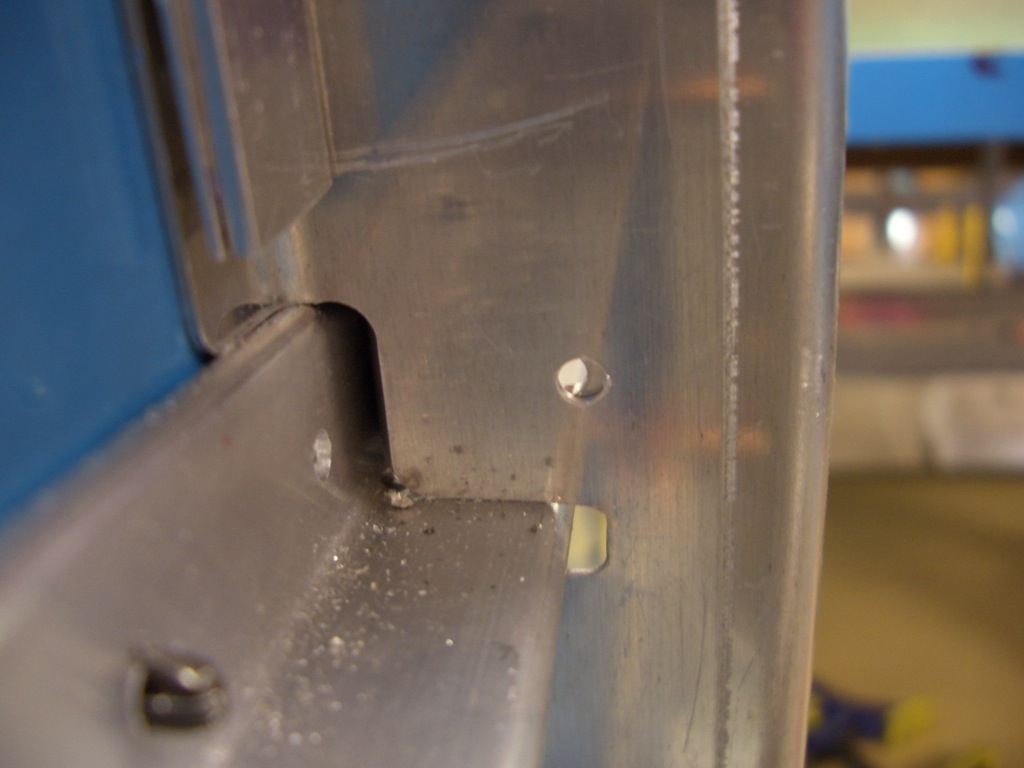

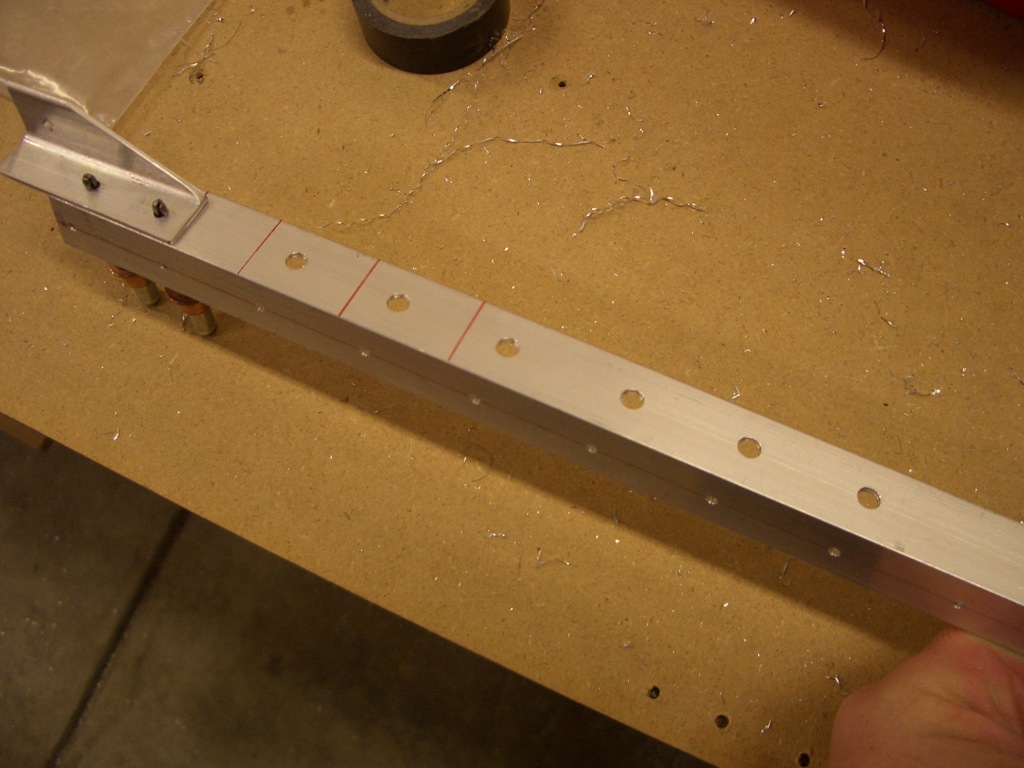

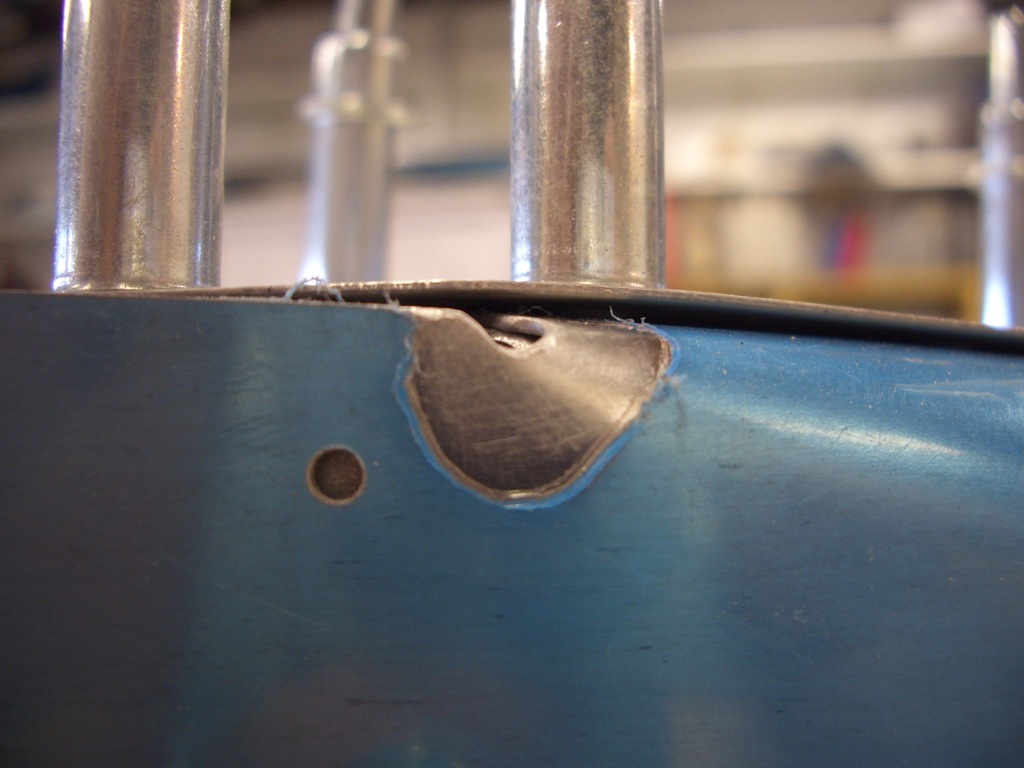

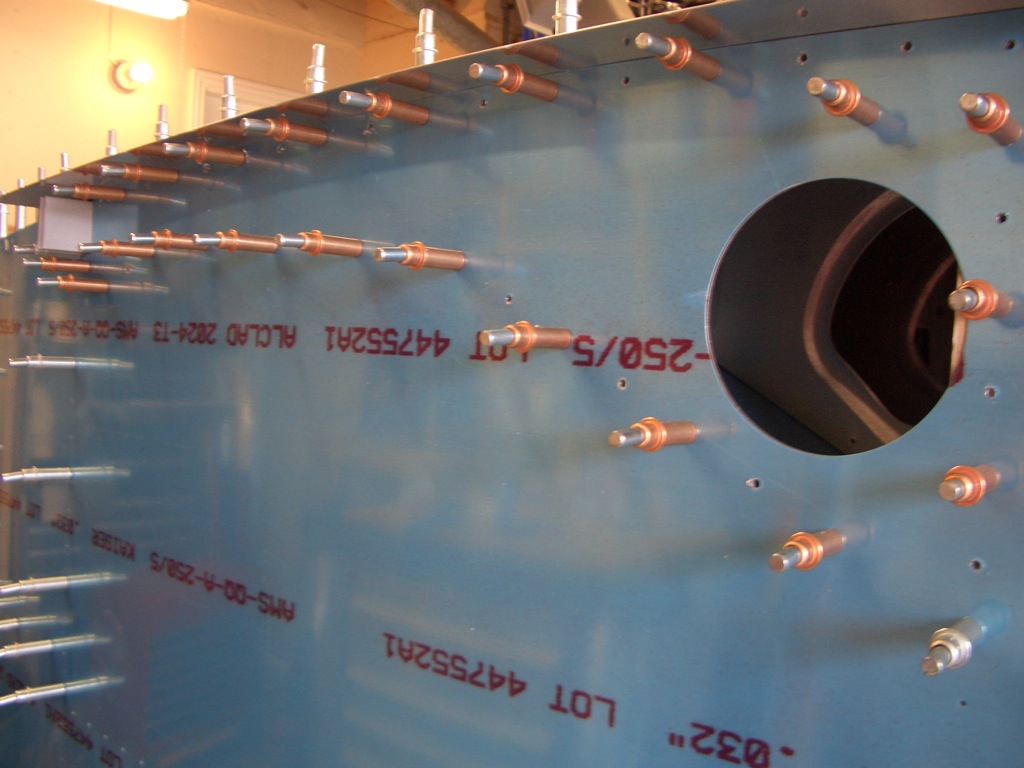

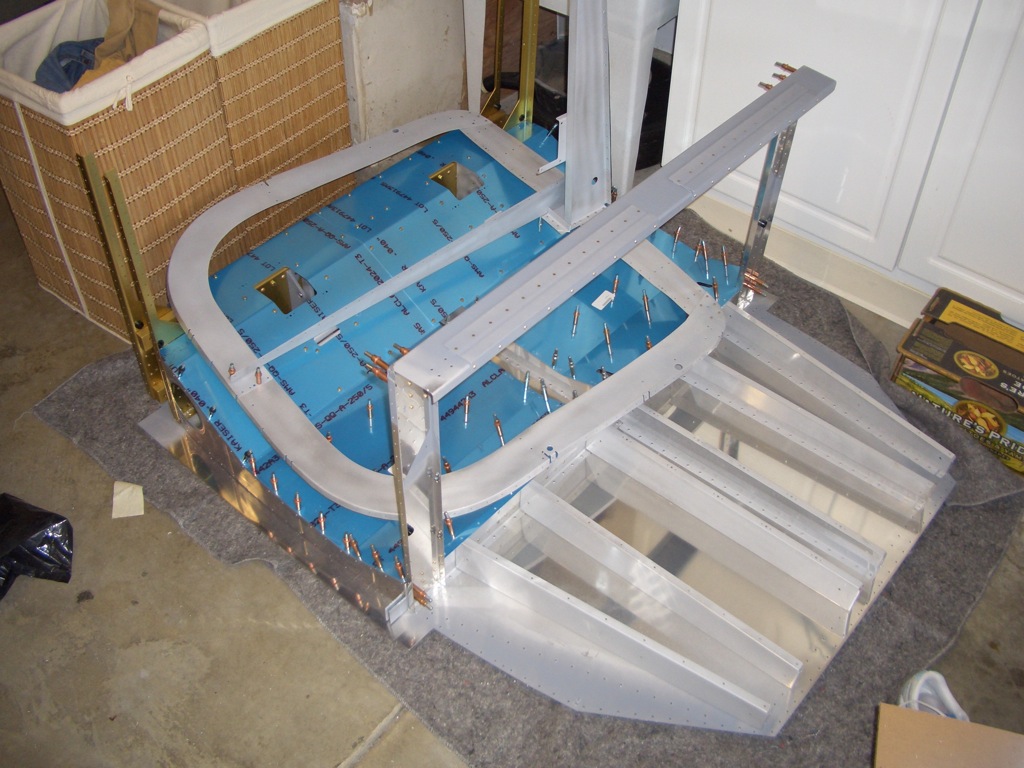

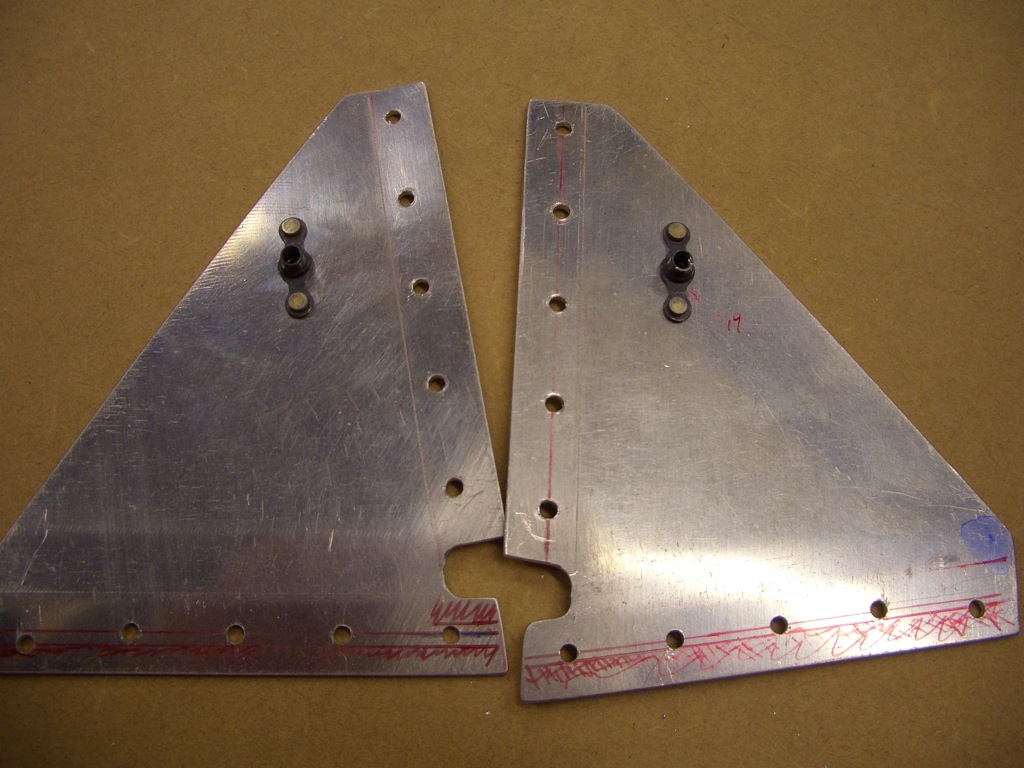

