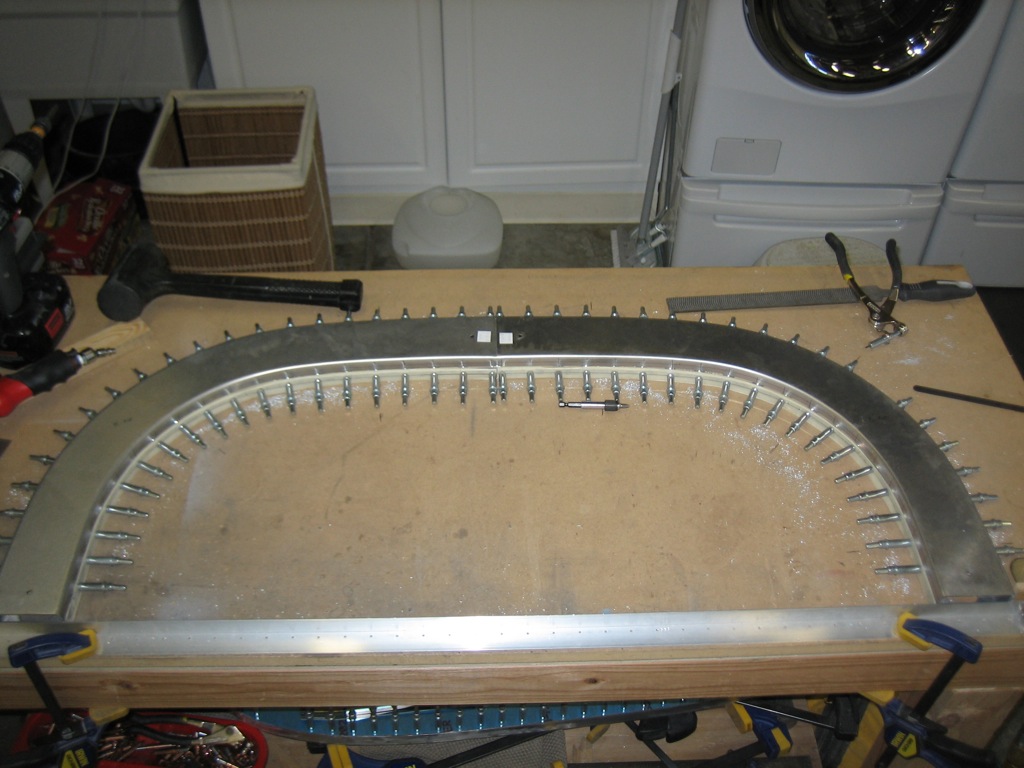

I fit the forward channels and filed the ends to ensure the center seam was tight.

I then transferred the lower hole locations to the upper channels.

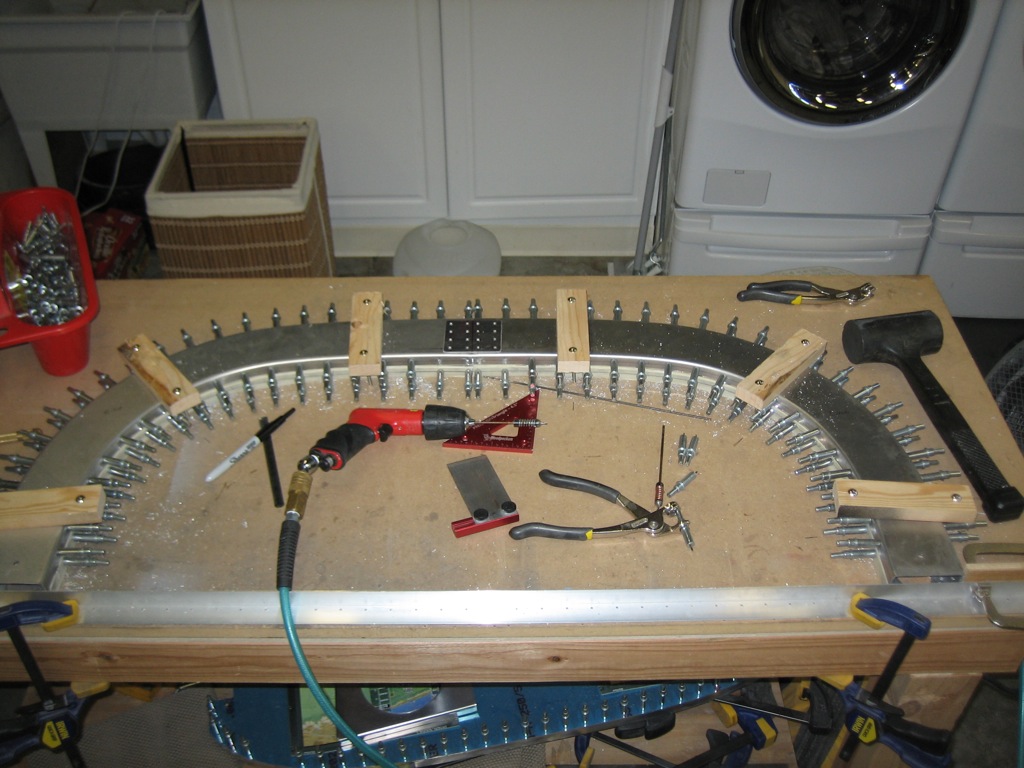

I then fabricated some spacers out of scrap 2x2s that were sanded down to 1.375″ thick. Since I’m fabricating the cabin frame flat on my bench, I used some scrap 1x2s and long screws to clamp the cabin frame down tight to the bench.

