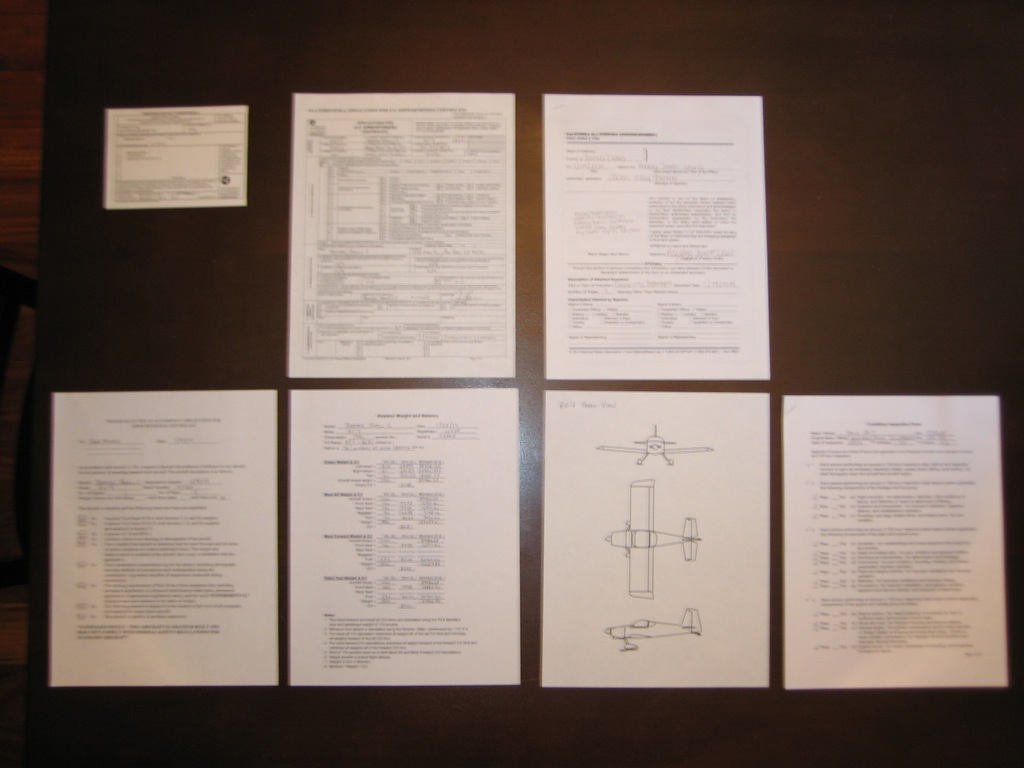

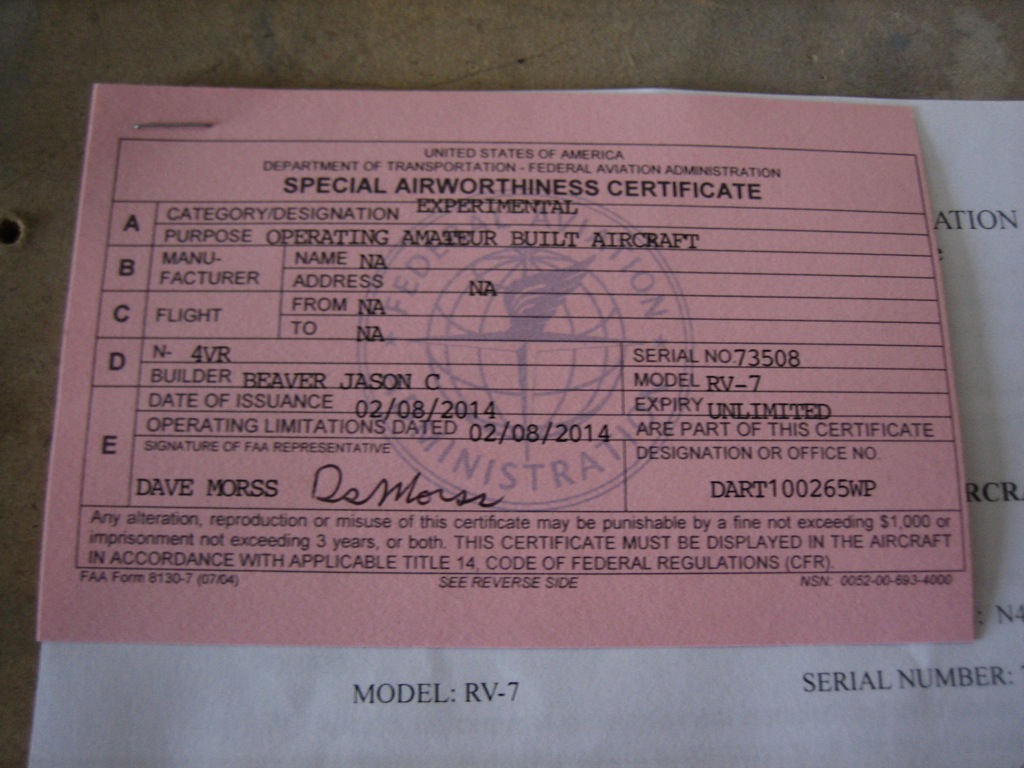

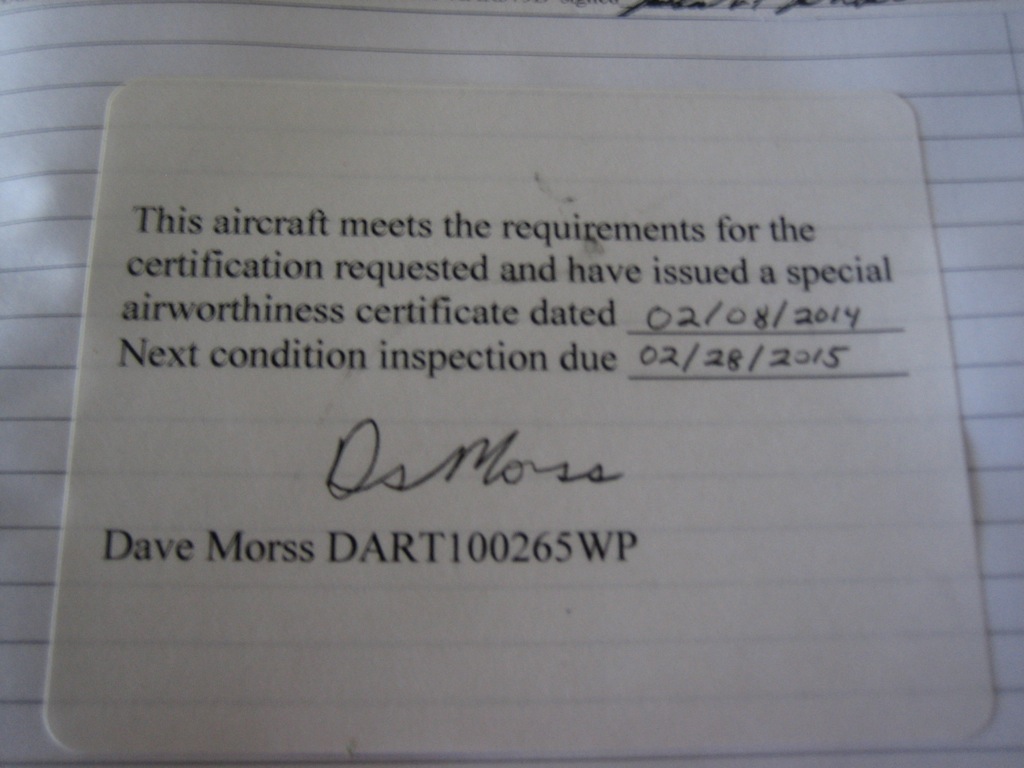

I had my airplane inspection party today. I invited RV builders from all over the region to come give my plane a good once over before scheduling time with the DAR. I had a great turnout; roughly 40-50 pilots and builders stopped by over the course of the day. Overall, the inspection went very well. Nothing major was found, but there were a number of small items people caught (some of which I knew about and some I didn’t). I just want to give a huge thank you to everyone who stopped by.

