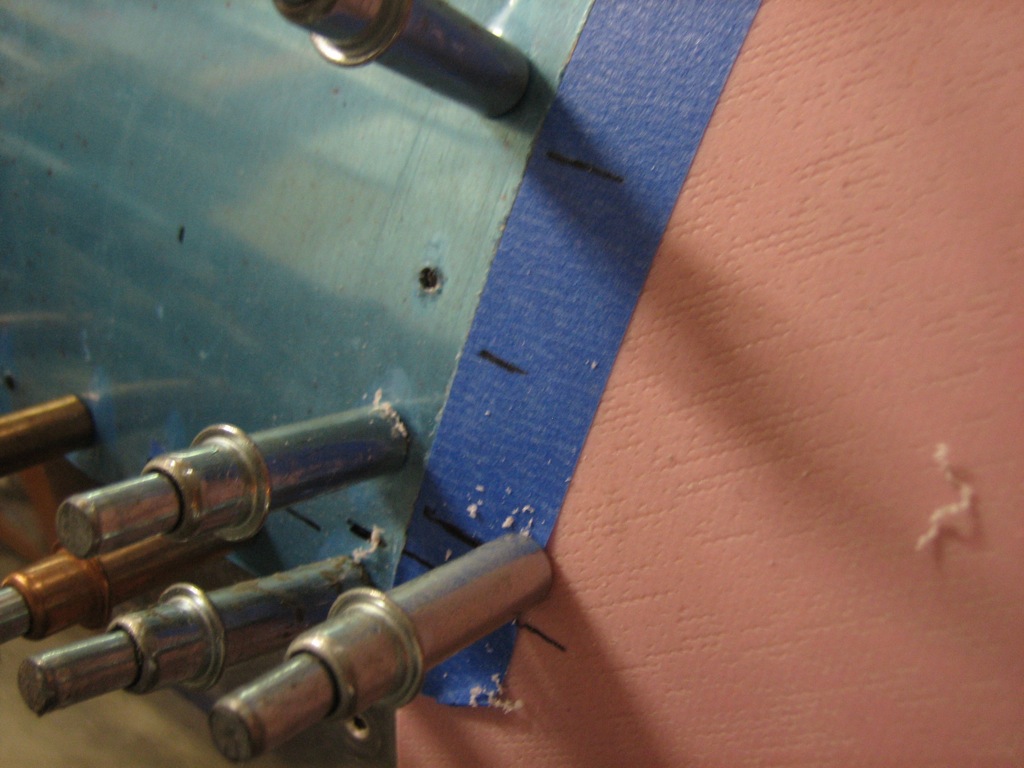

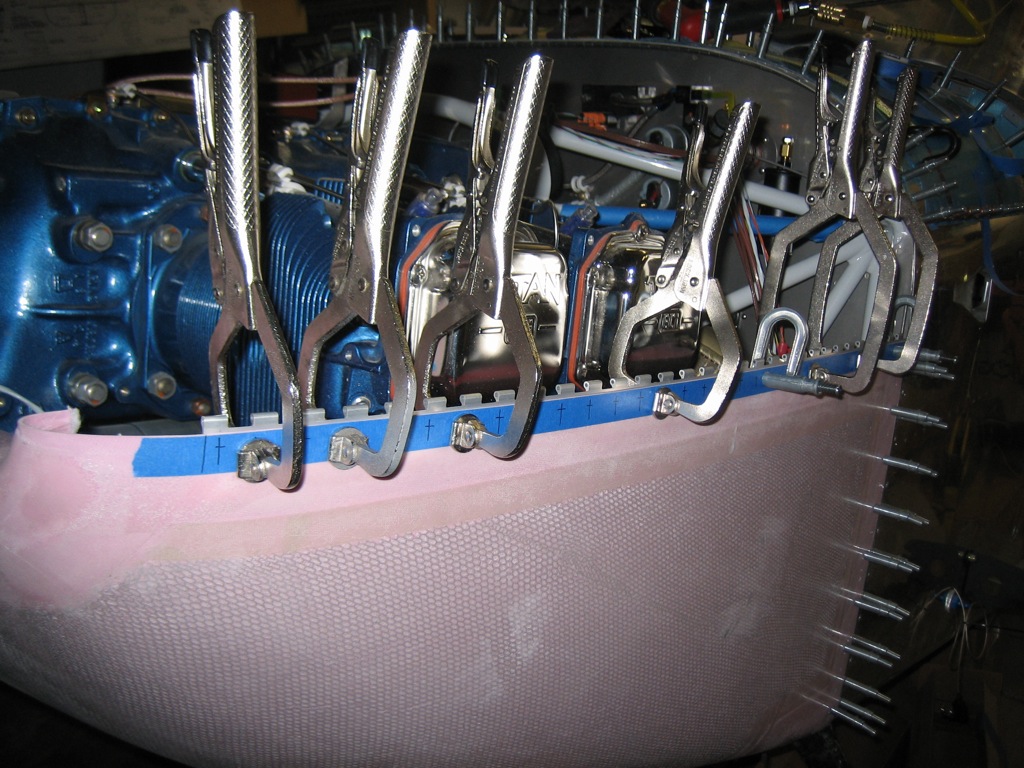

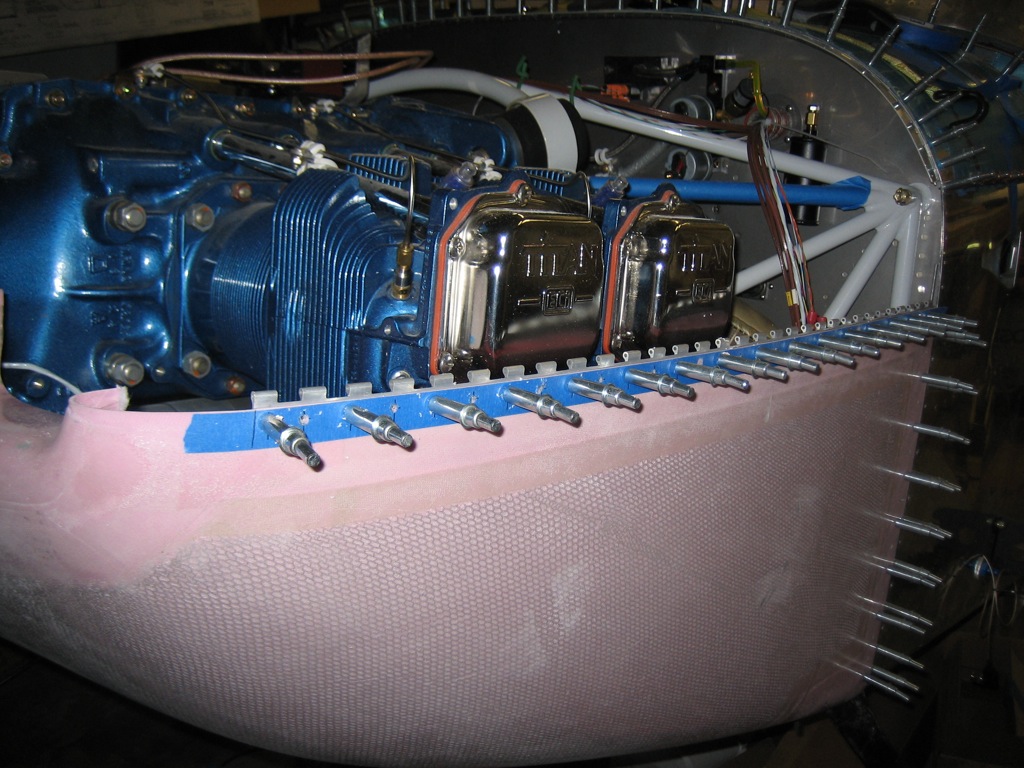

