The plane was down for over a month with this annual. Part of that was work as we had our developer’s conference a couple of weeks ago and that’s always a busy time of the year. I’m also running my boss’ team while he’s out, so that’s taking up much more of my time. The other factor is that I addressed several more issues than I normally do during the annual.

I spent the most time tackling several issues firewall forward. The first is that one of my upper exhaust mount support brackets broke. If you’ve been a long-time reader of this site, you might remember that I originally flattened and bent the stainless steel tubing (per instructions from Vetterman), but that broke and I replaced it with these steel brackets made from 18 gauge mild steel. This lasted over 600 hours, but it was apparently still too thin.

I fabricated four new brackets out of 12 gauge steel which will likely last longer than the airplane. I replaced both upper brackets even though only one of them bad broken. I have two spares now in case the lower brackets ever crack. Fortunately, the broken bracket didn’t cause any additional damage.

The oil dipstick tube was originally installed with a paper gasket that is notorious for leaking. It’s also been a minor irritation, but since the plane down for awhile and I needed to order some other things from Aircraft Spruce, I went ahead and ordered one of the Real Gasket RG-72059. Hopefully this will address the issue.

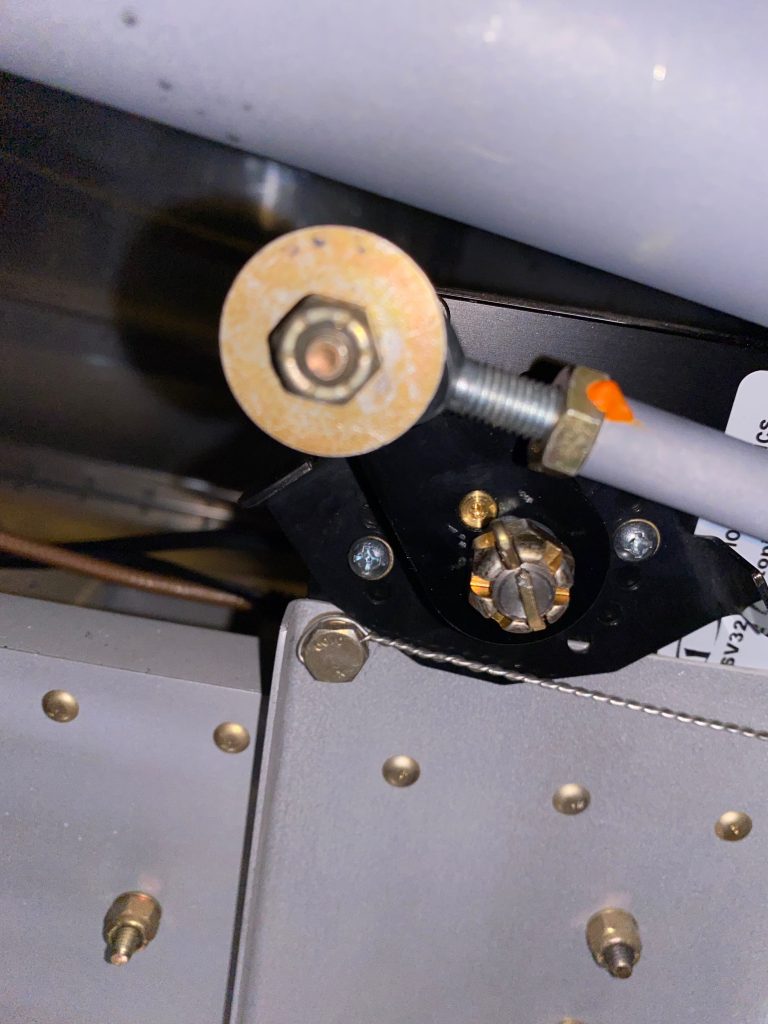

My engine has been sagging for some time. It has progressed to the point now that the alternator pulls is cutting a shallow groove in the lower cowl. I’d been putting it off because I expected it to be a pain, and boy was I right. This is the right side and access is reasonably good here. The left side though was a bear. I could barely see the nut behind all of the stuff in the way. To gain access, I ended up removing the #4 intake tube, disconnecting the mixture cable, and removing the mixture cable support bracket. Even with all of that out of the way, I could barely get my fingertips against the nut, and it was incredibly challenging to get any tool on it to loosen it. I eventually got it off though and the bolts slipped out easily.

The spinner was down about 1/4″, so my hope was that a single AN970-7 washer would be enough. It would be an enormous pain to have to install and remove these multiple times to fine tune the thickness of a shim. Fortunately, this worked out well. When I originally installed the engine mount bolts, I borrowed a friends bolt alignment bullet. I’m not sure where he got it, but it helped bring everything into alignment as we drove the bolts through. I didn’t have access to it anymore, so I whipped up a version on the lathe that worked pretty well.

You can see now that the spinner is nicely aligned with the cowling.

While I had the baggage wall out, I installed some expanding foam insulation in the bends to reduce the airflow from the tail. This should help a little bit with cabin temps at higher altitudes.

We recently added LEMO jacks to our Bonanza. I previously converted my Bose A20 headsets to LEMO connectors, and I’ve been using these adaptors in my RV. I originally installed my headphone jacks on the subpanel. This kept the headphone jacks out of the way, but it makes working on them difficult as it requires crawling under the panel. I probably should have left myself a reasonable service loop of wires, but I was trying to keep the plane light and didn’t do that.

Out of curiosity, I disassembled the LEMO adapter and found out that the internal alignment pieces exactly matched the panel mount LEMO jacks that I’d purchased.

Even the rear shell threaded on correctly.

I realized that this meant I could continue to use my LEMO adapters if I simply replaced the LEMO end with the panel mount jack. The only modification I needed to make was to install a power wire onto the unused pin in the jack and route it out of the back of the connector.

This let me install the LEMO jacks on the panel. I wanted to install them in a location that was as out of the way as possible, and ended up choosing the far edges of the panel. Here’s the pilot’s side.

And here’s the copilot’s side.

There’s a good 1/4″ of clearance from the cable to the gas struts that support the canopy

These can just stay plugged into my original headset jacks and can be unplugged someone ever wants to use their own headset without a LEMO connector.