I opened the new SkyView Display Harness and installed the panel mount USB cable.

I opened the new SkyView Display Harness and installed the panel mount USB cable.

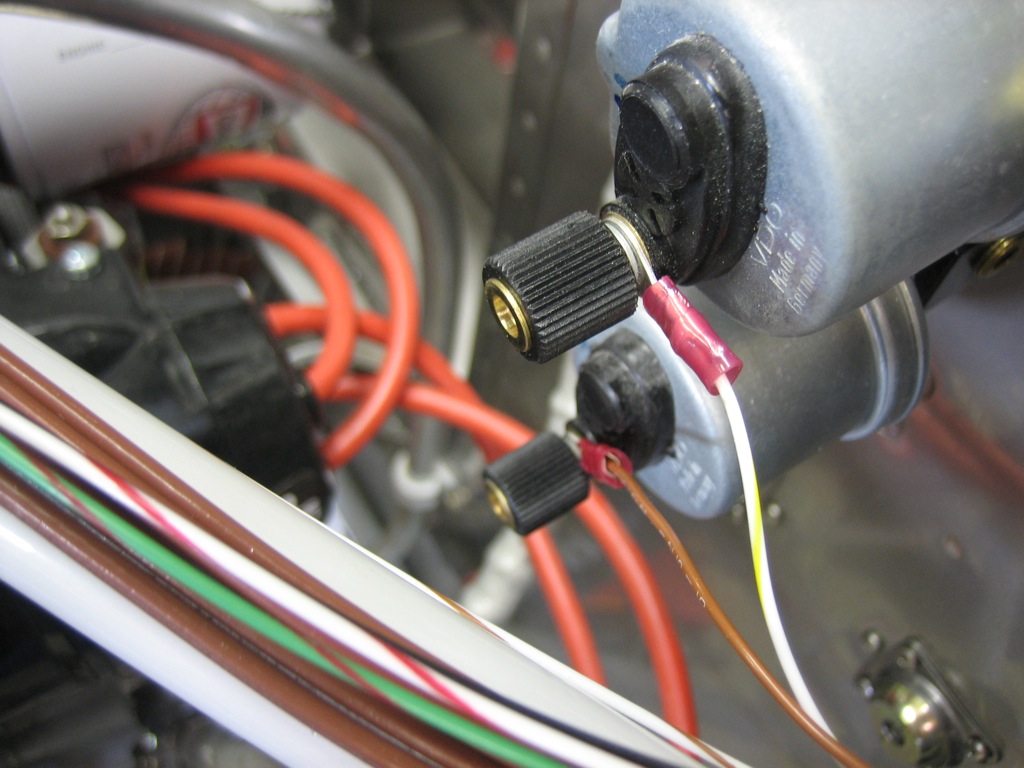

The Dynon transponder uses a TNC connector instead of an BNC connector. Fortunately, Fry’s carries RG-58 TNC crimp on connectors. I’m using RG-400 which uses the same connectors. I crimped it on to the end of a piece of RG-400. I’ll cut it to length and put a BNC connector on the other end to connect to the antenna.