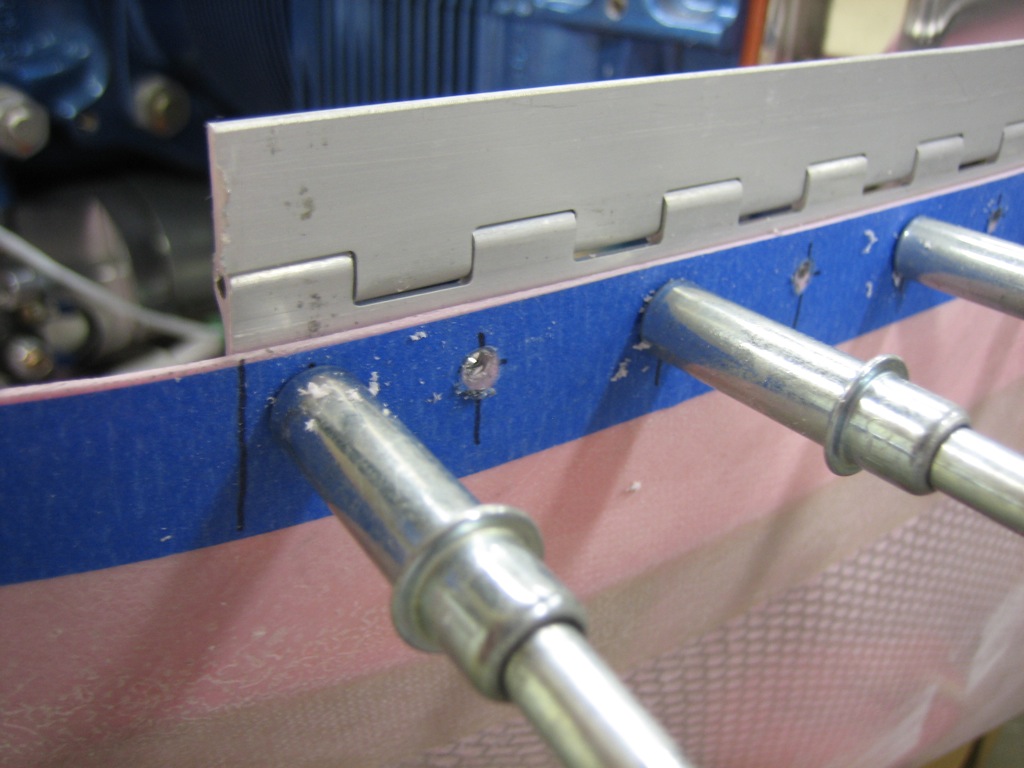

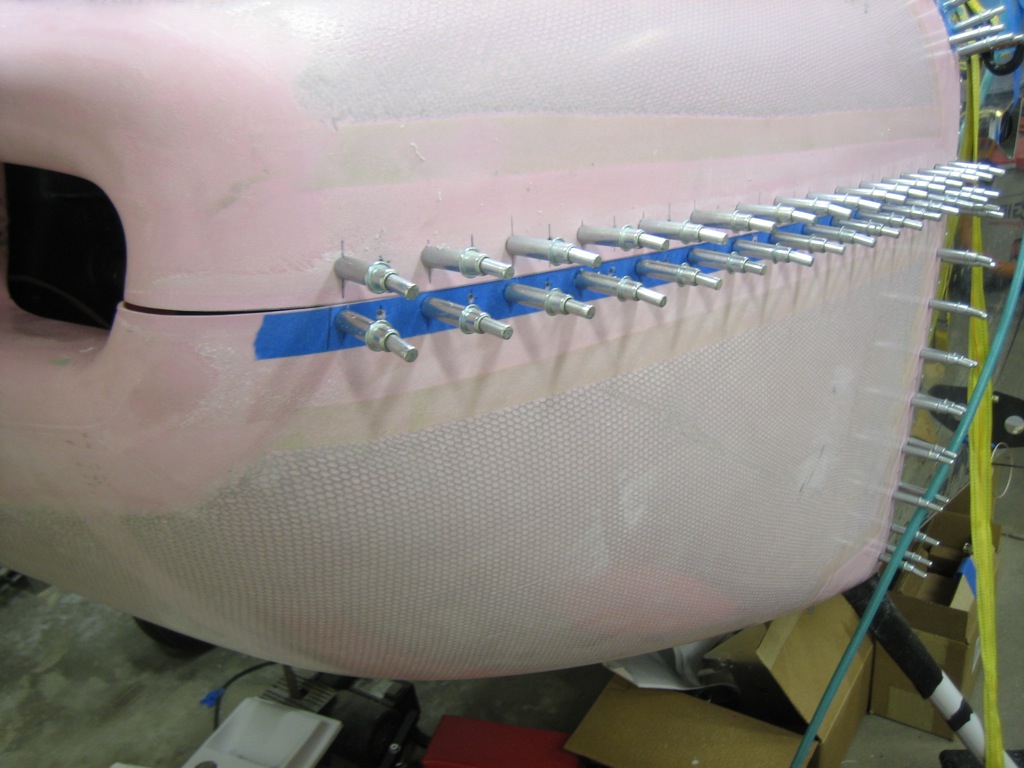

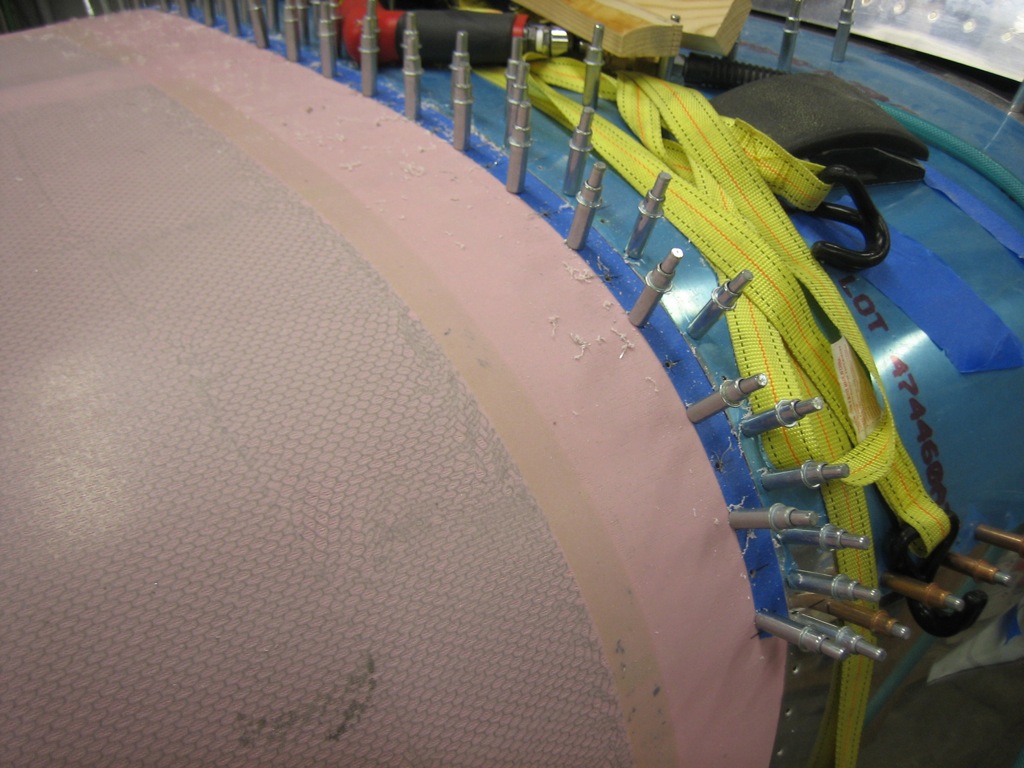

I spent a little time earlier today working on the cowl. I made the side cuts, then did a bunch more sanding to get the fit as nice as I can.

