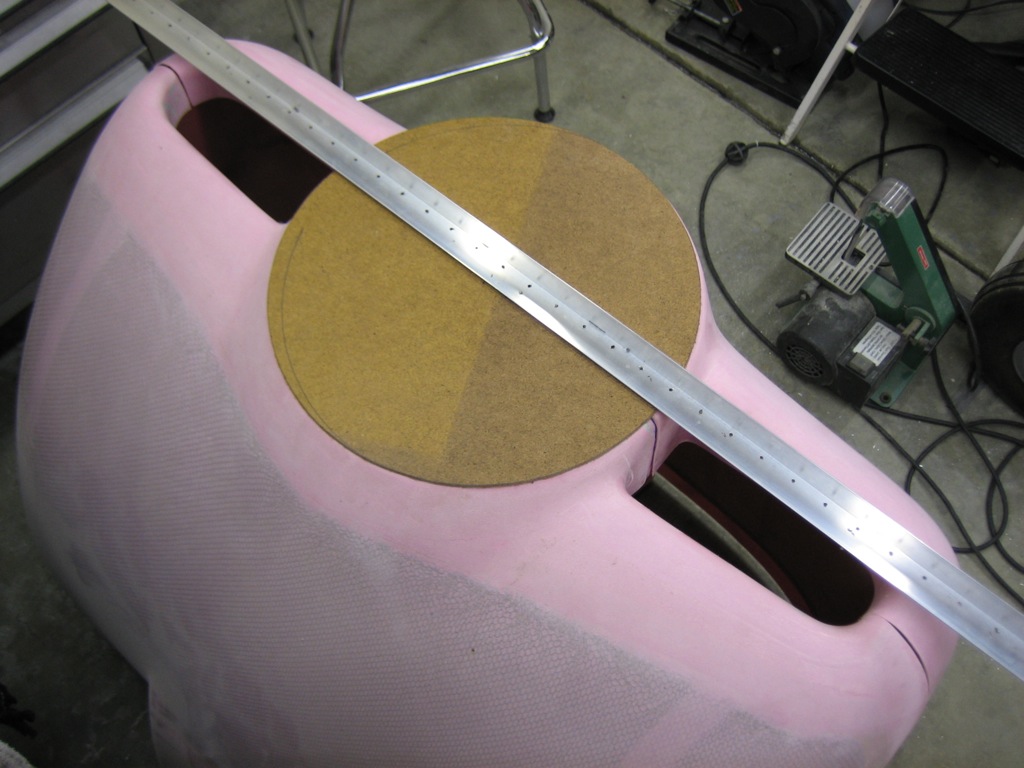

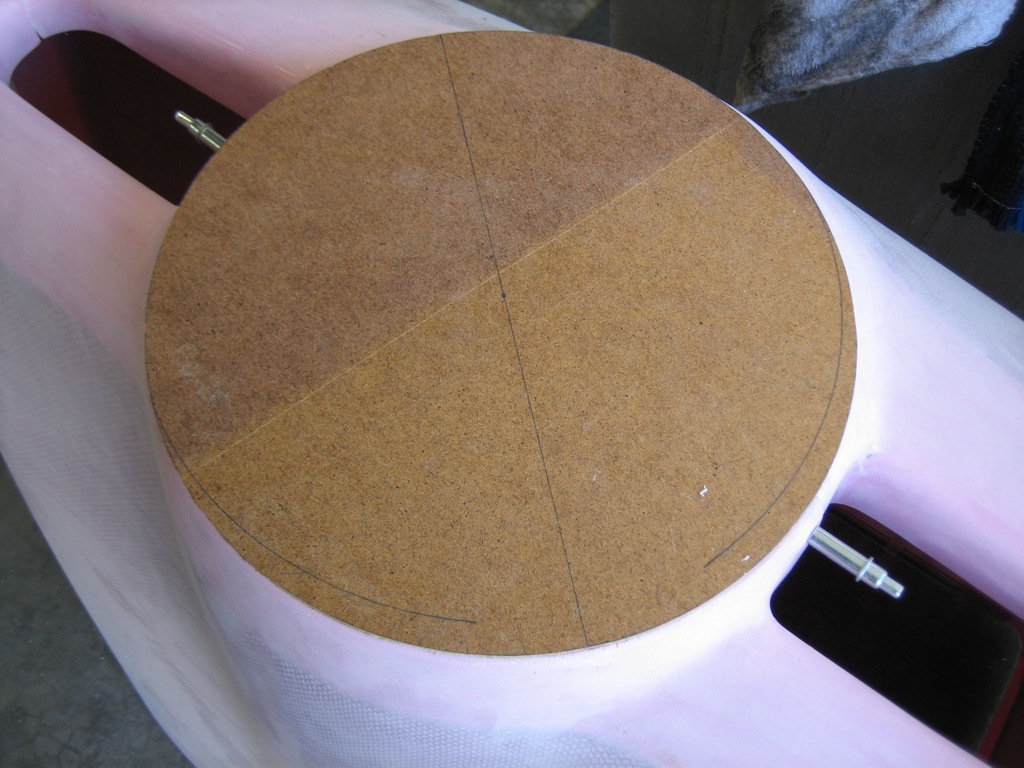

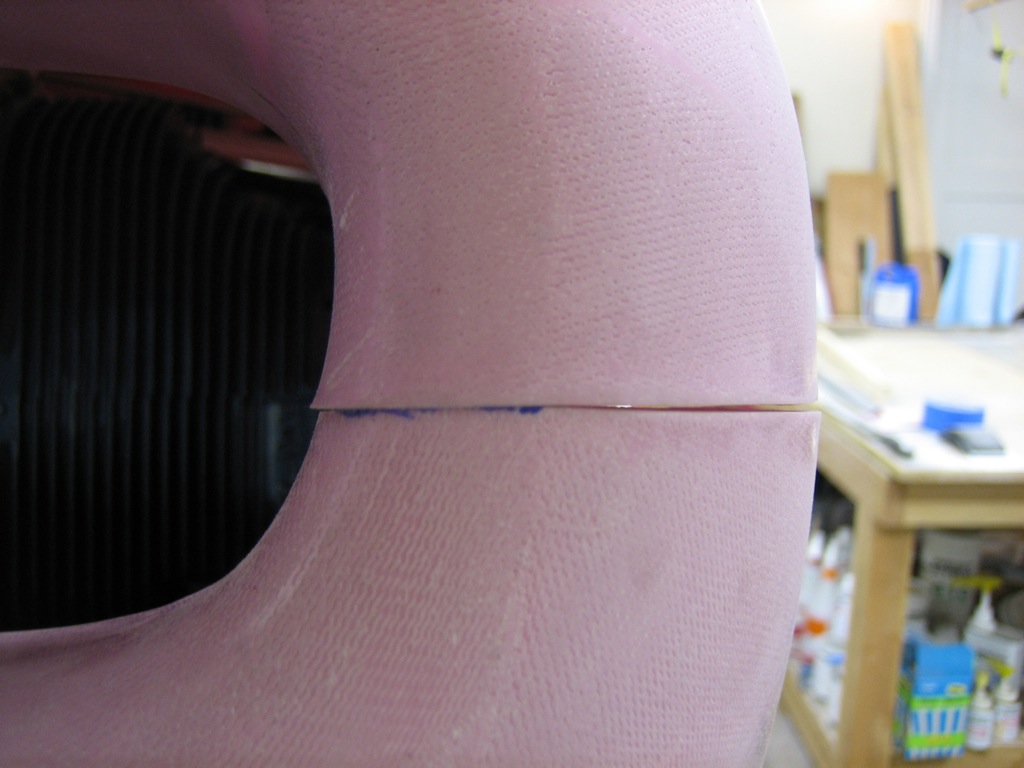

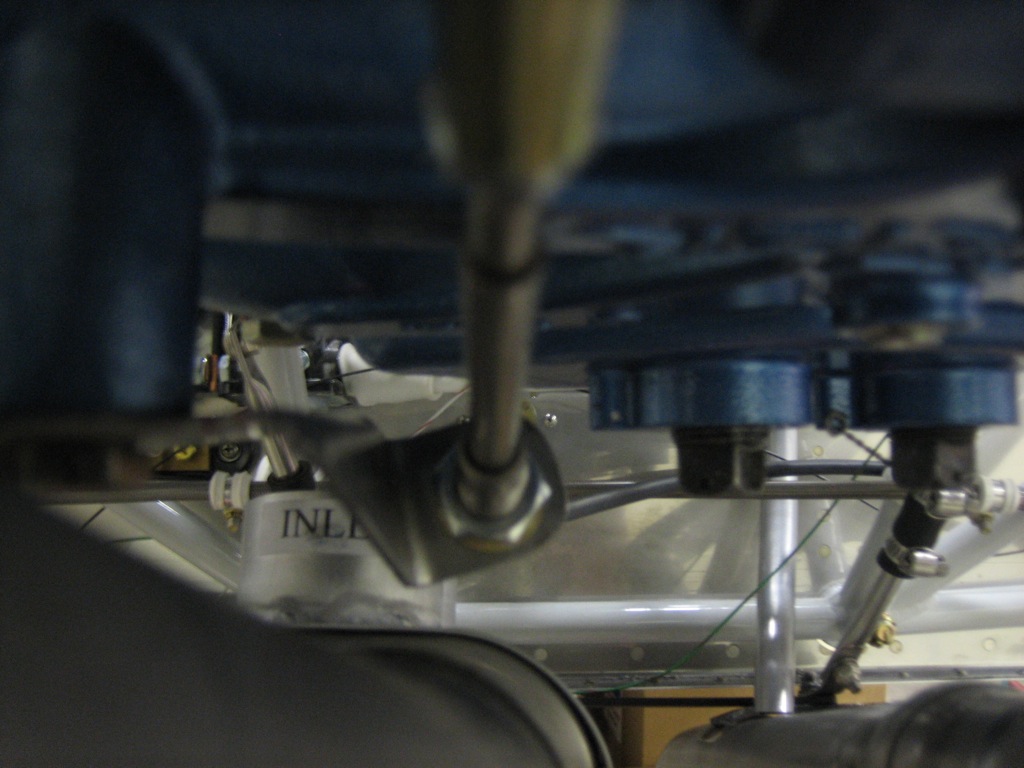

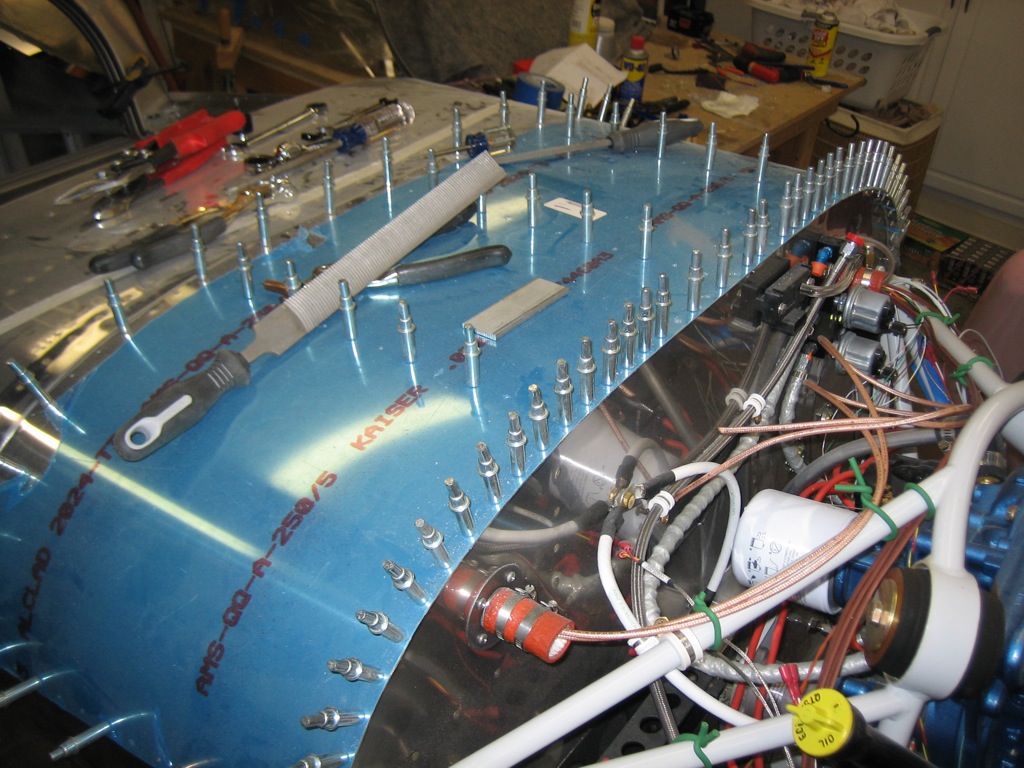