Here’s a closeup showing how the scrap wood is screwed directly to the bench. These are positioned directly over the internal spacers. This keeps the cabin frame thickness exactly 1.5″.

Finally, the top channel was drilled.

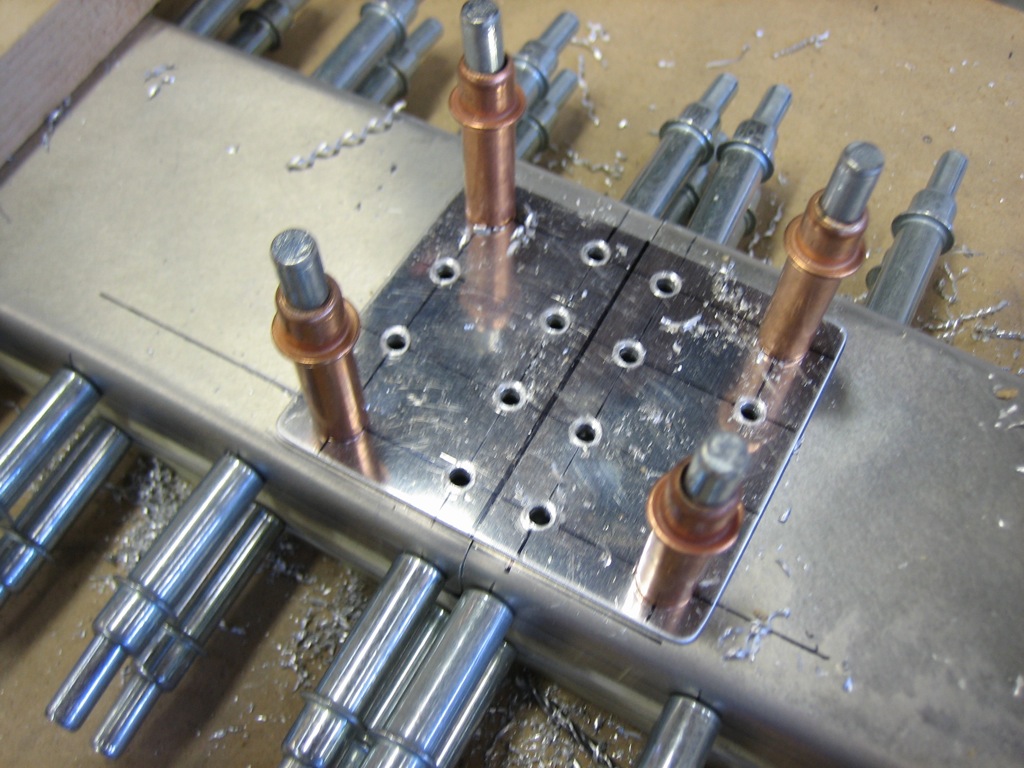

I then positioned the forward splice place and match drilled the channels to it. This will eventually be installed on the inside of the channel.

Now that everything was positioned and drilled, I went back through and enlarged all holes to #30.

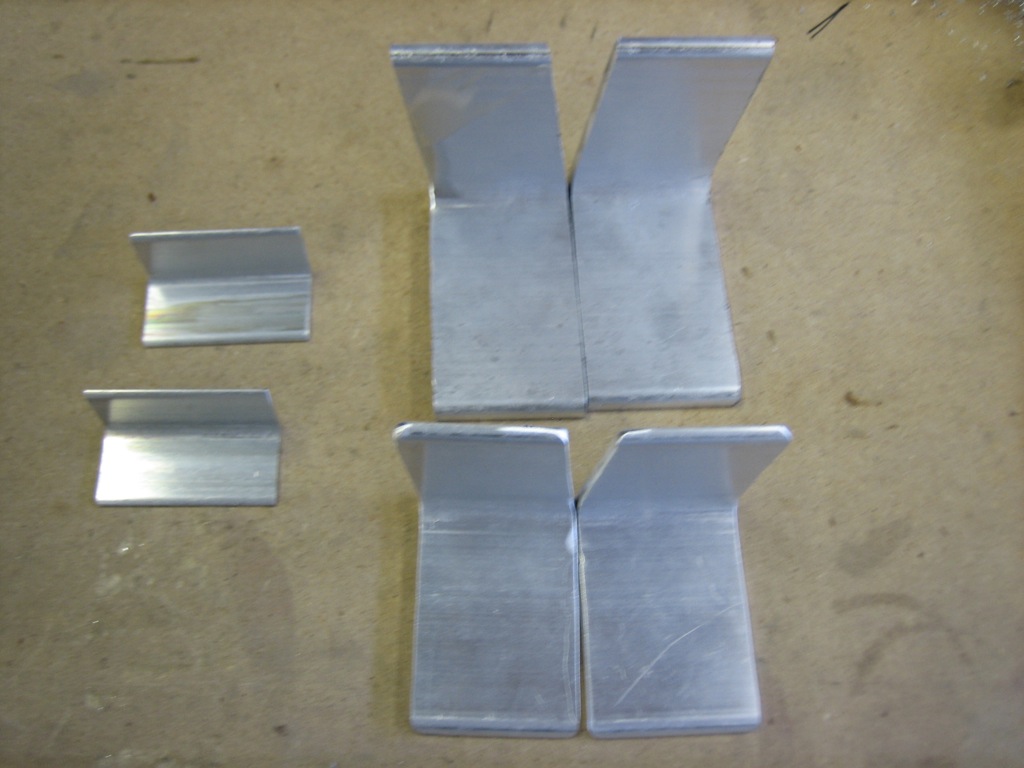

While I was doing that, Andre stopped by and fabricated a number of the attach angles. These are used to attach the cabin frame to the fuselage.