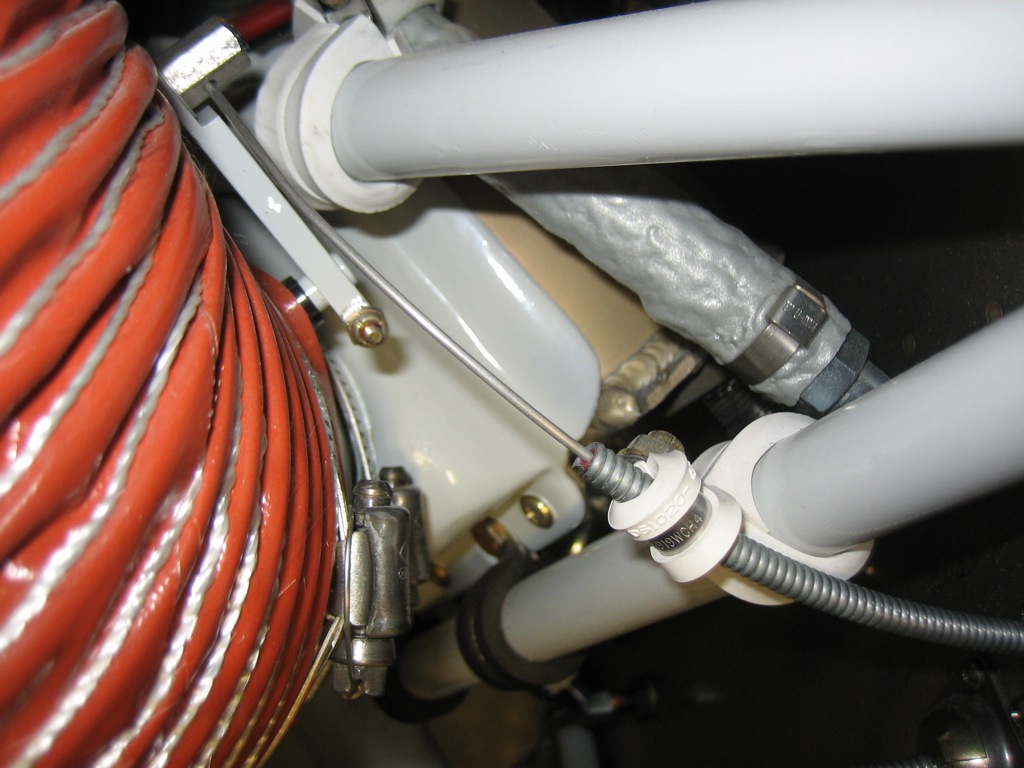

The day started with my transponder certification and pitot/static check. The transponder check passed with flying colors, but I had a leak in my pitot system.

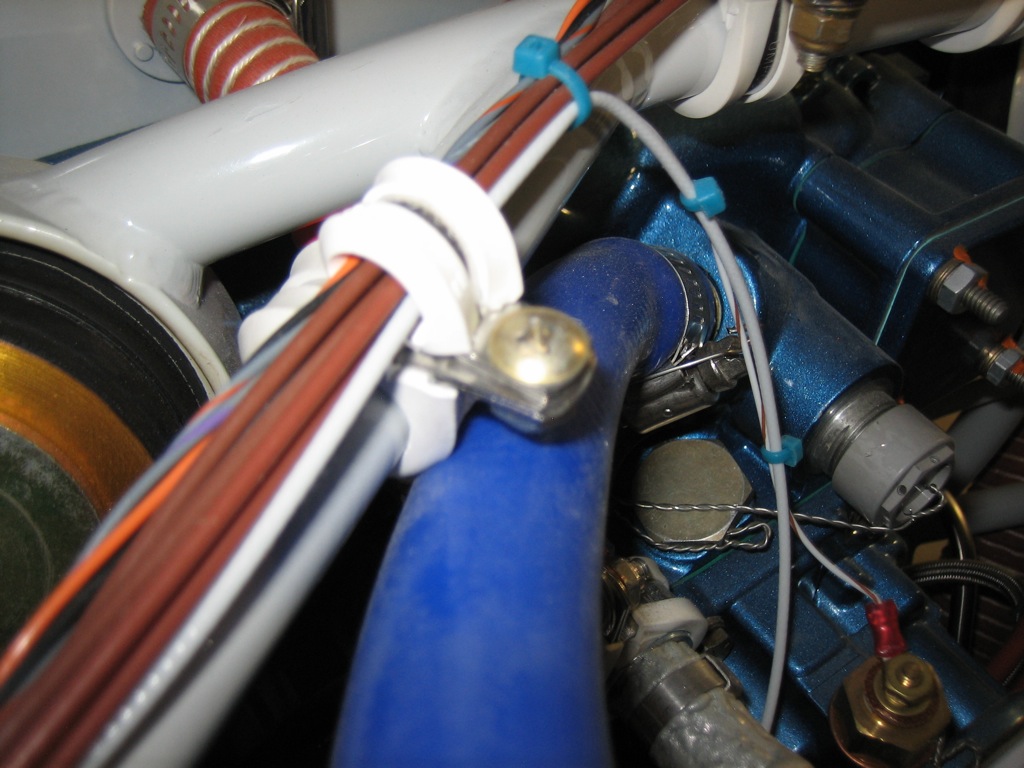

Unfortunately, the leak turned out to be in the wing root fittings where I didn’t quite get one of the pieces of tubing fully seated. In the process of trying to seat it, the tubing popped out and I had essentially no access to get it back in. This was really the wrong place to put these, so I’m probably going to have to pull new lines through the wings and make the connections under the pilot’s seat. Do yourself a favor and avoid all wiring and tubing connections between the fuselage and wing on the RV-7; there is simply no room to work in there.