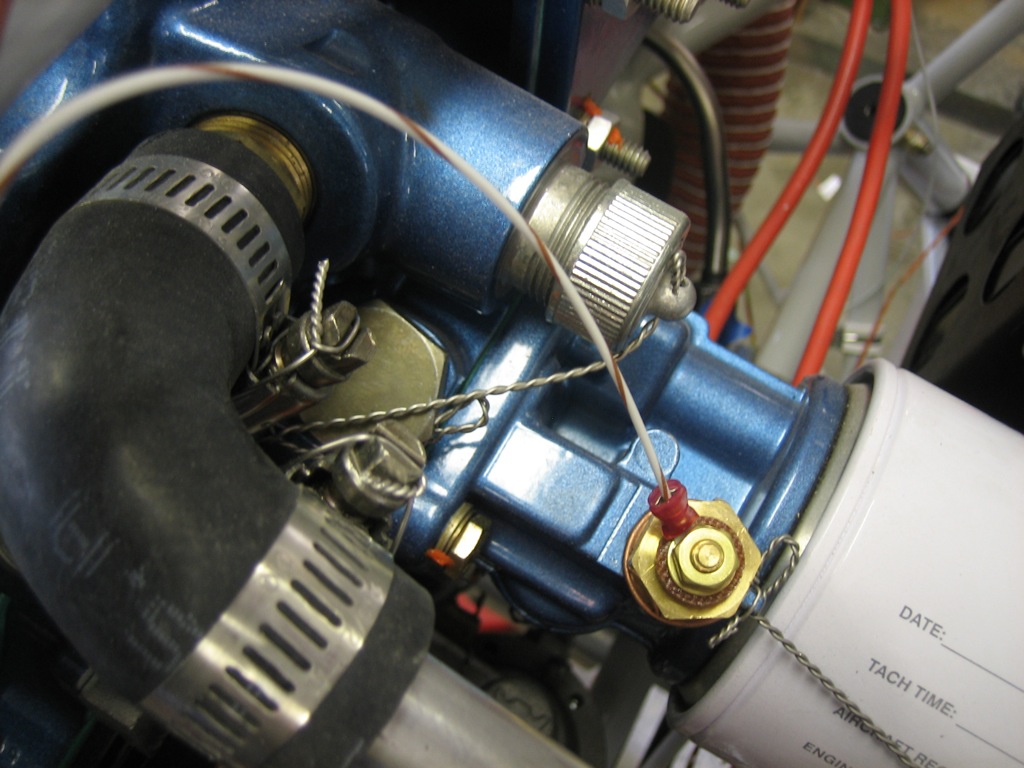

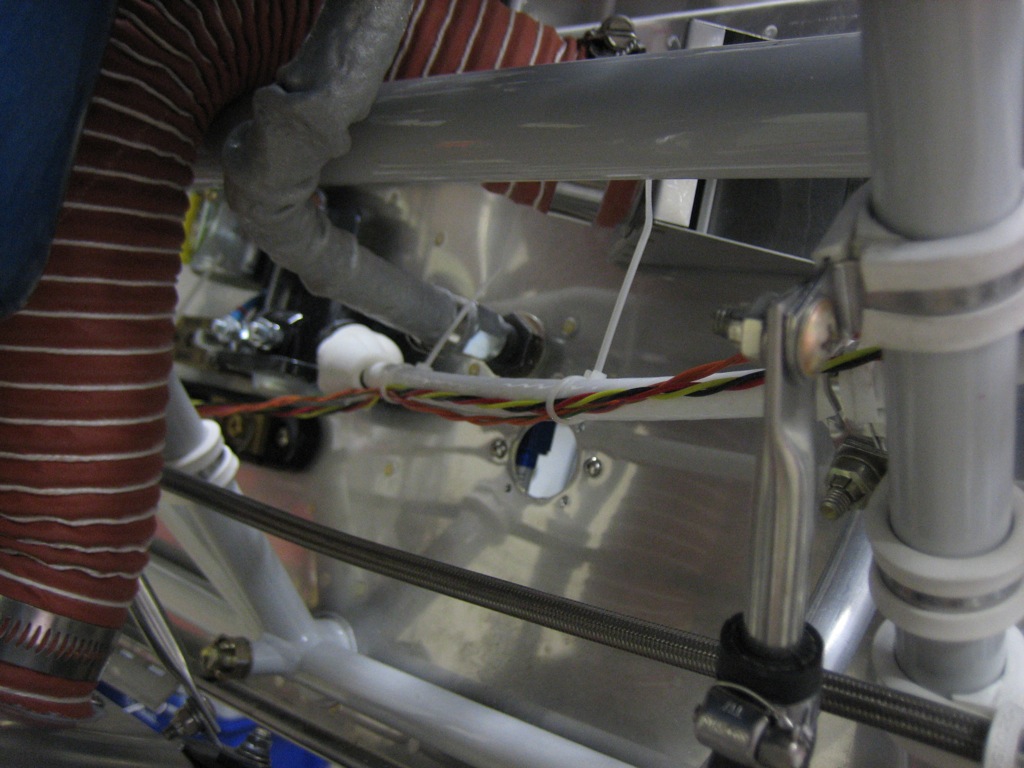

I got my transponder from Dynon. I purchased the high-power, class 1 SV-XPNDR-261. This thing is nice and tiny, but still puts out 250W of transmit power. It also meets the full ADS-B out requirement when connected to a TSO-C146A GPS (such as the Garmin GTN series that I’m going with). It also displays TIS traffic on the SkyView which is handy around the areas I fly in.

