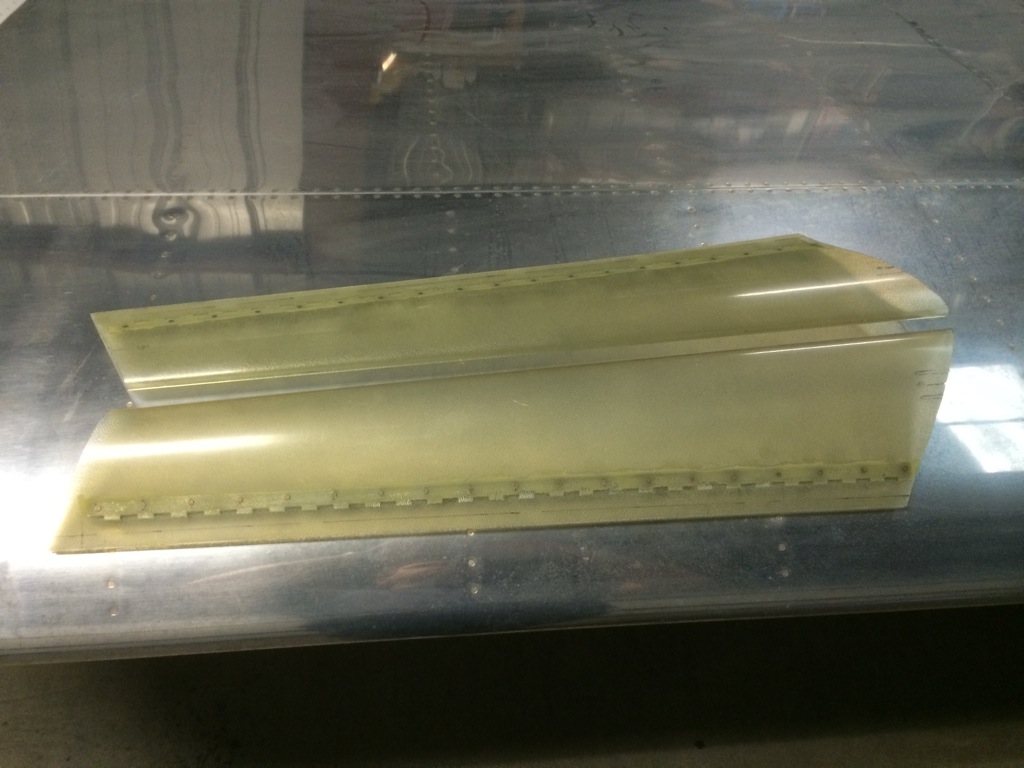

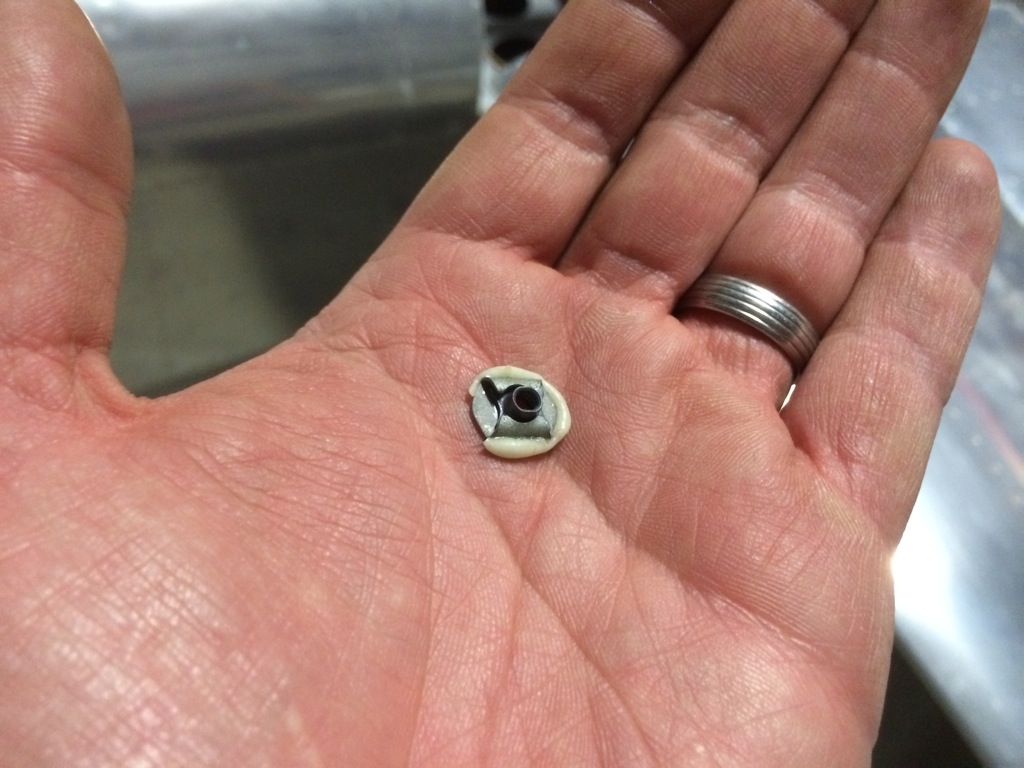

I got down to the airport mid-morning so that I could fix the lower empennage fairing. I trimmed the extra glass I added and then worked on the rivnut that replaced the ClickBond nut plate that popped off. I drilled the hole out to 0.182″ and then filed a notch for the keyed rivnut. The keyed variety has a small protrusion under the head to prevent the rivnut from rotating if it ever loosens up. Finally, I reinstalled the fairing. I still have some filler to apply, but it’s looking much better.