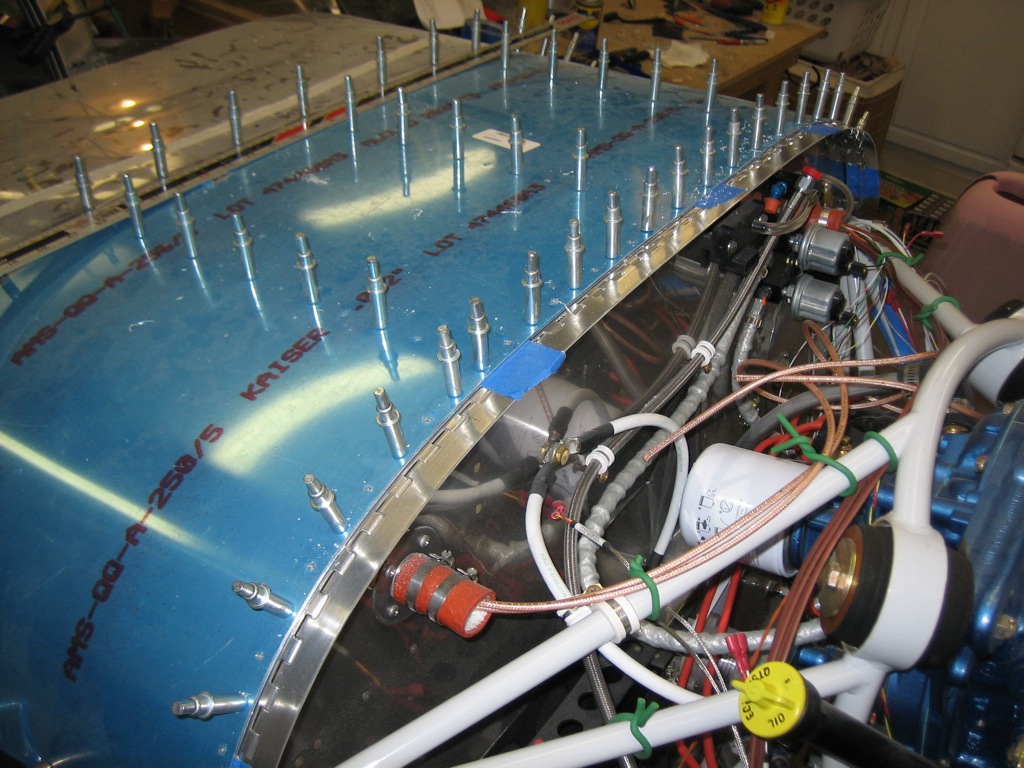

I’ve been laid up on the couch for the last day and a half with the flu, but I’m starting to feel better, so I’ll push myself as usual :-). I started by clecoing the forward top skin to the fuselage so that I could file the firewall flange back flush with the skin. This is because the cowl flange butts up against this skin, but it’s quite a bit thicker.

I also taped together some pieces of popsicle sticks to hold of the front of the cowl. This will allow me to adjust the height if necessary. This is roughly 3/4″ thick.

