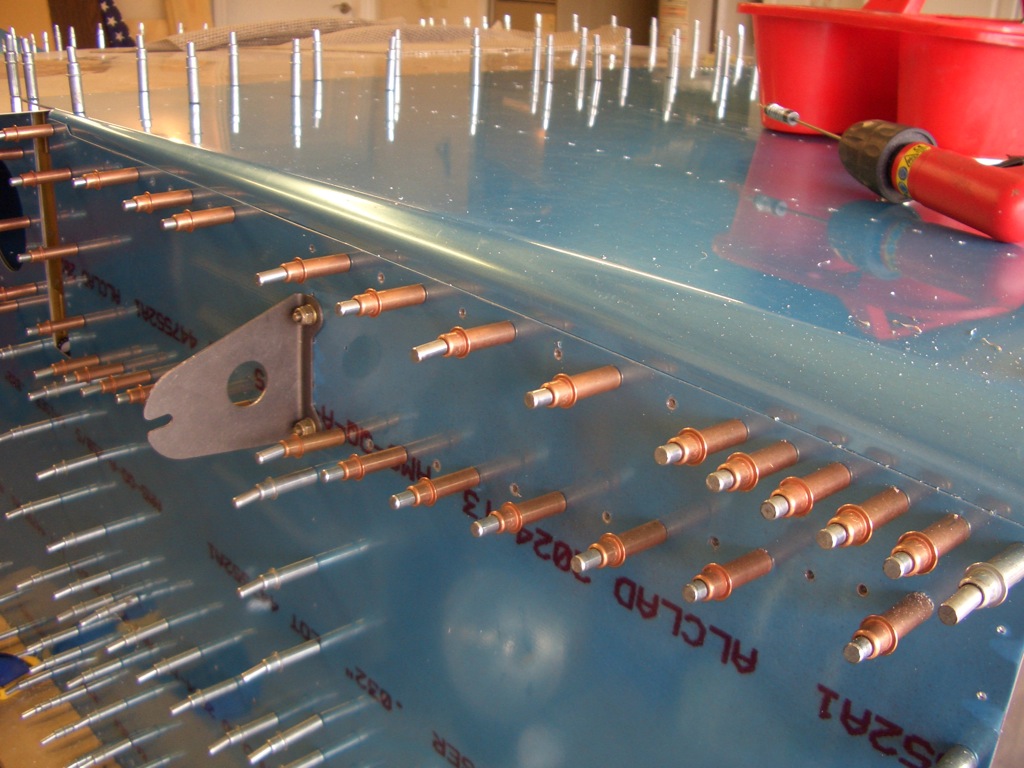

I got started today by finishing up the remaining drilling that needed to be done before disassembling the fuselage. First up is to match drill the outboard seat ribs to the side skins.

I also drilled the lower longeron to the side and bottom skins as well as the gear web and lower engine mount.