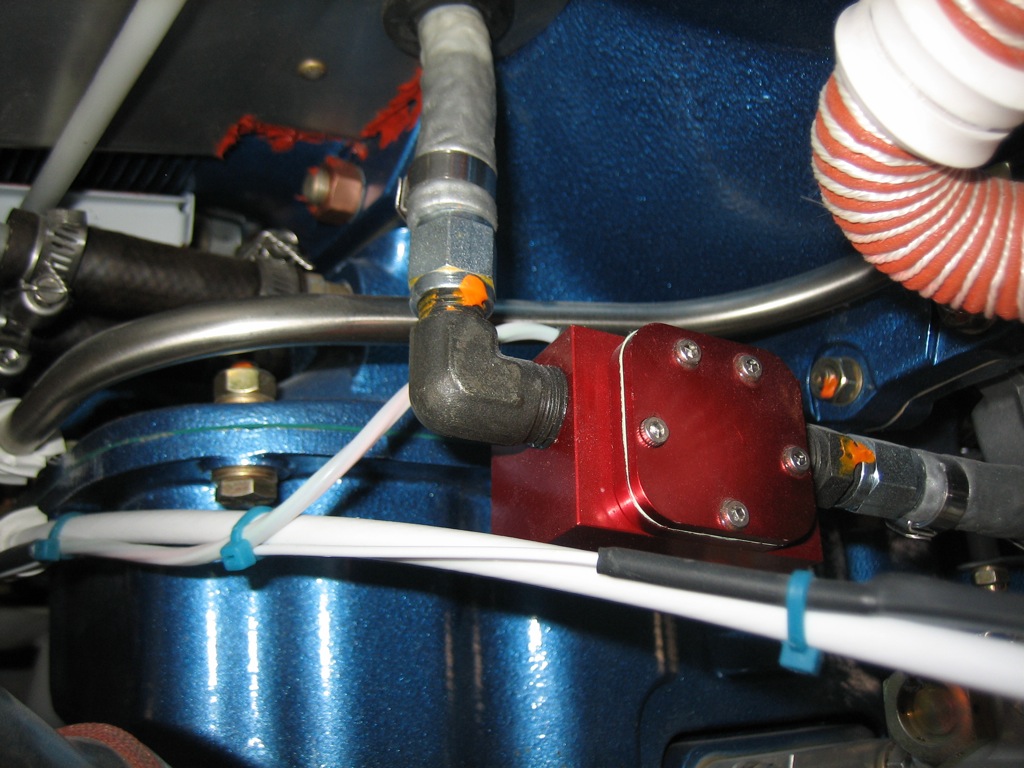

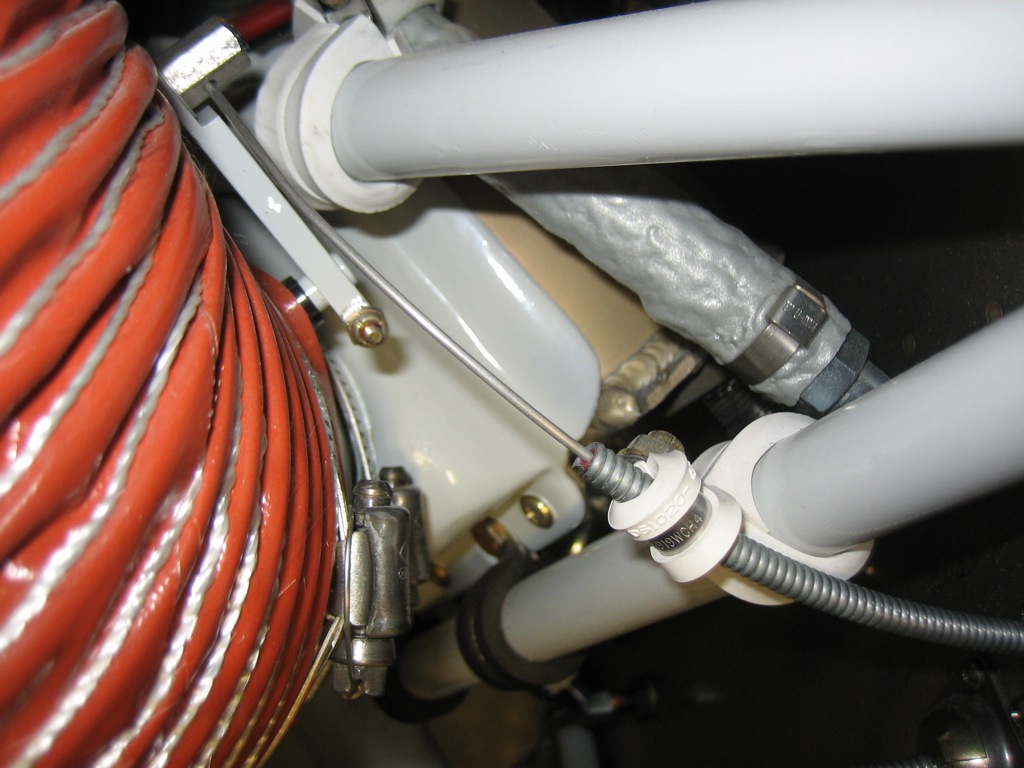

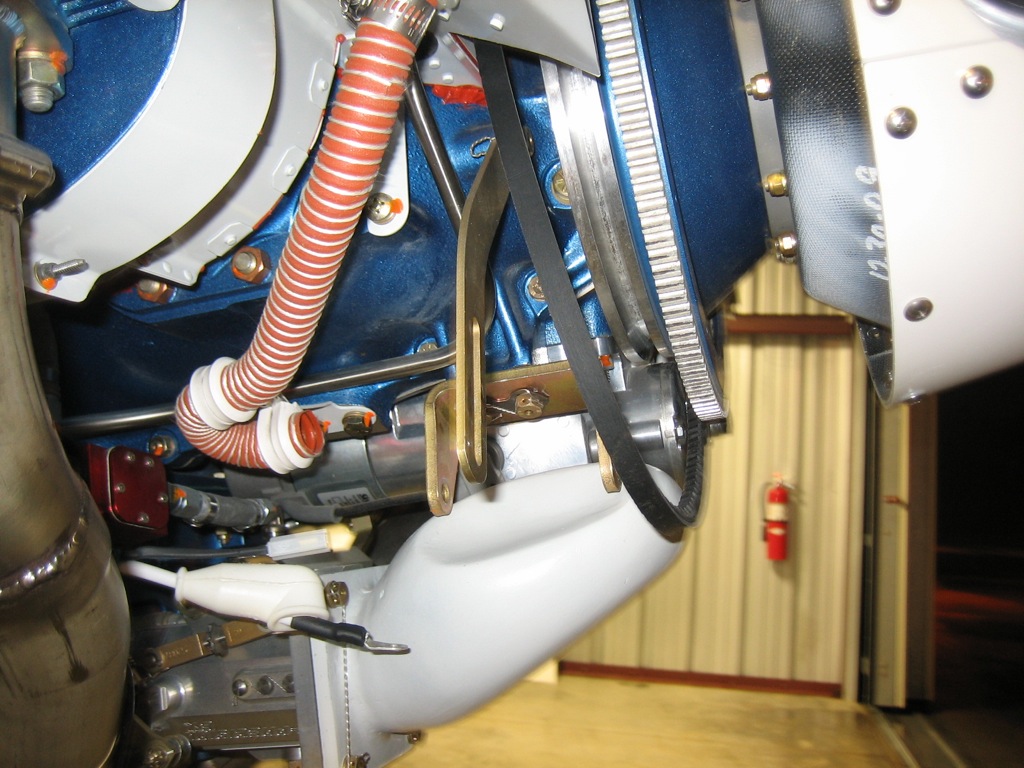

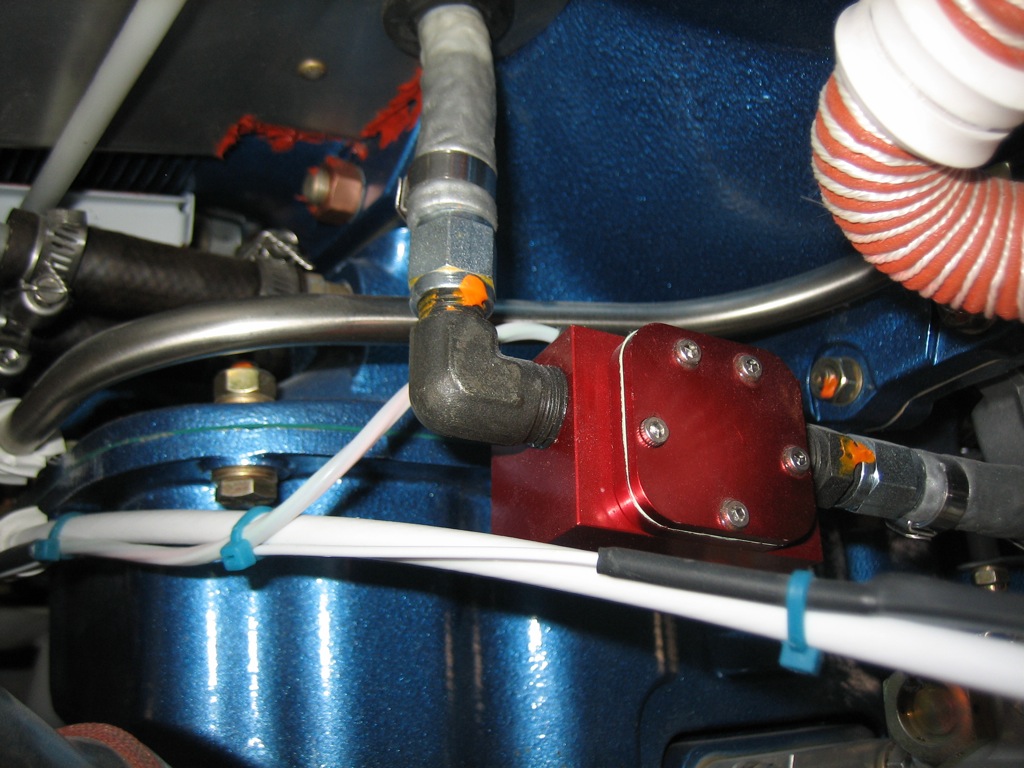

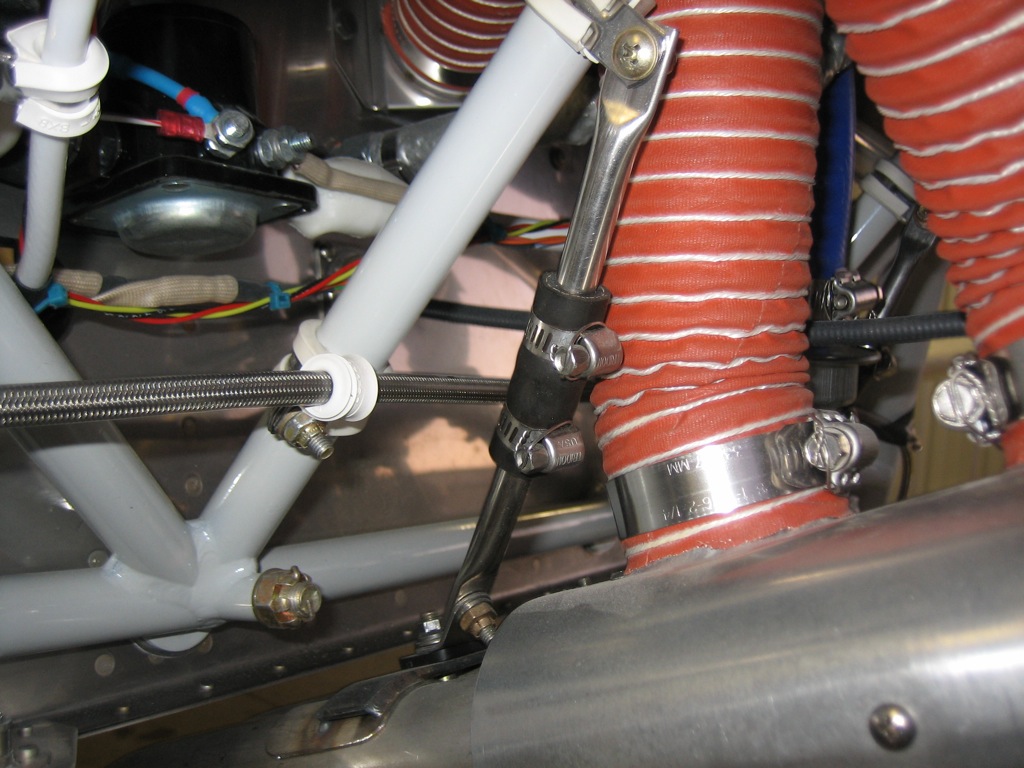

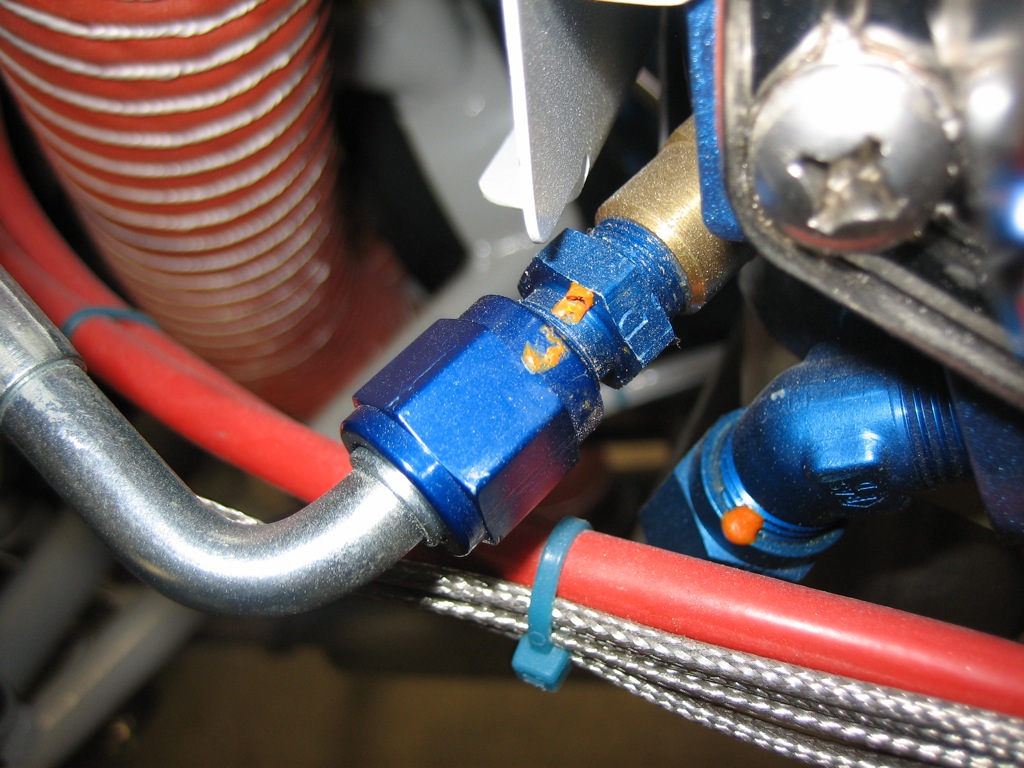

Now, on to the things that were caught during the inspection. Let’s start with a few things that were squawked, but are not actually issues. A couple of people questioned the mounting of my fuel flow transducer which is simply suspended from the fuel lines. Apparently, there are two versions of the red cube. The earlier