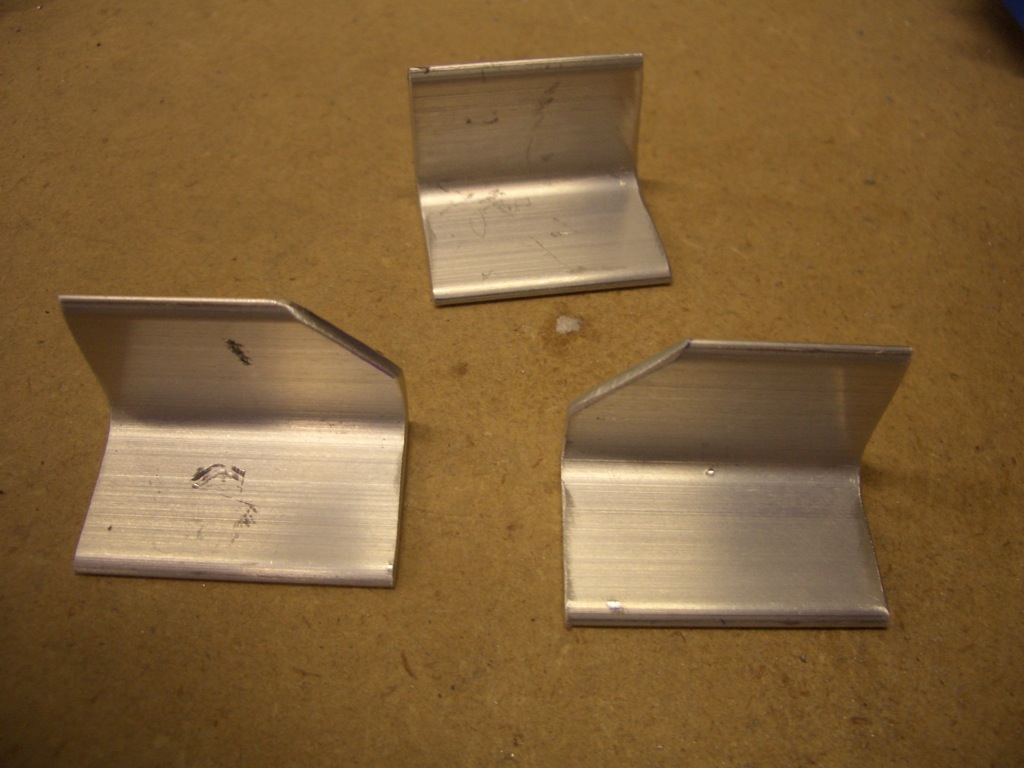

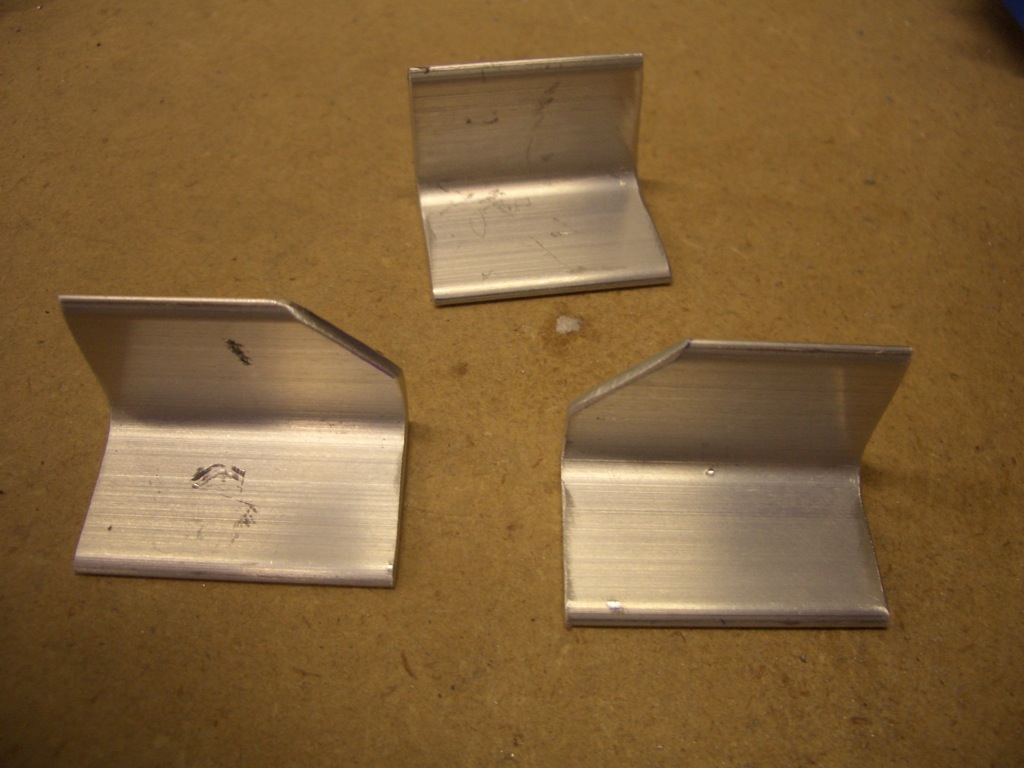

I got an order from Van’s today that included the fuel pump cover. This normally sits higher than this because the forward face of this is vertical and the angled face is more steeply sloped upward. This provides room for the much larger Airflow Performance fuel pump/filter/check valve assembly. This configuration won’t work for me because I had to move the fuel pump forward almost 2″ to fit the fuel line between the fuel selector and the fuel filter. This puts the pump outlet far enough forward that there is no room to allow the fuel line on the outlet side room to turn down and drop under the cover.

I reduced the angle of the bends in the cover, which simultaneously drops the height of the cover down as well as pushes the front end forward enough to make room for the fuel line.. I’ll have to fabricate new side covers from some scrap 0.020″ stock, but that’s pretty trivial.

I started fabricating some of the small components for the forward fuselage out of 0.063″ angle stock, but it’s late and this was making a racket.

Instead, I spent a little more time playing with panel layouts in the plane. The cockpit is small enough that I can reach every part of the instrument panel from the pilots seat without leaning over (I have really long arms though). This also means that it’s pretty easy to see everything, regardless of where it is on the panel. I’ve been planning on going with a single 10″ screen Dynon SkyView system, but lately I’ve been considering trying to fit a dual 10″ screen into the panel. Even with the 10″ screen, using just one screen for PFD, Map, and engine monitoring can get kind of cramped. I think dual screens would force me to remove the Dynon D6 that I was planning to use as a backup PFD though. Although I could add a second ADAHRS box, I’d still be relying on a single overall system which worries me a little bit.