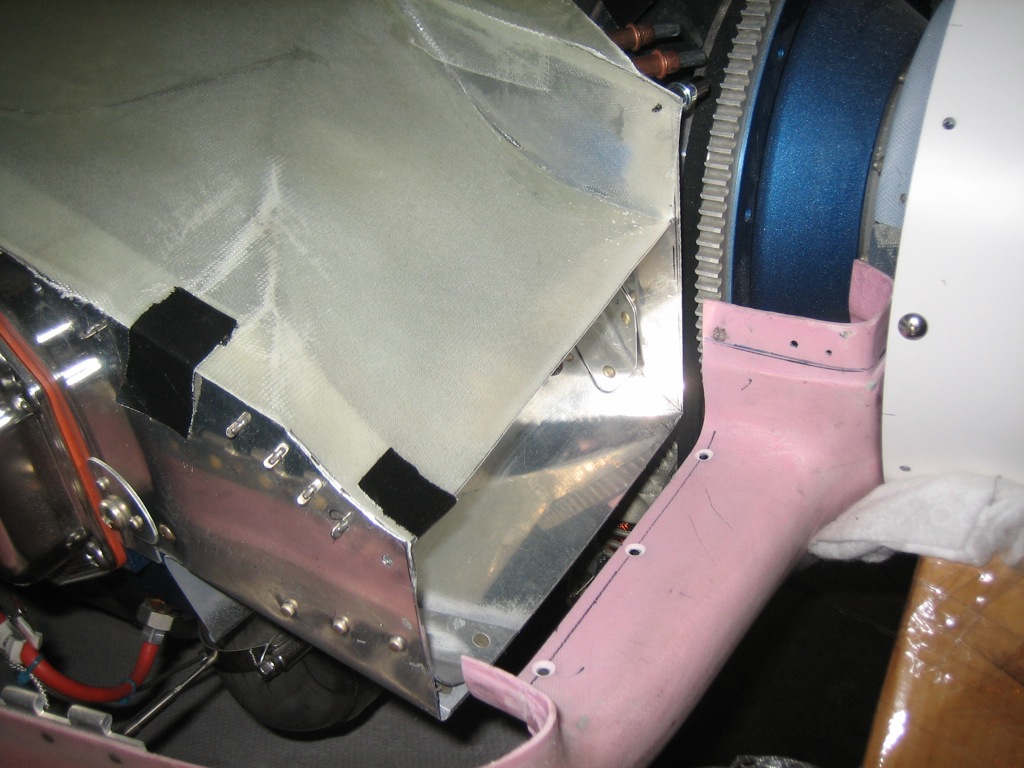

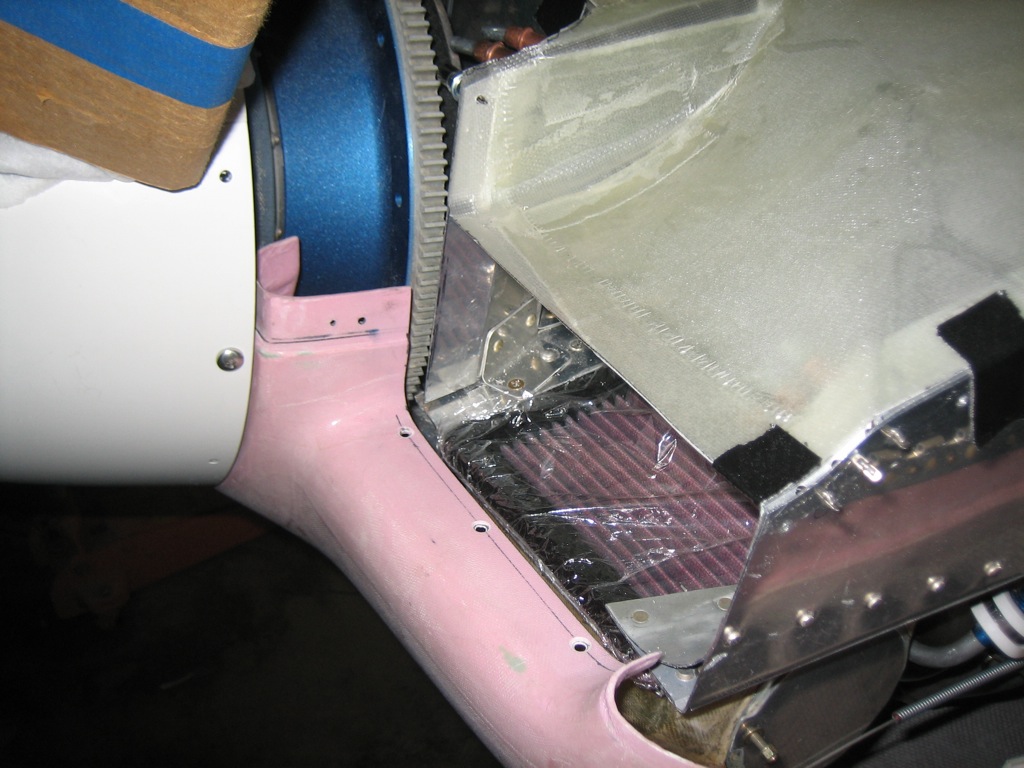

I reinstalled the plenum and adjusted the inlet height so that there’s just enough room for the upper baffle seal material. You can see a small cleco holding this in position just behind the flywheel gear. I then trimmed the plenum back flush with the baffles.

Here’s the other side.