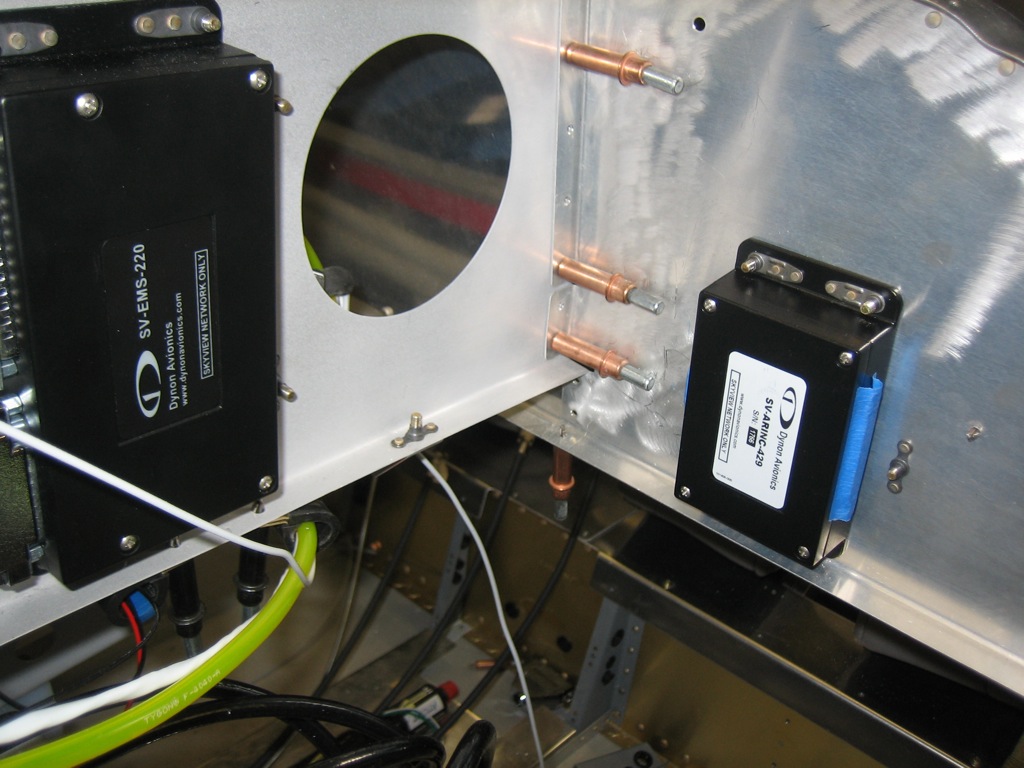

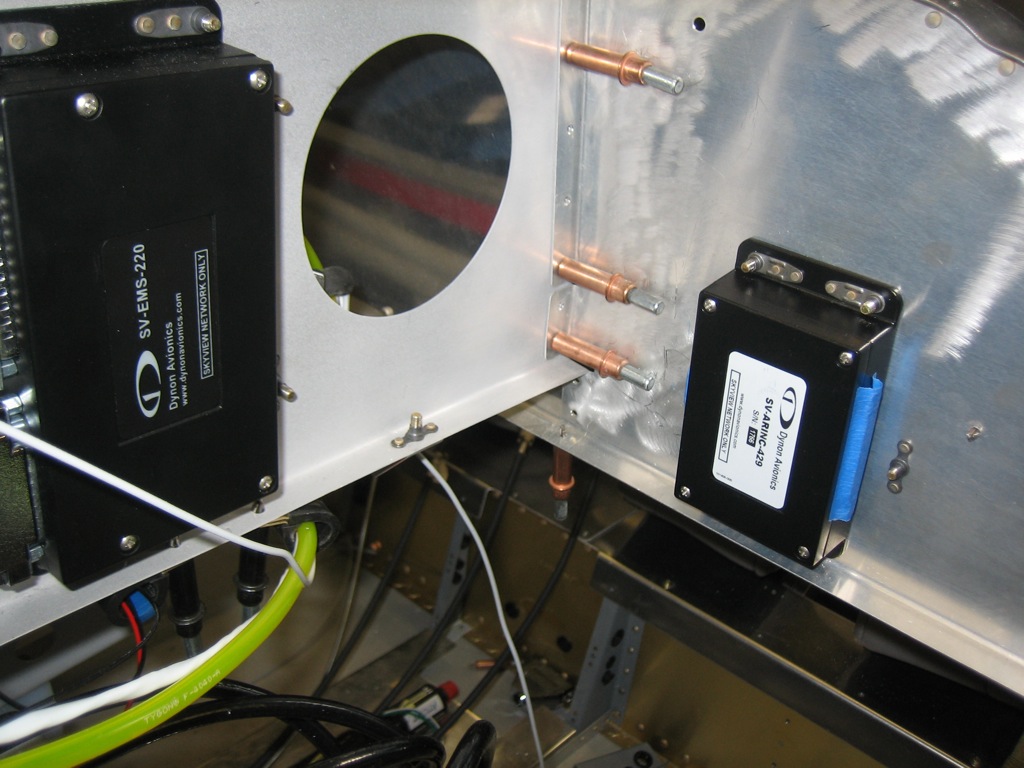

I also received the ARINC-429 module. This lets the SkyView interface fully with the Garmin GTN unit to get features like GPS steering for the autopilot, CDI autoscaling, and vertical guidance for approaches.

I also purchased a second SkyView Display Harness. I decided to purchase this separately so I can hold off on purchasing the second display until just before flight. I can move my single display between sides on the panel when building the overall harness. You can also see that I purchased a second panel mount USB cable.