one didn’t tolerate being rigidly mounted to the engine, but the later one could be mounted like this or to the sump. When I purchased this, I called the manufacturer and they recommended this mounting approach.

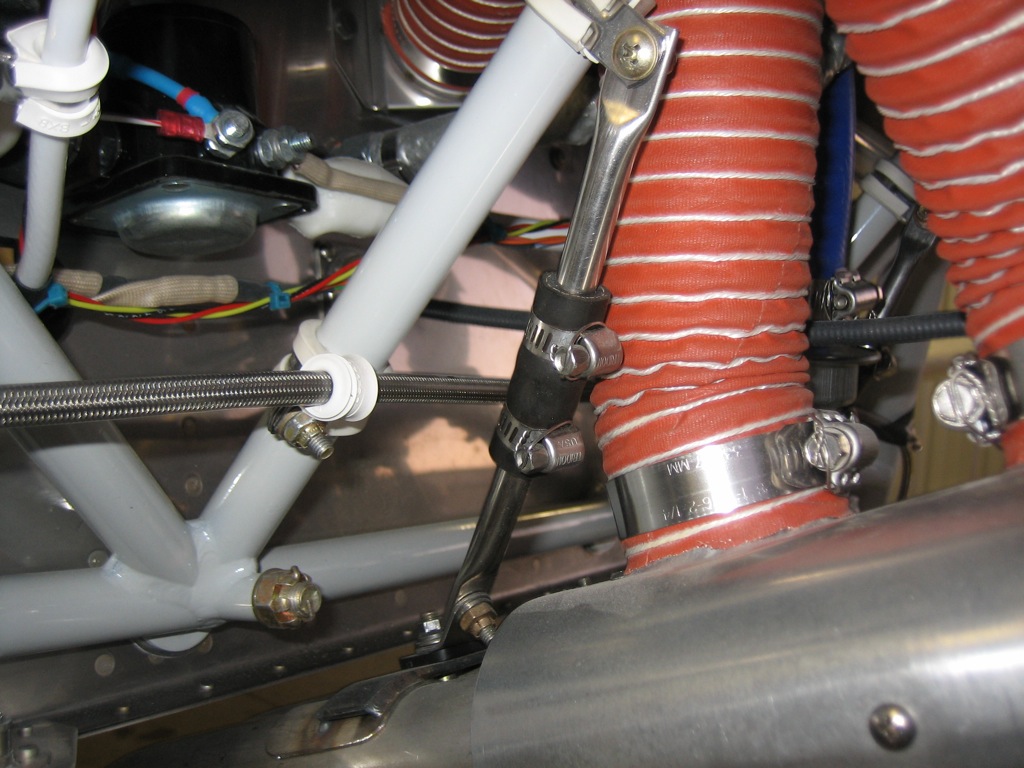

Another builder squawked that there was not enough rubber material on the exhaust hangers which would not allow sufficient movement in the exhaust pipe. Larry Vetterman specifies that the stainless steel tubes only be separated by 1/4″ inside the rubber tubing, so this is installed as the manufacturer recommends.

