Happy Father’s Day everybody!

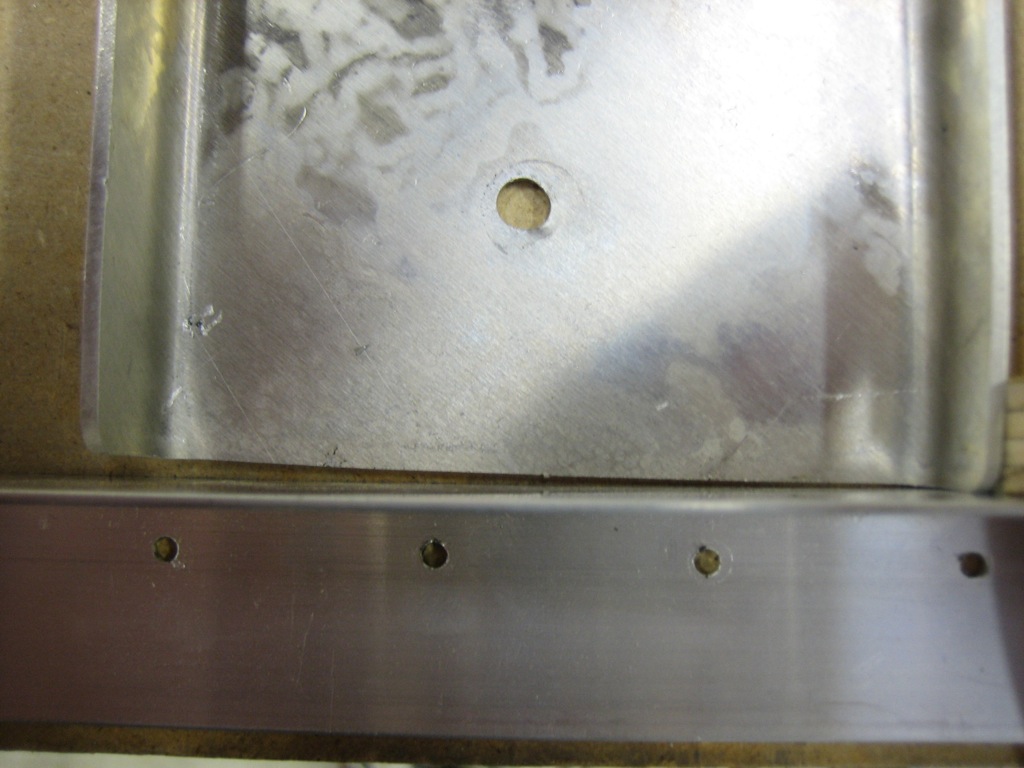

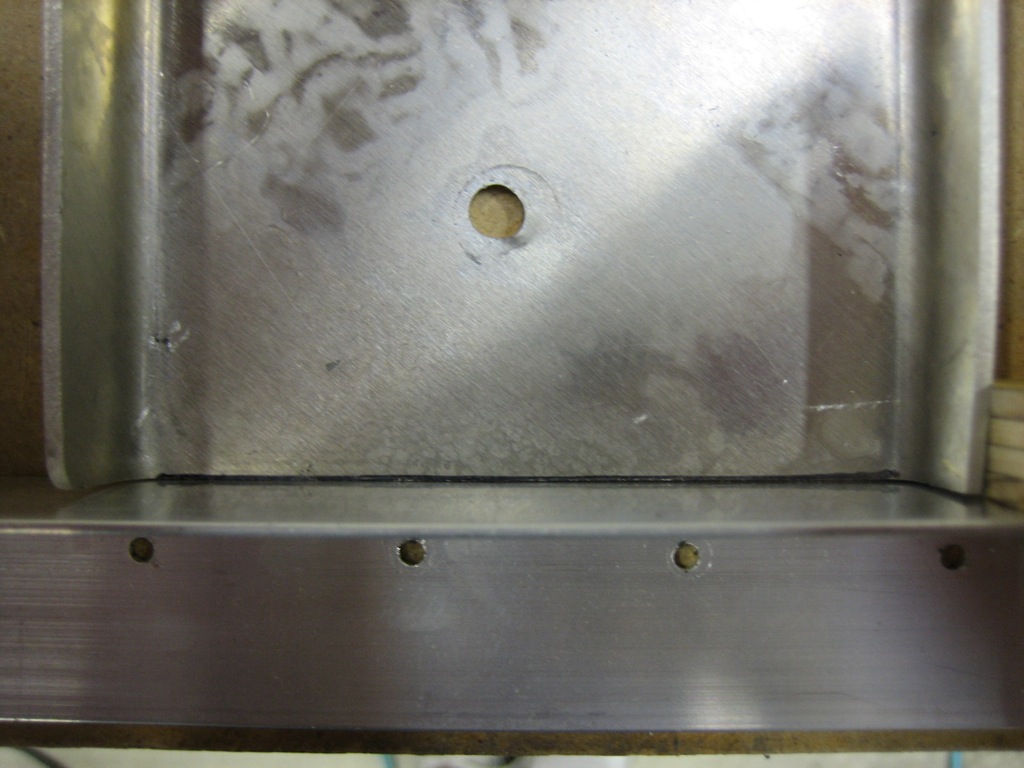