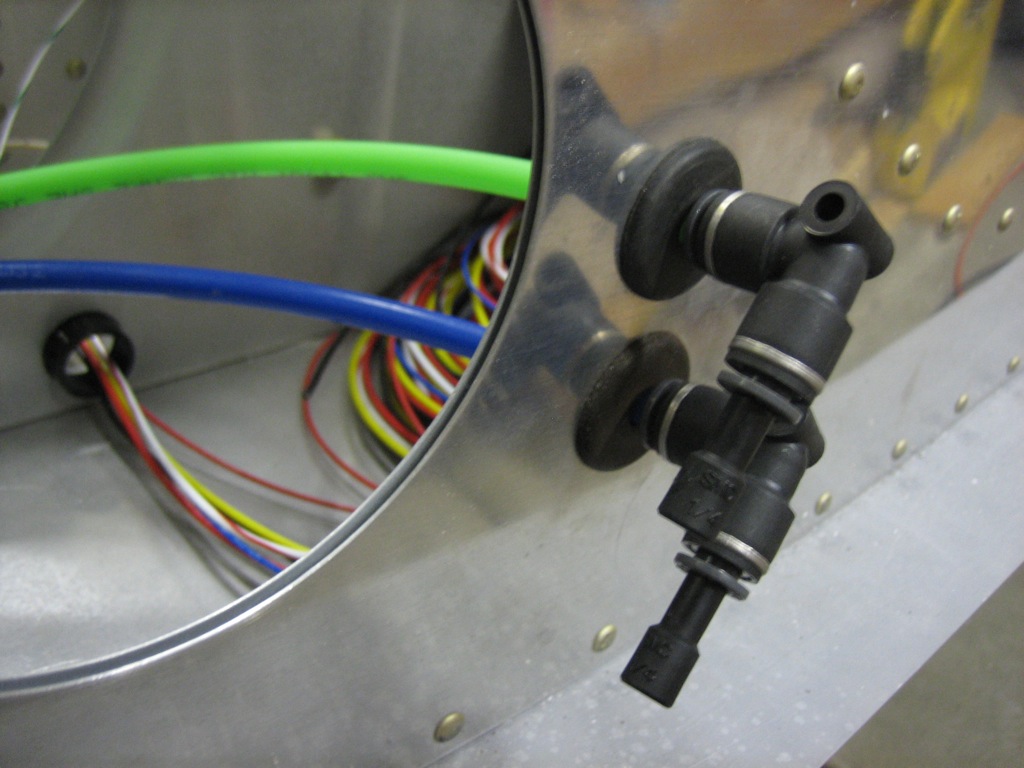

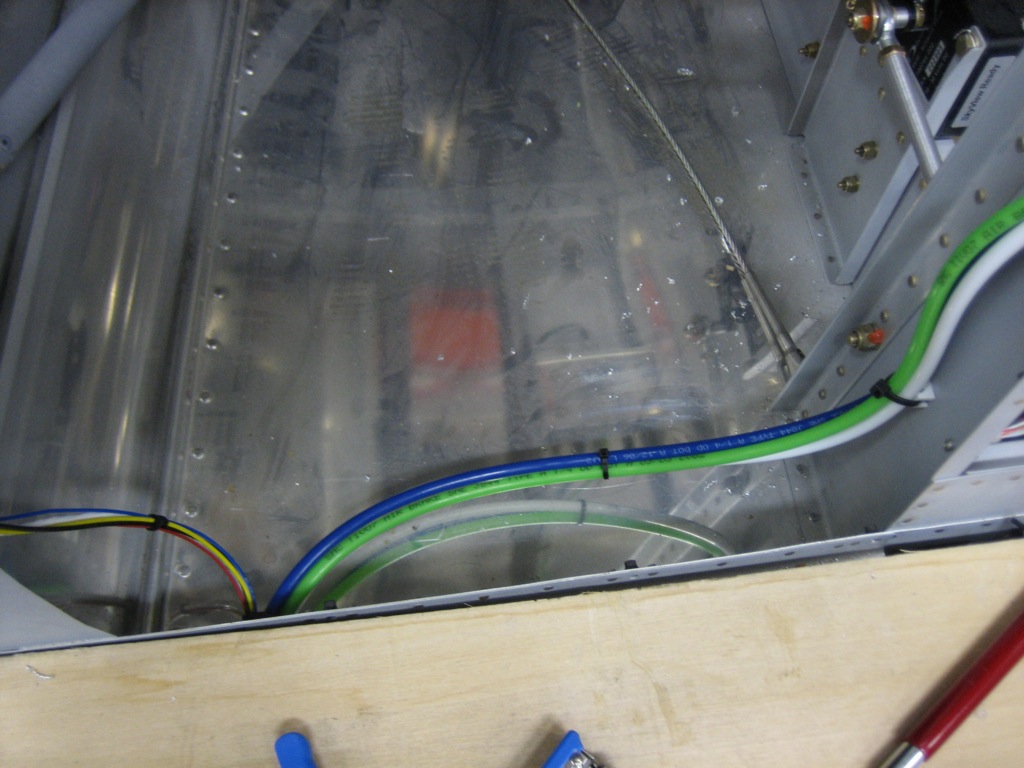

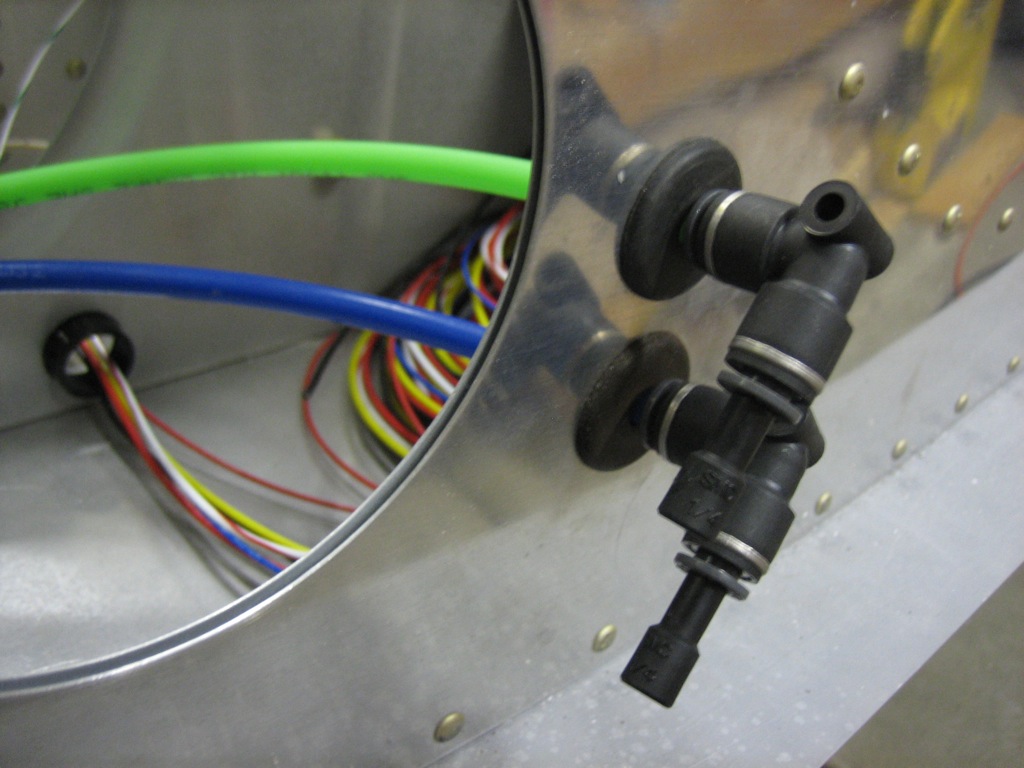

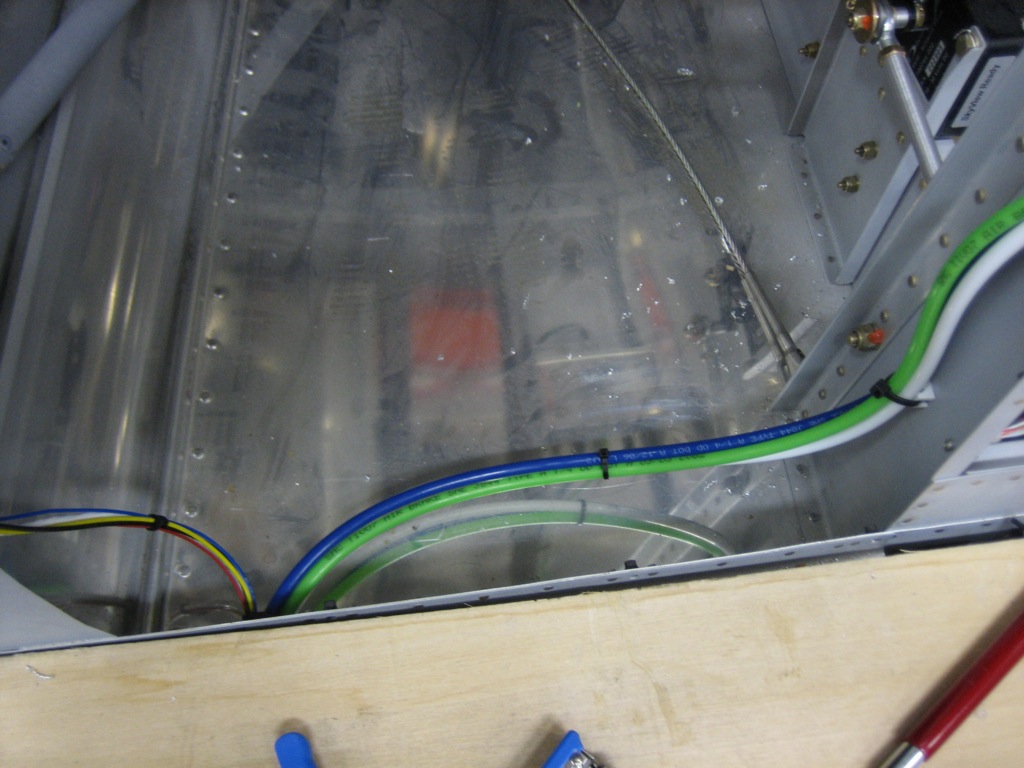

