I called Bonaco this morning and put in an order for a few hoses. I ordered a short hose that will run from the fuel bulkhead on the firewall to the inlet of the engine driven pump. I also ordered the hose that run from the outlet of the engine driven pump to the fuel servo. This hose needed 45º fittings on each end with 270º clocking. We’ll see soon if I measured correctly. I also picked up the hoses that run from the brake fluid reservoir down to the master cylinders. Since all of my other brake components are black, I had Brett do these in black as well. Finally, I ordered the brake lines that go from the bulkhead fittings on the firewall down to the wheel cylinders. Van’s plans call for rigid lines from the bulkheads down to the wheel cylinders with generous service loops inside the wheel pants to allow for flex and vibration. This is a notorious source of cracking though due to flex in the aluminum line. Since aluminum doesn’t have a fatigue limit, even minor flexing will eventually result in failure. Even the MIL-PRF-83282D brake fluid (which is a huge improvement over the old MIL-H-5606 fluid) is flammable, so a brake line failure can really ruin your day. Some people run rigid tubing down the leg and transition to flex line near the wheel cylinder, but the whole gear leg flexes when on the ground, so this really doesn’t eliminate the line flex.

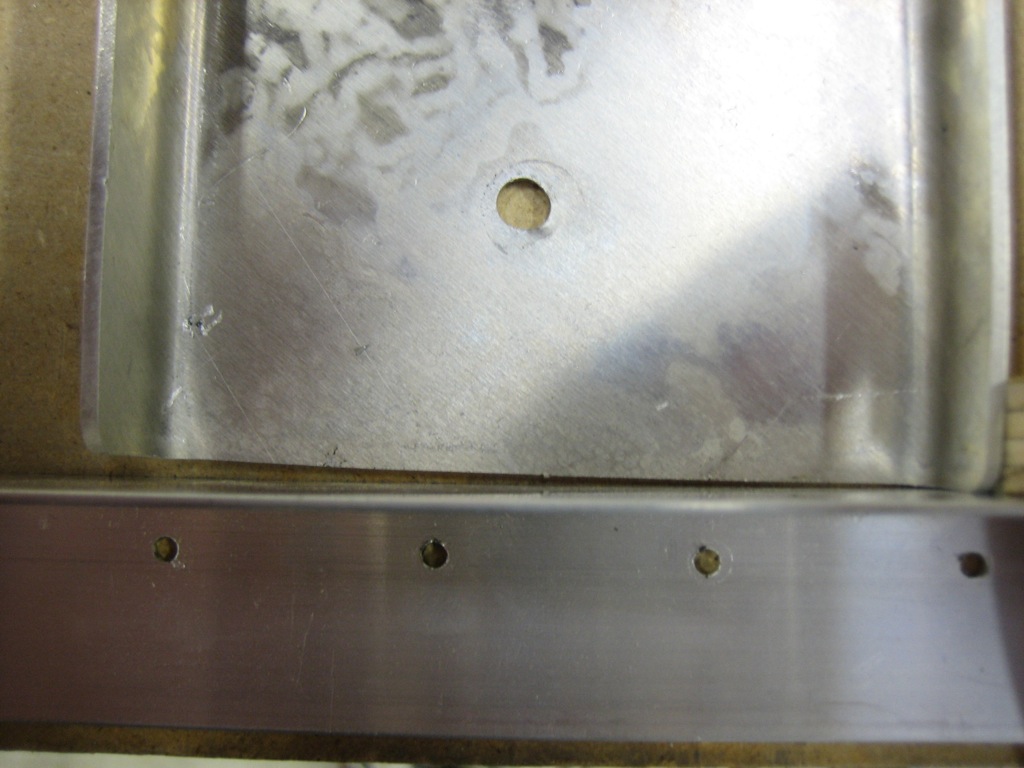

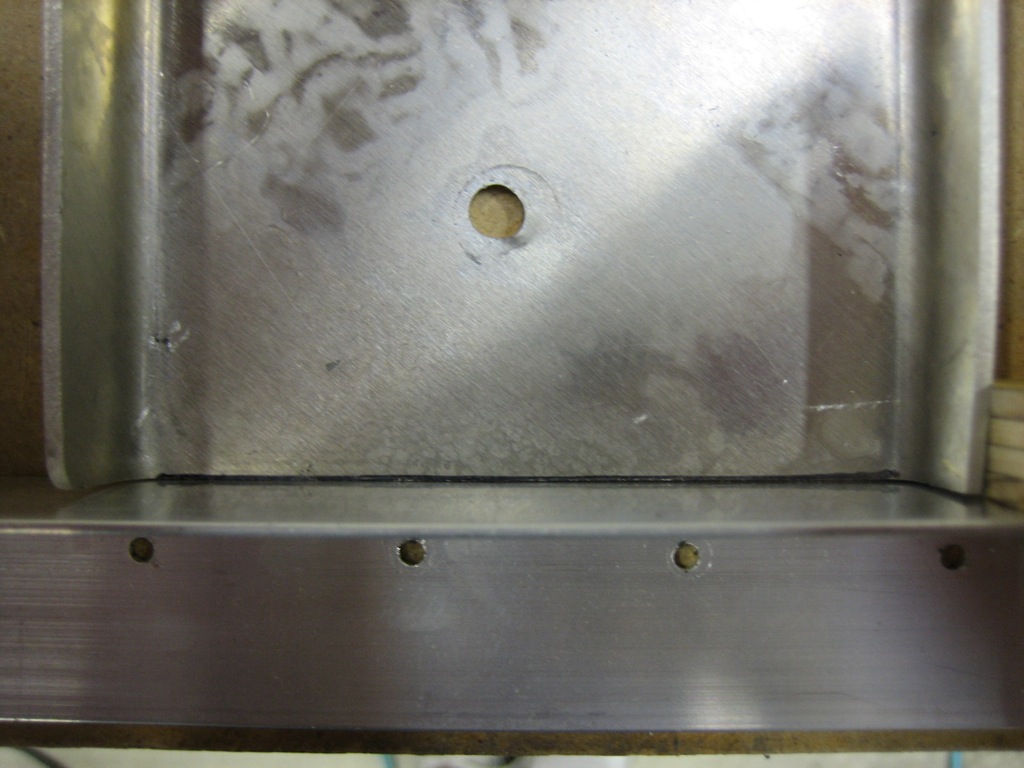

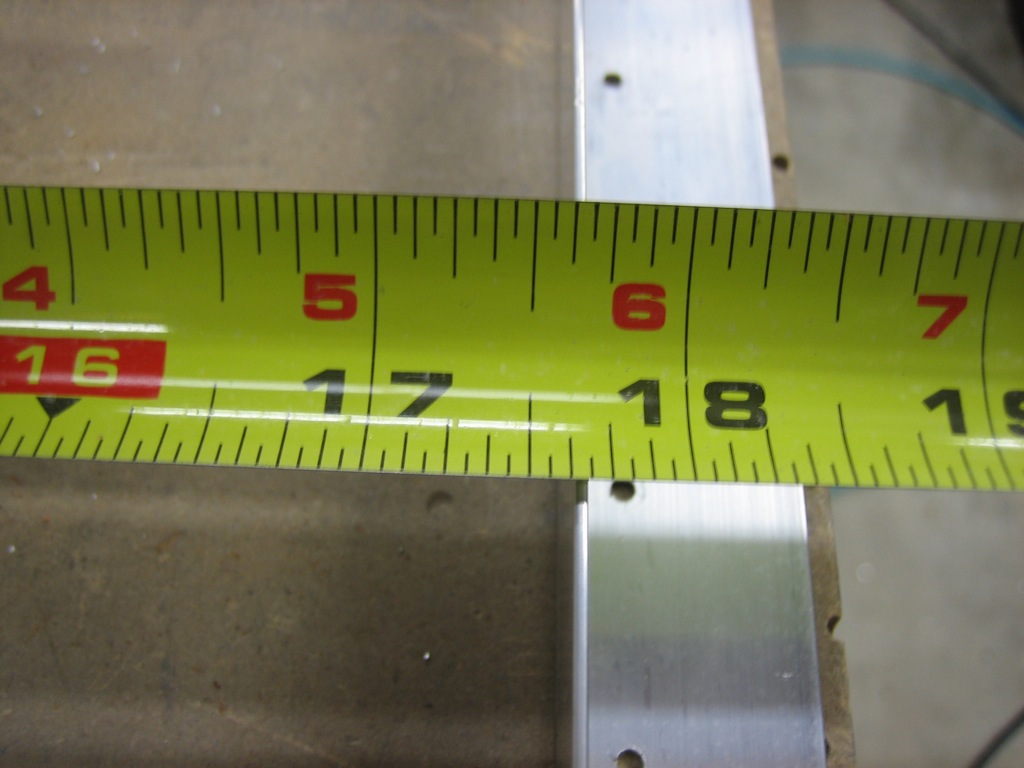

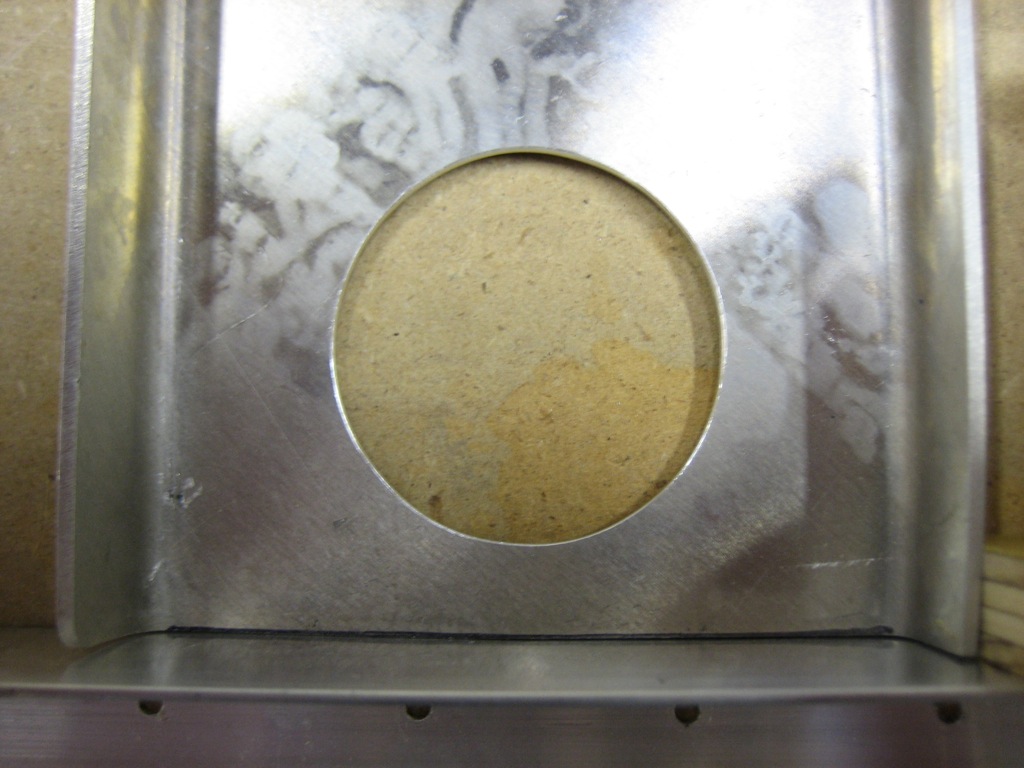

Since I’m waiting on an order from Aircraft Spruce for new 5052 brake lines, I decided to get started on the cabin frame. I clamped a straight edge to the bench and then clamped wooden blocks to the vertical legs to define the overall width of the frame.