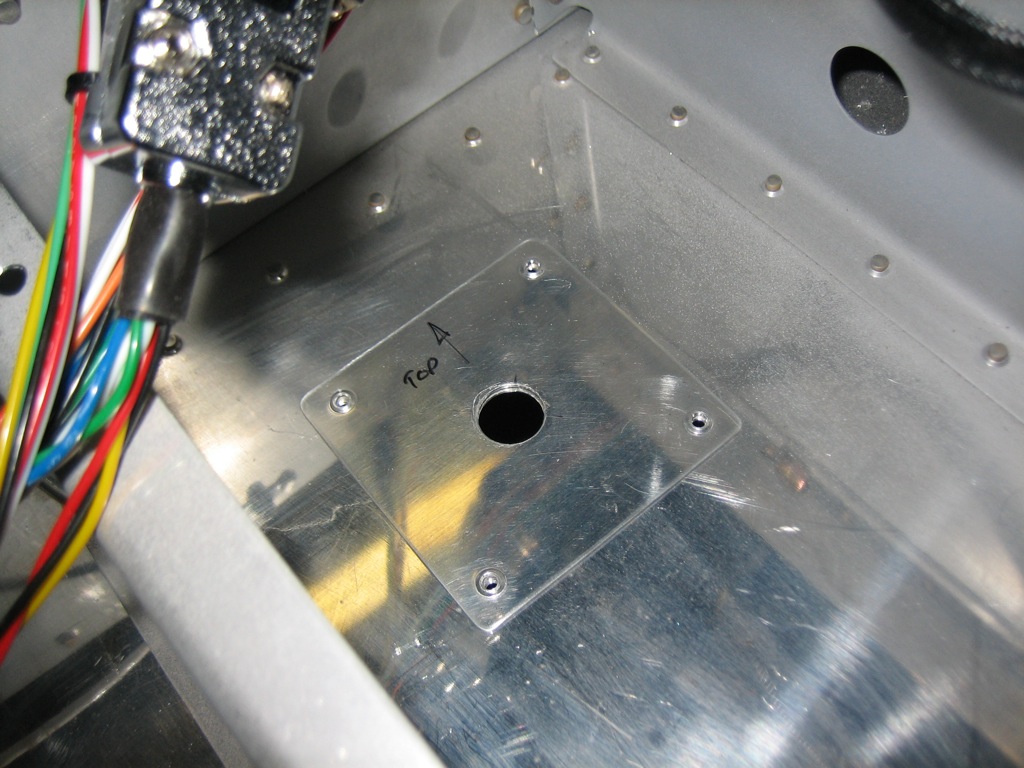

I decided to get started on the oil door tonight. I started by grinding down the edge of the flange to create a better-defined joggle.

I then trimmed the door itself and radiused the corners so that the door fits down nicely in the cutout. The trims on the cowl itself are a little sloppy as you can see below, but that won’t matter. Once I have the door exactly where I like it, I’ll put some structural filler here and use the door itself to mold it perfectly.