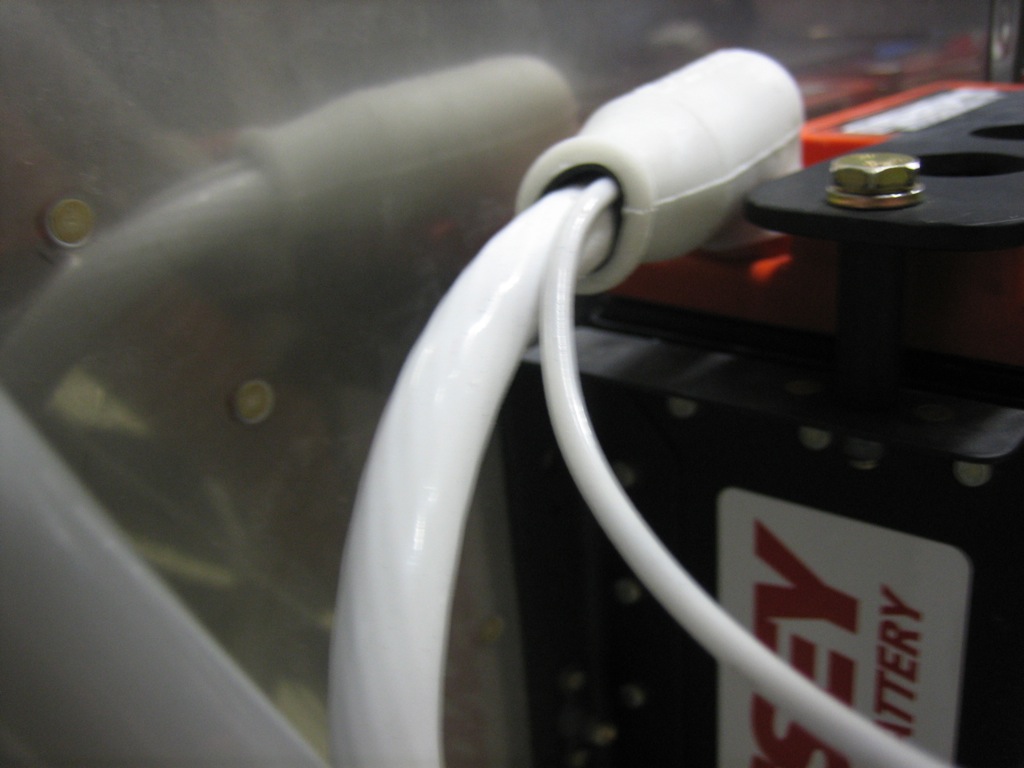

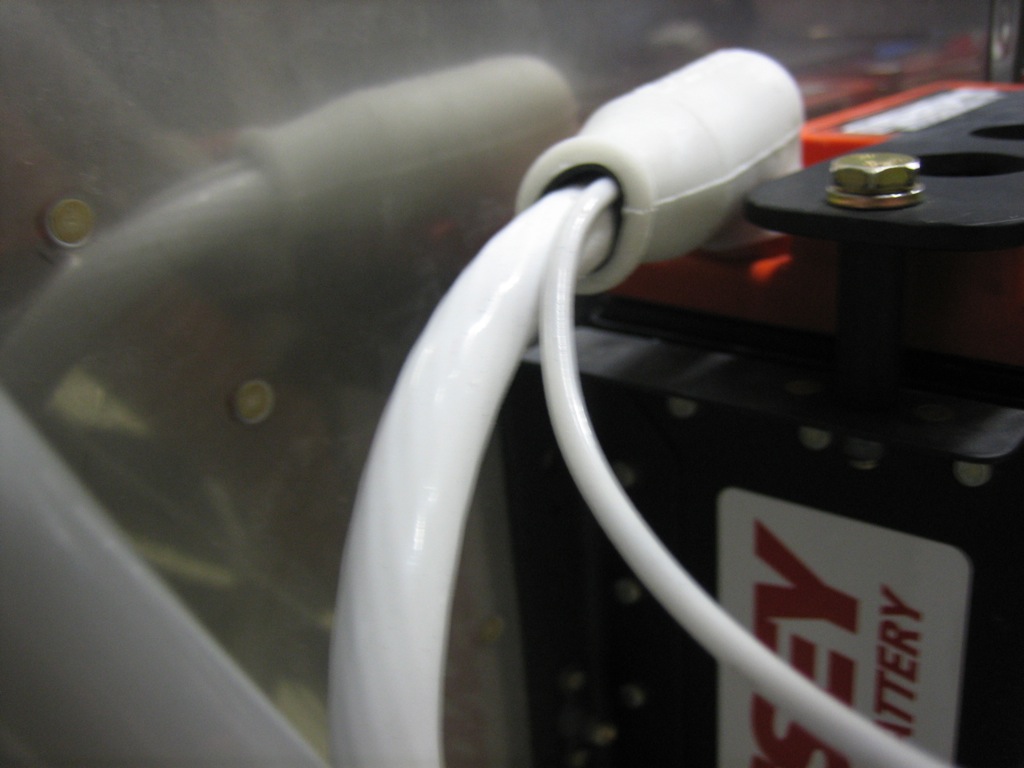

I also received a second battery for the right display. I can go ahead and mount this and connect it to the right display harness.

