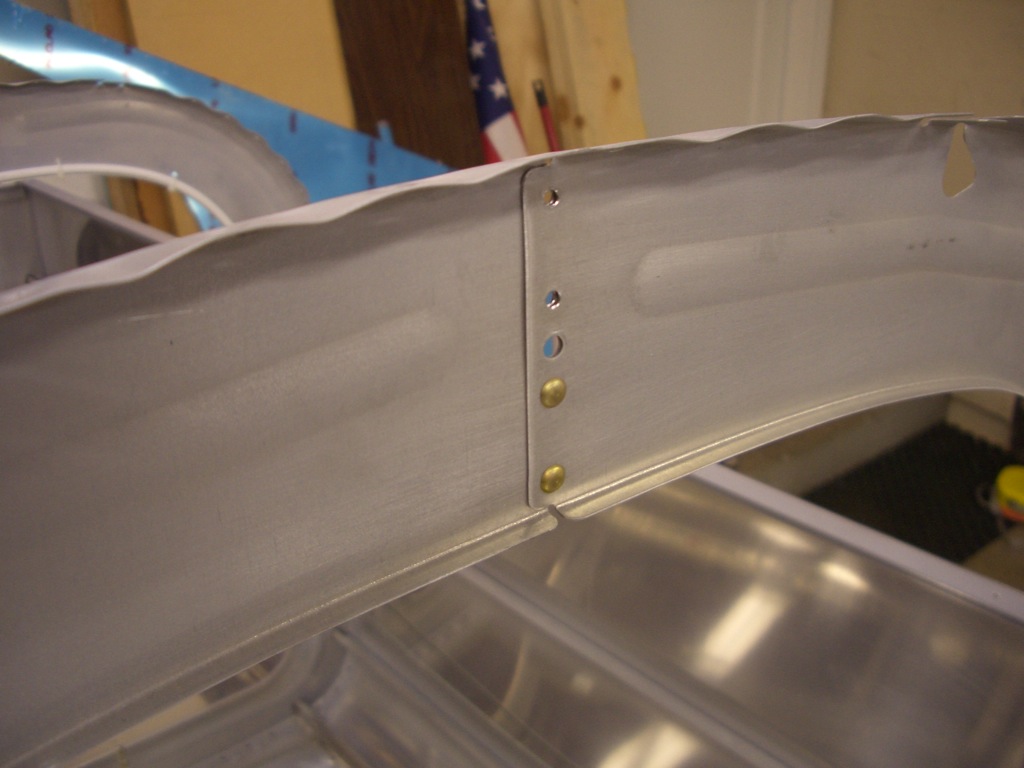

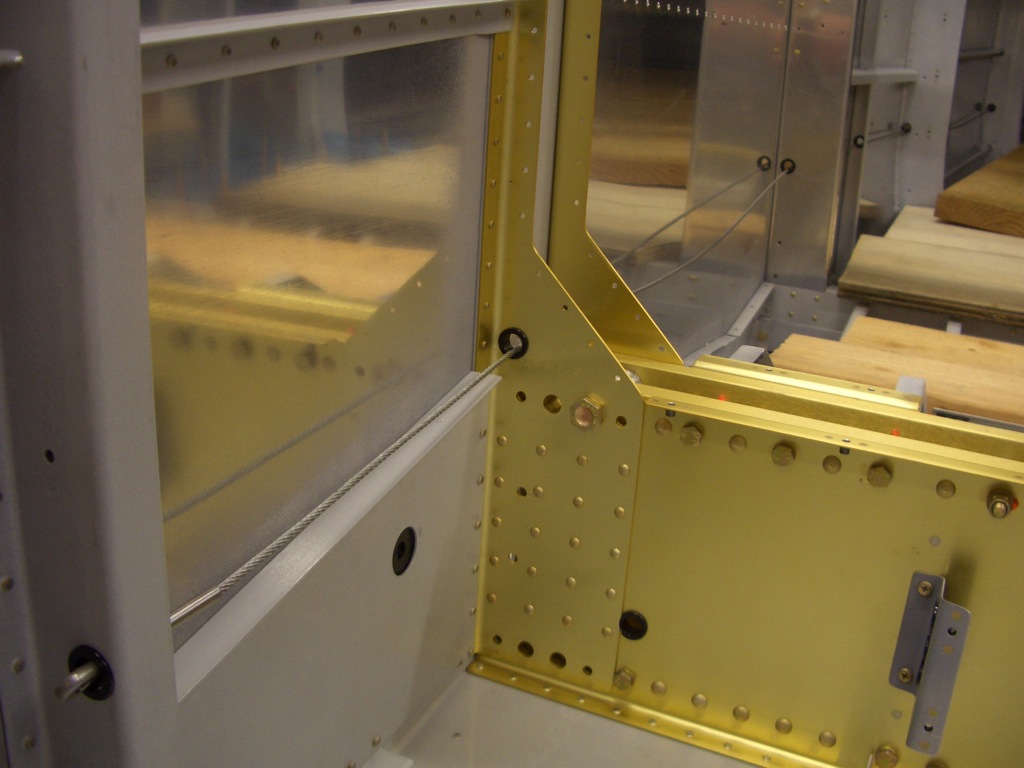

I installed the seat belt anchors tonight. Other than it being pretty cramped where the outboard anchors attach, making it difficult to get a torque wrench in there, these were pretty straightforward. I clamped a piece of scrap 1/4″ thick steel between each pair of anchors and used an AN4 bolt to keep the upper holes aligned while I torqued these down.

