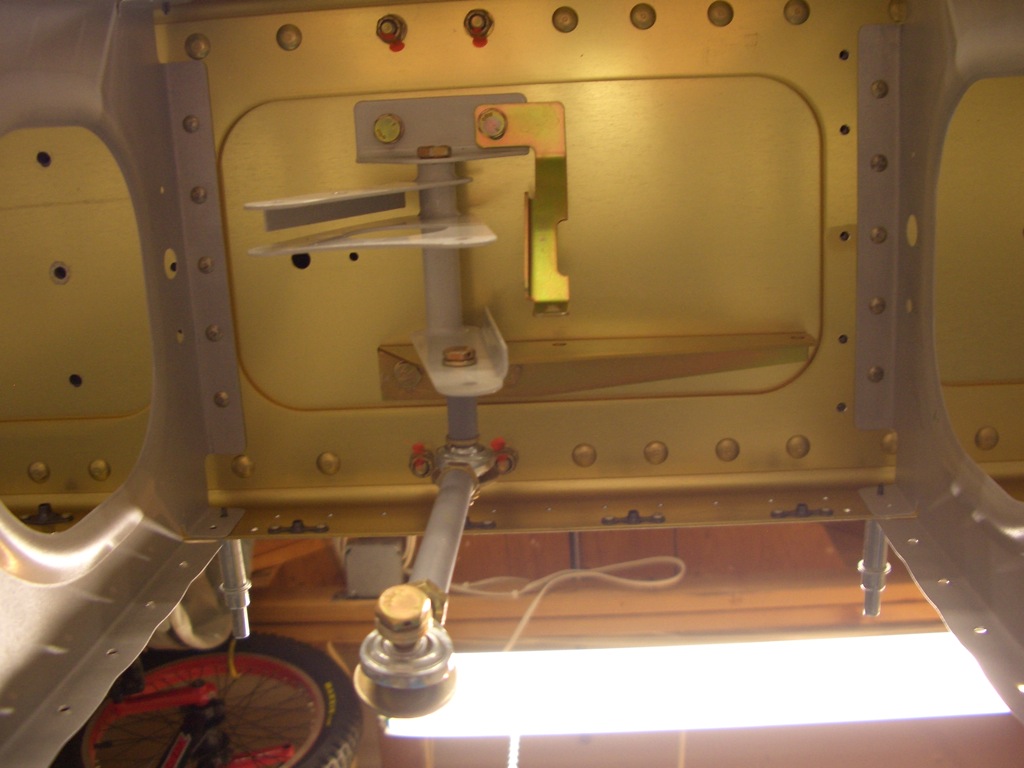

I picked up some Aeroshell 7 grease today and installed the aileron bellcranks permanently. When torqued to the wing, I found I had a little bit of binding. I traced this to making the brass bushings about 0.030″ too short. The plans say to make them 1/64″ to 1/32″ longer than the steel bellcrank tube, but you really want to make them whatever length will just fit between the brackets. I ended up elongating the holes in the upper brackets to allow them to be installed without bending towards the bushing. Here is the right bellcrank with autopilot servo pushrod (currently just hanging down) installed. This side also has a longer bracket on the bottom side of the wing where the servo will mount and a brace that is installed diagonally from the top bracket to the servo (you’ll see when I install the servo).

Here is the bracket installed in the left wing.

To install the leading edges, you need to grind away part of a double offset rivet set because the manufactured heads are right up against the main wing ribs. This allows you to get the rivet set square to the rivet.

Really jumping around now, I pulled out the rough stock for the aileron stiffeners and cut them down to size and began cutting the tapers.