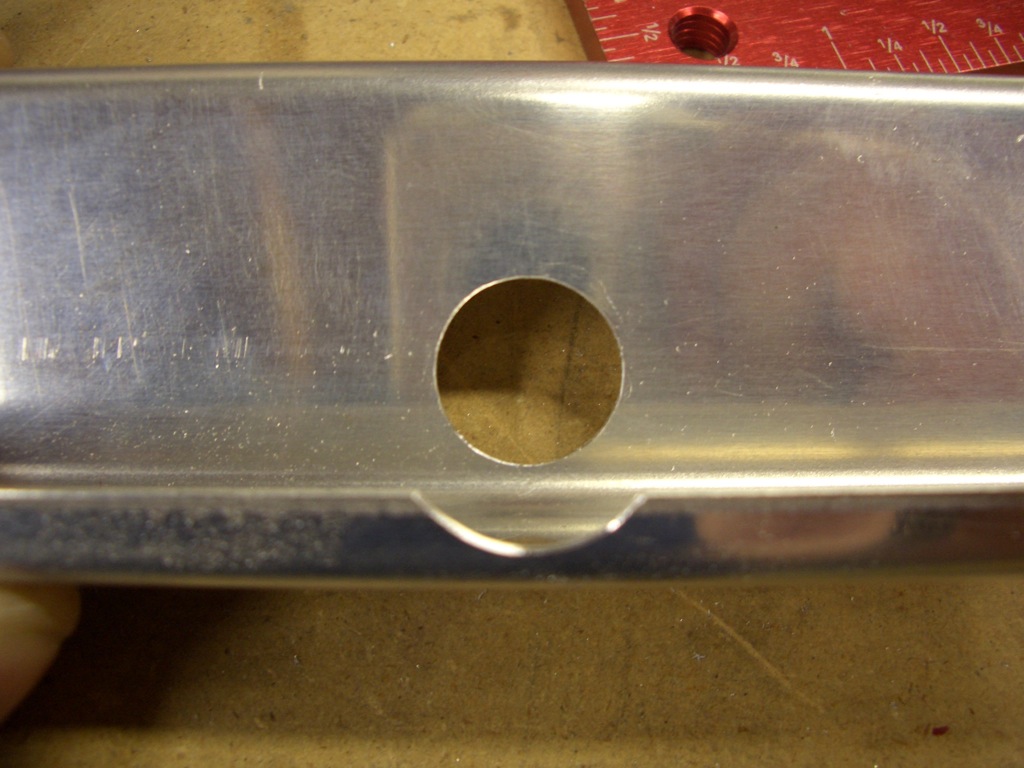

The F-902 bulkheads need some tooling holes enlarged to 5/8″ for the rudder cables. The aft flange also needs to be relieved so that it won’t interfere with the cable. I also fluted the outside flange to bring the holes in line.

