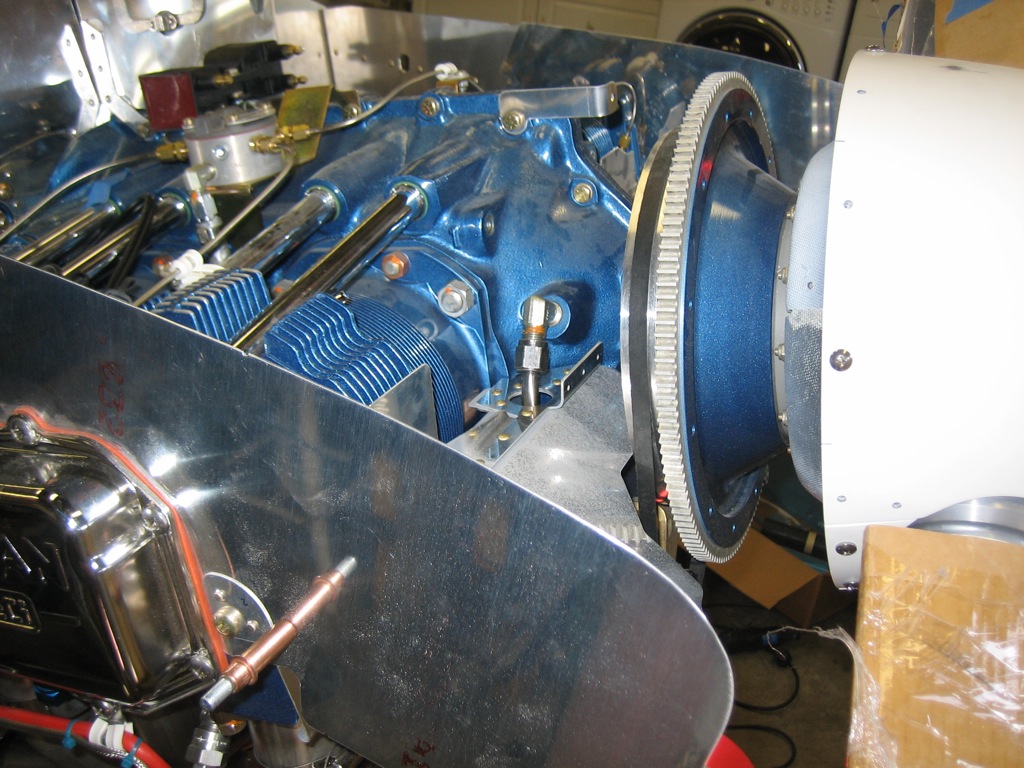

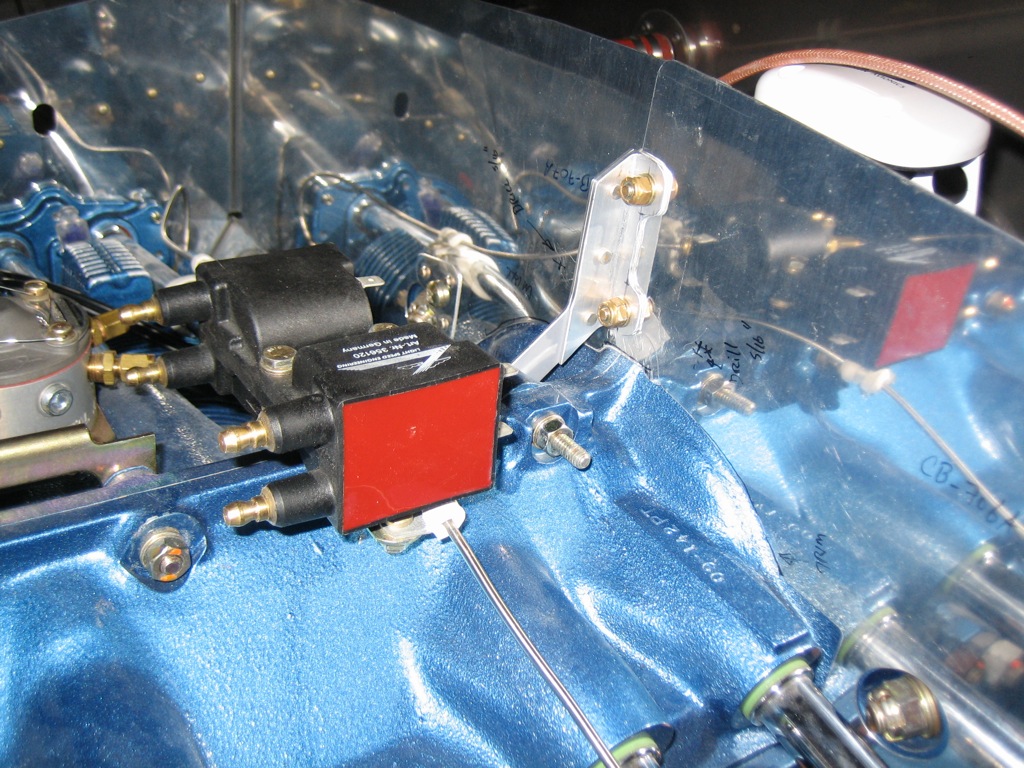

With the cowling fit, I resumed work on the baffles. After a little trimming where the baffles fit around the rocker arm covers, I got everything mounted to the engine except for the part behind the spinner.

