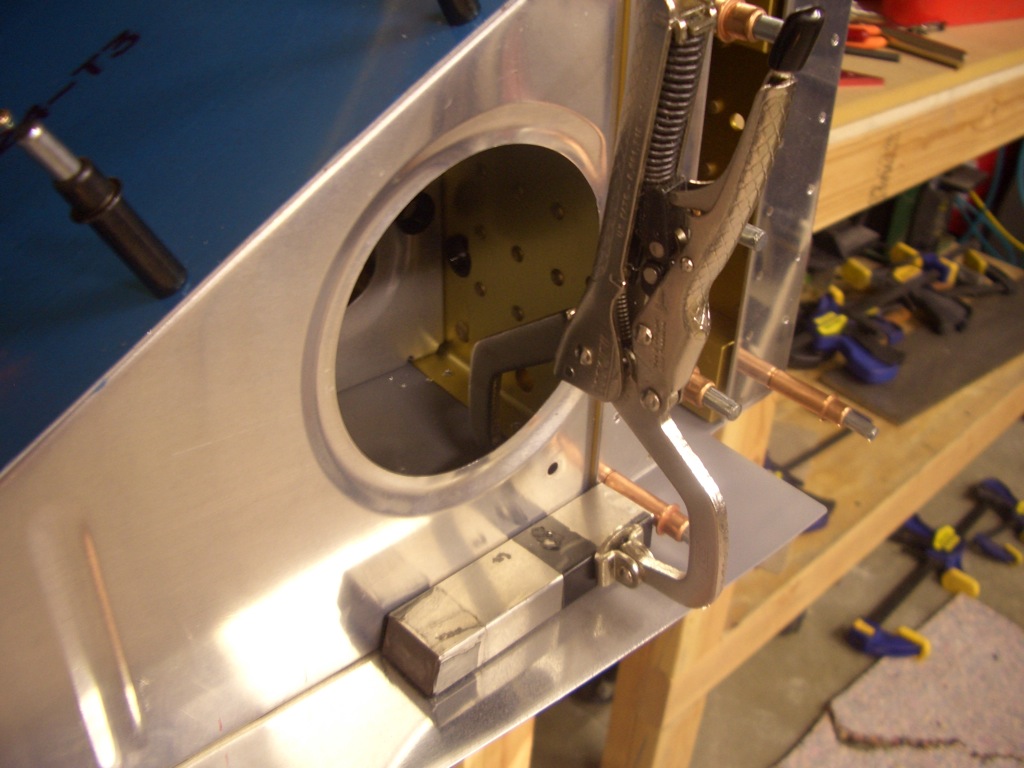

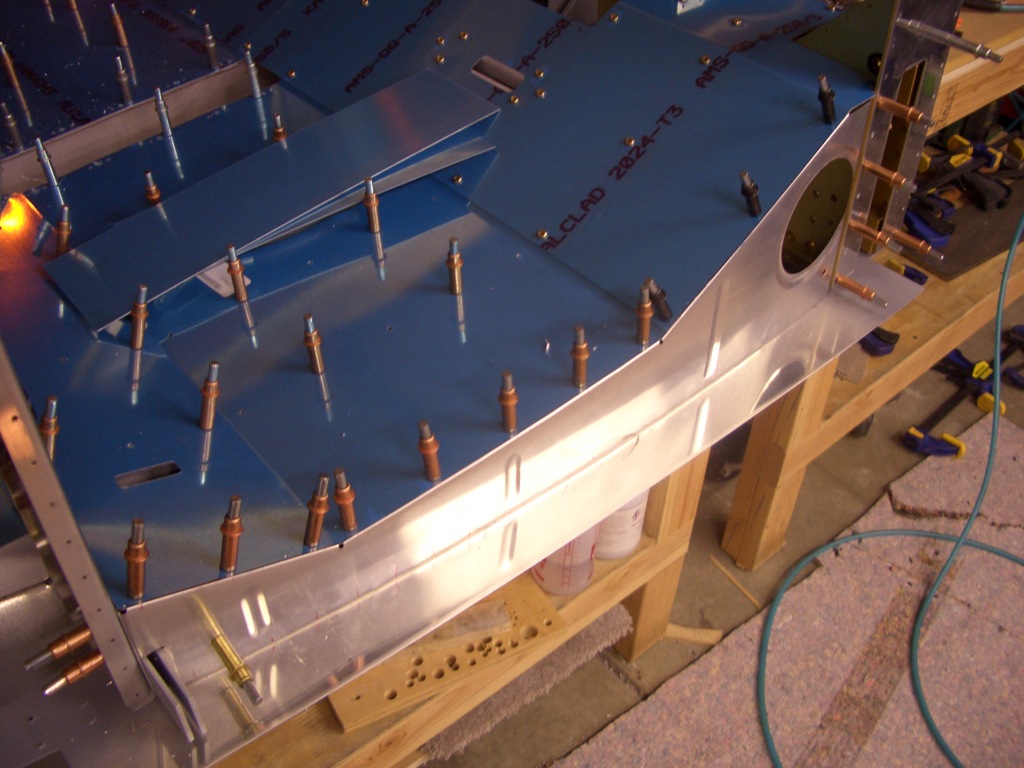

I positioned the web of the outboard seat ribs 1/32″ past the end of the seat pans and drilled the top flanges out with #19 near the front (the black cleco near the upper left of the picture) and #30 the rest of the way. Afterward, I clamped my tungsten bucking bar to the forward end with the tip just hanging over the F-704 side doublers. This ensures these two parts