Afterward, I decided to do the pitot/static/AOA plumbing. This is where the pitot (green) and AOA (blue) lines will go into the fuselage. The lines from the wings will connect to these connectors.

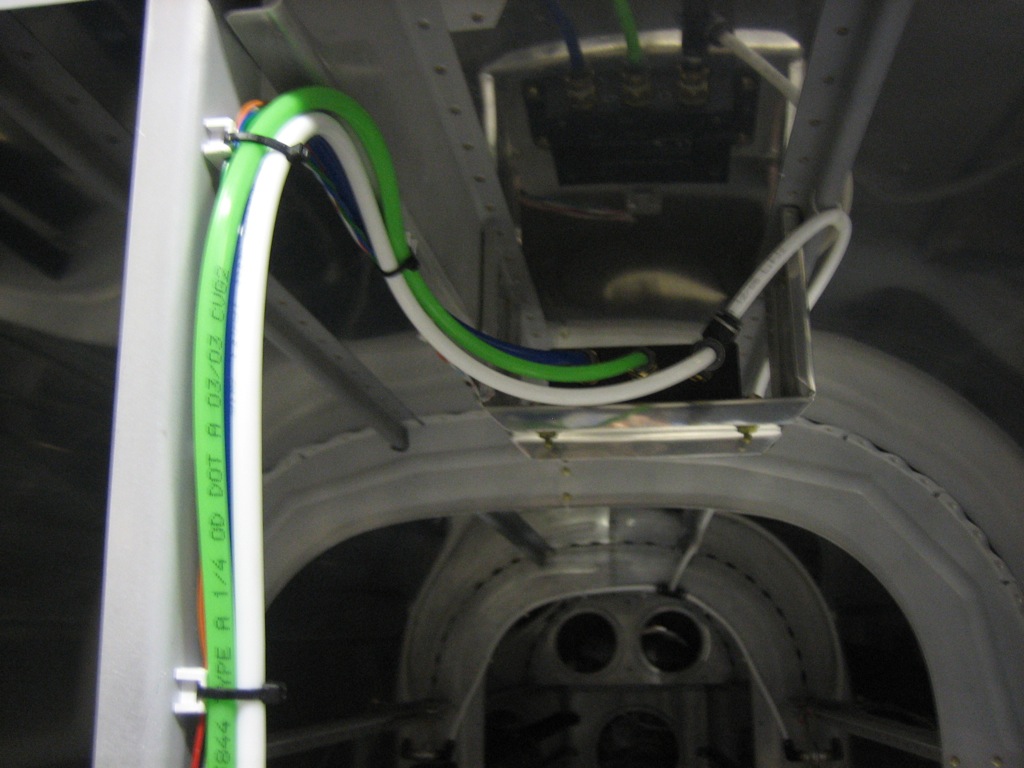

The pitot and AOA lines run forward of the spar and then across the fuselage.