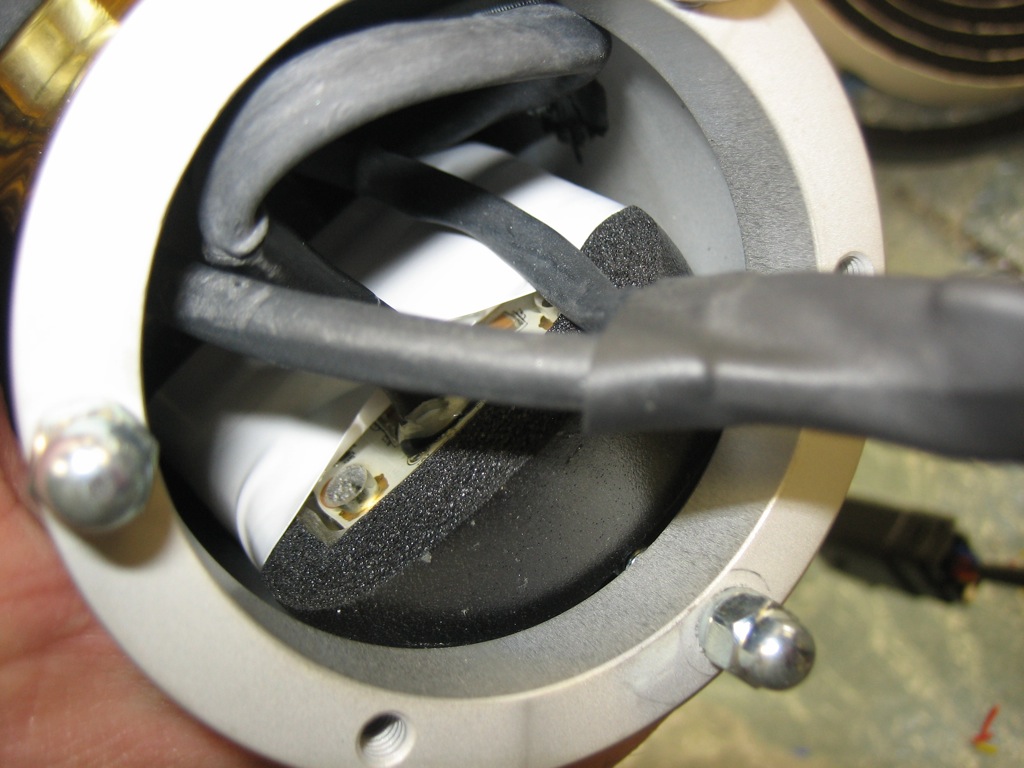

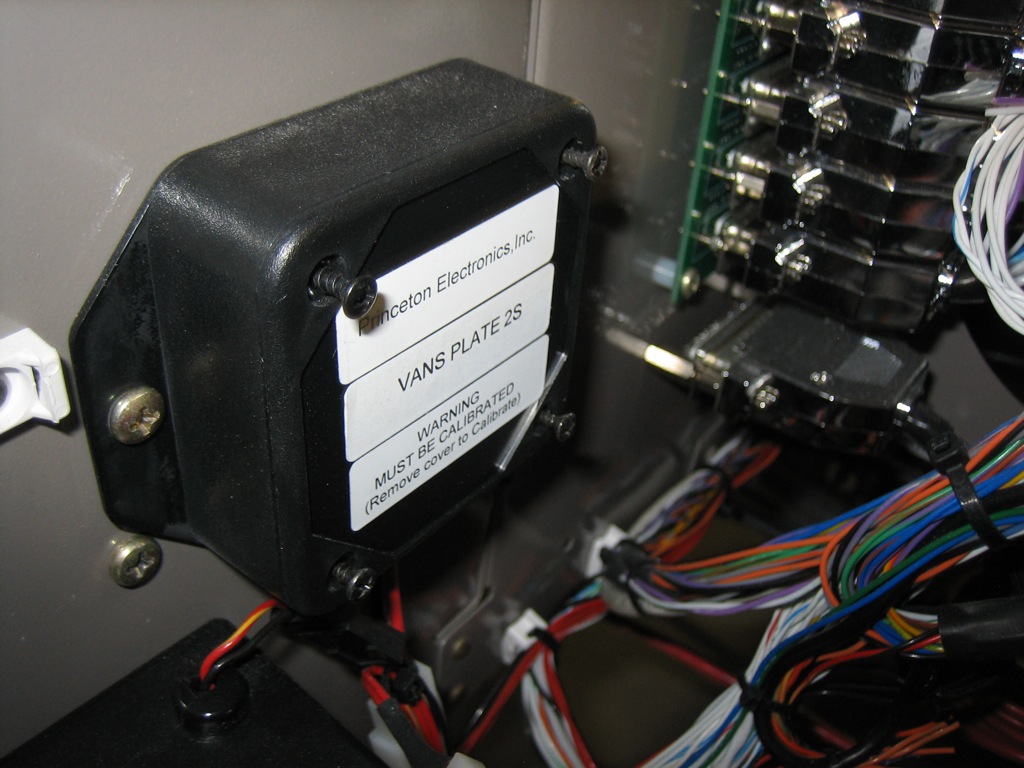

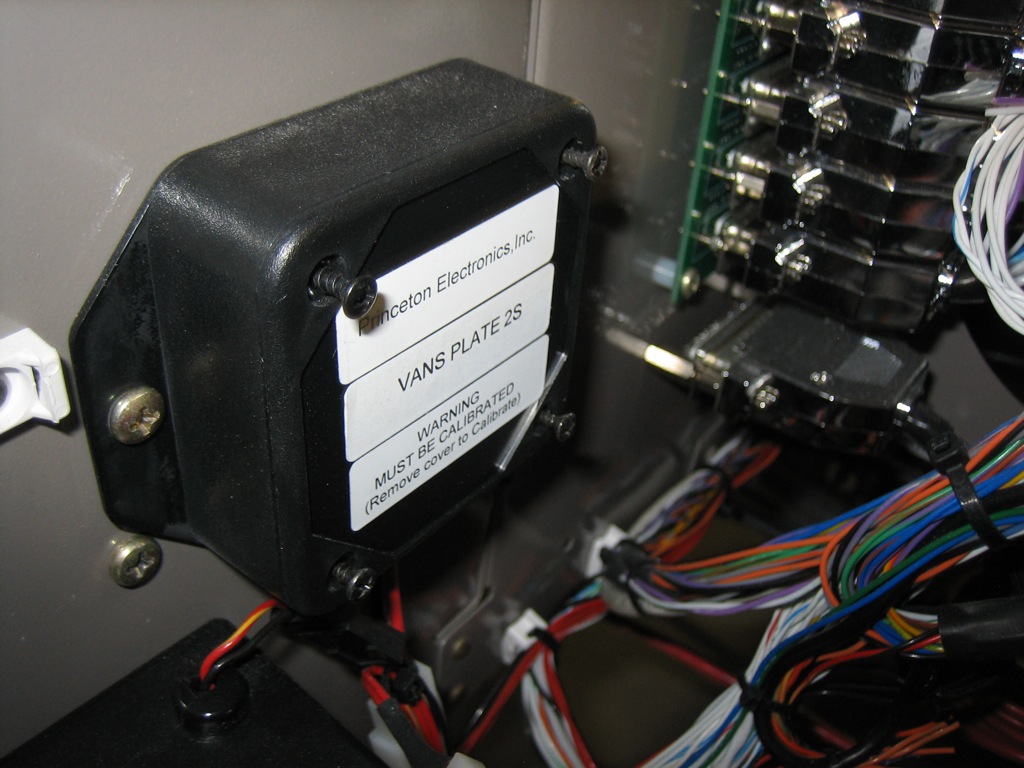

Next, let’s move on to some things that are actually issues, but I knew about. Someone mentioned that the screws weren’t fully installed in the fuel senders. This is because I haven’t had a chance to calibrate the fuel tanks. I have to remove this cover plate to do the calibration, so I left the screws loose until this is taken care of.

