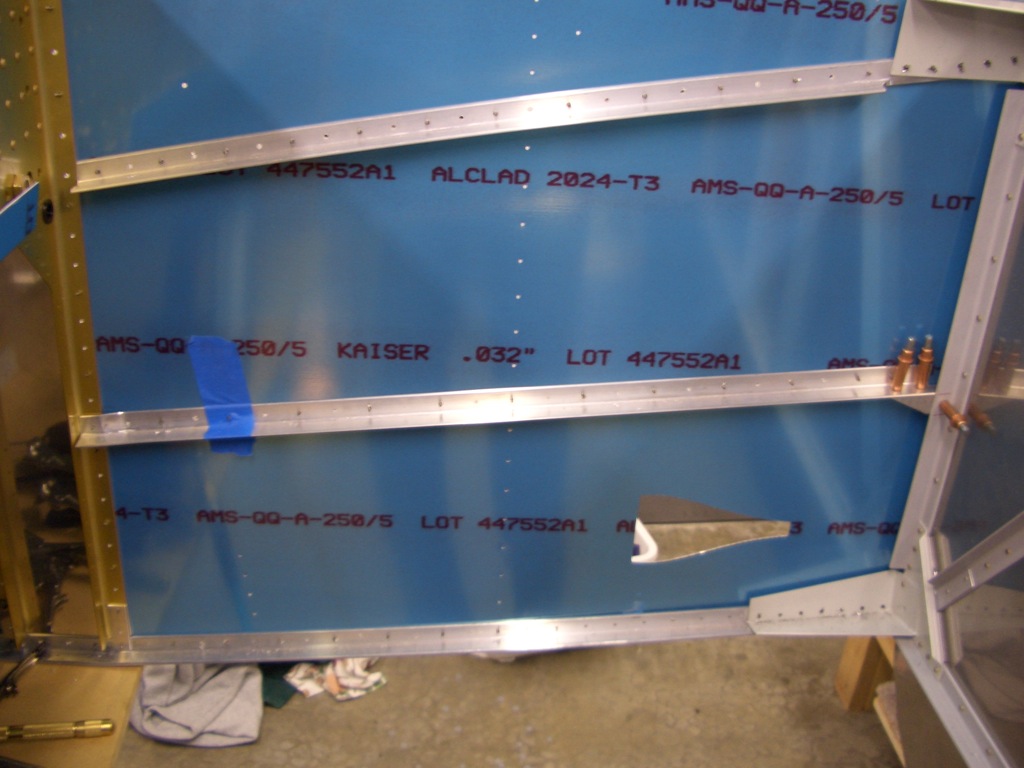

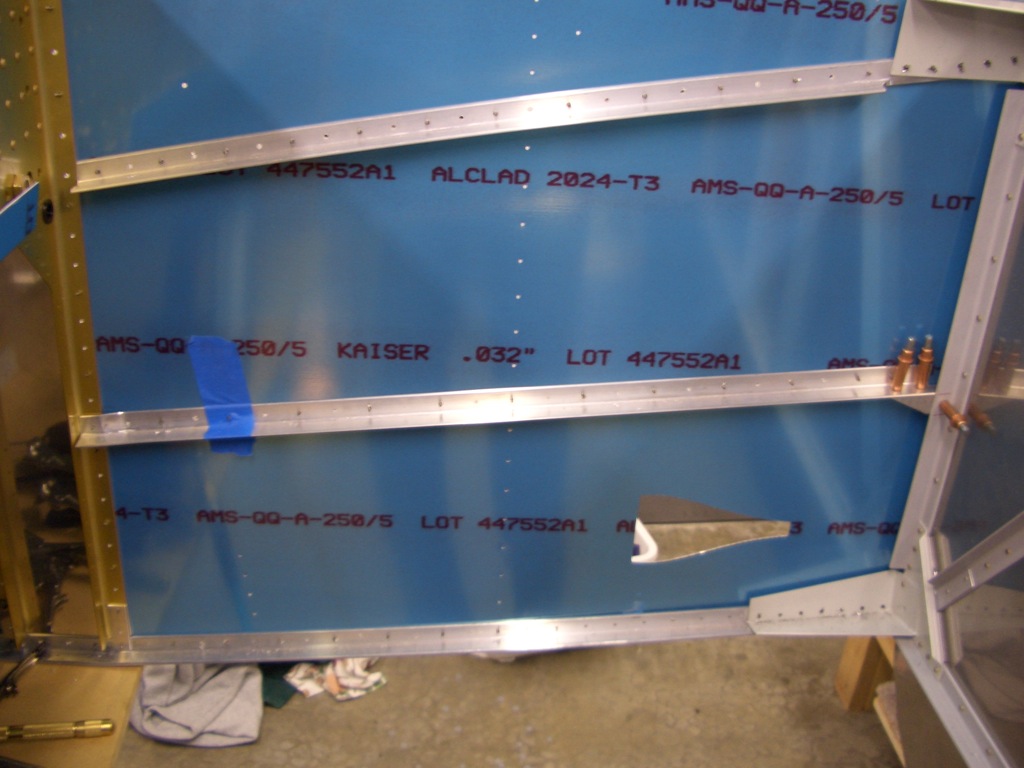

I got started tonight by drilling the right skin stiffener. Just like most other tasks, the second time went much faster than the first.