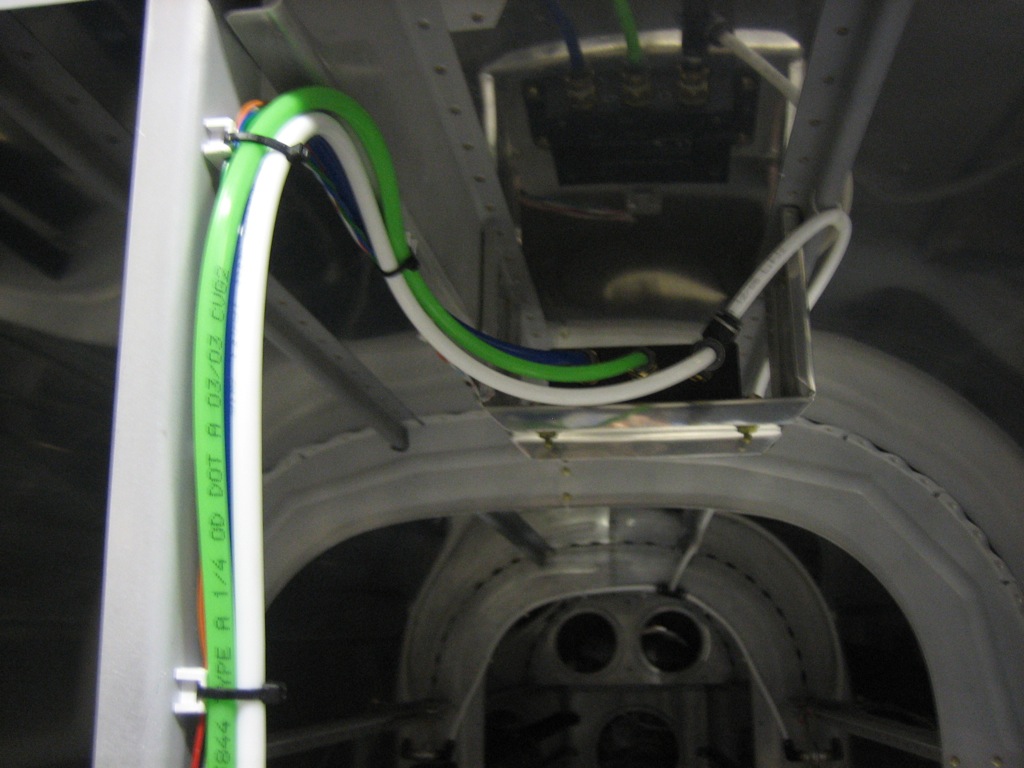

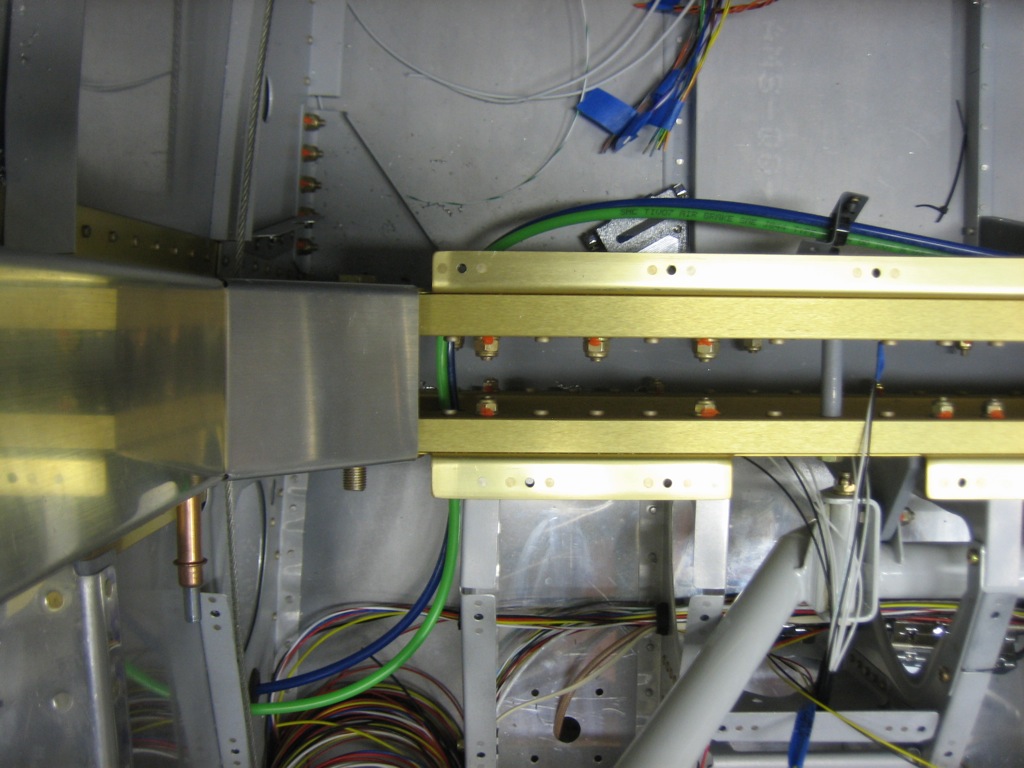

They then run back through the spar along with the static tube (white). This may seem like a somewhat circuitous route, but the left under-seat conduit is pretty full, so I needed to run the lines through the right under-seat conduit. Unfortunately, there’s no good path across the fuselage aft of the spar for lines this large. I could have drilled more holes in the seat ribs and installed snap bushings, but that’s a real pain in the ass at this stage of construction.

