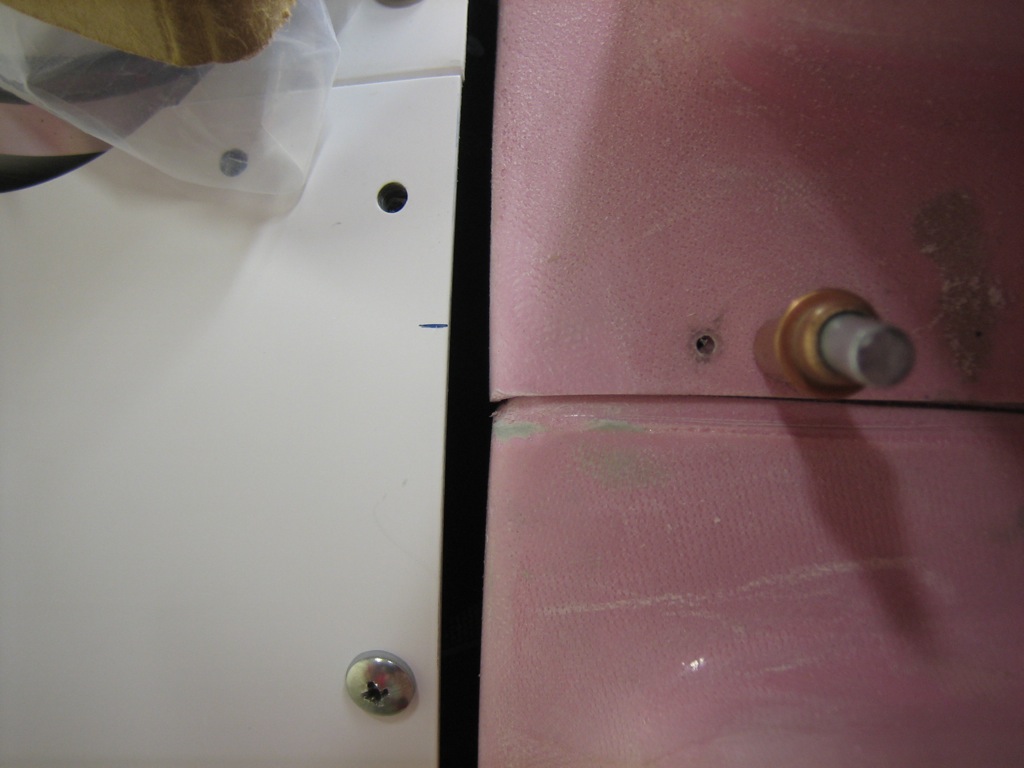

One thing that has been bugging me about the fit between the upper and lower cowl halves is the fit between the cowl and the spinner. If you go back and look at this entry, you can see what I’m talking about. Because any further work will lock in the fit between the upper and lower halves, I needed to take care of this now. I cleaned up a few boogers inside the flange of the upper cowl and then ground away a fair amount of the face of the lower flange to allow the upper cowl to slide backward over 1/16″. Now the gap is really nice all the way around the spinner. I’ll probably still add a little filler to make the gap perfect, but I want to have the two cowl halves completely trimmed and joined along the sides. Here’s the fit on the right side.