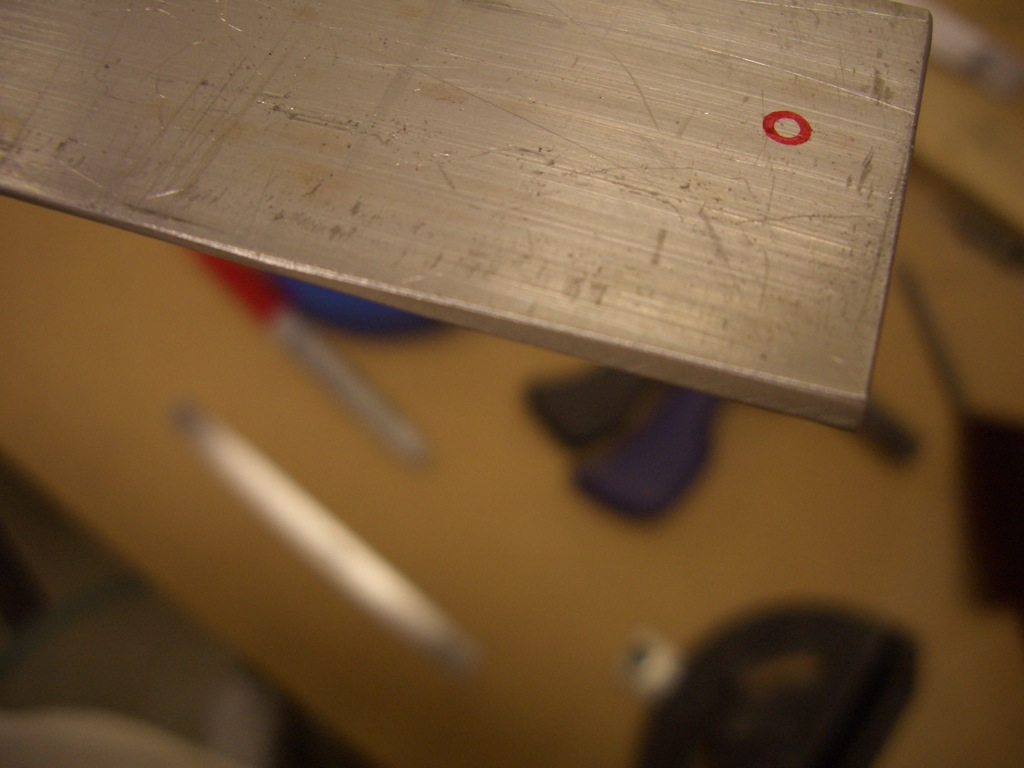

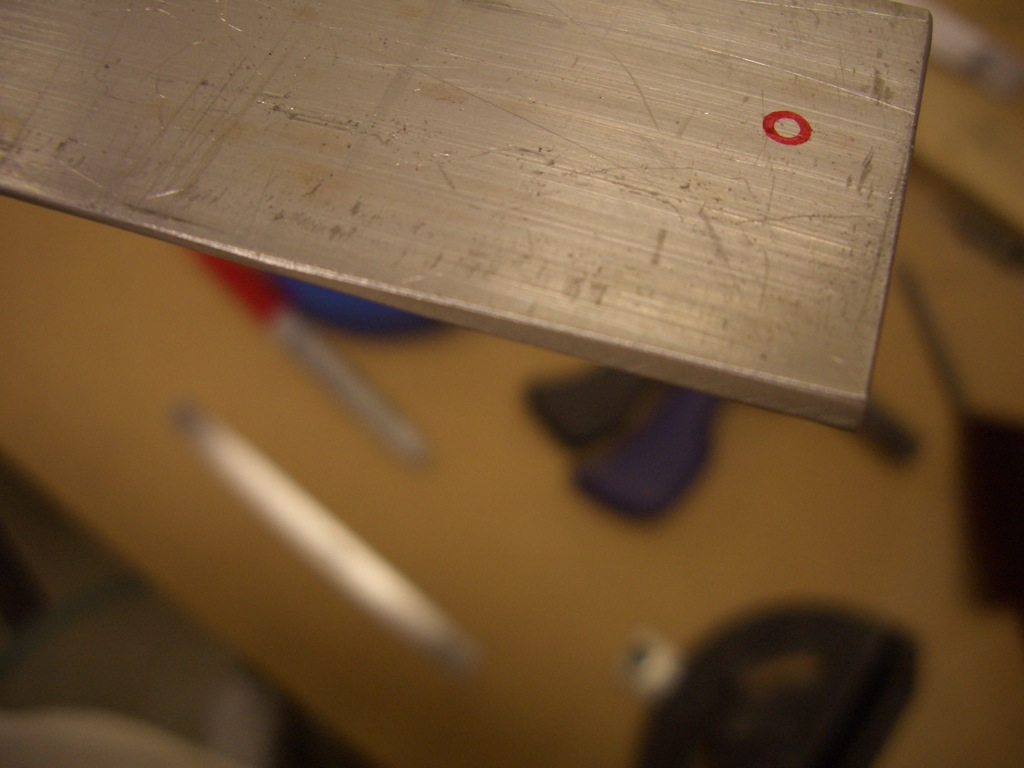

Next, I got started fabricating the lower longerons. These are cut from raw 1″x1.25″x0.125″ angle stock. The short leg of the angle needs to be removed for the aft 4.125″ of the longeron to provide clearance for a gusset that will tie this to F-704. I made the rough cuts on a bandsaw and then used various