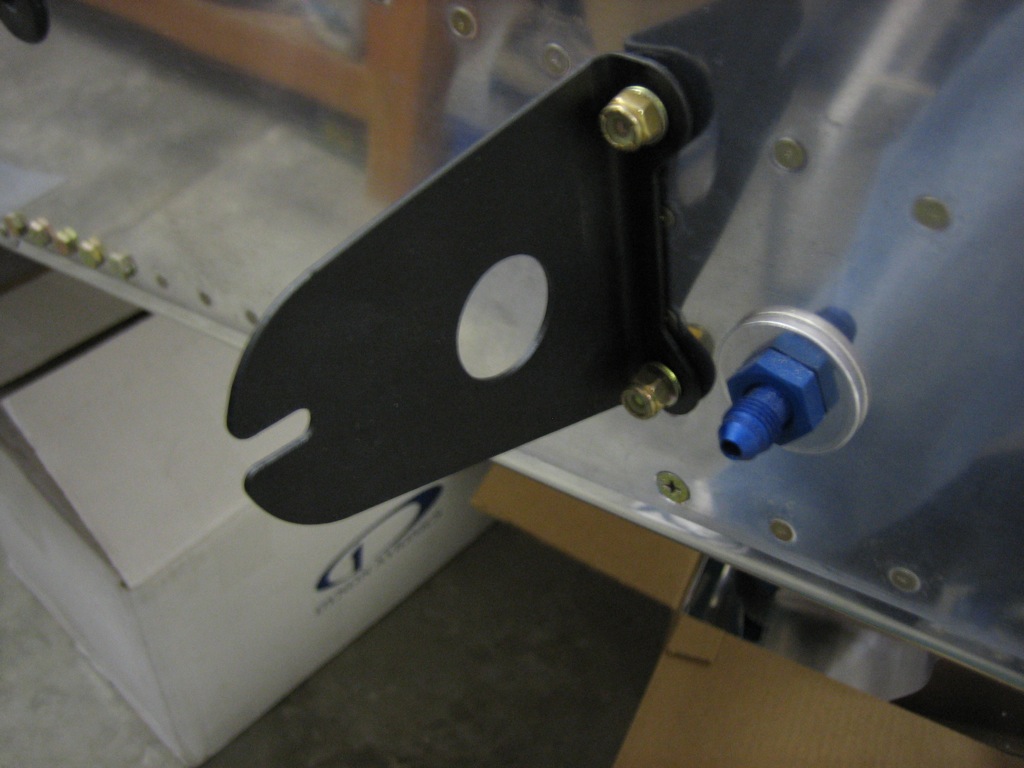

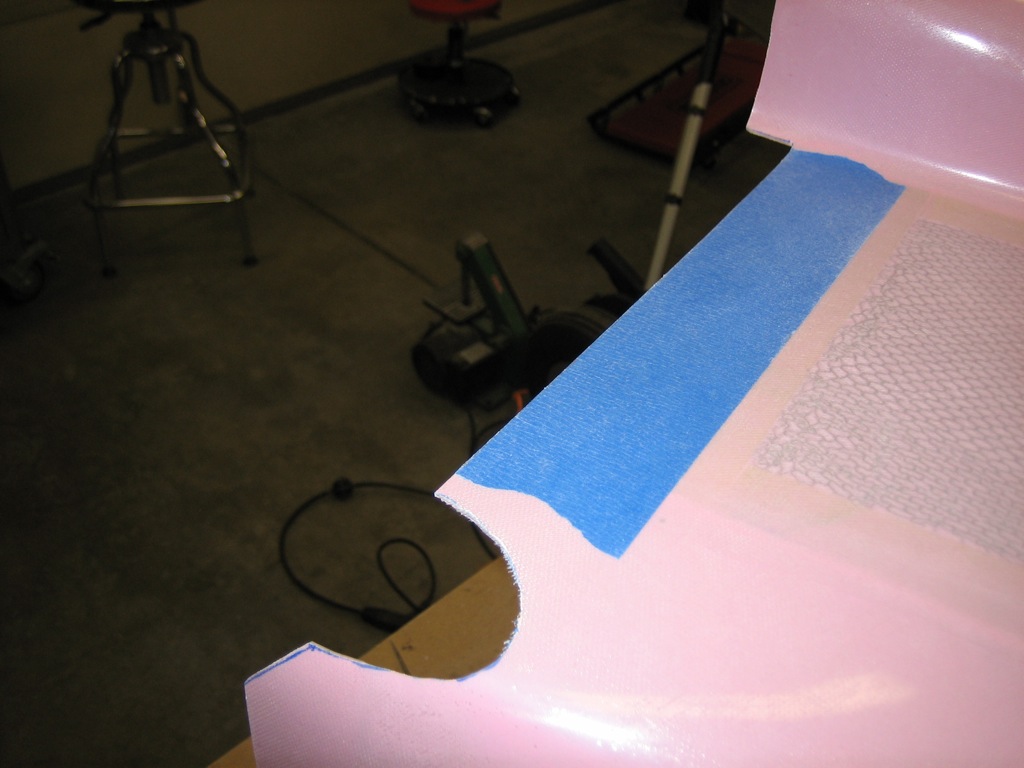

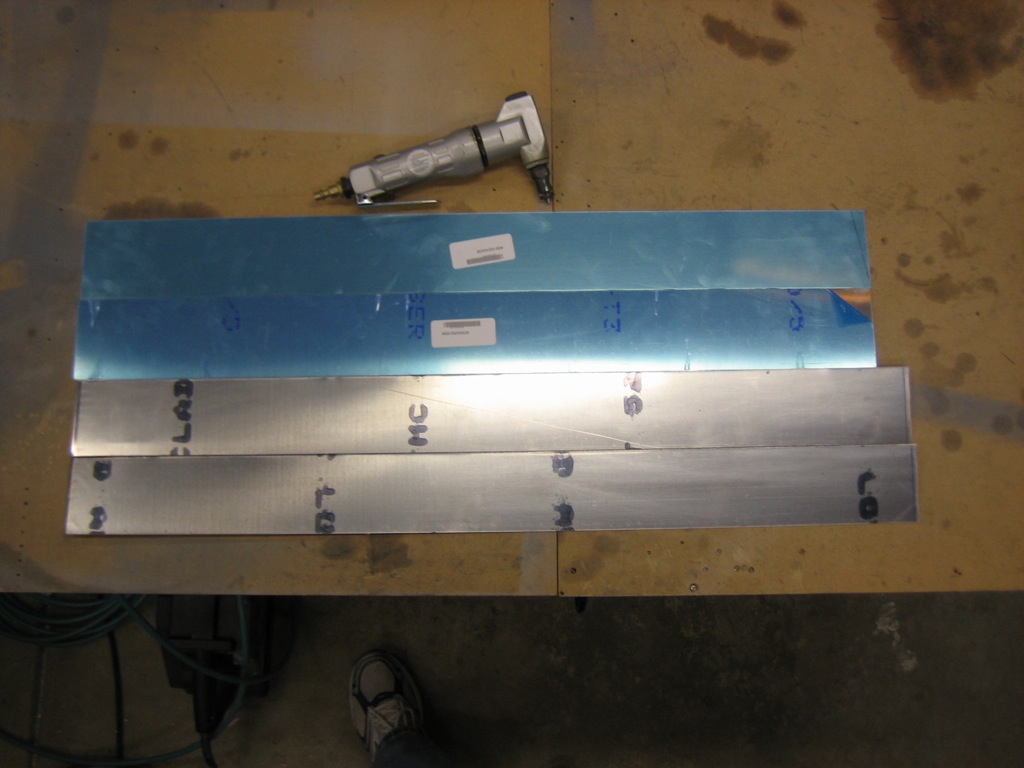

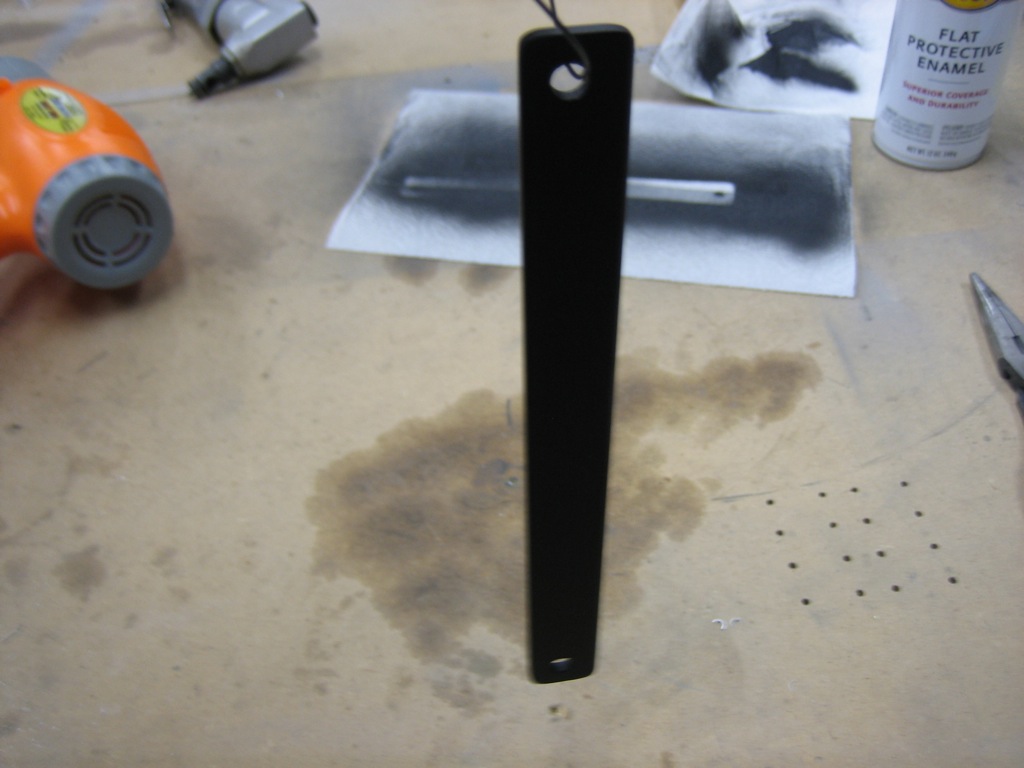

