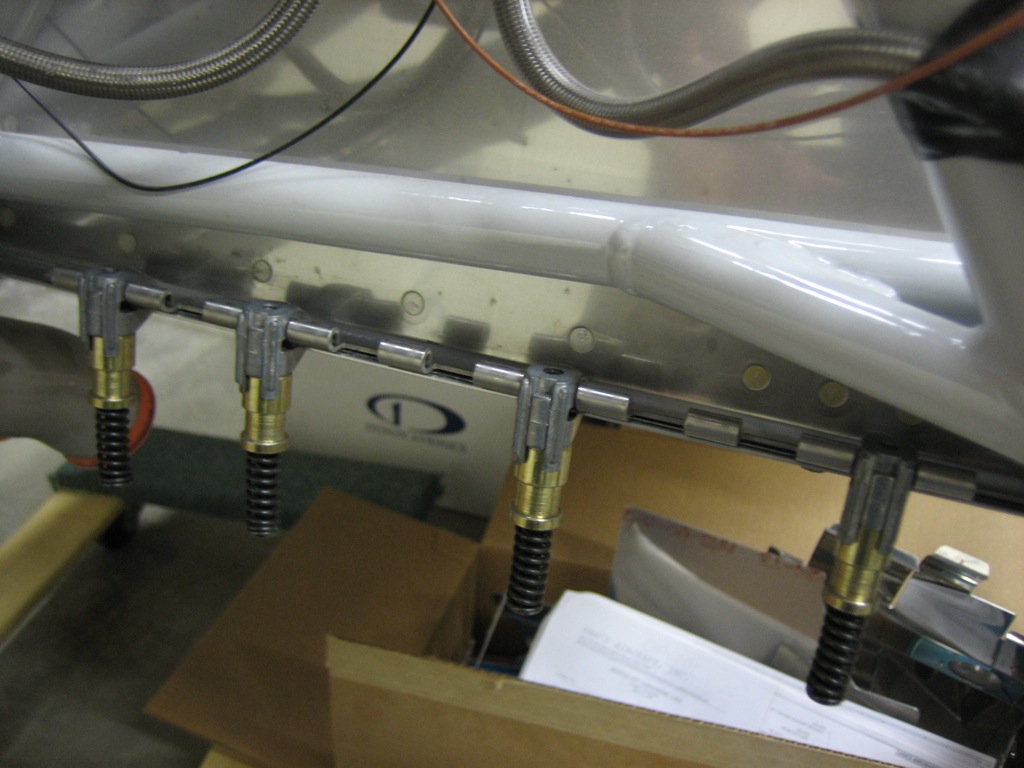

After deburring everything and priming the aluminum spacers, I riveted the hinges to the firewall flange using the hand squeezer. I was able to reach all but the outer two rivets on each side. I’m going to have to shoot and buck these, but the access is really tight due to the engine mount. I’m going to have to find something really thin to use as a bucking bar.

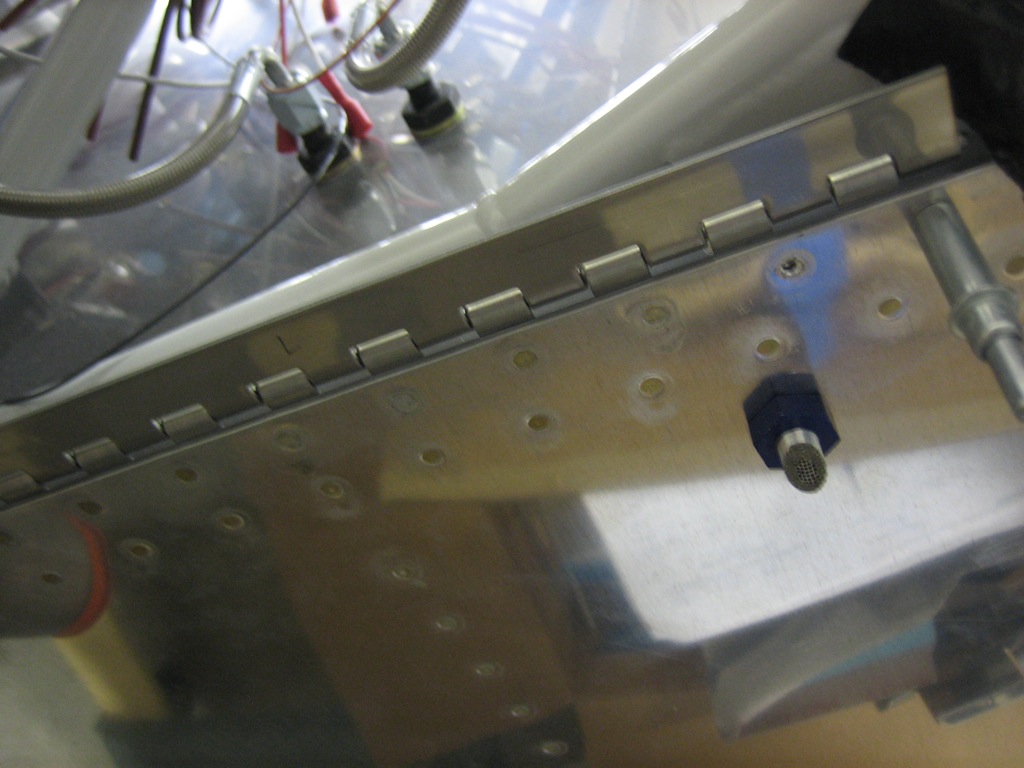

I installed the other half of the hinges using the included hinge pin. The fit is

really tight, so it took a bit of work to get the pin in. I’ll try lubricating the pin to see if that helps.