files and scotchbrite roloc disks to get this nice and smooth.

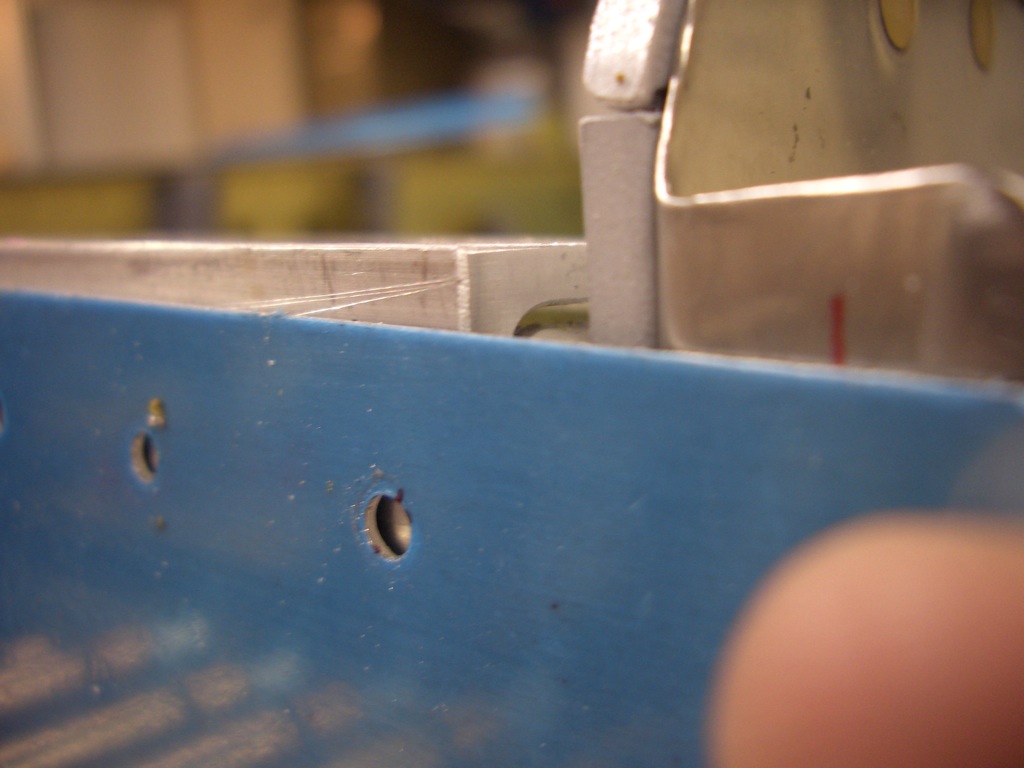

If you look closely, you can see a gap between the horizontal leg of the longeron and the engine mount. I anticipated that because

Mike Bullock ran into the

same problem. The issue is that the lower longer and aux longeron meet at this bracket at an angle and the forward ends interfere.