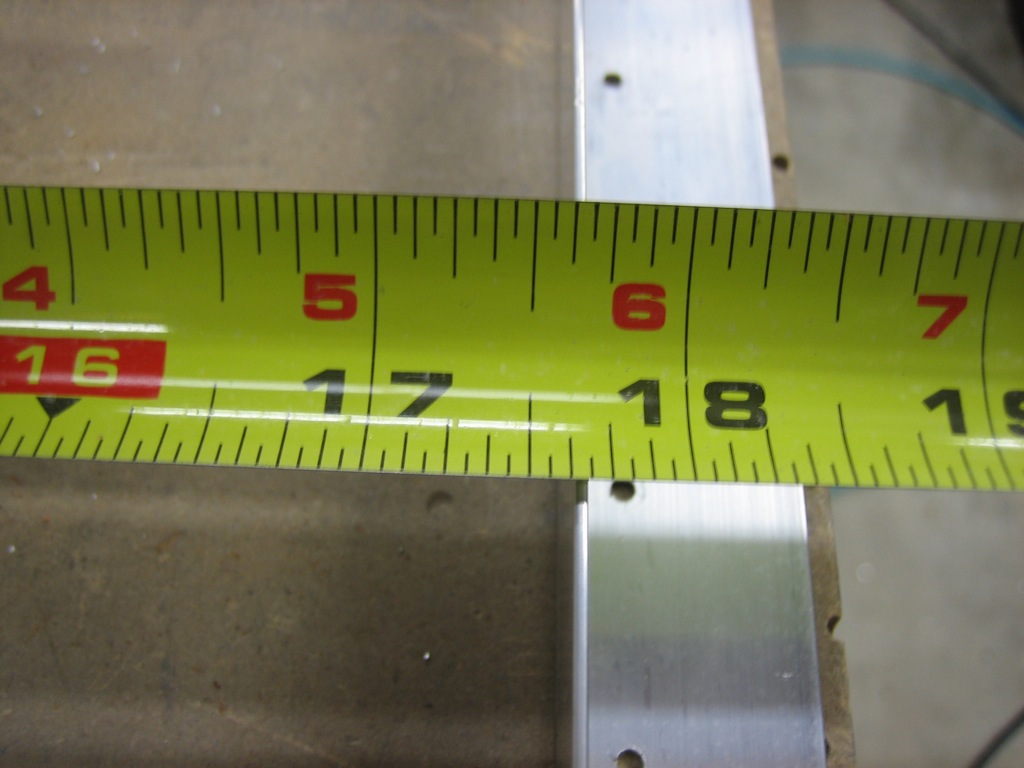

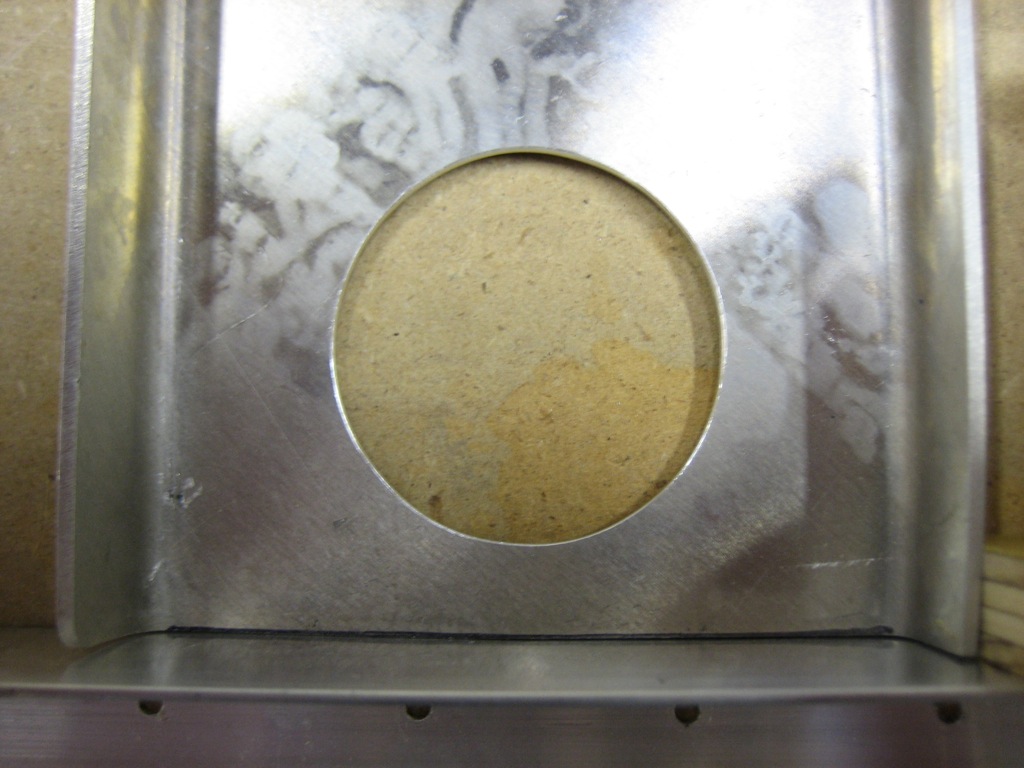

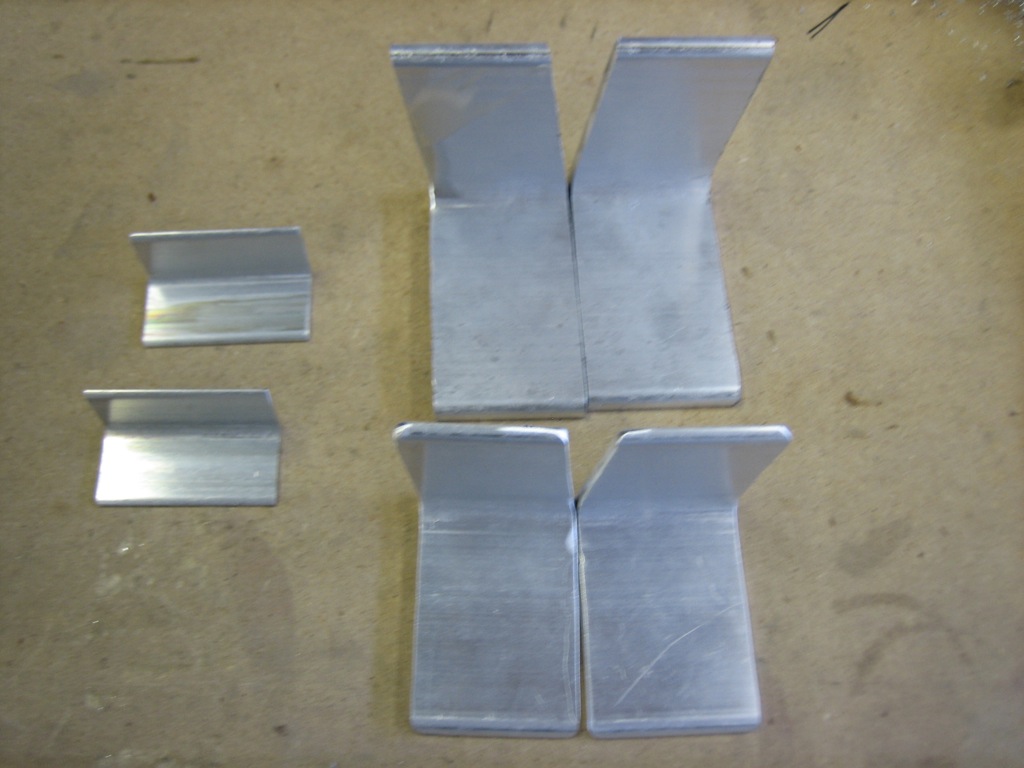