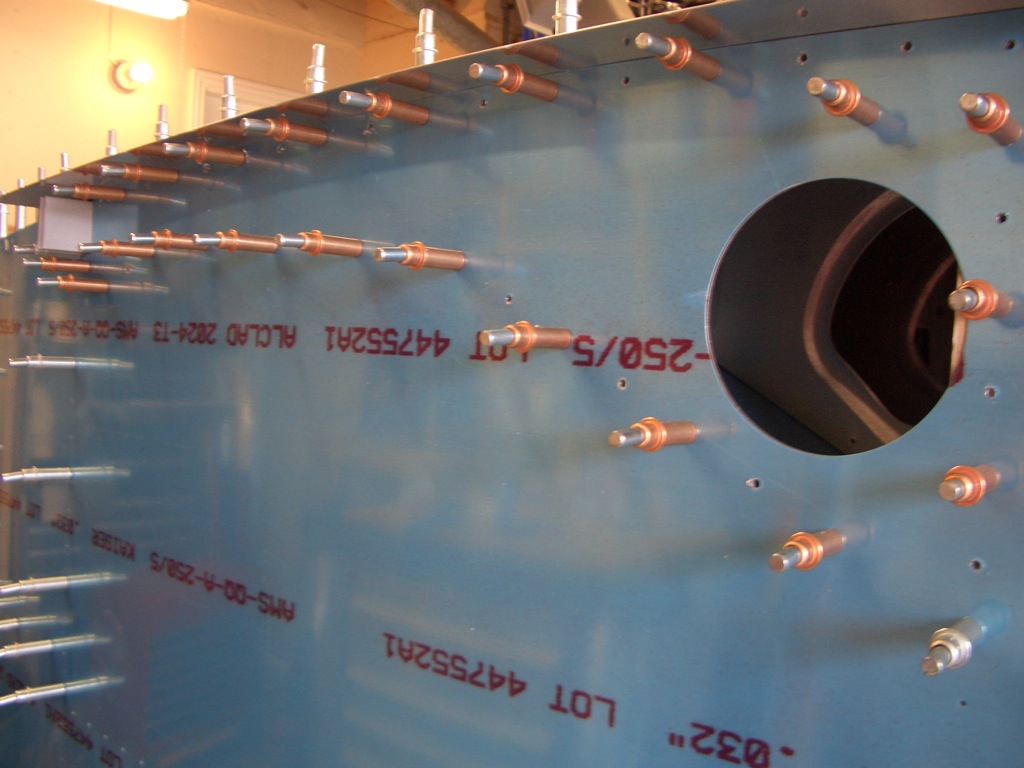

Two holes on the bottom skin just aft of the firewall need to be enlarged to 7/16″ for the fuel vents.