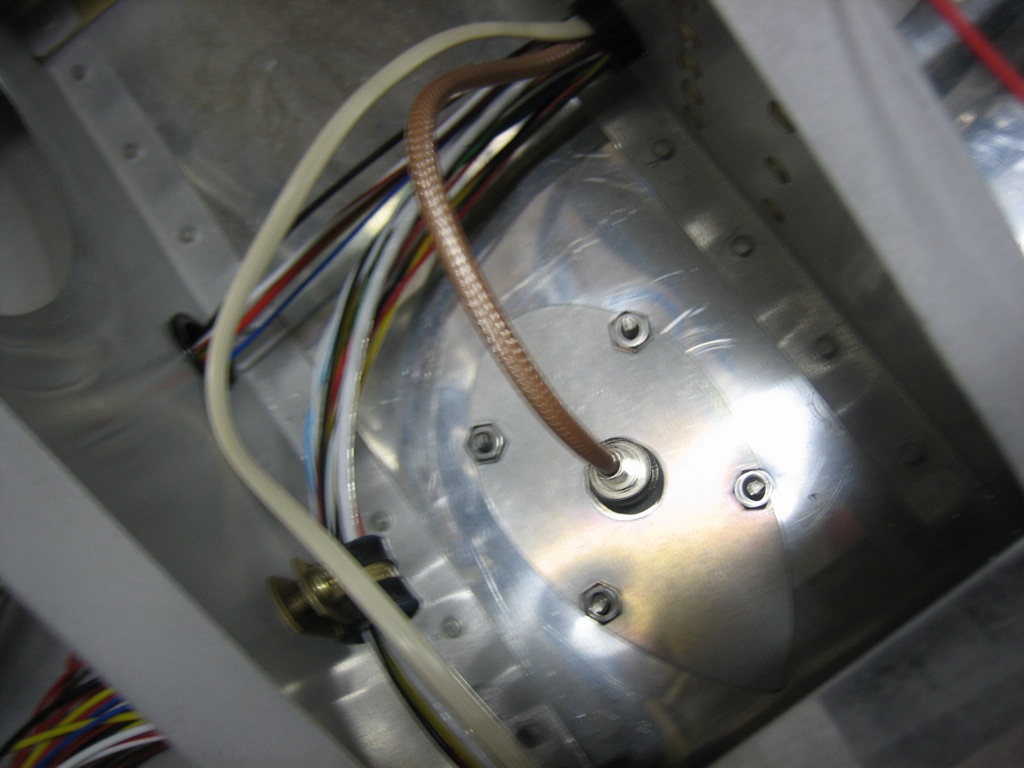

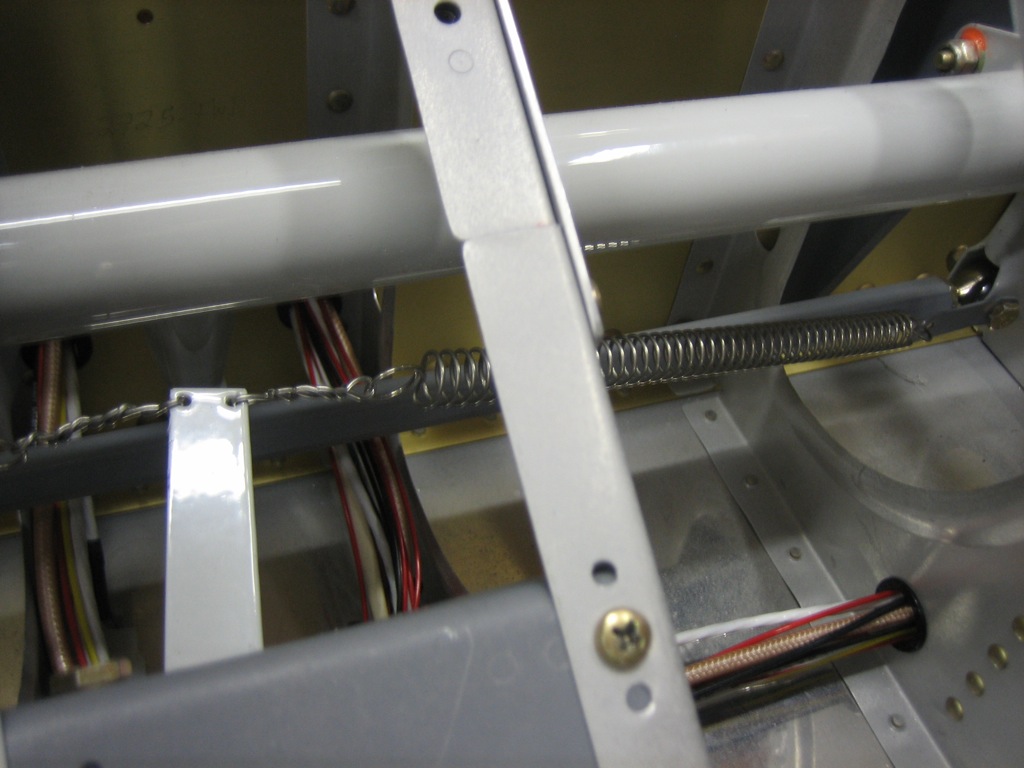

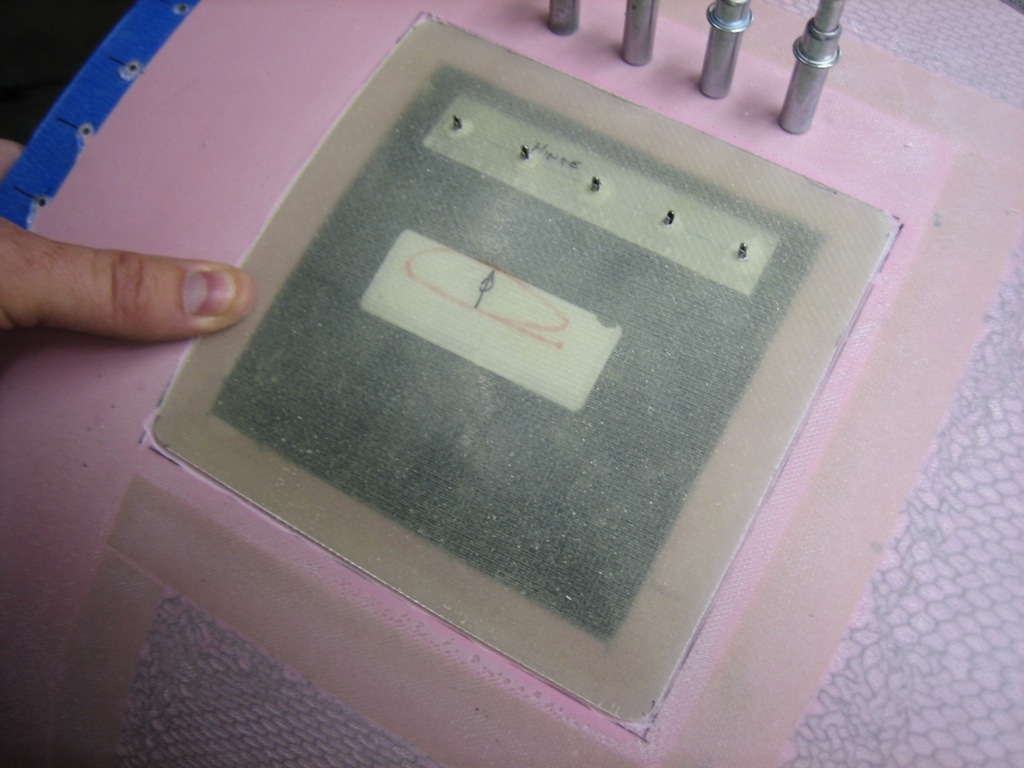

I then drilled the hidden hinge to the cowl and door.

The hinge has a spring that will hold the door open while I’m checking the oil. The door is pretty flimsy right now. I’m going to need to stiffen it in order for it to work.