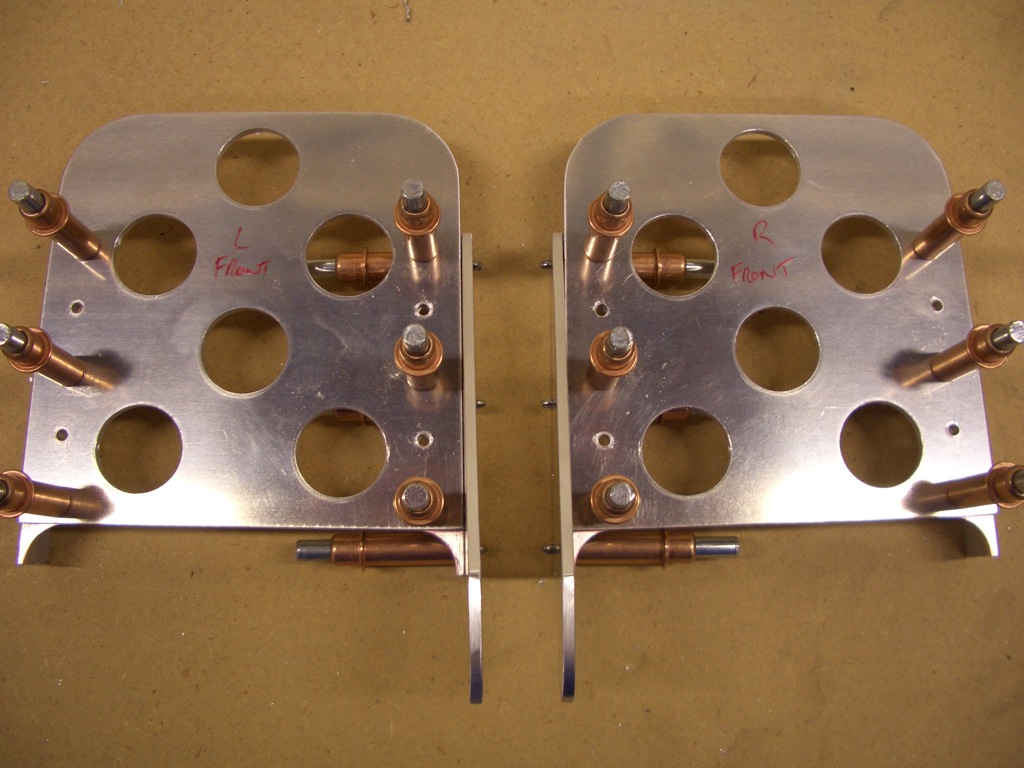

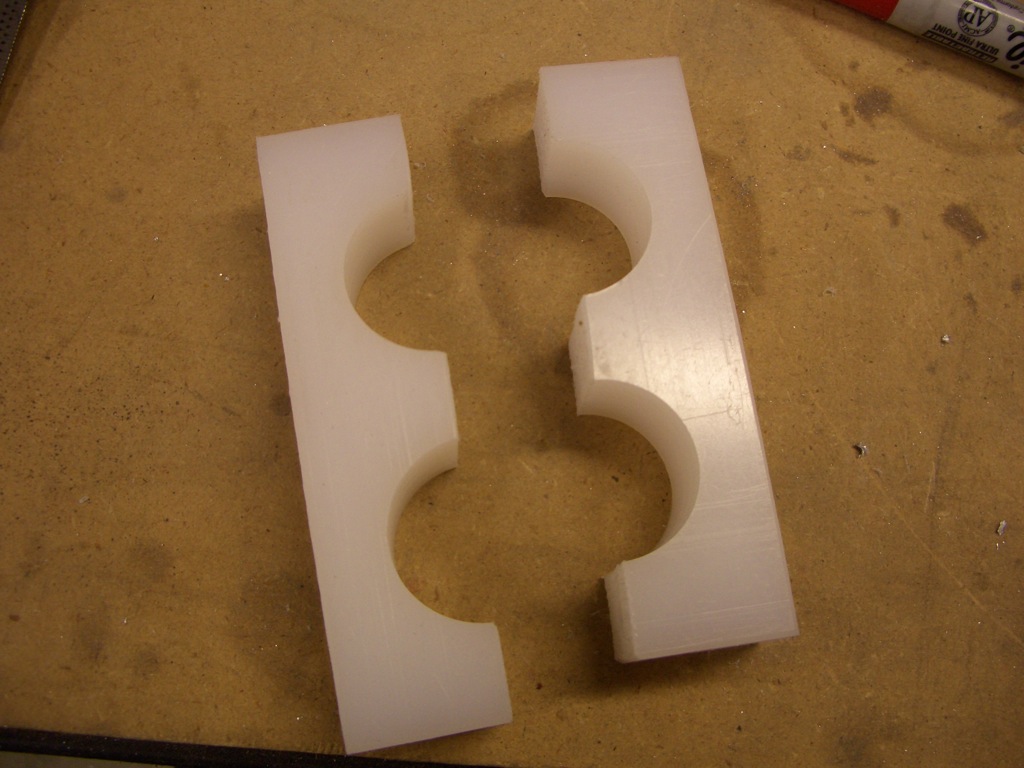

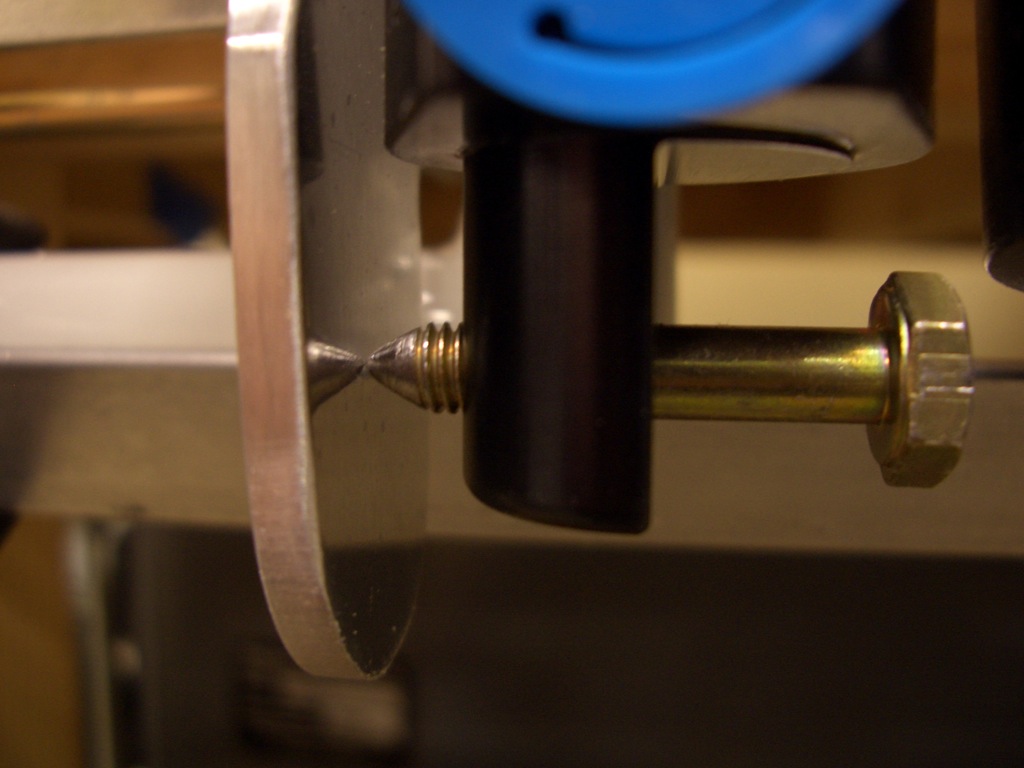

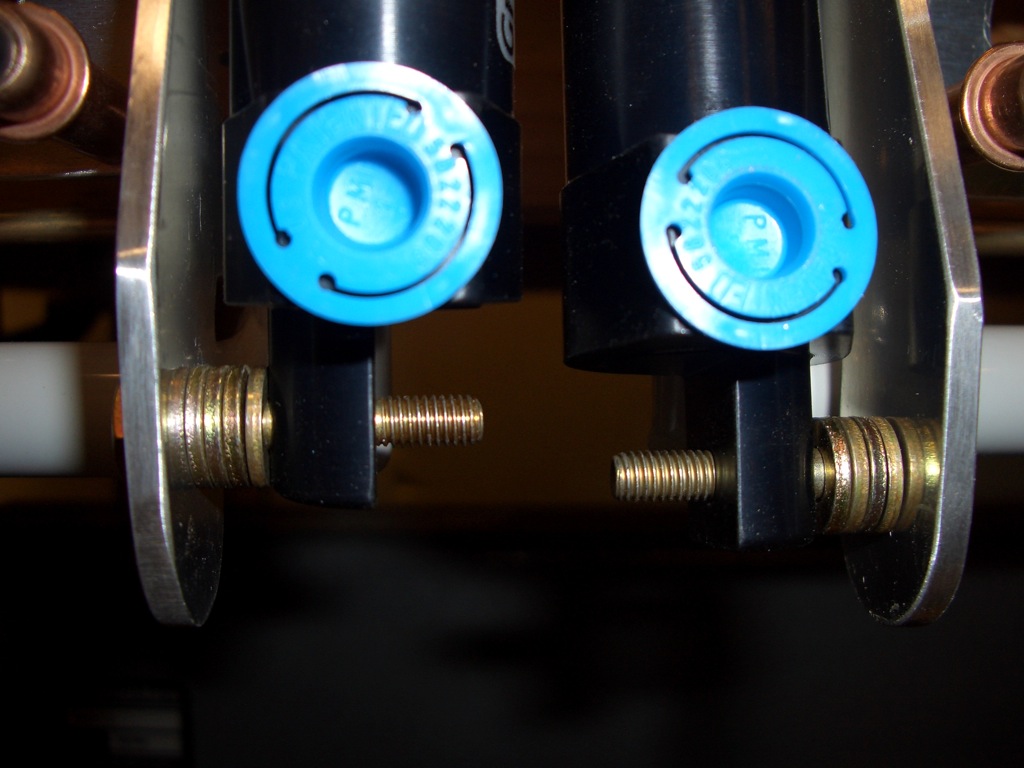

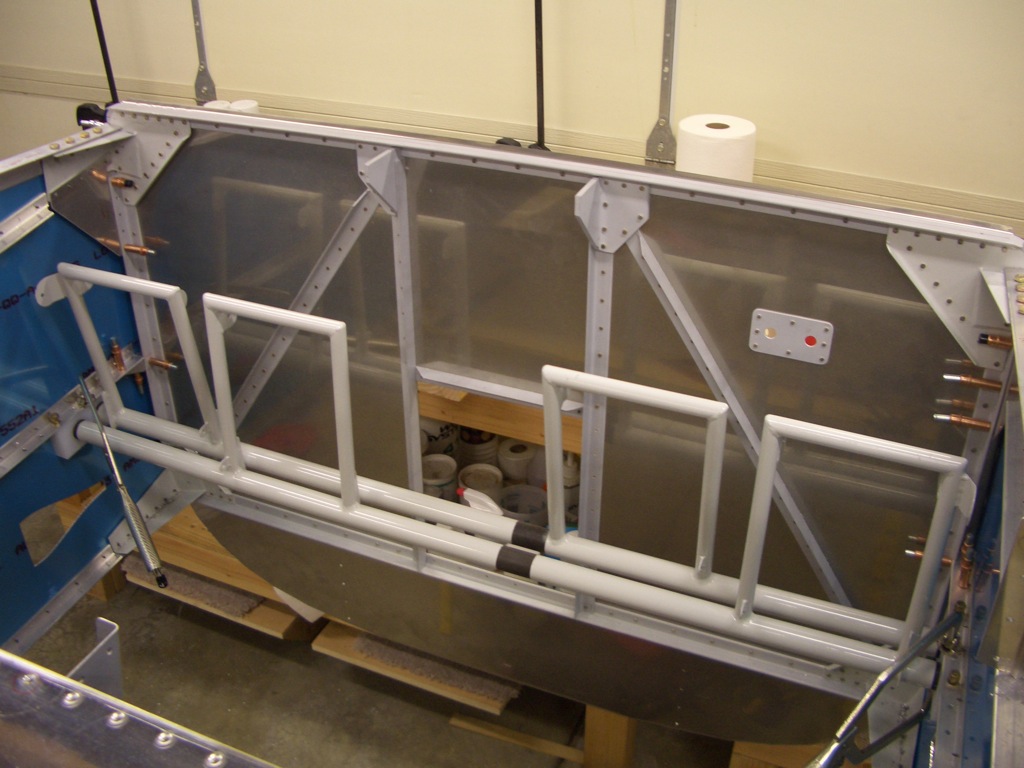

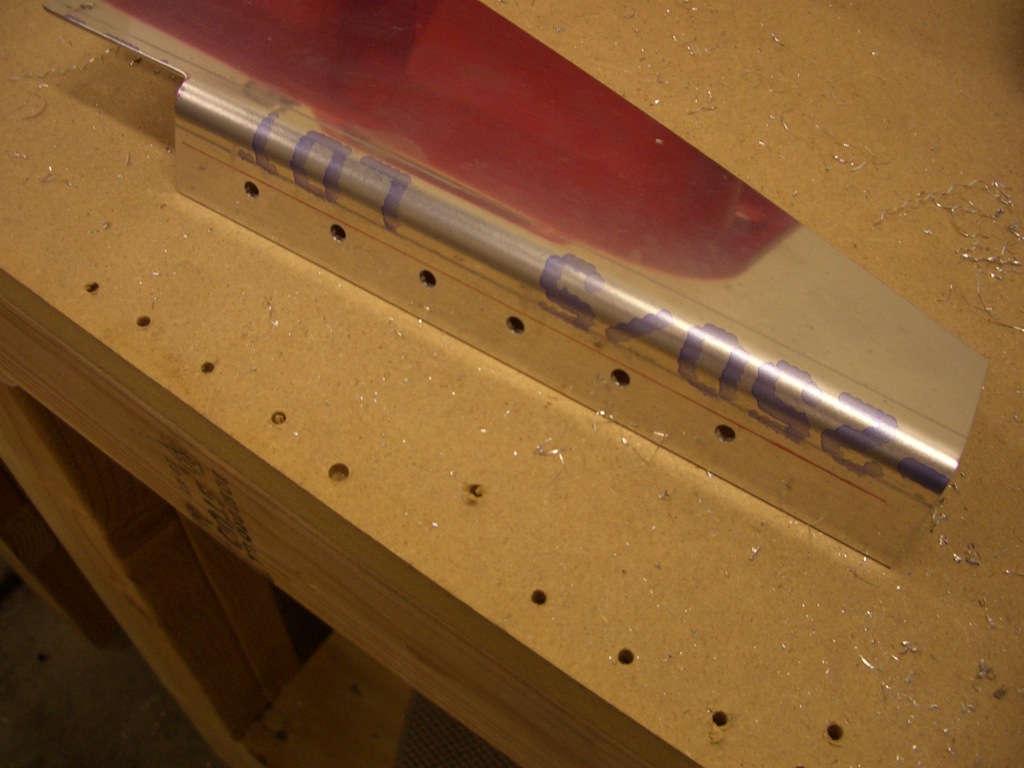