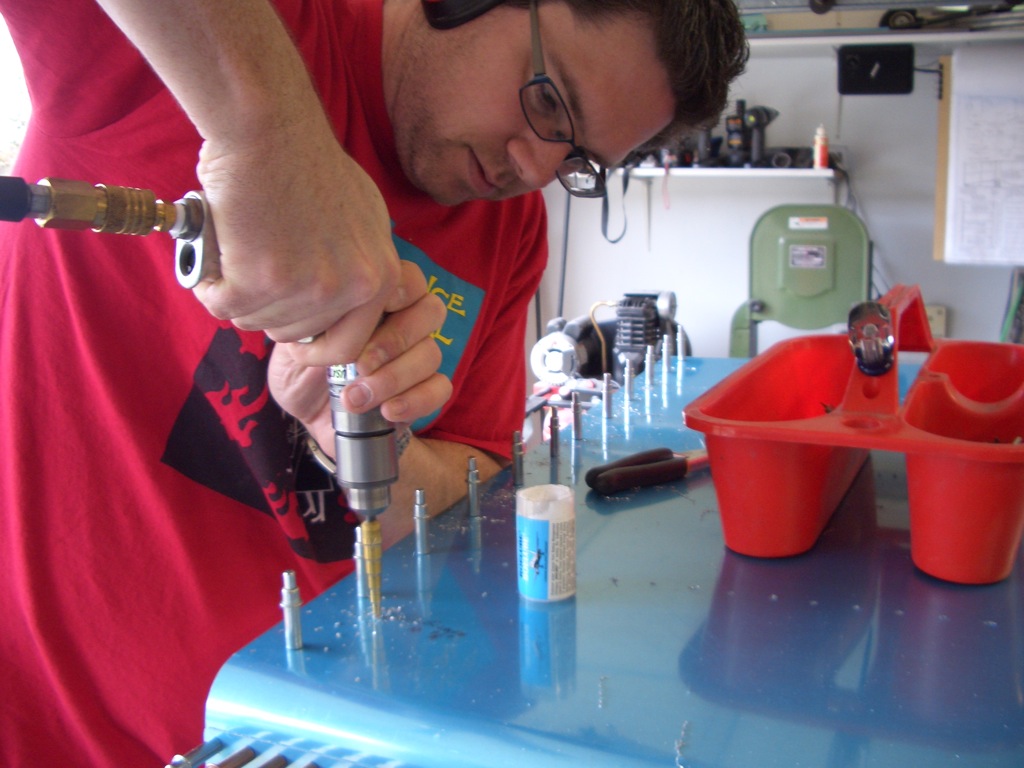

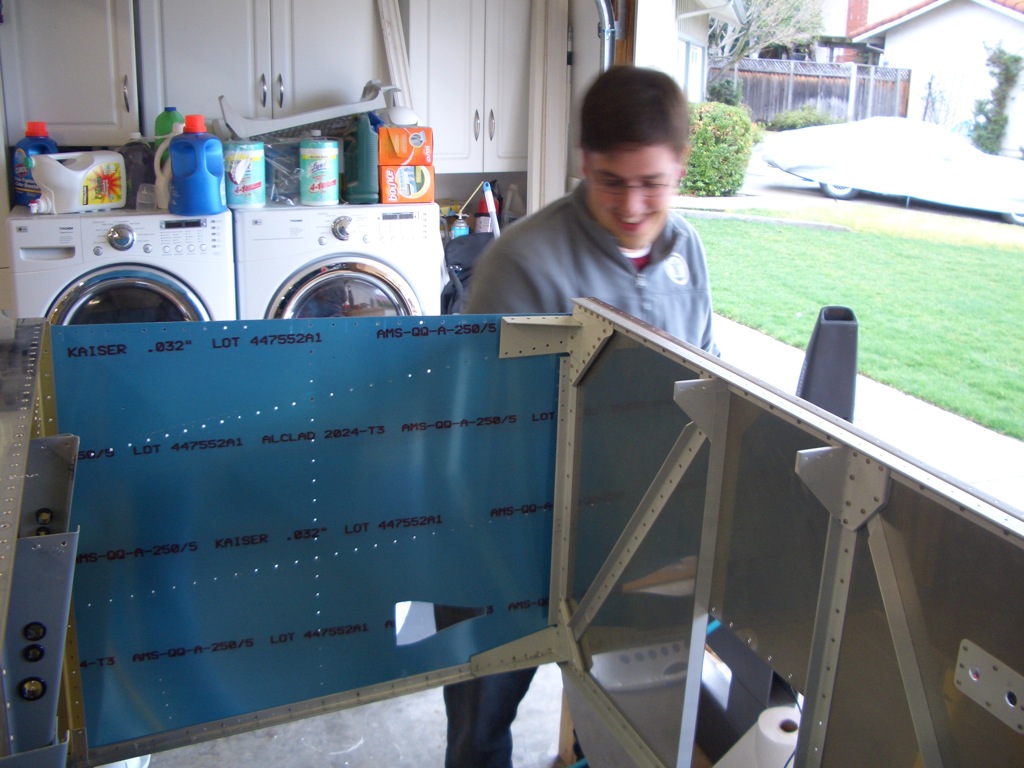

Andre took a picture of me drilling the other one.