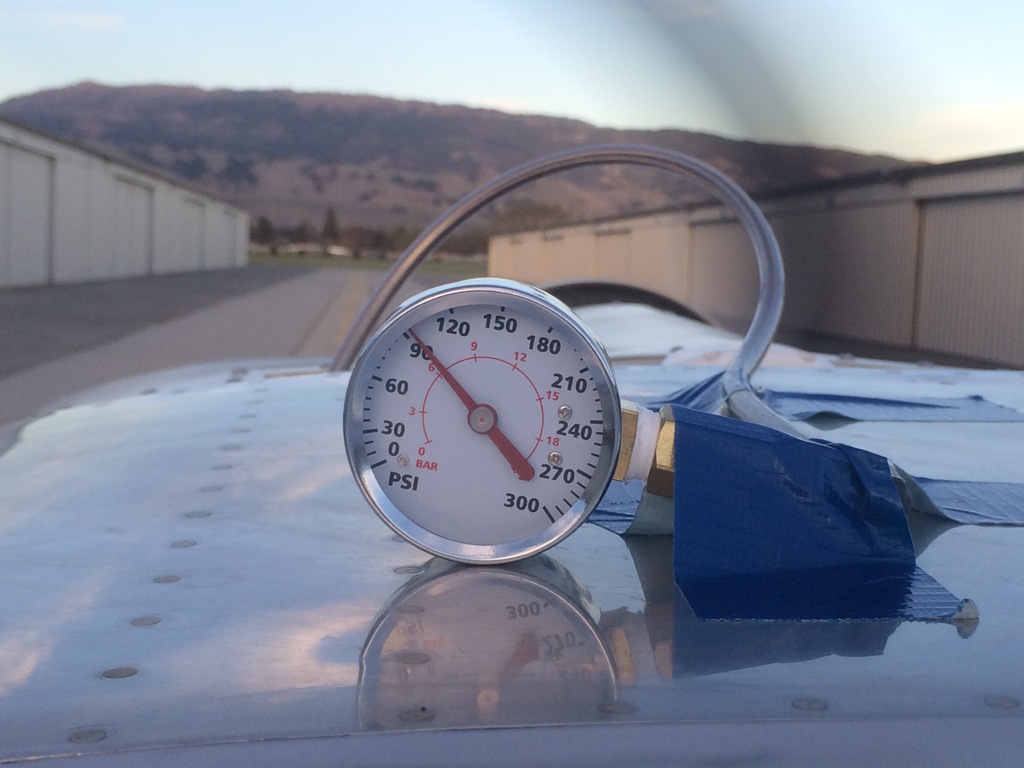

After buttoning everything up, I took the plane out and flew for a little bit. The right fuel tank calibration looks good and showed a full tank, so I switched to the left tank so I could run it dry in order to calibrate it. I headed down to Hollister so that I could help Greg with the reassembly of his RV-8. I got there a little bit before the plane and the crew showed up, so I stayed in the pattern for a bit and practiced wheel landings. I bounced one, but the other three were very nice.

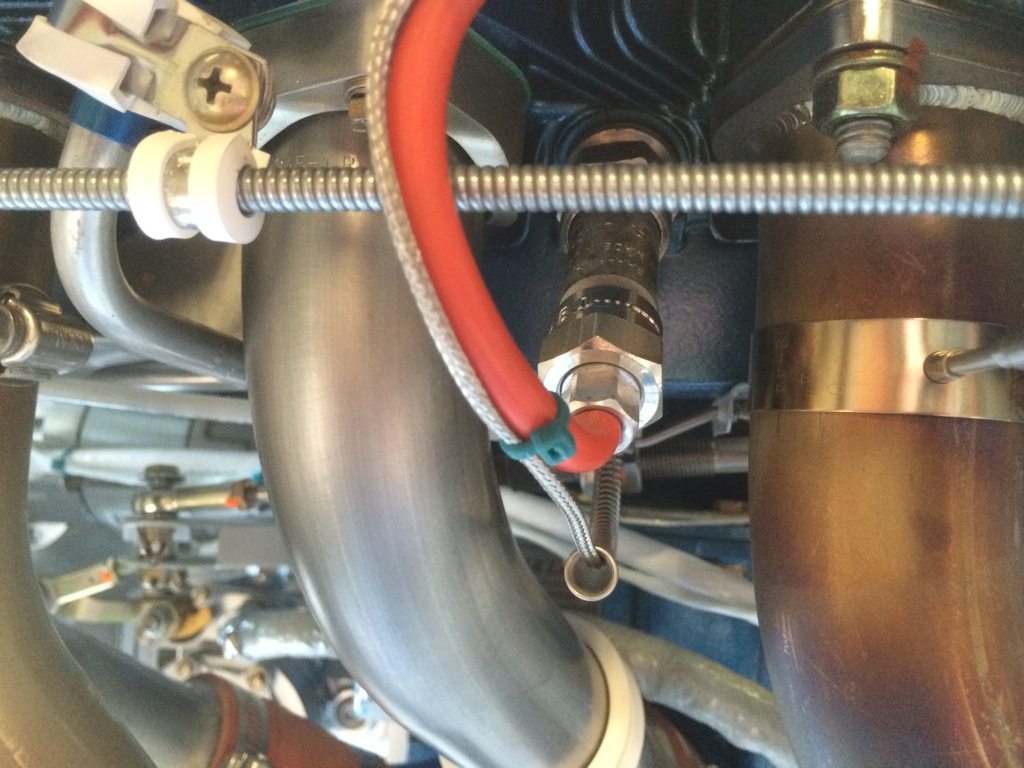

After helping to unload, we grabbed some lunch and got started on the reassembly. After some final prep work, we got the wings slotted in and a couple of close tolerance bolts in on each side. We got both ailerons attached and hooked up the fuel and vent lines.

It started getting dark and I needed to be back on the ground at South County before night. I headed out right around sunset and got back up to South County in just a few minutes. It was still fairly bright out, so I stayed in the pattern for a bit and did some touch and go’s as the sky darkened so that I could get used to the sight picture and get a feel for how bright the landing and taxi lights are. I stopped about 10 minutes before it got truly dark, but it was good practice and it looks like the lights are plenty bright.