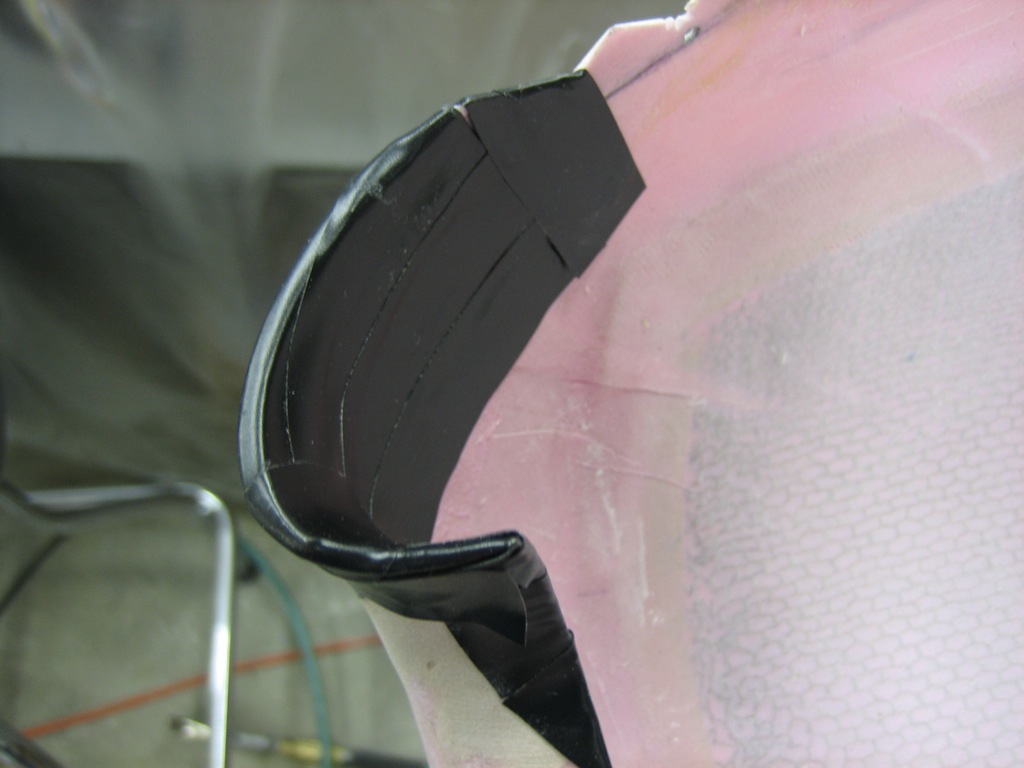

Where the upper and lower cowl halves meet on the outer ends of the inlets, the top and bottom sections simply butt together. There is nothing tying the two parts of the cowl together at this point which allows some relative movement, and air entering through the gap is just added drag since it doesn’t help with engine cooling as it’s dumped directly into the low-pressure area outside the baffles. To address this, I’m adding some flanges to the lower cowl that the upper cowl will nestle over. This will reinforce this area a bit and seal the gap. To prevent the epoxy from sticking to the upper cowl, I covered this area with electrical tape. I would normally use packing tape, but it can’t conform to the curves like electrical tape can.

The lower cowl protruded beyond the upper cowl a small amount, so the glass wouldn’t have laid flat across the transition. To fill in that step, I mixed up some epoxy/flox and made a small fillet.

I then laid up about 6 layers of glass across the joint. I’ll trim this back quite a bit after it cures. It really only needs to stick up into the upper cowl 1/2″ or so.

Here’s the other side. You can see better here that the glass overlays the oval where the hinge pin covers will mount, so I’ll end up cutting back part of the flange to make room for the cover.