I was getting tired of having to squeeze under the engine to get from one side of the plane to the other, so I took the tailwheel spring off and tucked the tail up tight against the wall.

This gives me almost two feet between the spinner and the garage door; perfect.

While I had the tail spring off, I took the opportunity to get a bunch of the parts ready for powder coating. Since I’m using the JD Air Parts tailwheel link which only attaches on one side, I sliced off the other arm from the tailwheel linkage and ground the part smooth.

I also stripped the primer from the Bell tailwheel fork so that it can be powder coated. Afterward, I wrapped silicone tape around all surfaces of the tailwheel parts that I don’t want to be powder coated and set them aside. The tailwheel spring is too big to fit in my little powder coating oven, so I’m going to see if I can drop by a friend’s place who has a pretty big powder coating oven and do them there.

I needed to get the joint at the front of the spinner adjusted so that the opening is circular. Instead of measuring, I just put the spinner on the front of the cowl and adjusted the fit until everything lined up nicely.

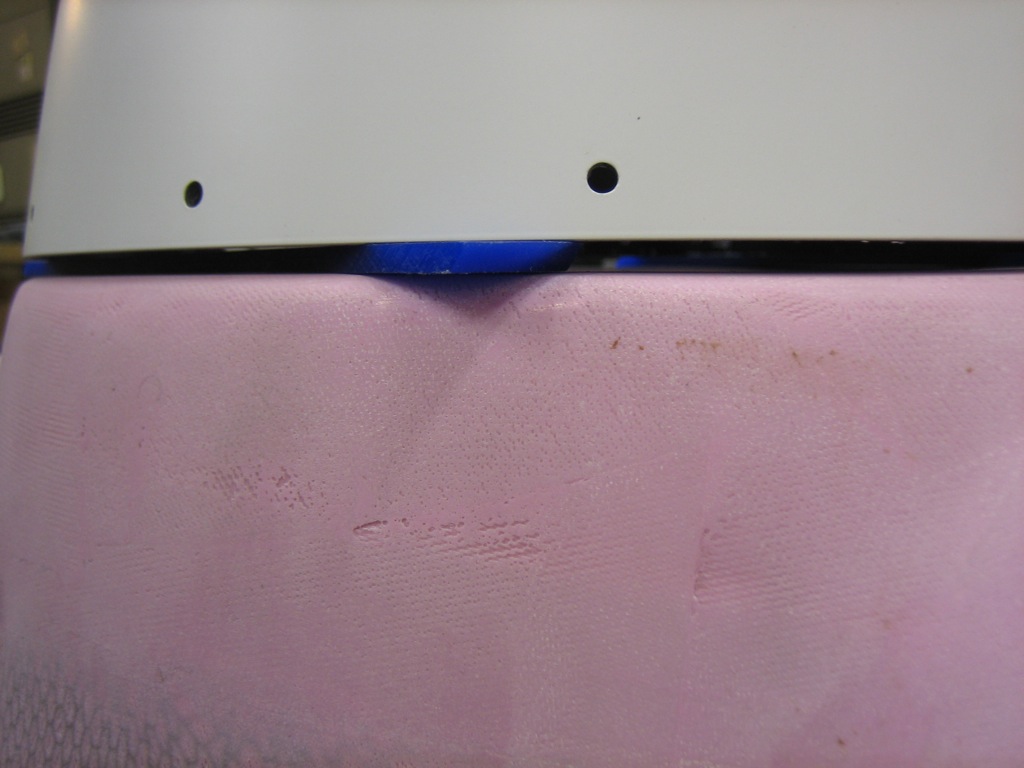

I’m using 1/8″ spacers between the cowl and the spinner. The gap is surprisingly good along the top.

However, the joint between the top and bottom leaves a lot to be desired.

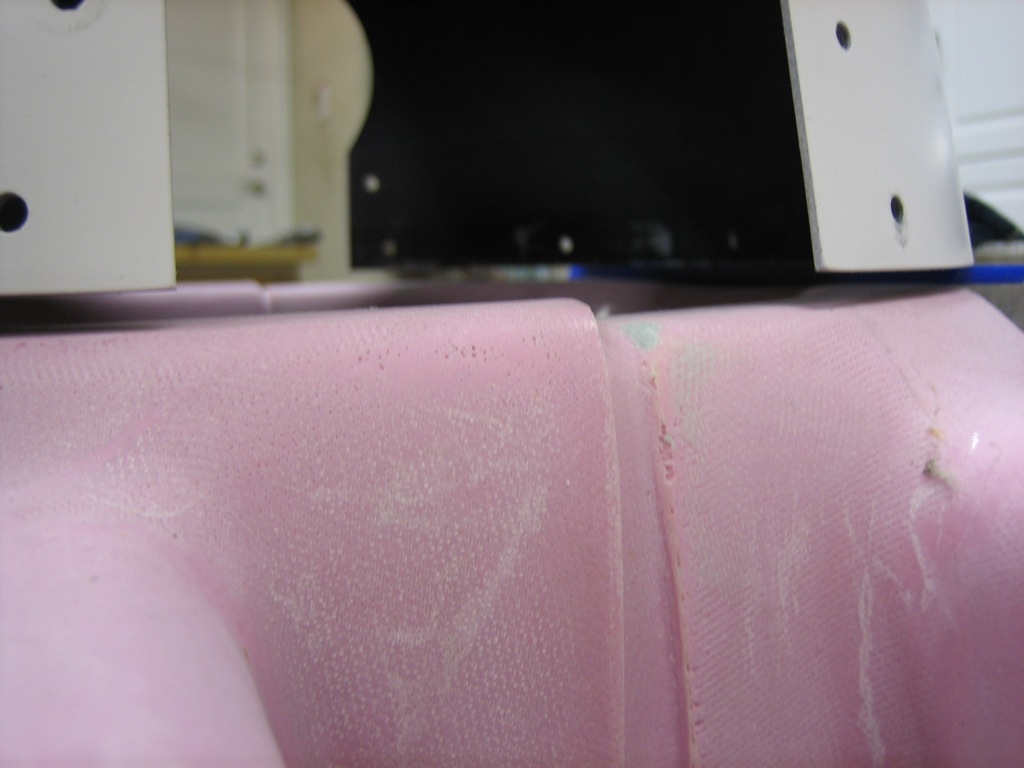

The left side is a little better, but there’s still a noticeable step. I spent a little time working on the fit, but there is still a lot to do before this will look good. I’ll probably end up making the gap between the cowl and spinner a little larger to start with and I can tighten it up with some fiberglass layups at the same time I’m fixing the fit between the top and bottom halves.

I spent the rest of the night digesting the instructions and plans for the cowl. This is likely going to be one of the tricker parts of the build.