are perfectly coplanar since the side skin spans this joint. I then drilled the first hole in the bottom skin to lock in the lateral position of the rib.

The center line that I drew on the bottom flange of this rib was perfectly centered for the entire length of the rib, so I match drilled it to the bottom skin.

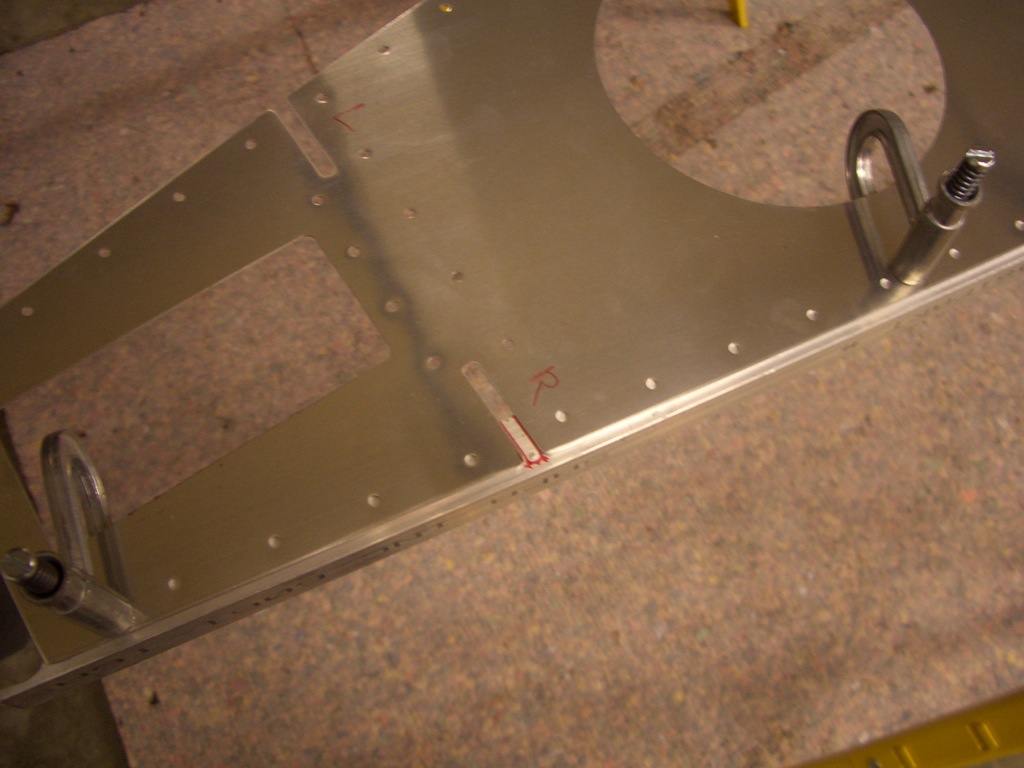

Here is the rib fully drilled to the center section. I then repeated these steps on the left side.