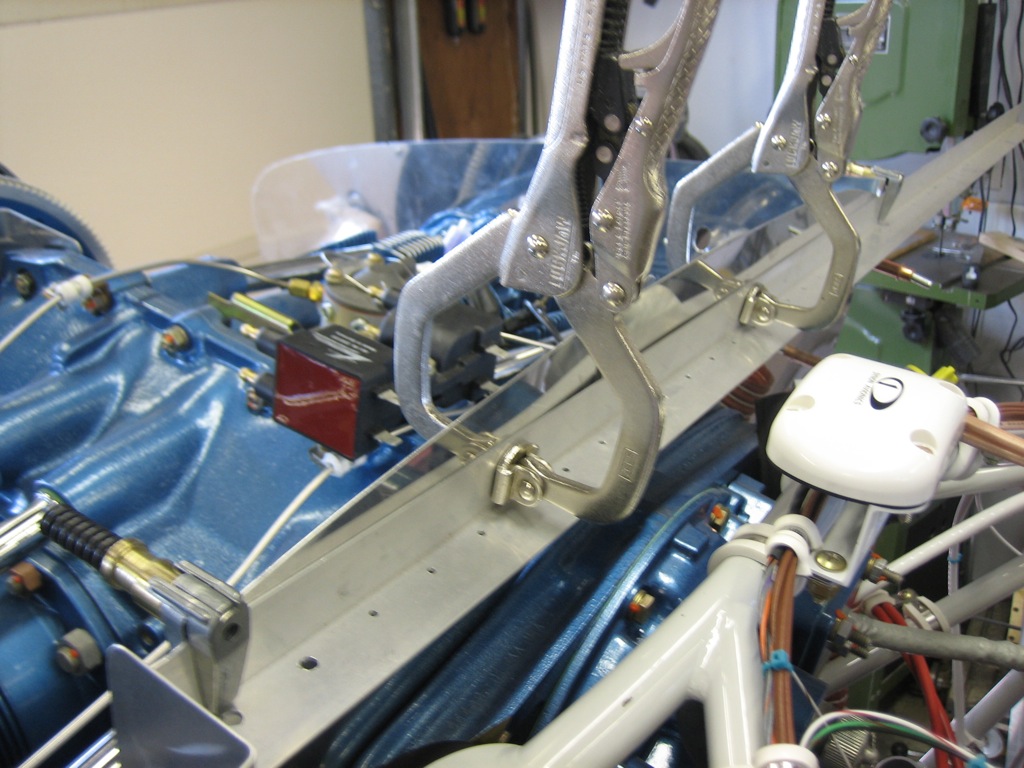

I had previously cut off the flange from the aft baffle support since it pushed the aft baffle walls too far back. I fabricated I replacement from some 1/16″ angle stock and riveted it to the baffle support.