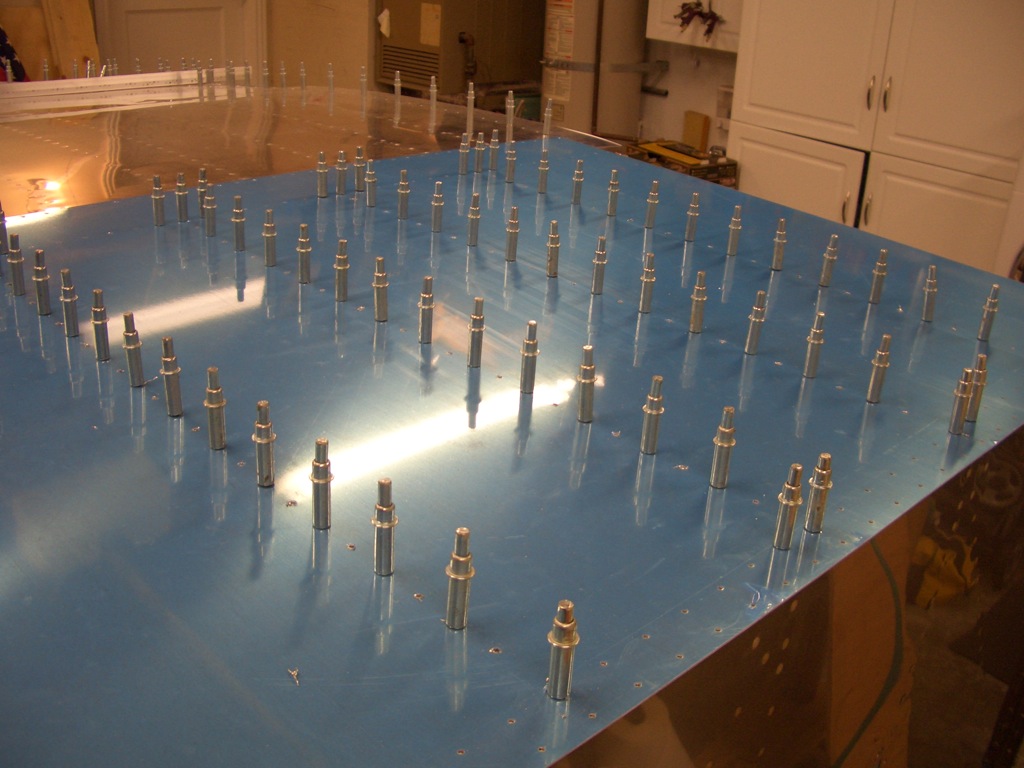

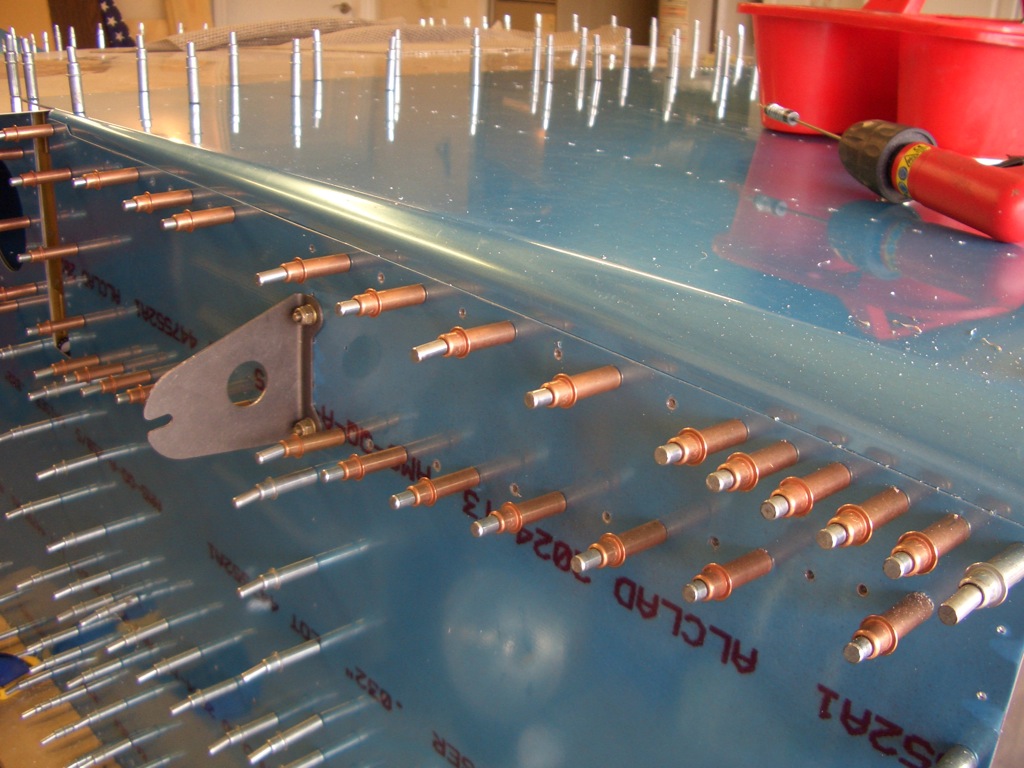

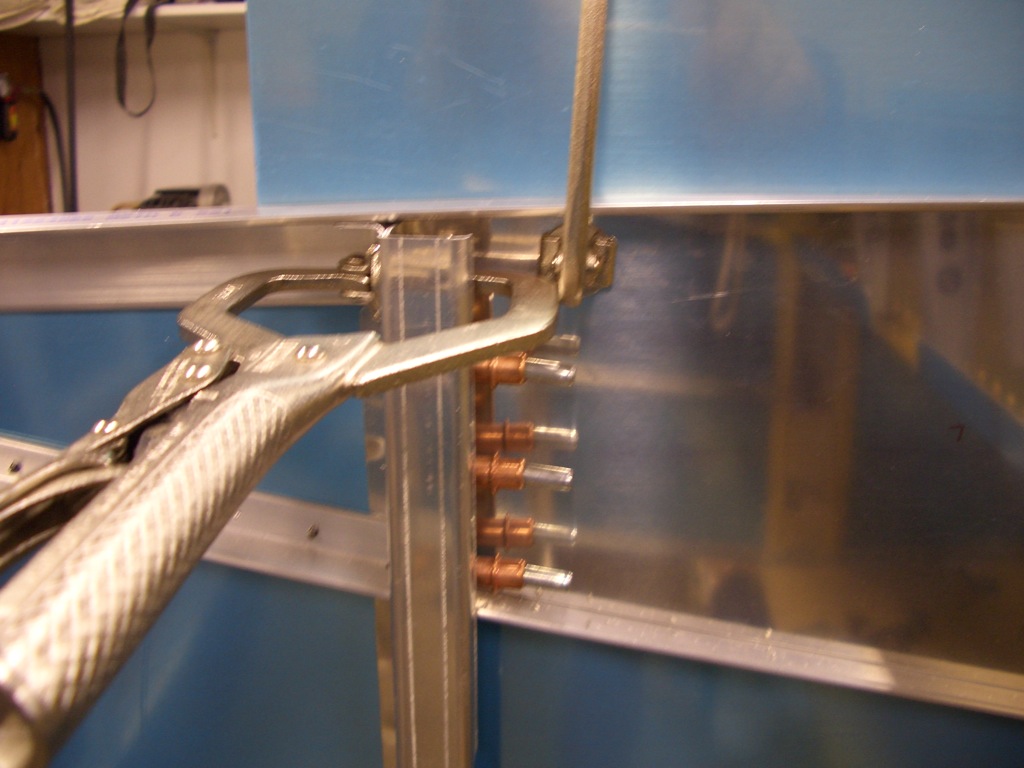

Nutplates are attached to the aft side of the bulkhead so that the fuel vent line can be attached with adel clamps.