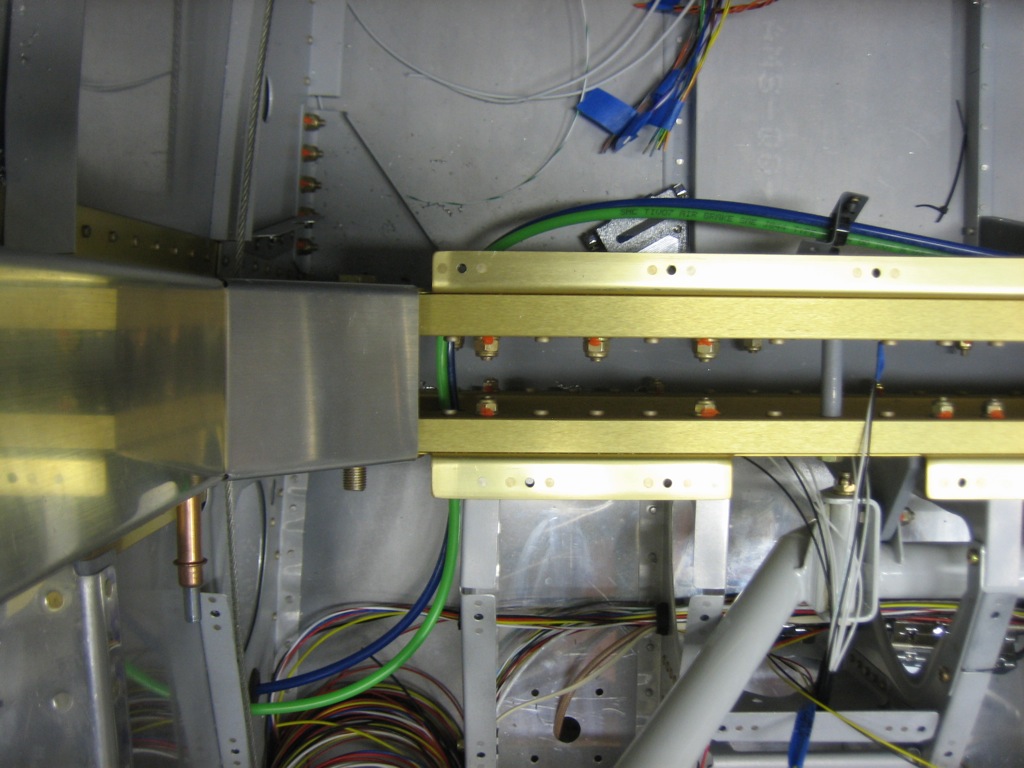

The pitot and static lines needs to run up to the instrument panel to connect to the backup EFIS and alt static valve.

The lines come out of the right under-seat conduit and then run up the center post.

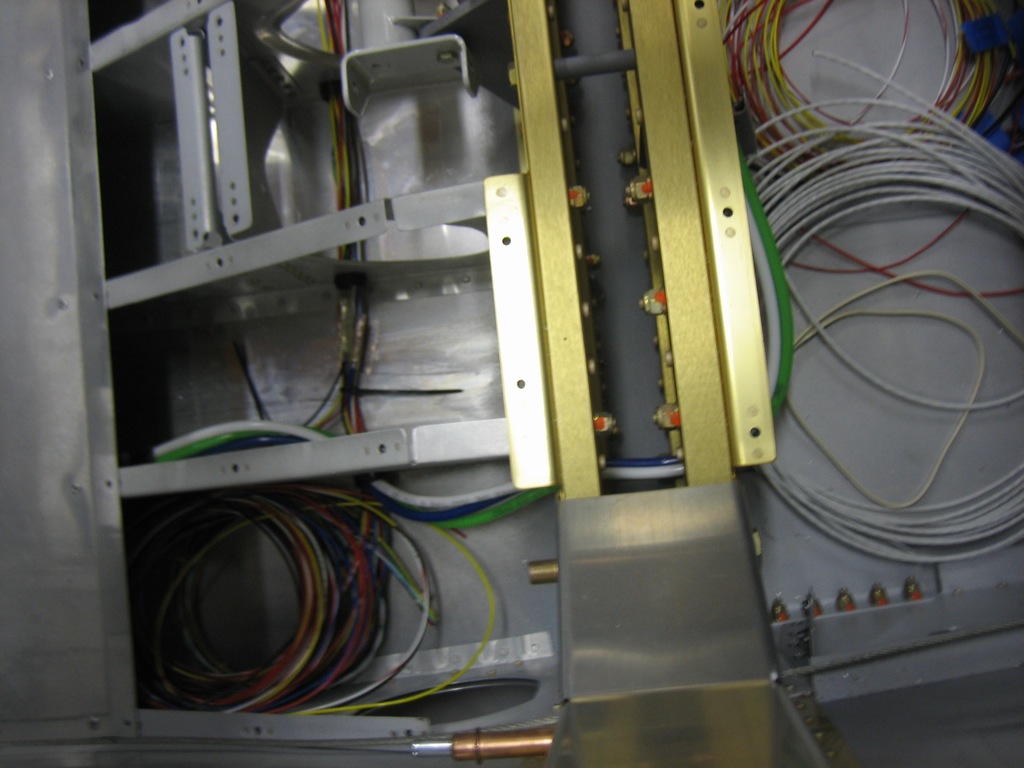

The lines cut through a hole in the post and then join the network cable in the run up to the ADAHRS.

The pitot and AOA lines connect directly to the ADAHRS. The static line connects to a tee to join the aft tailcone run to the forward fuselage run.