Tyson Weihs, one of the co-founders of ForeFlight, stopped by tonight to check out the project along with my buddy Andre. We spent an hour or so talking about RVs before I got started building.

I spent most of the night working on the cowl attach hinges. First up was to pull the lower cowl and finish drilling the stainless hinges along the bottom edge of the cowl. Drilling steel is a pain, and you really want to drill the hinge before drilling the cowl to avoid elongating the hole in the cowl. Next up, I removed some of the eyelets in the hinge that runs along the top of the firewall. The hinge pin has to be removed and installed in two separate pieces through the oil door.

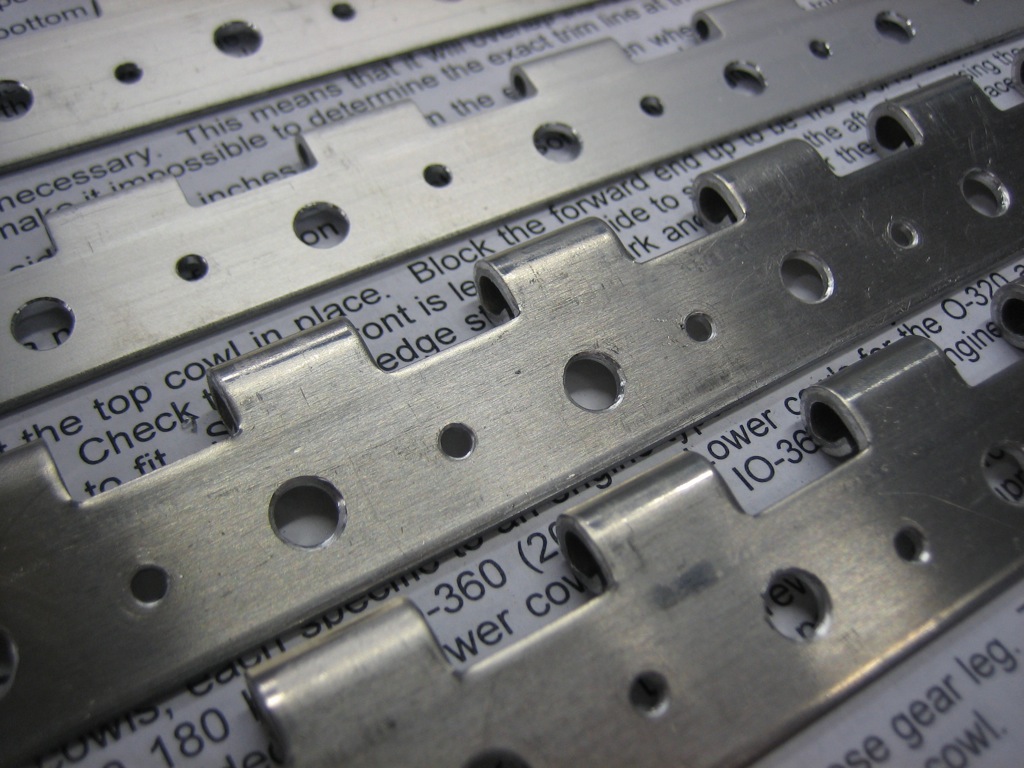

I then drilled additional holes in all of the hinges that will bond to the cowl (nine total) and deburred everything. The small holes will be used for AN426A3-5 rivets (not AN426AD rivets since that can crush the fiberglass). The larger holes will allow the epoxy/flox mixture to squeeze up through the holes and bond to the layer of glass that will be laid over the rivet shop heads. This will provide a far stronger joint than just rivets alone. I will be using West Systems G/Flex epoxy which has a modulus of elasticity of 150,000psi. This is substantially more flexible than their 105/205 epoxy which has a modulus of elasticity of 450,000psi, but substantially more rigid than adhesive sealants like the MC-236-B2 sealant I used on the tank.