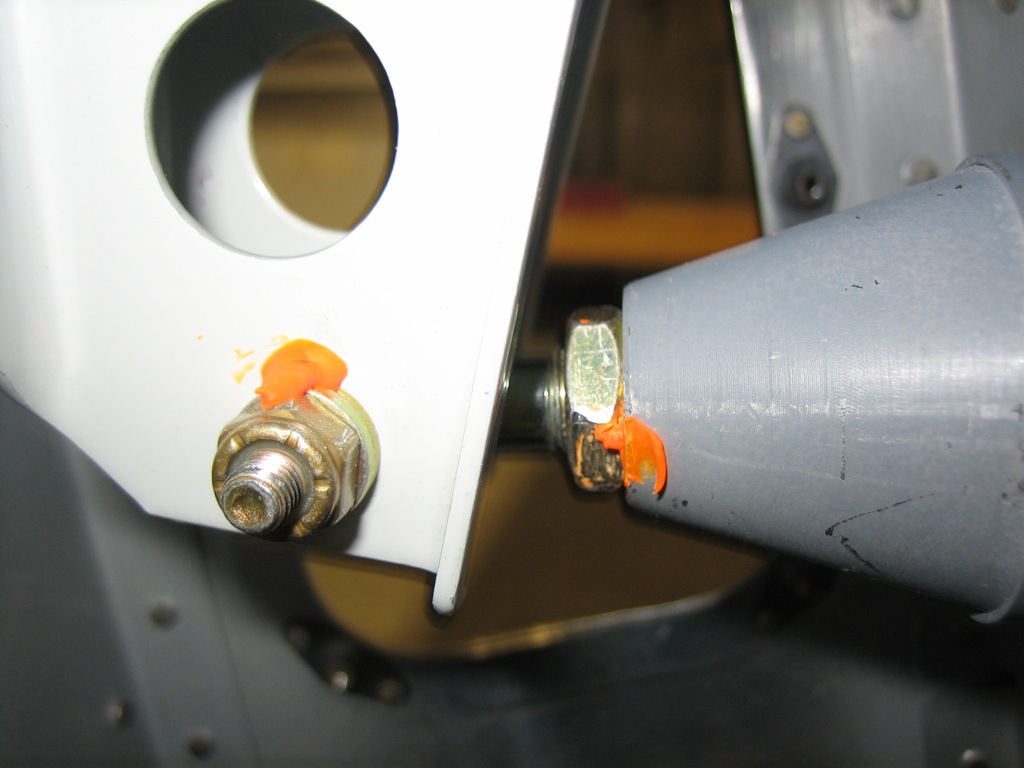

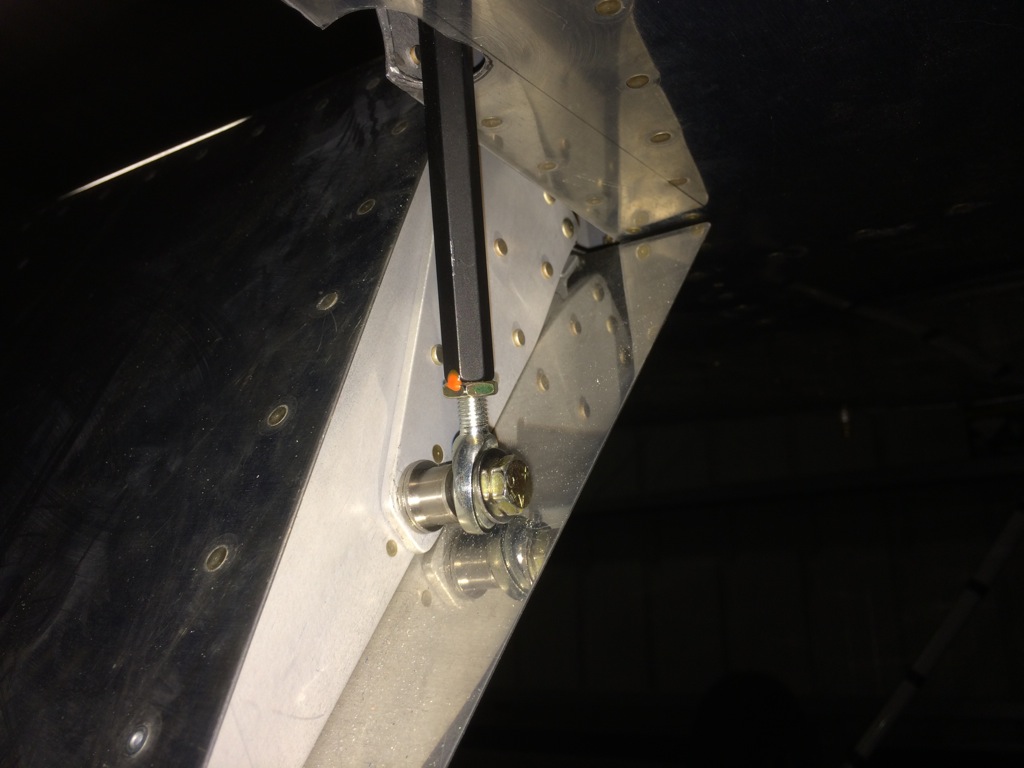

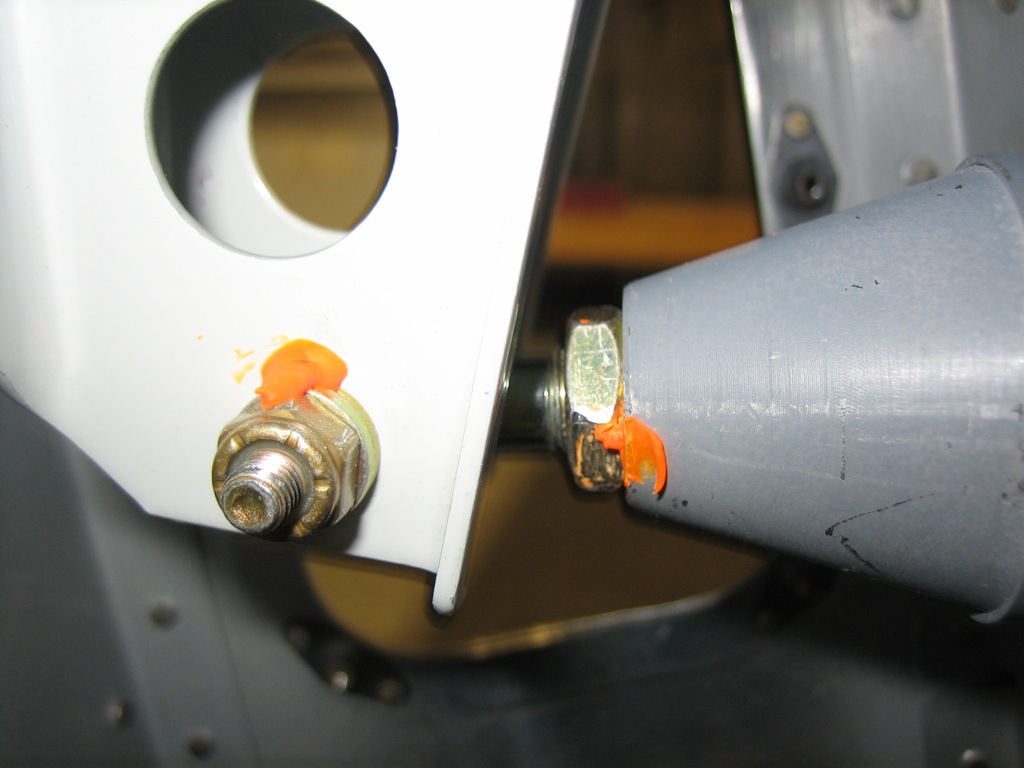

Another builder noticed that the jam nuts on the empennage bearings weren’t torque sealed. Although I modified a tool to fit in here, I wanted to modify it further before torquing these down for good.