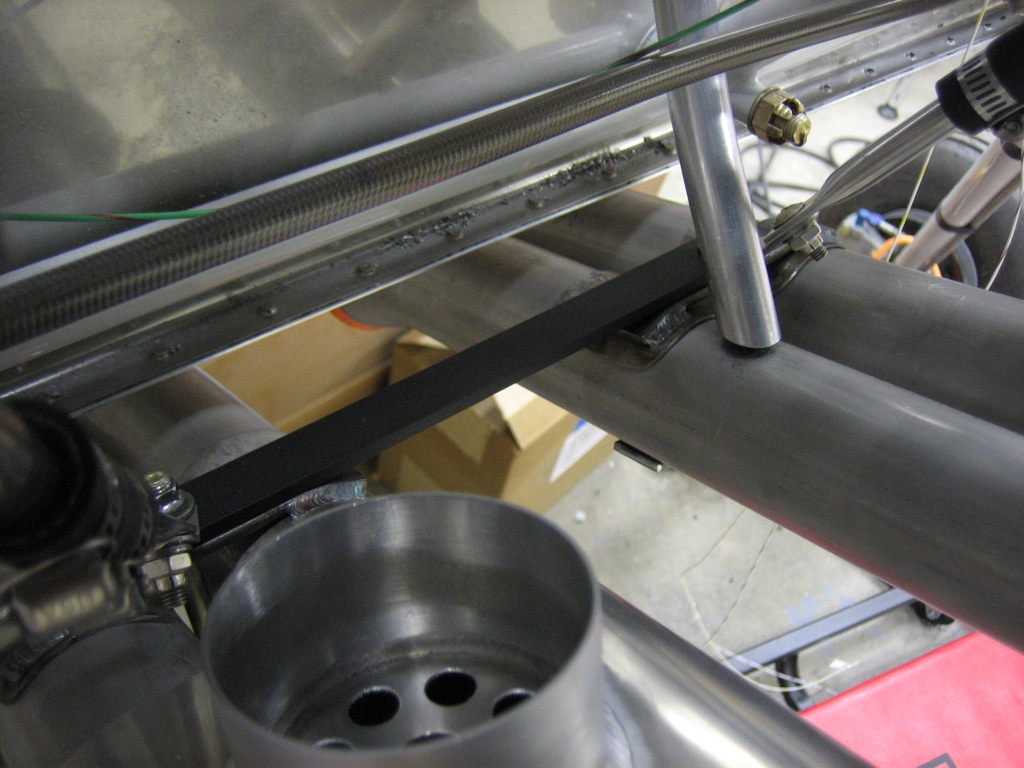

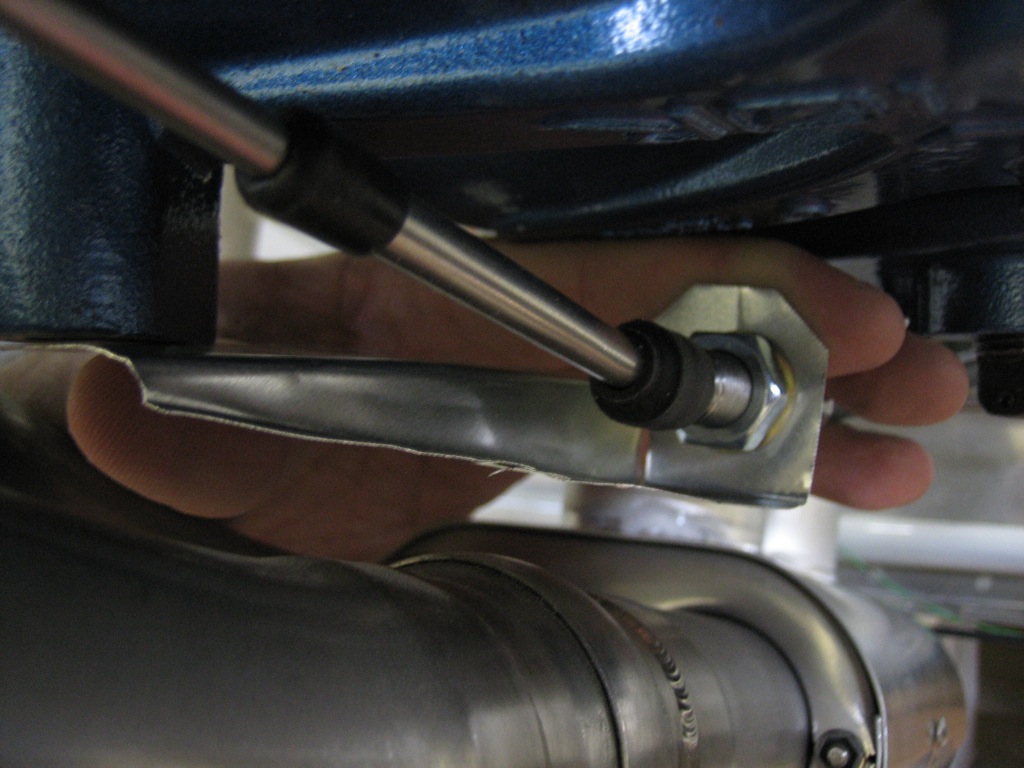

I cut a 44″ long piece of the 1/8″ hinge material. I sandwiched a strip of 0.020″ aluminum between