To ensure the aft wall is in the right spot, I clamped a straightedge across it. I then clamped the bracket to the wall and drilled the holes.

With the aft baffle wall bolted to the support, the back wall becomes very rigid.

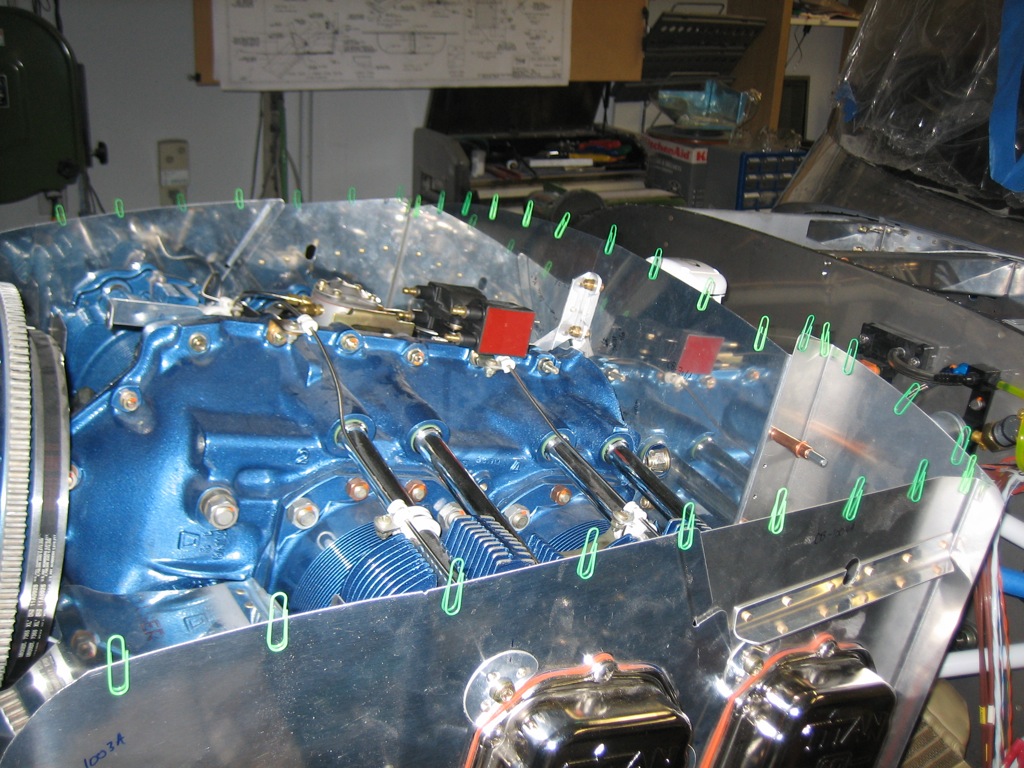

I made the preliminary angled cuts on the ramps and made the necessary bends in the forward side baffles.

With a little trimming back of the side baffles, I got the cowl to fit down behind the spinner. You can see that it’s still nearly 1″ too high, so I’m going to have to cut off quite a bit of material to get the cowl to drop all the way down and then further to have the necessary clearance between the cowl and the baffles. The engine can move around quite a bit due to the flex of the engine mounts, and you don’t want the baffles to contact the cowl.

The standard way to trim the baffles is to line the top with paper clips and then put the cowl on top. The cowl will push some paper clips down more than others. You can then measure down some amount from the top of each paper clip to create a cut line that perfectly follows the curvature of the inside of the cowl.