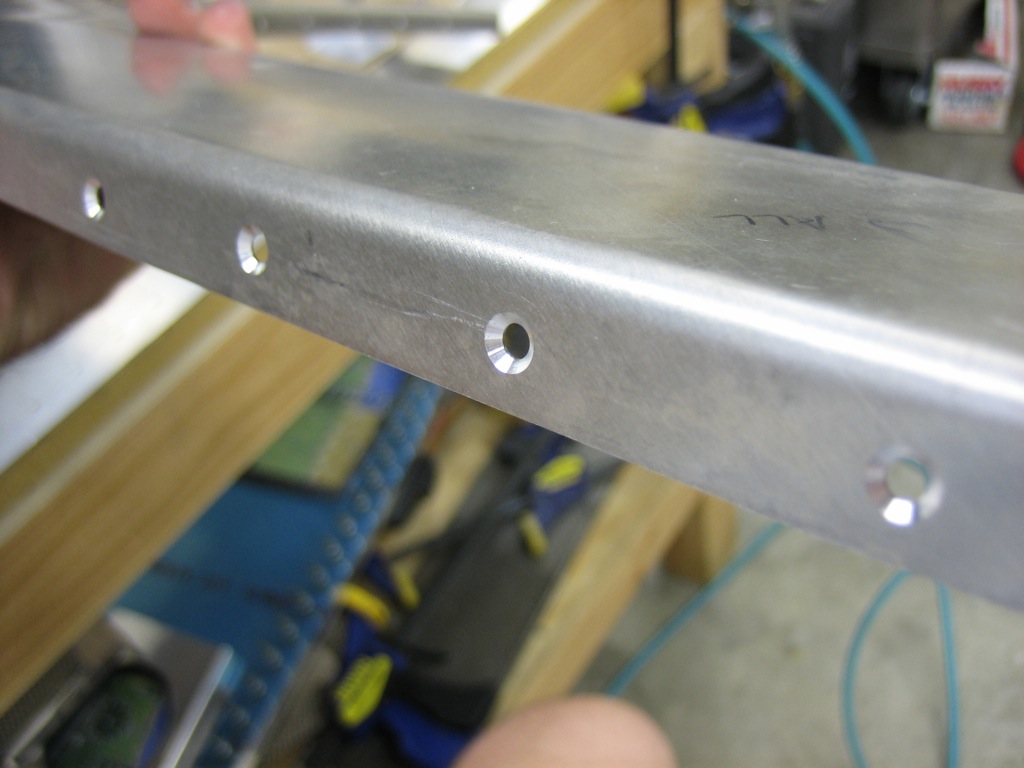

I spent most of the day with family and some friends, but had a little chance to get out into the garage late tonight. First up, I marked and cutout the notches in the outboard forward spar cover attach angles.