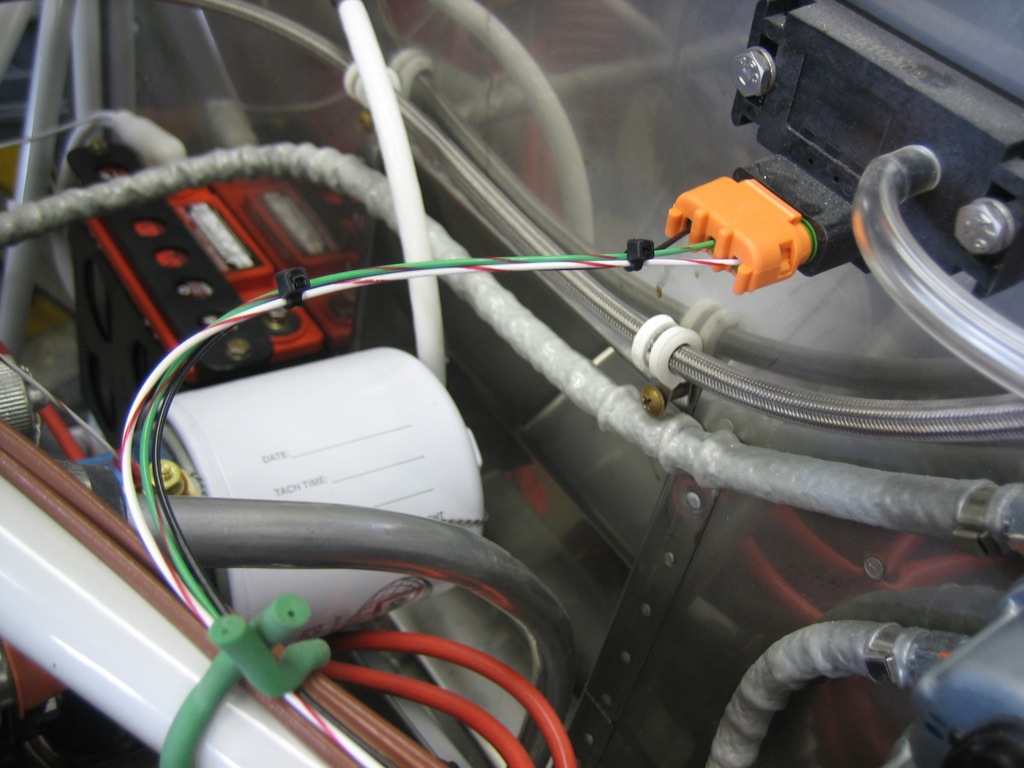

I also picked up two 30′ network cables. I’ll cut these up to the custom lengths I need when connecting components.

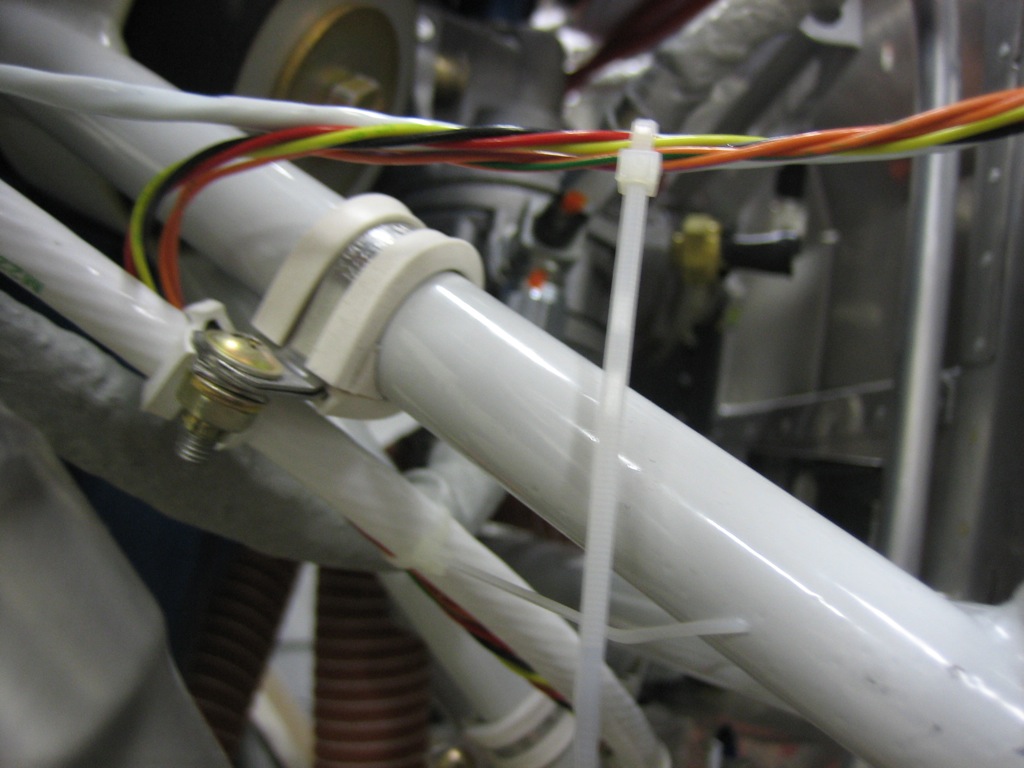

I also picked up a hobbs meter from Aircraft Spruce. Although the SkyView has a hobbs built in, I don’t like the idea of having the only record of aircraft flight time being stored electronically. If there is a failure or I have to send a display back for service, there is always the possibility that the total flight time is lost.