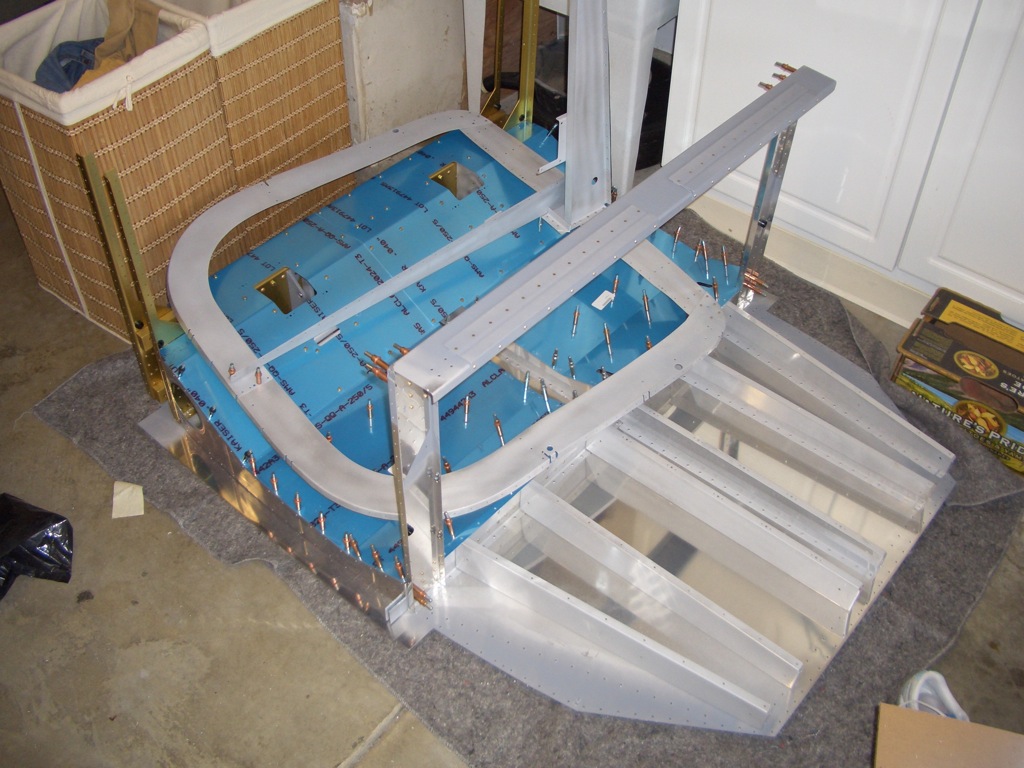

After drilling the side skins to all of the various bulkheads and drilling the center section bottom skin to the tailcone, we started disassembly.

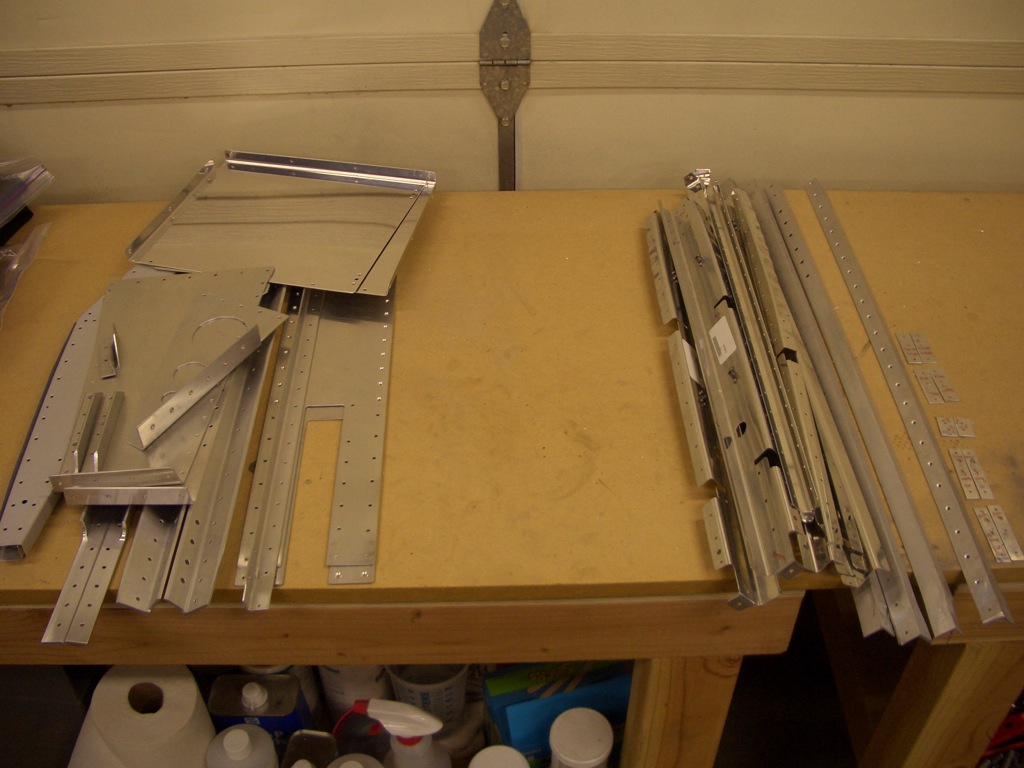

Here’s the growing pile of parts from the disassembly. My cleco tote is overflowing with clecos again.