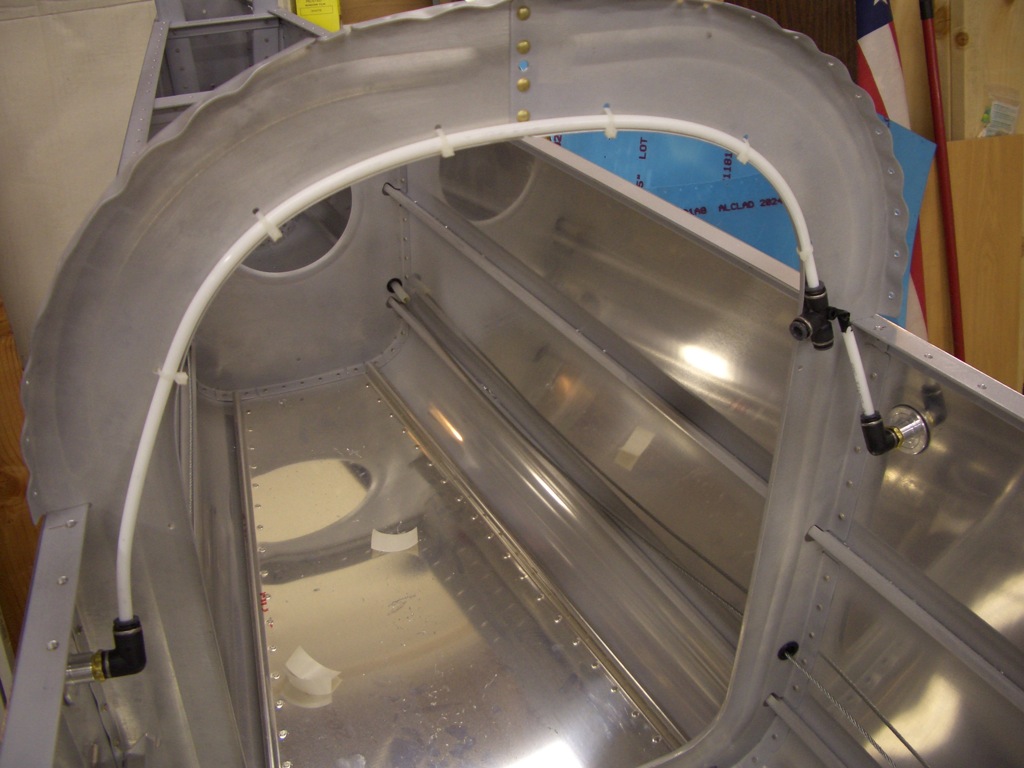

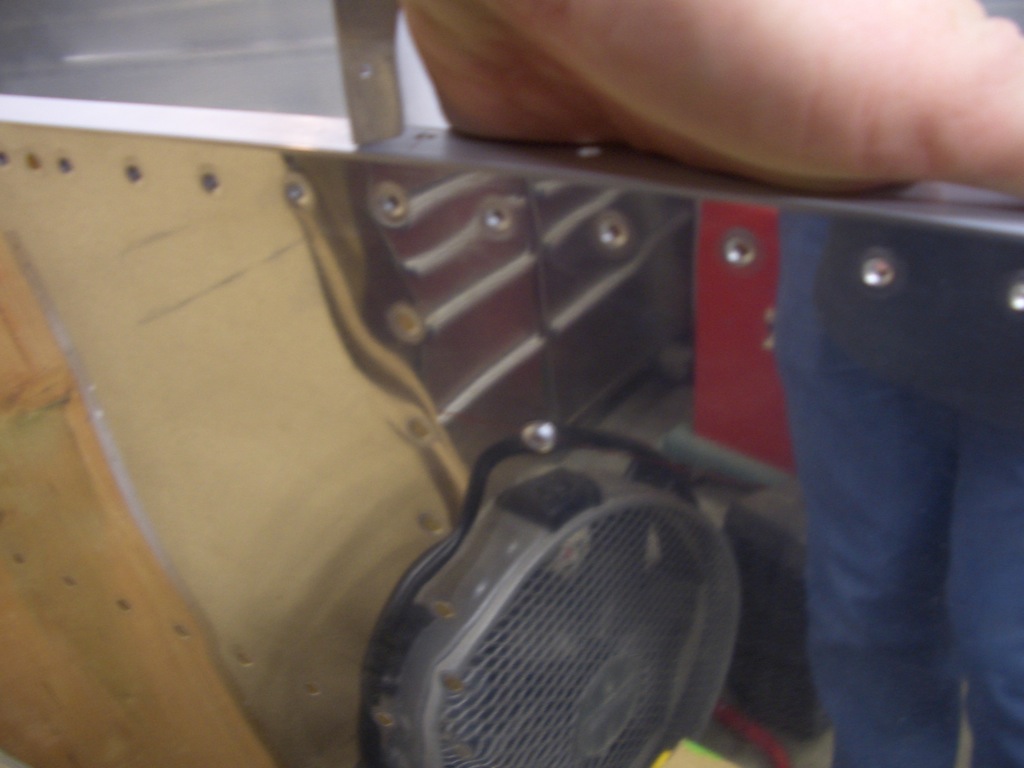

Next, I laid out and drilled for the static ports. I’m using the SafeAir pitot/static/AOA kit, so the flange of the static port doesn’t allow you to install them precisely where Van’s recommends (11/16″ forward of the vertical row of rivets). The position I used is 2″ down from the horizontal row of rivets and 1 1/4″ forward of the vertical row of rivets). Here I’m holding the SafeAir static