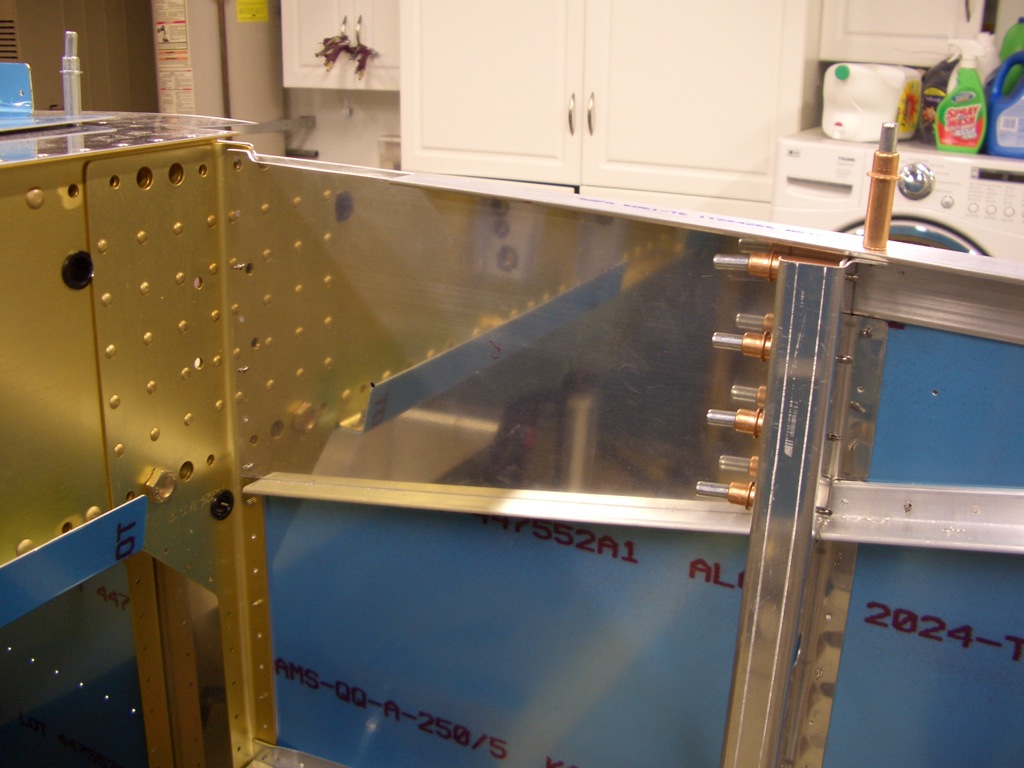

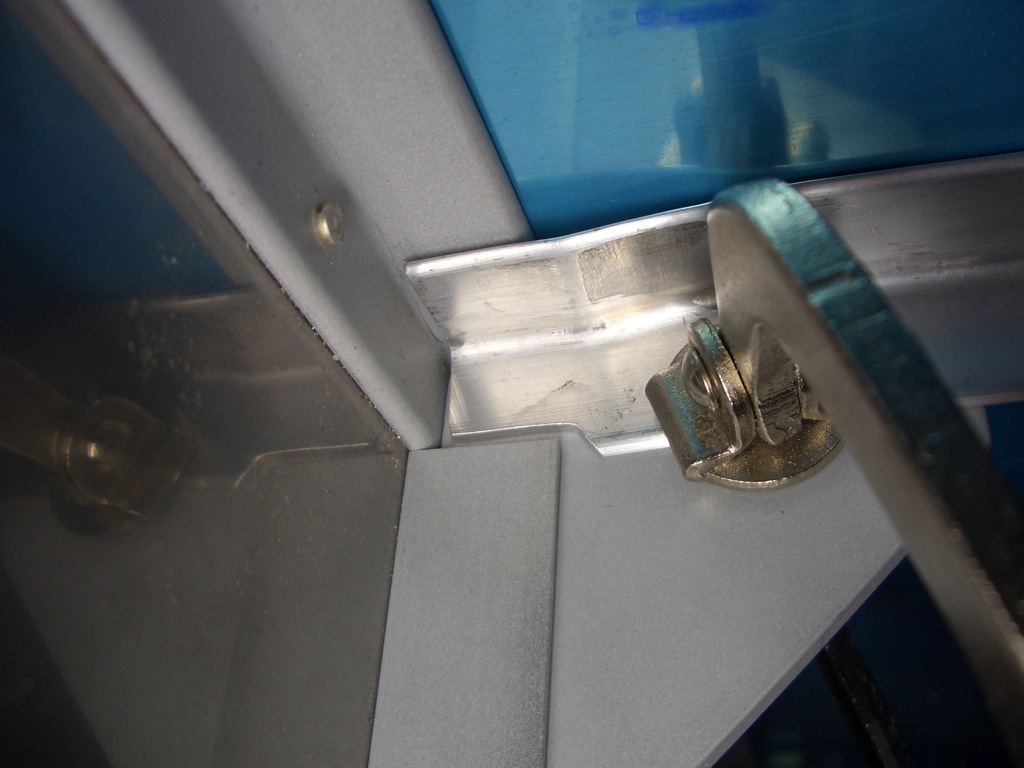

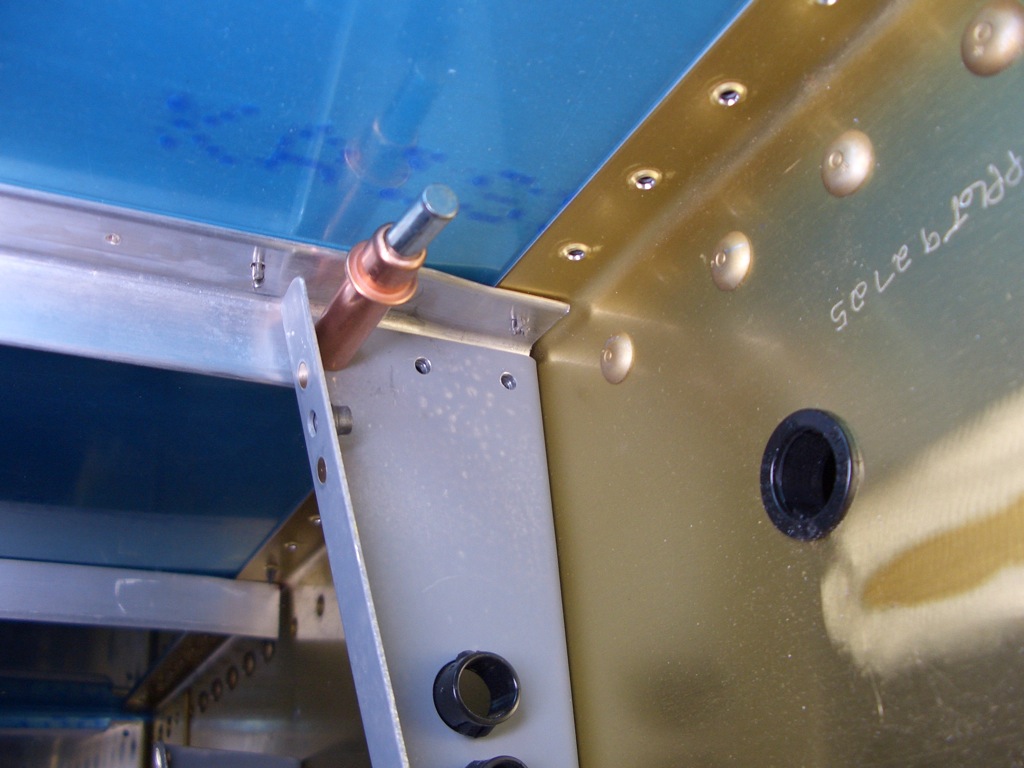

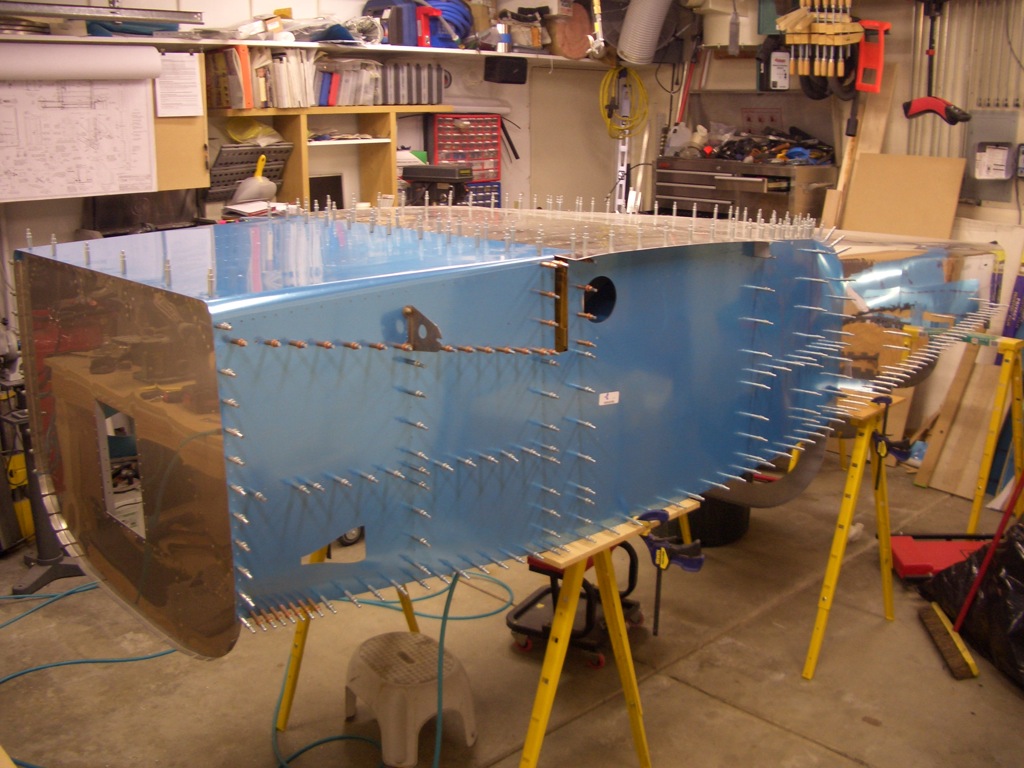

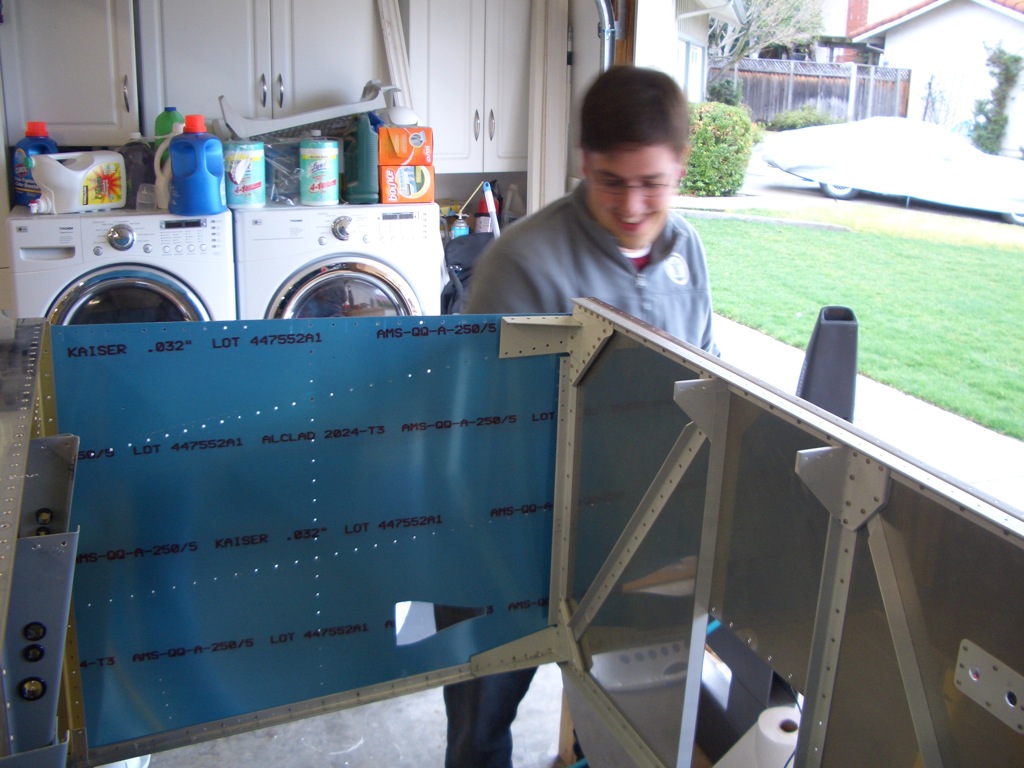

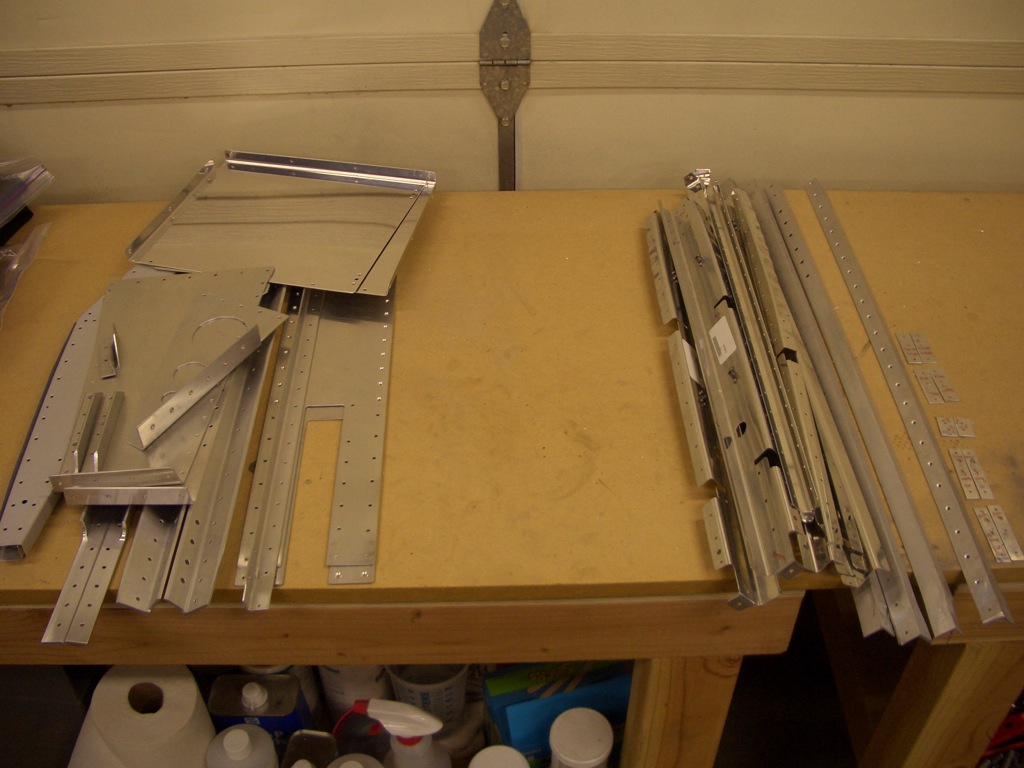

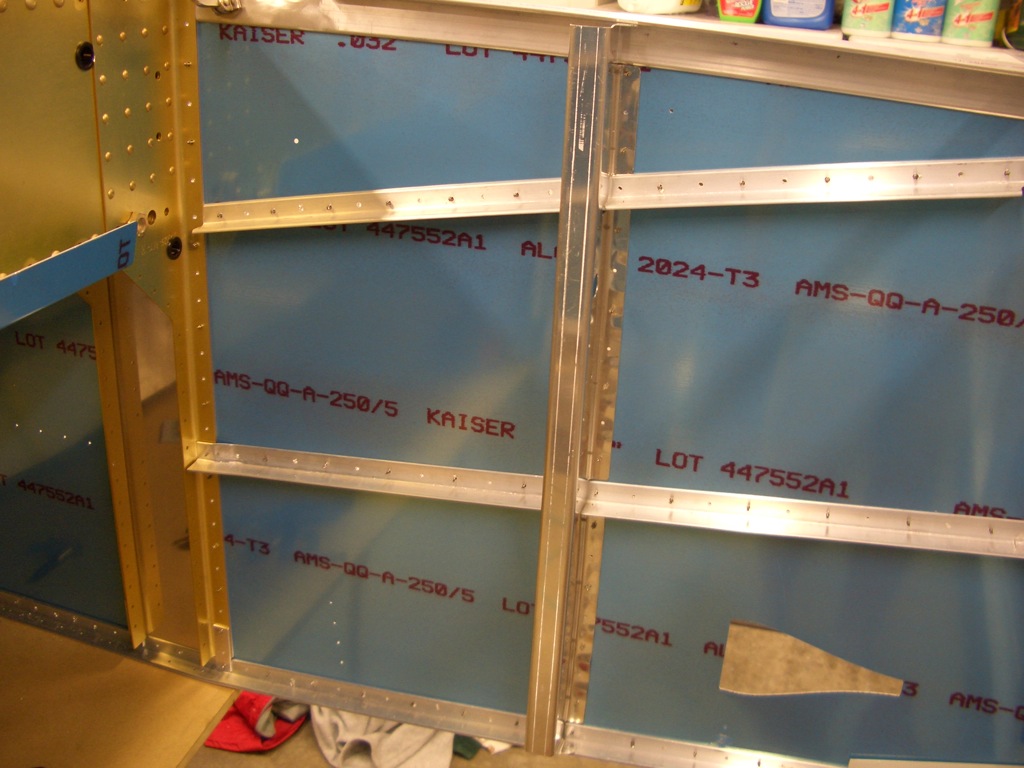

Here is the right side clecoed in place. Don’t bother at this point, I had to remove it to get the gear attach web in place.