Finally, we separated the center section from the tailcone.

The tailcone is all that is left on the sawhorses.

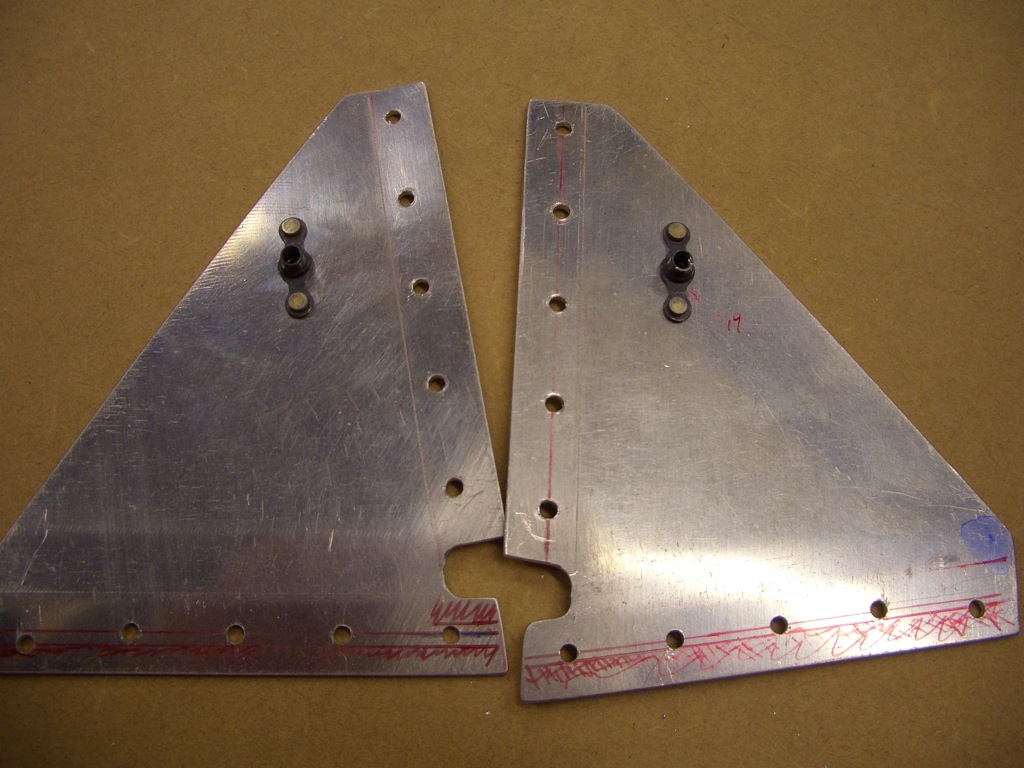

I next started working my way through a small list of tasks left to complete before priming. Here, I’ve riveted K1000-08 nutplates to the outboard side of the lower engine mount gussets. These will be used to anchor the vent line.

While deburring one of the skin stiffeners, I noticed this crack. I’ll call Van’s tomorrow and get another one sent. Hopefully, I can just use this one to match drill the new one so that I don’t have to reassemble the fuselage to drill it.

Here’s a shot from a slightly different angle. The crack goes all the way through and is visible from the inside as well.

I made it through a good chunk of the small parts before calling it a night. All of the pieces on the left are deburred and dimpled/countersunk. I should be able to get through the remaining pieces on the right in one more session. I’ll still have the longerons to countersink (over 400 holes), and a number of holes in the tailcone and center section to debur/dimple.