The throttle bracket that I mocked up a couple of days ago had an extra bend that was unnecessary and I couldn’t figure out how to bend it using the tools I have. Instead, I mocked up a simpler bracket. The slot on the end was only to make it easier to fit while mocking it up.

I unfolded the prototype and transferred it to a piece of 16 gauge steel.

I marked out the bends and bent them using this vise brake that I borrowed from my dad. This thing had no problems bending 16 gauge steel.

I drilled the mounting and cable holes and temporarily mounted it to the engine. Unbelievably, I absolutely nailed it on the first try. The 1/4″ mounting holes perfectly lined up with holes on the sump and the placement and angle of the cable hole was spot on.

Here’s a closeup of the mounting end. This picture makes it look like it comes pretty close to the exhaust pipe, but there’s quite a lot of clearance.

After some adjustment, here’s the throttle in the full open position. Notice the slight gap between the nut behind the throttle nob and the friction control. This ensures that the throttle arm hits the stop on the fuel injection servo which ensures that you can reach full throttle.

Here’s the throttle in the full closed (idle) position. Again, I’m hitting the stop on the fuel servo which ensures I’ve got the throttle fully closed.

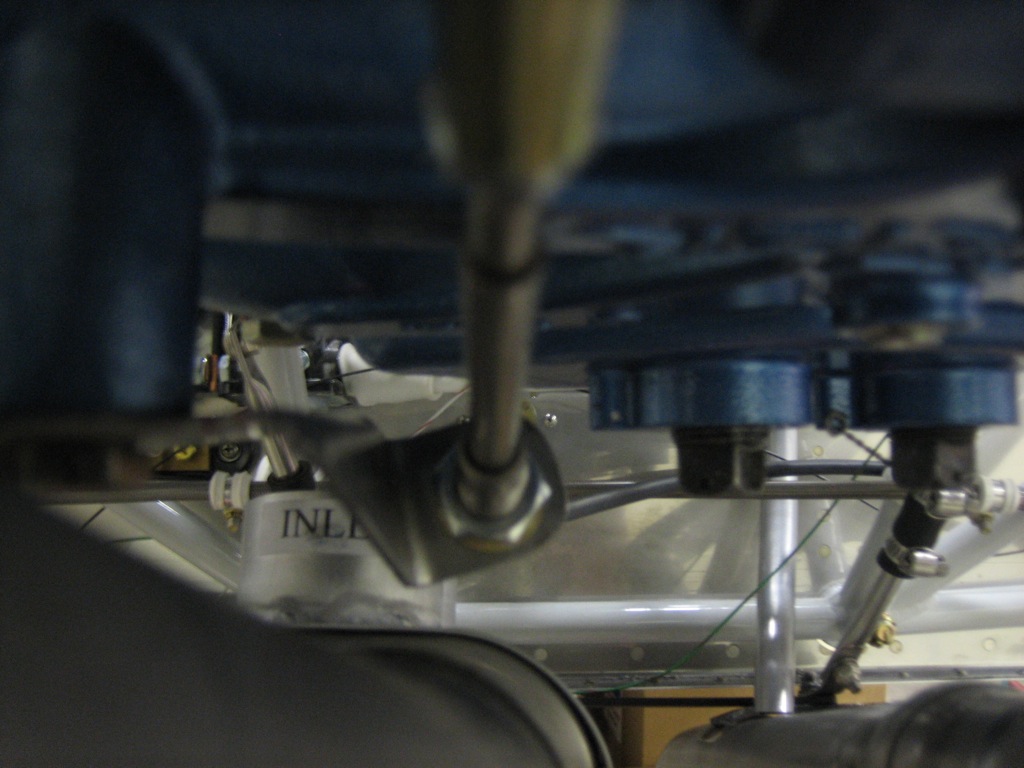

This is a poor picture, but it shows the alignment between the throttle cable and the hole in the firewall. It’s a perfectly straight shot back to the firewall from the bracket and clears the heat muff inlet by a 1/2″ or so.

Now that the throttle bracket fits correctly, I can clean it up and powder coat it before installing it for good.