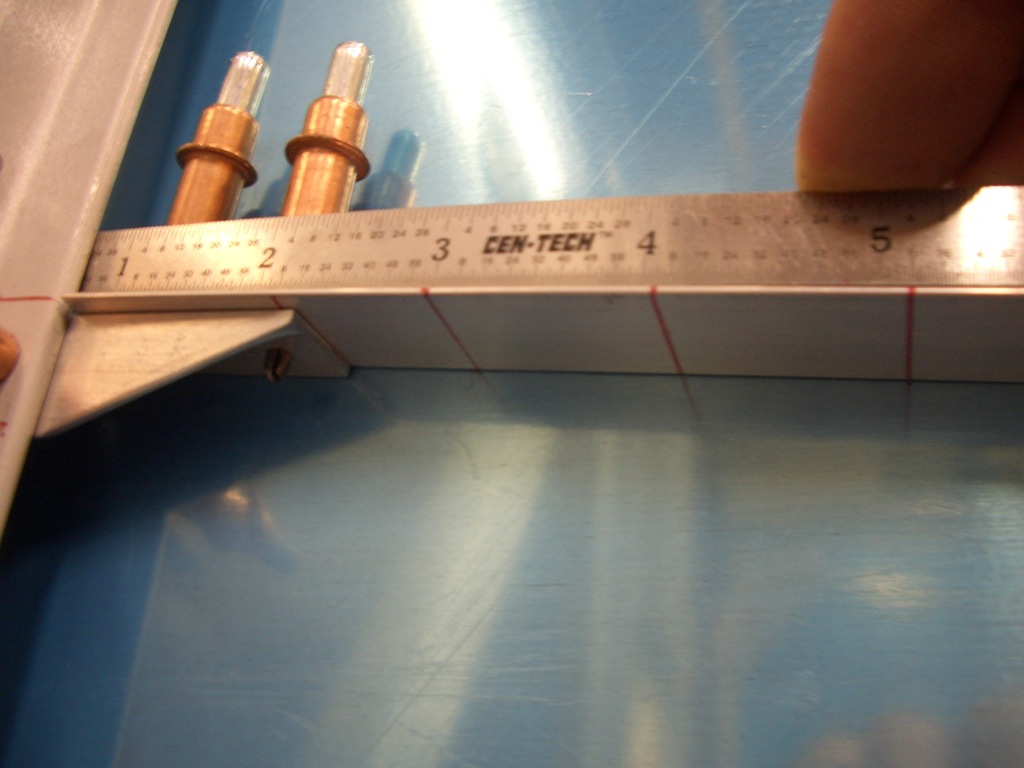

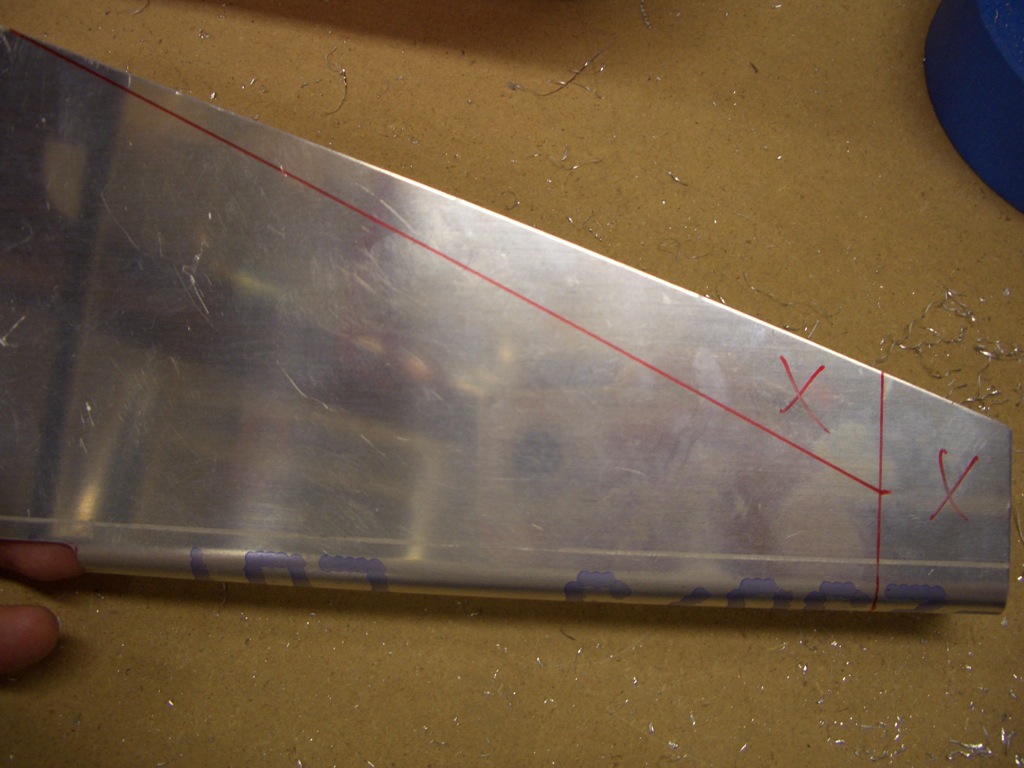

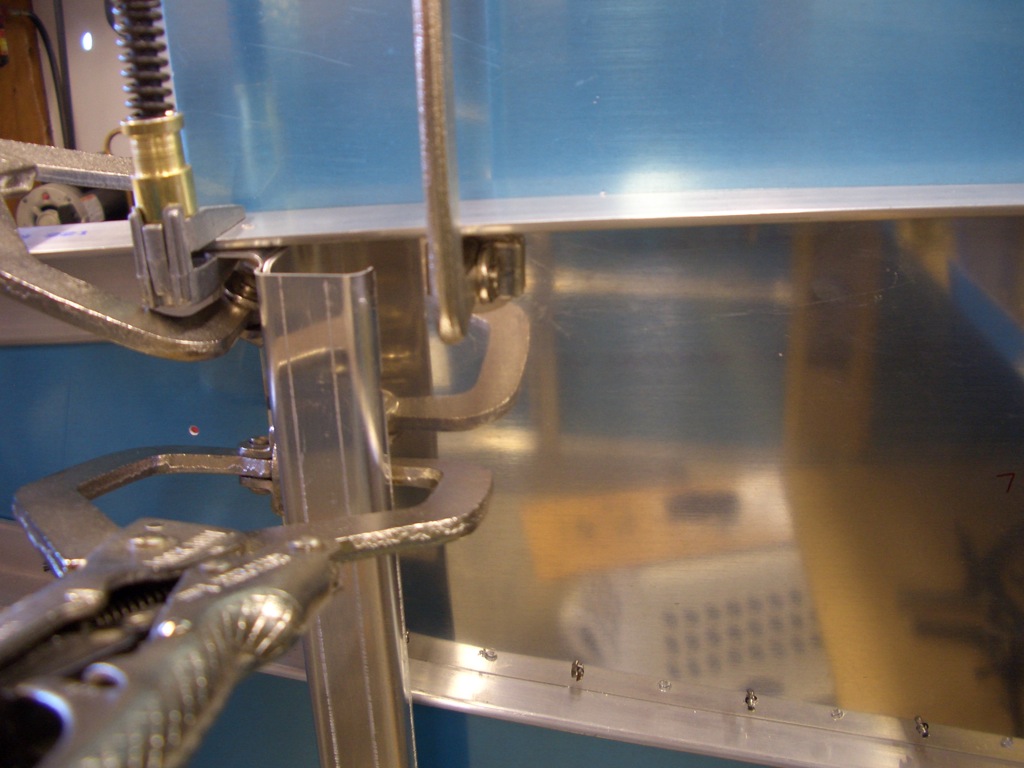

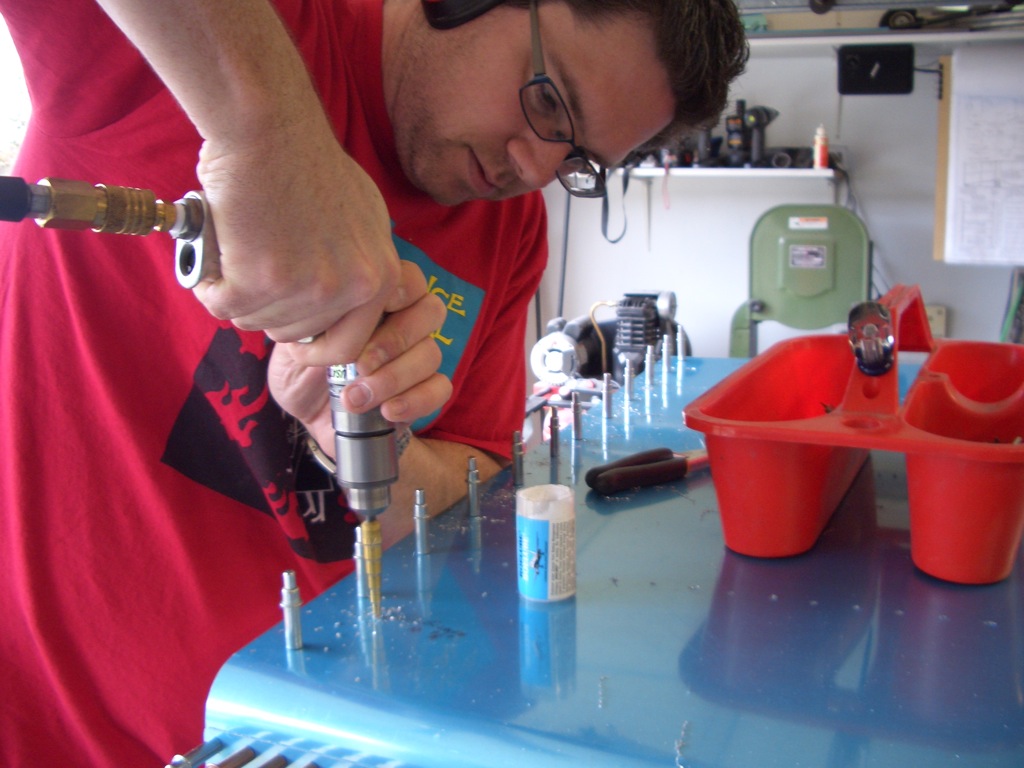

I fit some 0.040″ thick scrap (the blue piece at the top) in place to correctly space the lower longeron away from the side skin. I then clamped everything tightly together and drilled the gear attach web to the F-902 bulkhead.