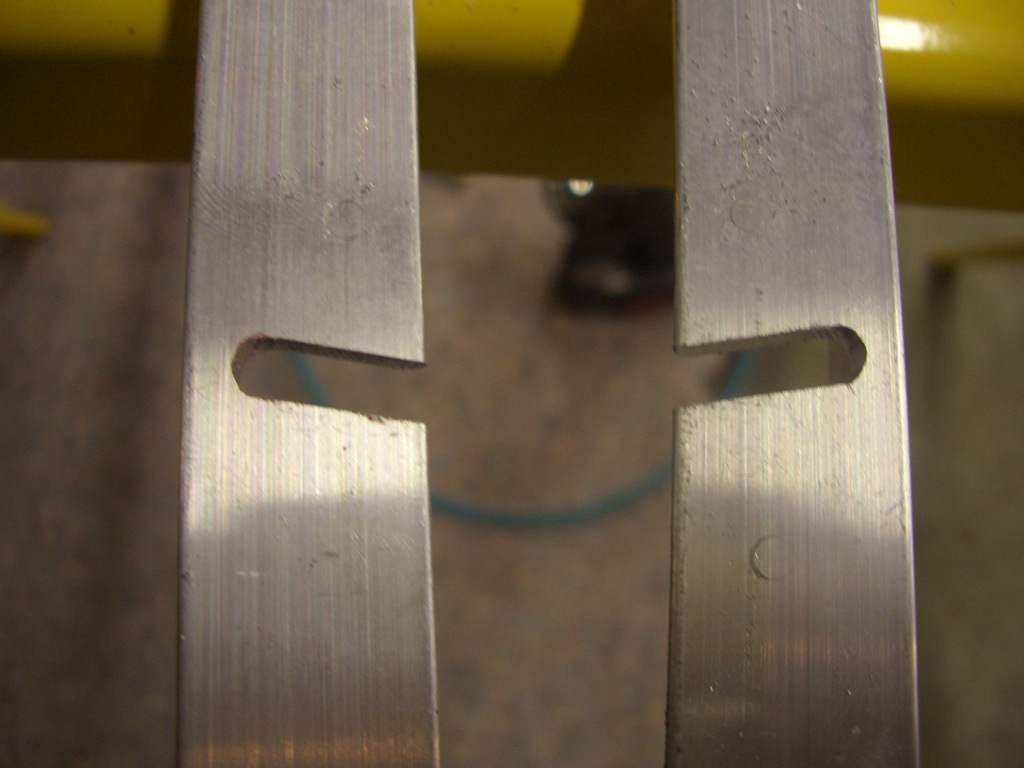

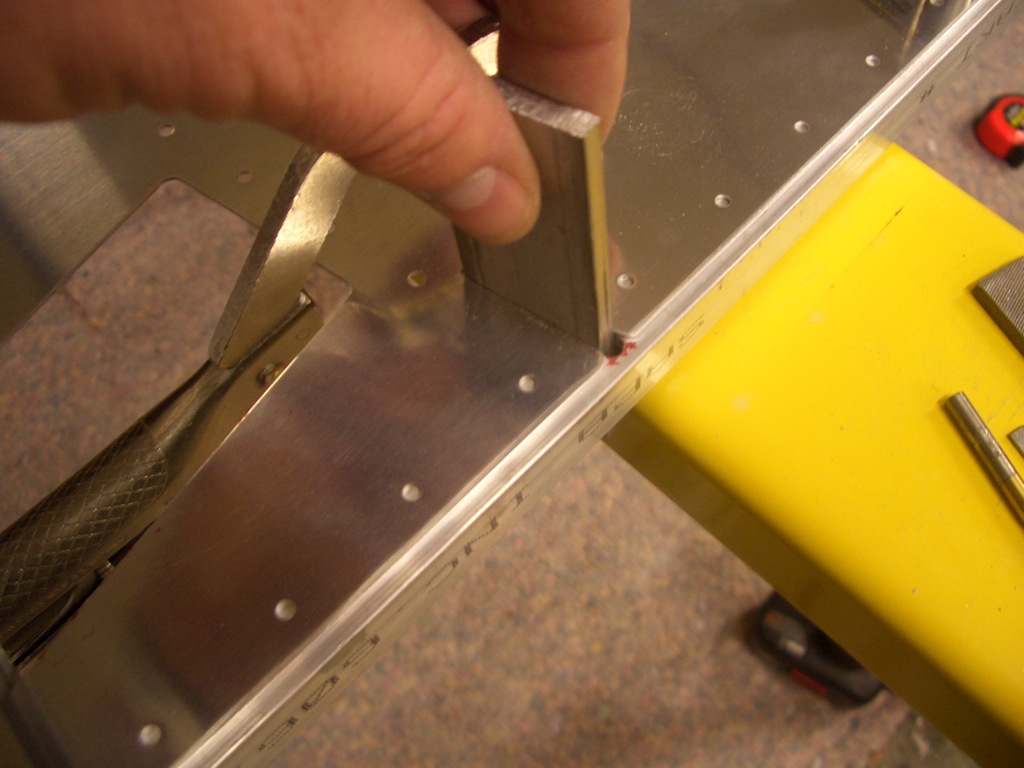

Before the center and aft fuselage sections can be mated, a notch has to be cut in the longerons to allow the vertical bars on F-711 to slip through. The plans provide dimensions on where to position this aft deck, and the existing slot can be used to mark for the notch.

After drilling the end to just under 3/16″, I used a mini hacksaw to cut out the waste (a regular hacksaw would have required me to remove the aft deck to make the cut). I then filed the longeron until it exactly matched the cutout in the aft deck and had a perfect 3/16″ radius starting 1/8″ from the outer leg of the longeron.

I then repeated the procedure on the other longeron. I’ve noticed several builders drilling two 3/32″ holes to define the radius at the end of the notch, but check the plans carefully, the radius is supposed to be 3/32″, so you need a 3/16″ diameter curve at the end of the notch. I filed this until a 3/16″ drill but nestled into the curve. I still need to smooth everything out with some scotchbrite, but the aft and center fuselage sections are ready to join.