Several builders noticed that my brakes weren’t safety wired. I had intentionally put this off since I thought I might need to pull the wheels off again, but I don’t think I have any need now before first flight.

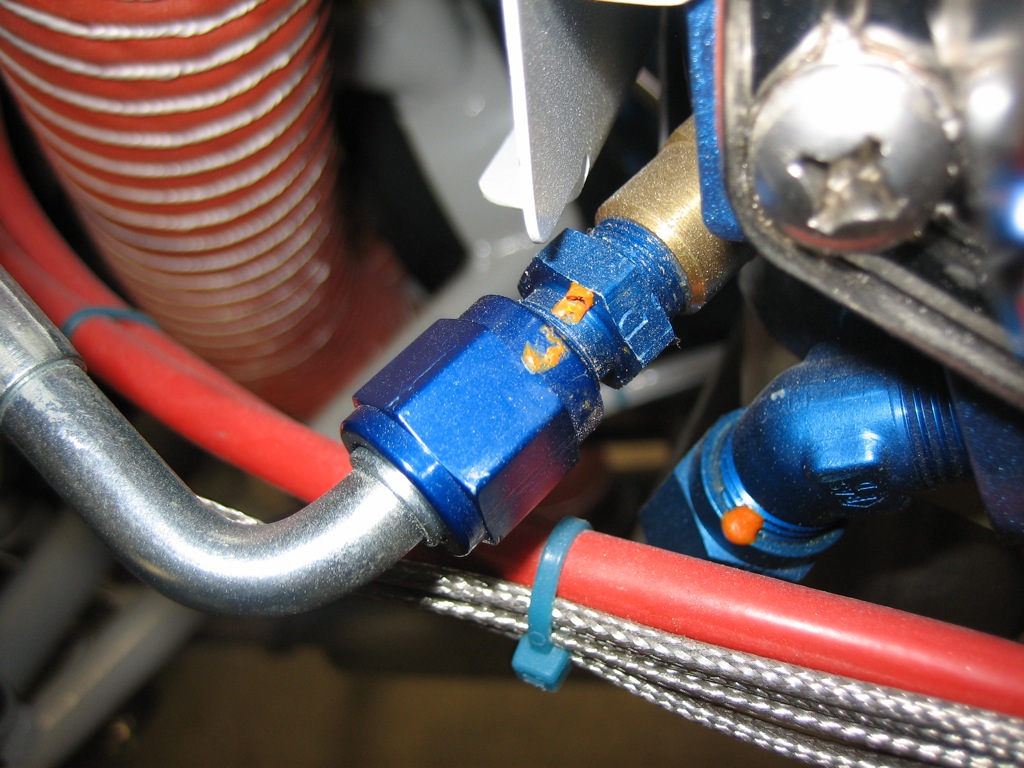

A builder noticed the torque seal was broken on the inlet to the spider. I had pulled this off before first engine start because I wanted to run some fuel through the line to flush any debris out so that it wouldn’t clog the injectors. We hooked the line back up before the engine run, but I didn’t put a torque wrench on this then.

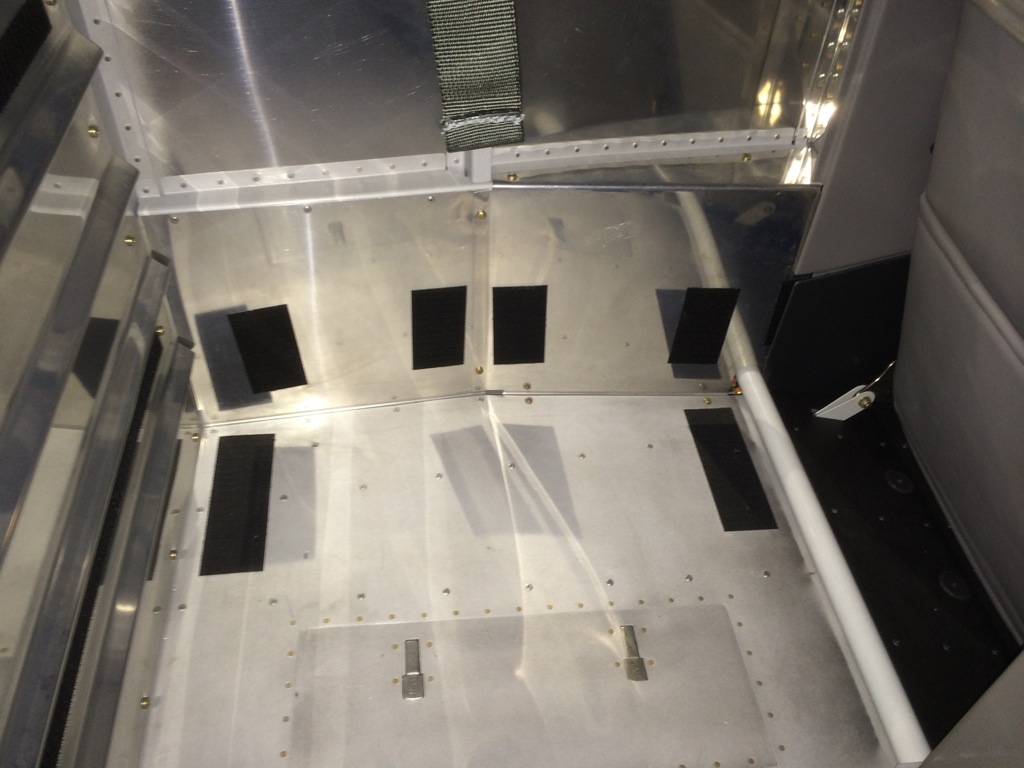

When I was doing the final adjustment of the control sticks, I noticed that the torque tube that connects the control stick was slightly rubbing on the seat ribs. The builder that also spotted this said it is worse when people are sitting in the seats, so you really want some clearance here. Fortunately, I made this section removable on all four of these ribs. I’ll pull these off and remove some material to get a good 1/8″ or so between the ribs and the tube.