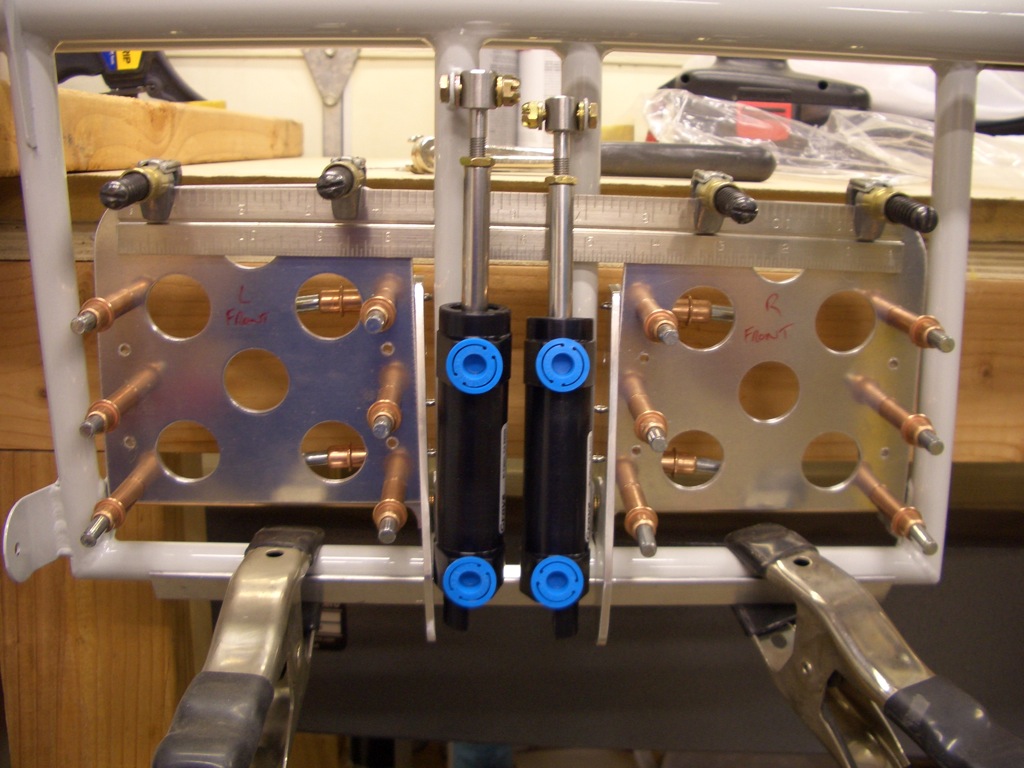

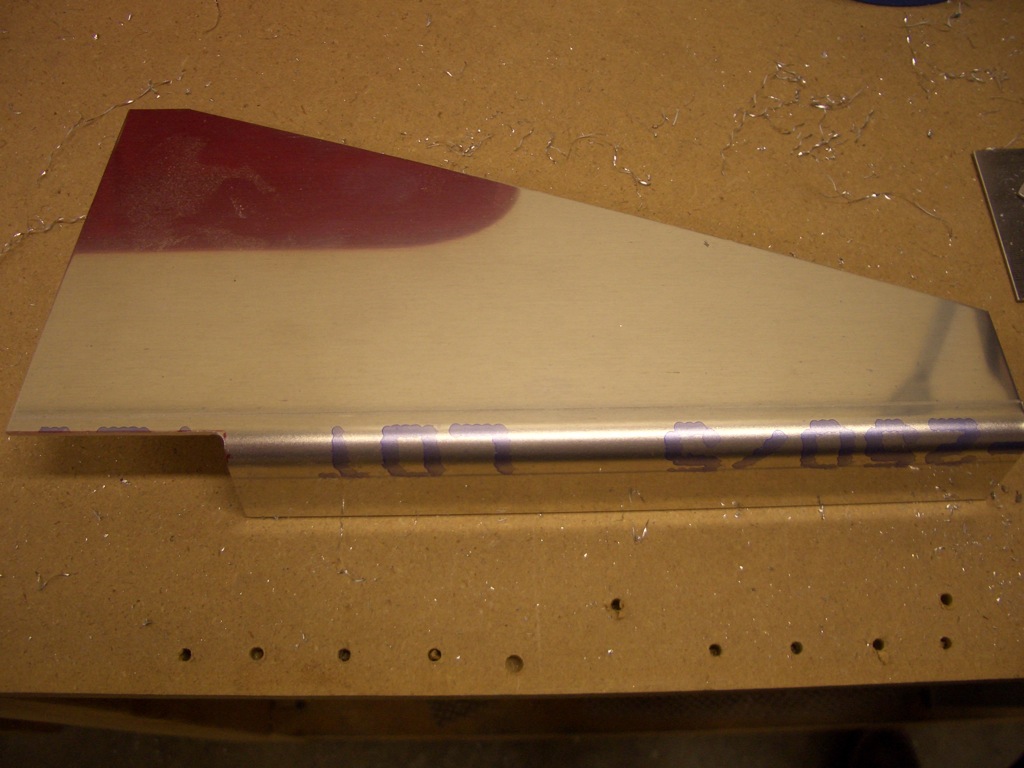

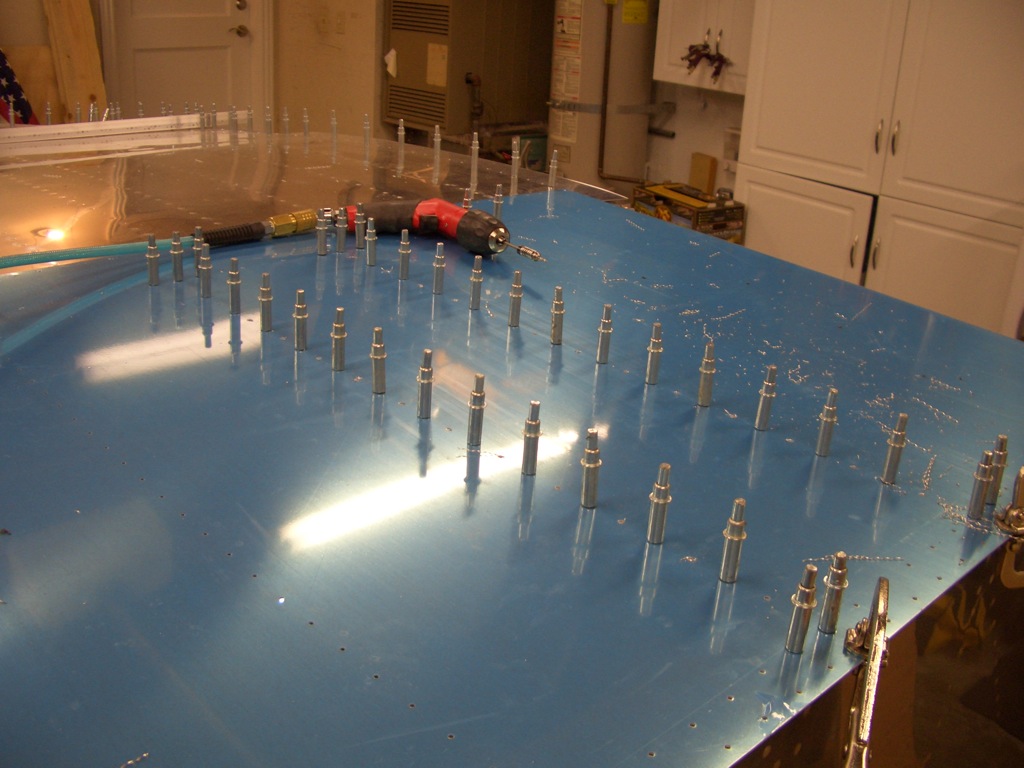

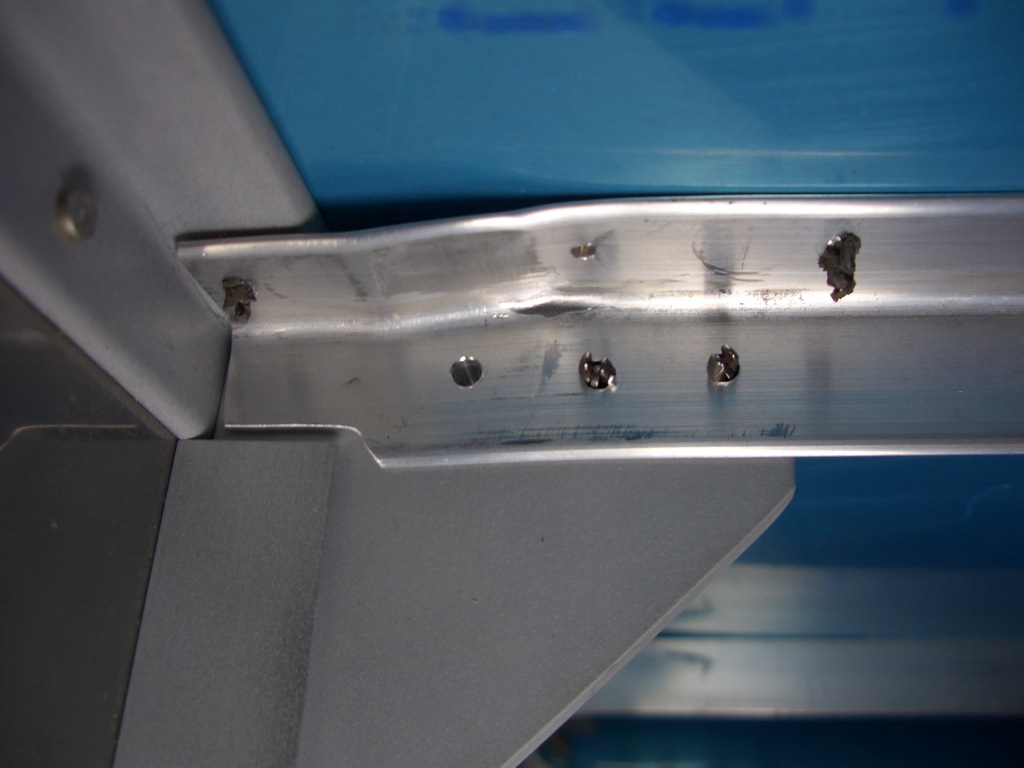

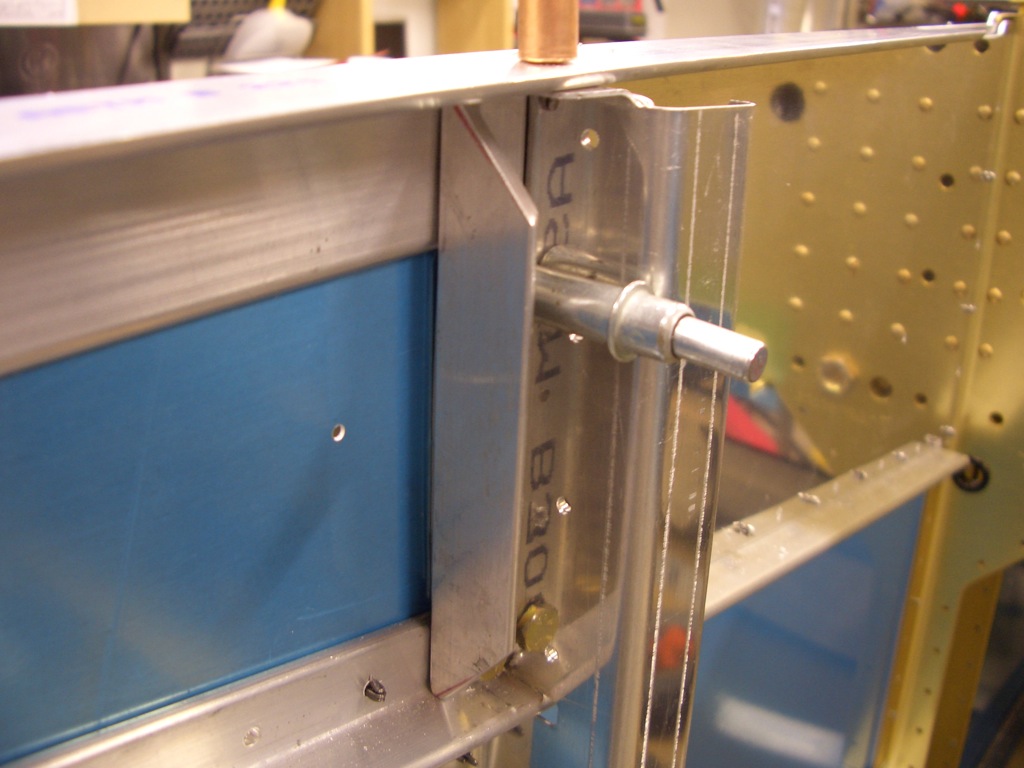

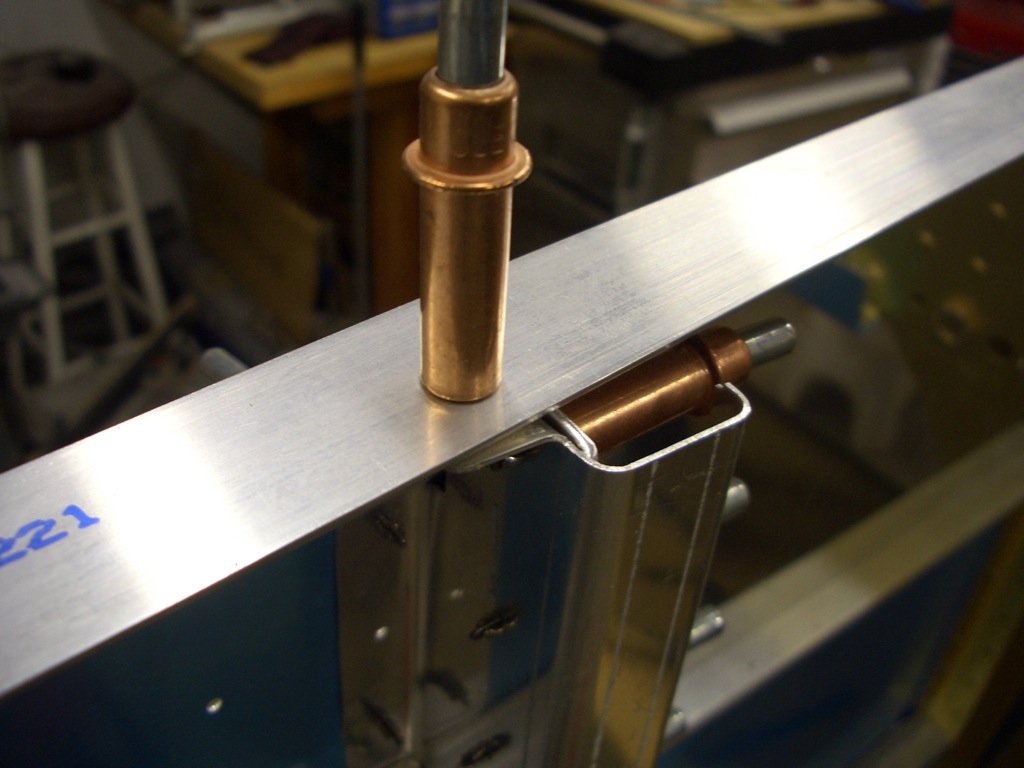