the hinge and the firewall flange and then drilled the hinge to the flange. This was slow going since I couldn’t use clecos to keep the holes in the skin and the holes in the flange aligned.

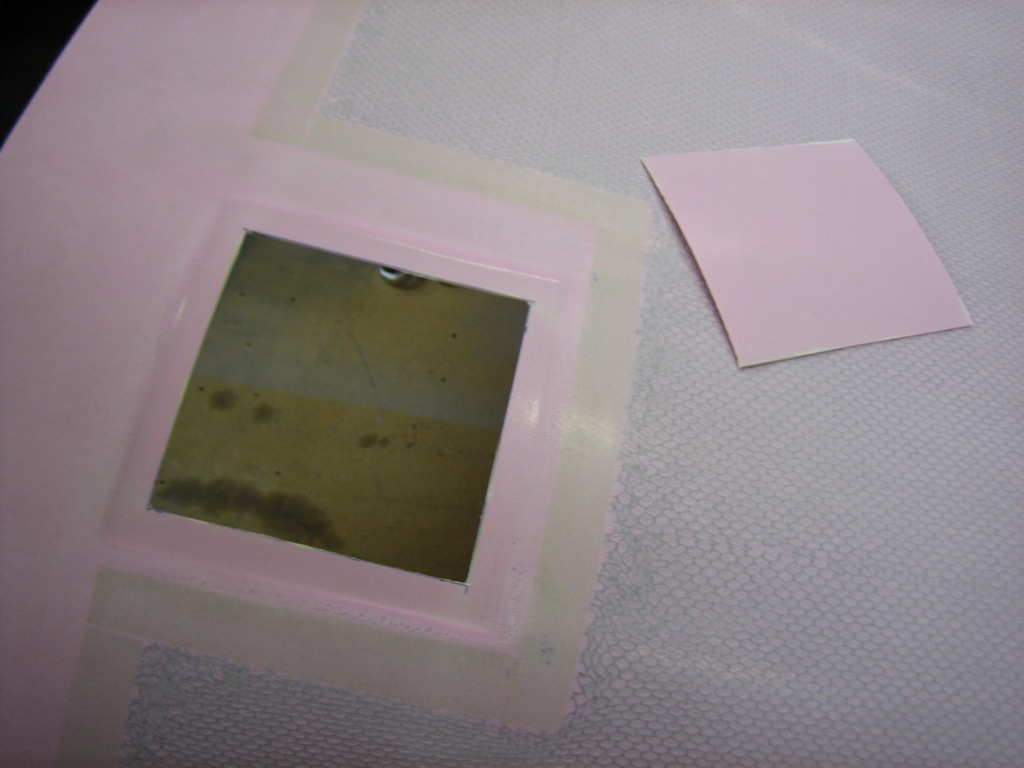

I biased the hinge forward slightly so that you wouldn’t see the eyelets between the forward top skin and the cowl.