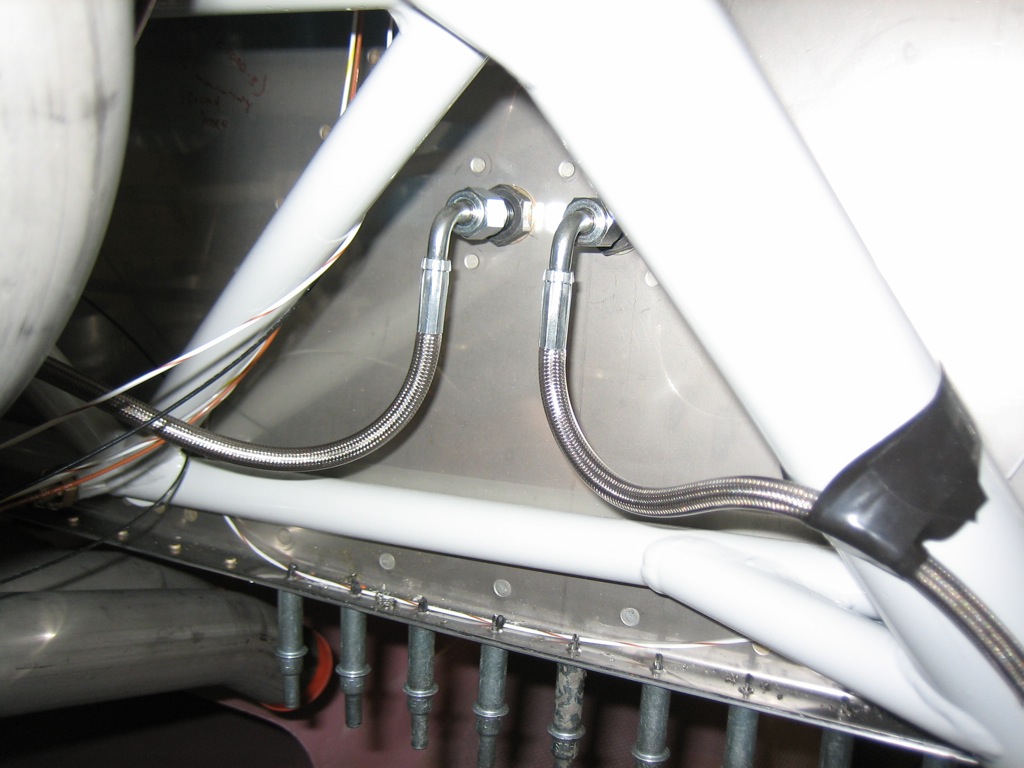

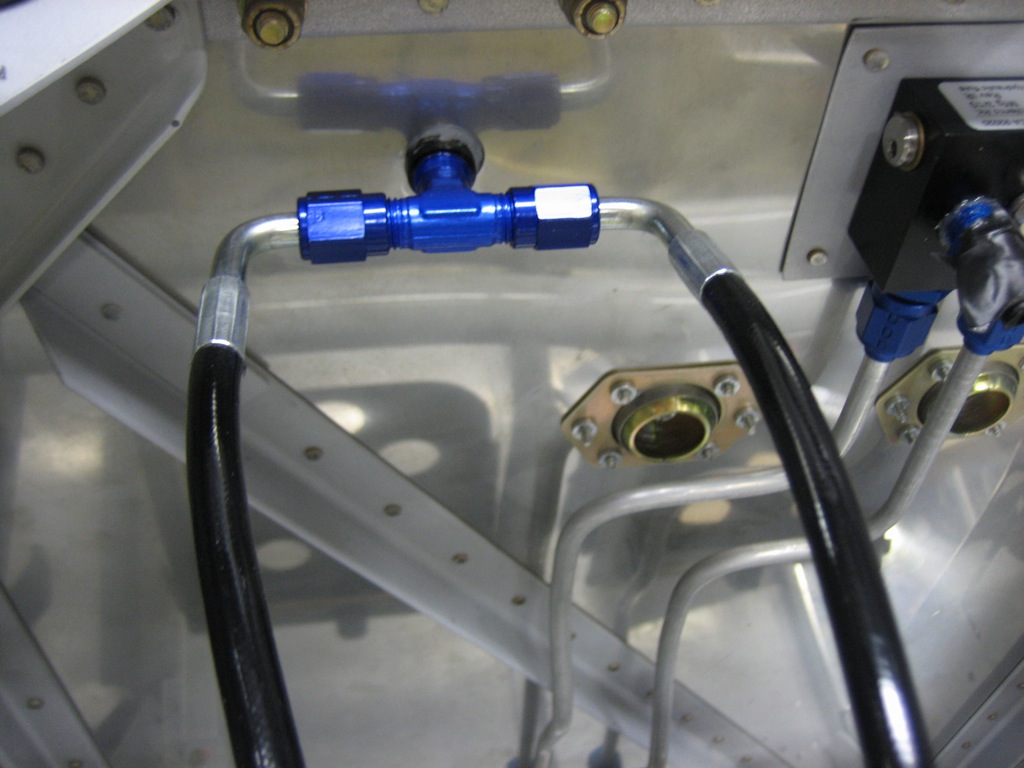

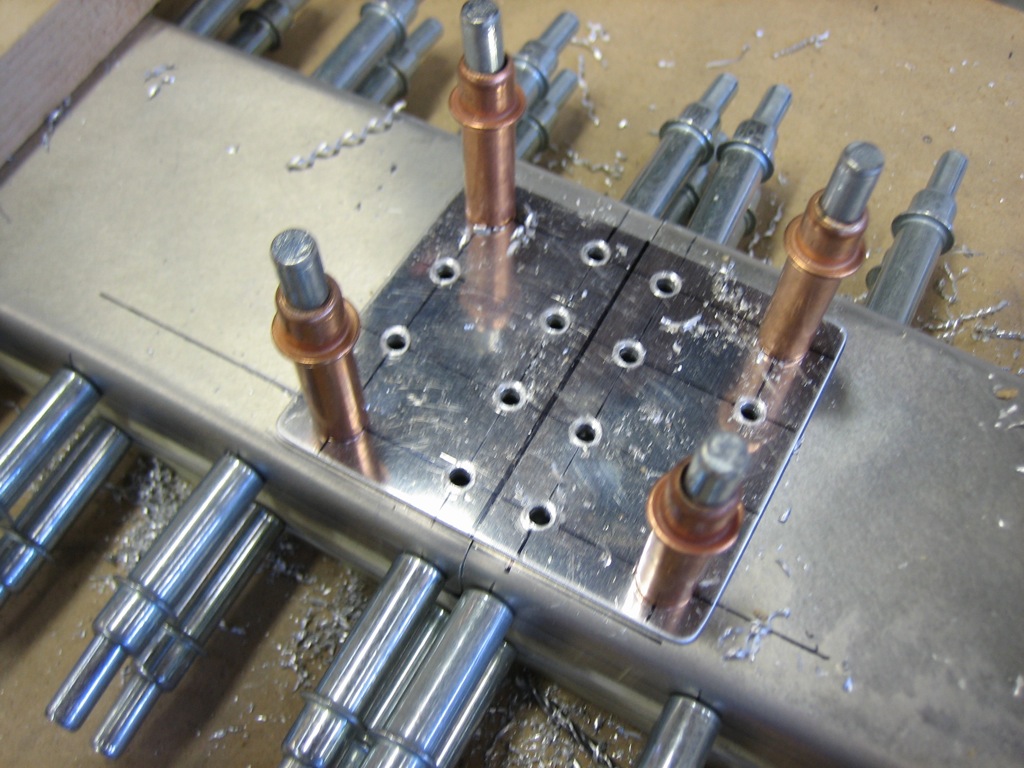

Next, I decided to try and bend the fuel lines that come in from the sides of the fuselage and connect to the fuel selector. I knew I shouldn’t have started something like this at 11:30 at night. I got the first piece mostly bent, then realized that I put one of the lines on the wrong mark on the bender and left one leg too long. Attempting to fix it only fucked up the tube enough that I couldn’t get a sleeve to slide over it anymore. I then took the only remaining piece of tubing I had and tried again. After carefully measuring the bends, I proceeded to put one of the lines on the wrong god dammed mark on the bender again and left a different leg too long. Holy fucking christ! I was pretty pissed off by now. I’m out of tubing and it’s expensive as shit to ship these 6′ long pieces from Aircraft Spruce. I don’t want to order just one piece either, because what’s the chance that I’ll bend the next two perfectly. So this was probably a $50 fuck up tonight just because I was not thinking clearly. I’m going to bed…