port in the hole while trying to take a picture. I had a hard time getting my camera to focus on the static port, so this is a little blurry.

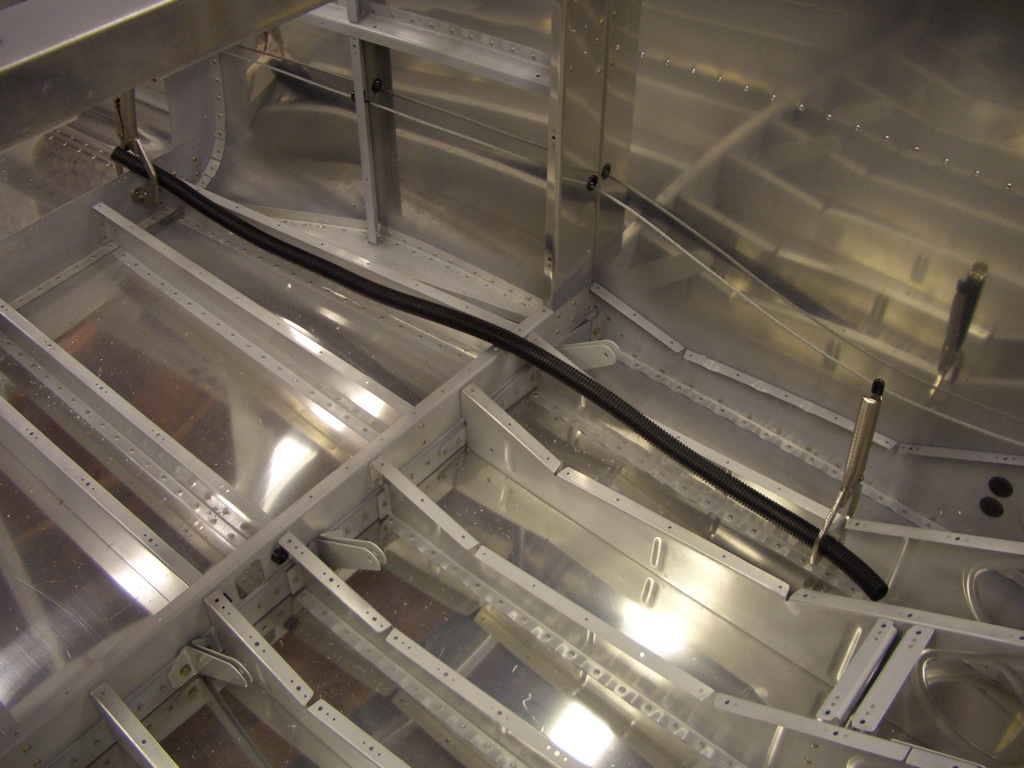

I mixed up a small batch of proseal and bonded/clamped these in position. I installed the 90º adaptors in the ports before doing this so that I could ensure both of them are pointing upward. I’m not going to use any rivets to secure the ports since the proseal is plenty strong to secure these.