Now that the bulkhead is positioned correctly, the bottom flange can be drilled to the lower longeron.

The upper flange can also be drilled to the upper longeron.

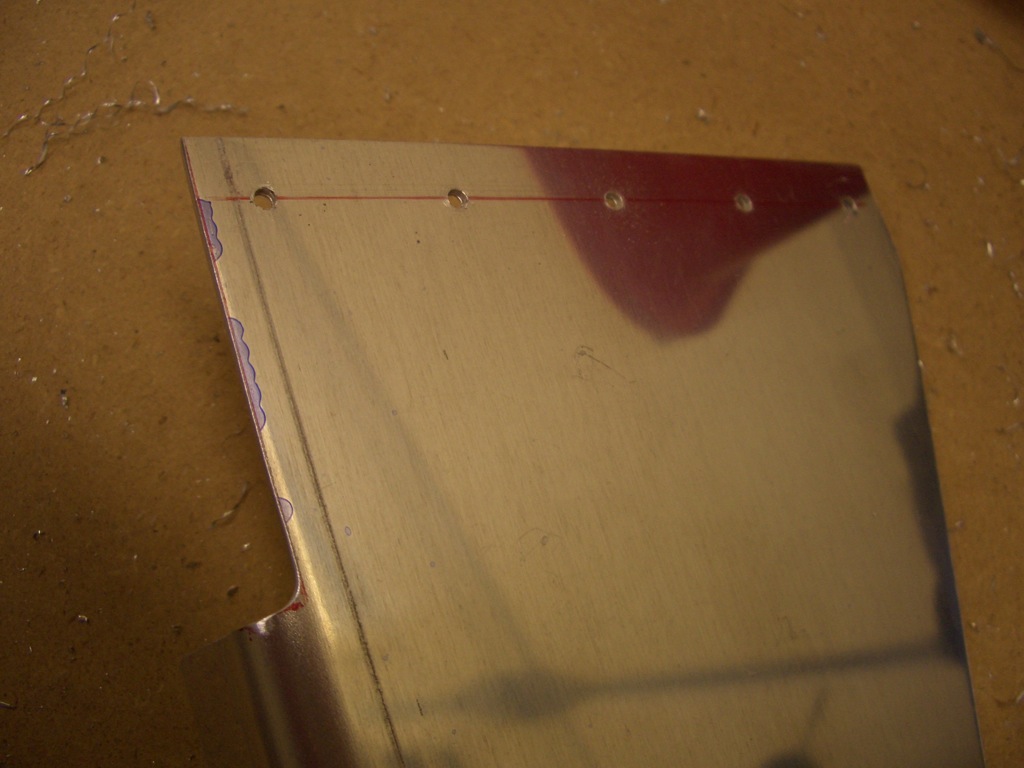

I then repeated the steps on the right side.