A few seconds on the sanding wheel removed enough material that the lower longeron can nestle tightly into the bracket.

The longeron also needed to slide forward a bit to allow the rear end to fit next to F-704. I could have just cut this off flush, but this relief cut gives me more edge distance on the frontmost bolt on the top and rivet on the side.

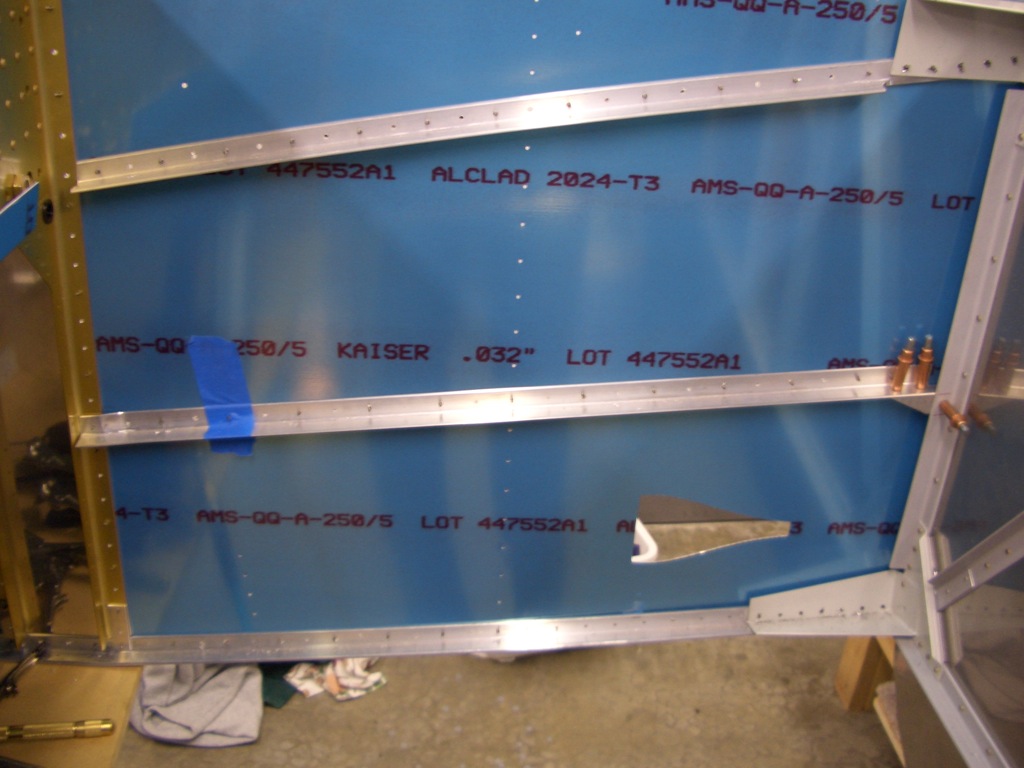

Here you can see how the aft end sits flush against the forward edge of F-704.