I then trimmed back the upper cowl inlet so that it’s flush with the lower cowl inlet and 3/8″ back from the forward edge of the plenum.

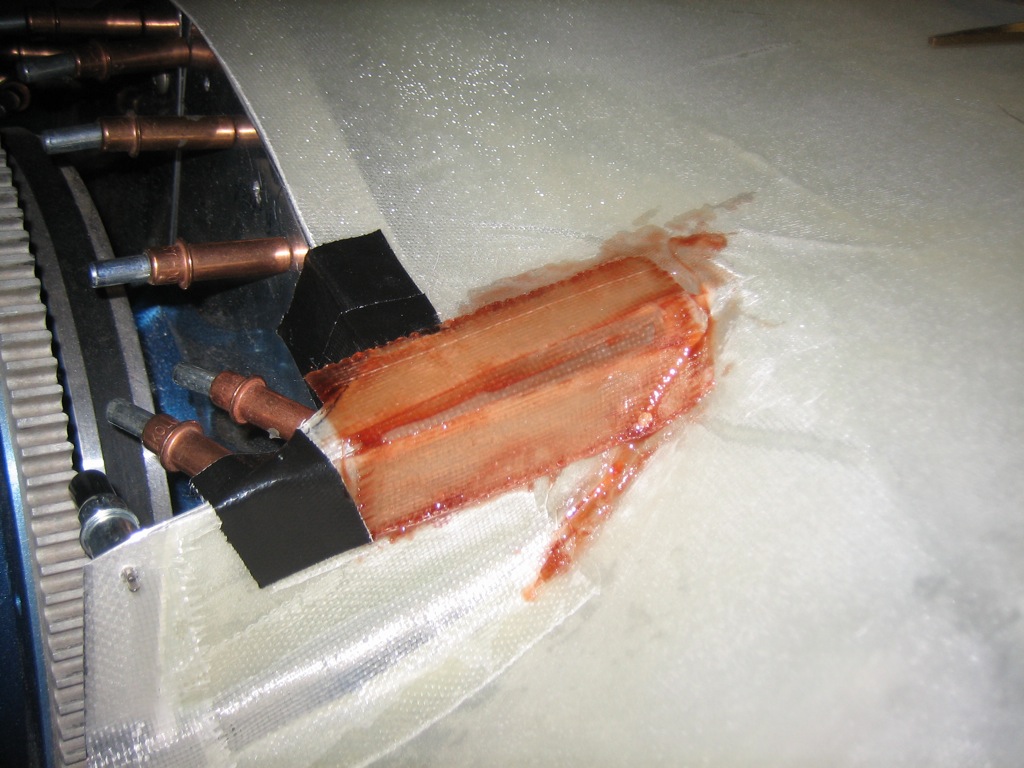

The left side of the plenum needed one more adjustment so that it lays flush with the mounting angles. I cut the plenum and laid up a small piece of glass over the joint to tie it back together.