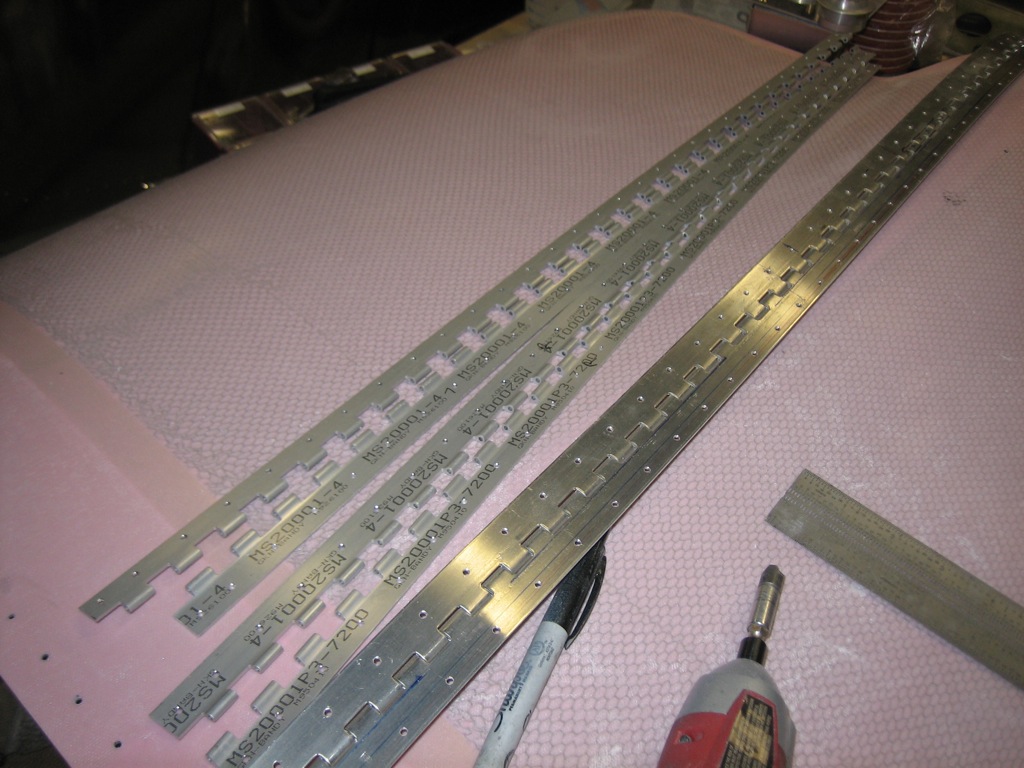

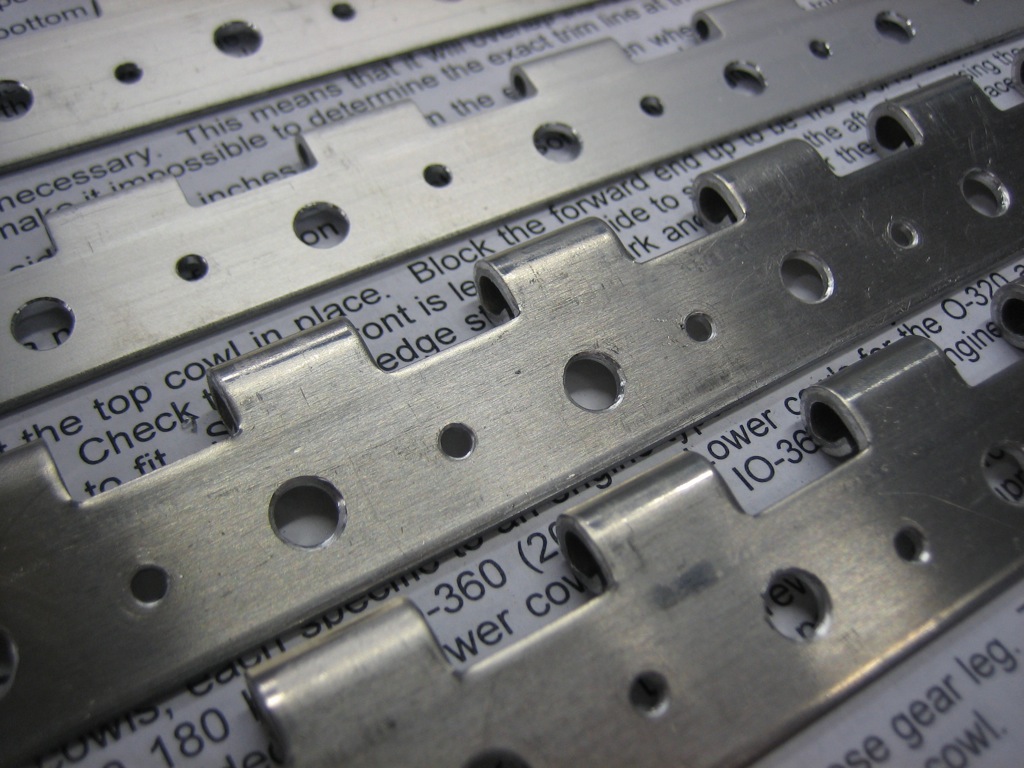

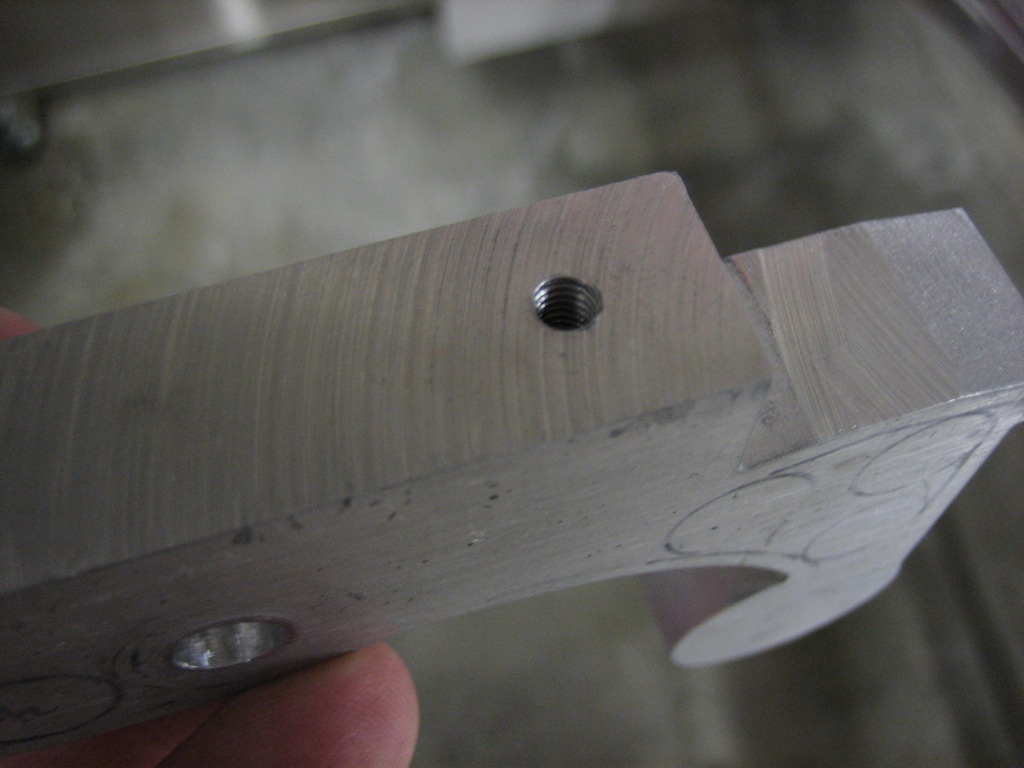

Finally, I spent a little time debarring all of the holes I drilled in the cowl attach hinges. I still have a few more to go, but this makes a big dent in the deburring.