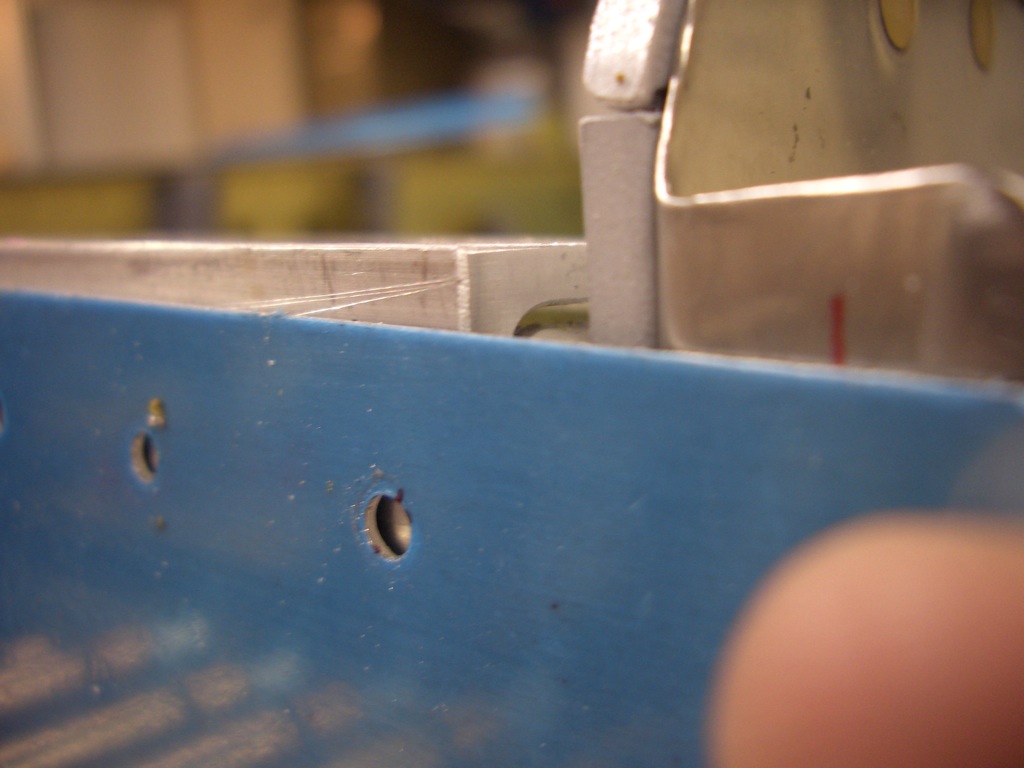

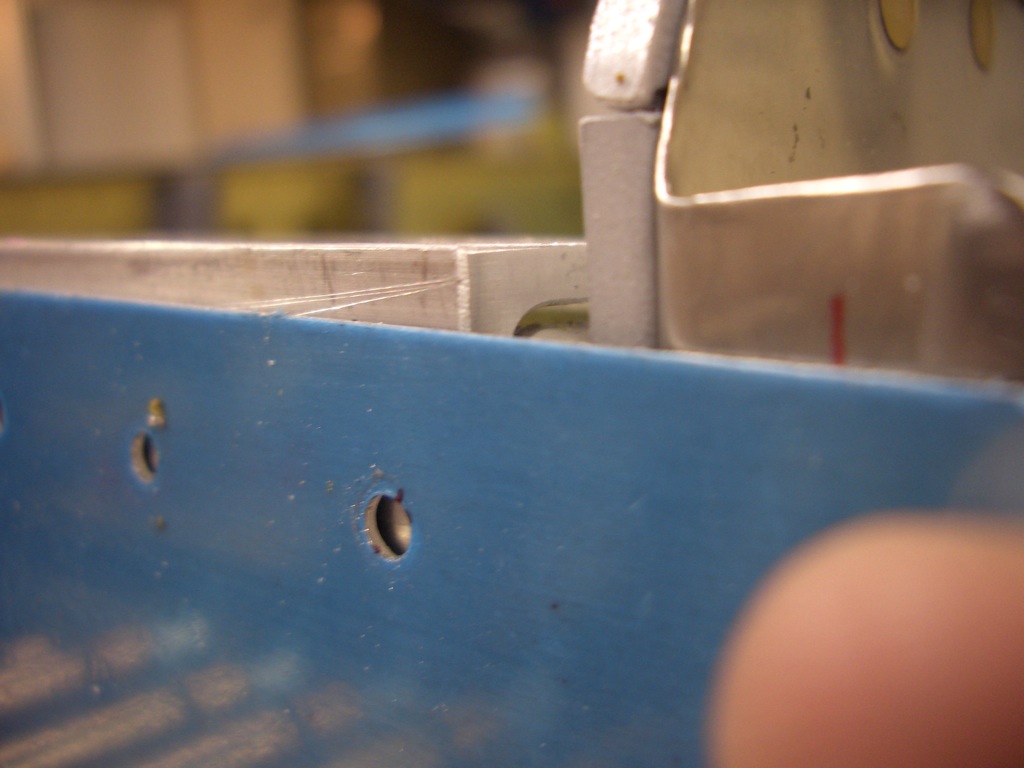

Before drilling any holes, I wanted to see what kind of edge distance I would have on the AN3 bolts that tie the longerons to the engine bracket. The bolts are supposed to be centered in the longeron (1/2″ from the left edge where my finger is). This gives me about 5/16″ edge distance for the bolt. I know other builders have run into issues with edge distance here, so I want to make sure this is sufficient.

Update: I spoke with Ken at Van’s the next morning and he confirmed that 10/32″ was fine.