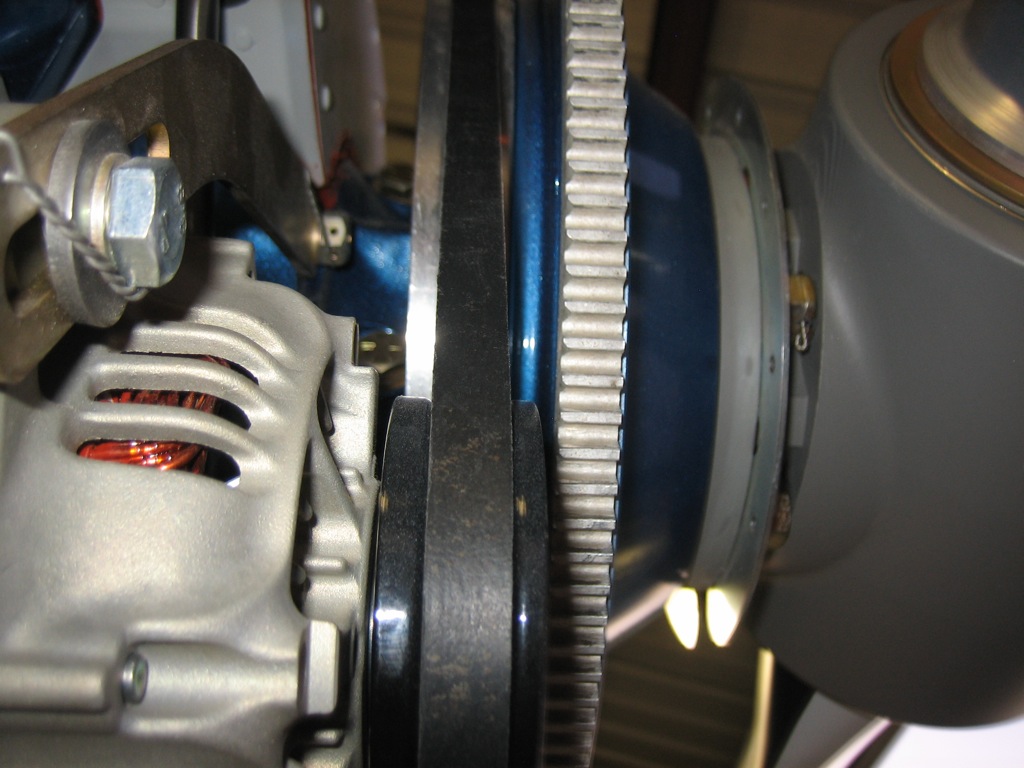

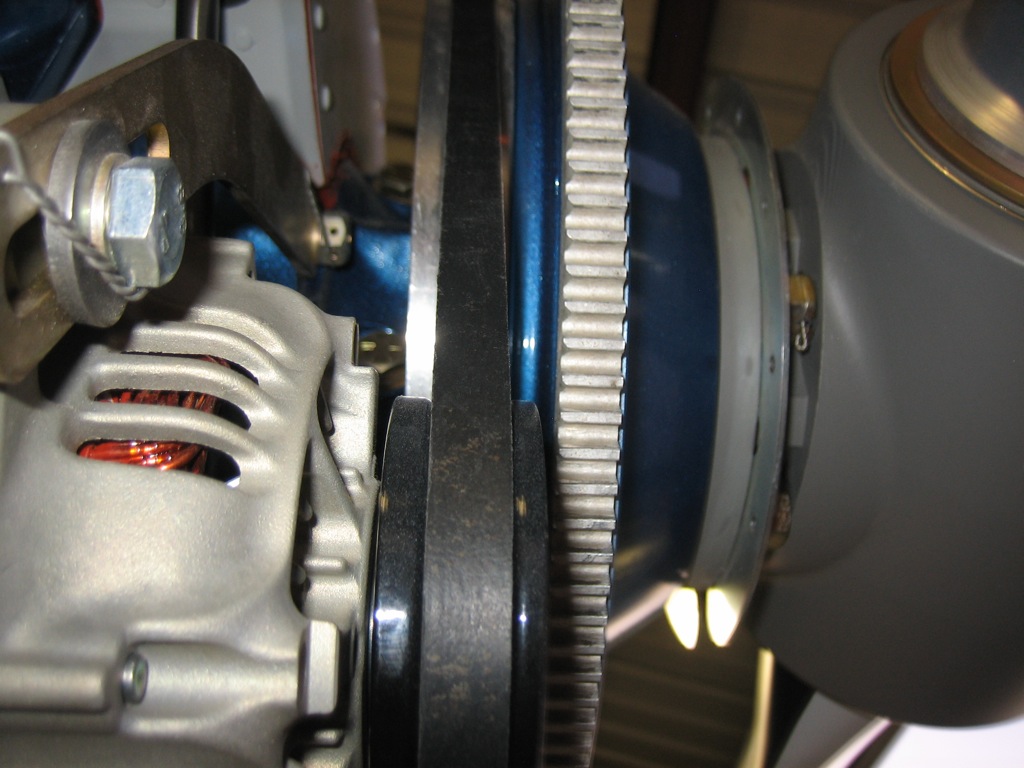

Finally, let’s move on to the things I hadn’t caught. I couldn’t get a great picture of it, but a couple of people noticed that the alternator pulley wasn’t perfectly aligned with the flywheel. This will not only make the belt wear faster, it also is apparently hard on the alternator bearings.

There are four thread showing on the outer aileron bolt. I’ll probably have to add another washer here.

There are also four threads showing on the bolt attaching the pushrod to the elevators horns.

The torque seal was also broken on the manifold pressure hose. I don’t recall why I removed this, but I’ll need to retorque and seal this.

The cushion clamp anchoring the cable sheathing on the oil cooler butterfly valve wasn’t gripping the sheathing well enough and was allowing the cable to move. I’ll need to swap out this for a non-cushion type clamp. There was also not enough thread showing on the bolt holding these adel clamps together.

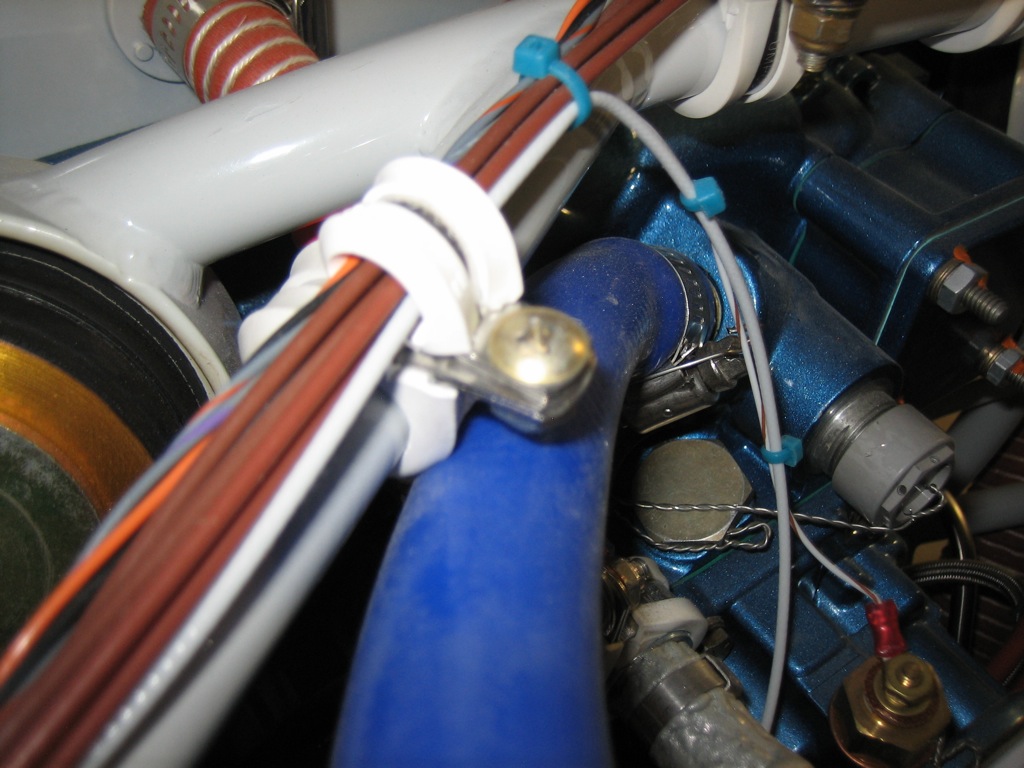

The crankcase breather hose was rubbing on the adel clamps securing wires to the upper engine mount tubing. I’ll probably add another adel clamp to this group to keep this from chafing.

Apparently, the top of the gear leg will rust if left unfinished like this. I’ll clean it and paint it with the touch-up paint that Van’s sells to match the powder coat on the engine mount.