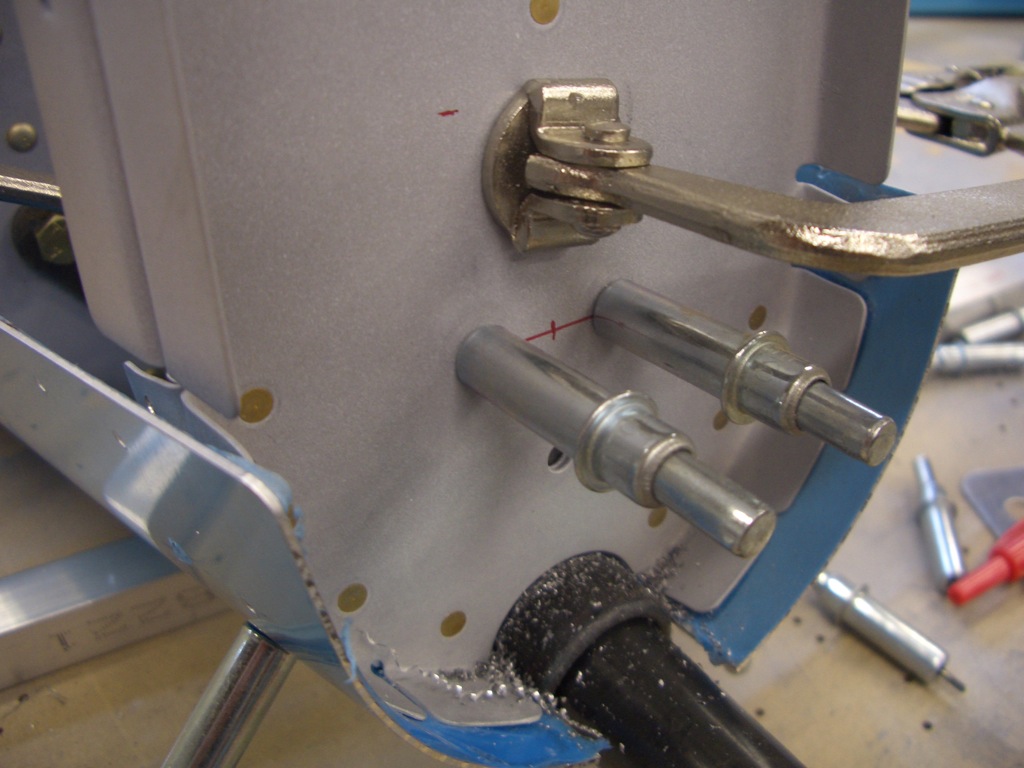

I went out this morning before work and drilled the tailwheel spring mount to the F-711. It took quite a while to ensure that the mount was centered, square, and the tailwheel was exactly vertical.

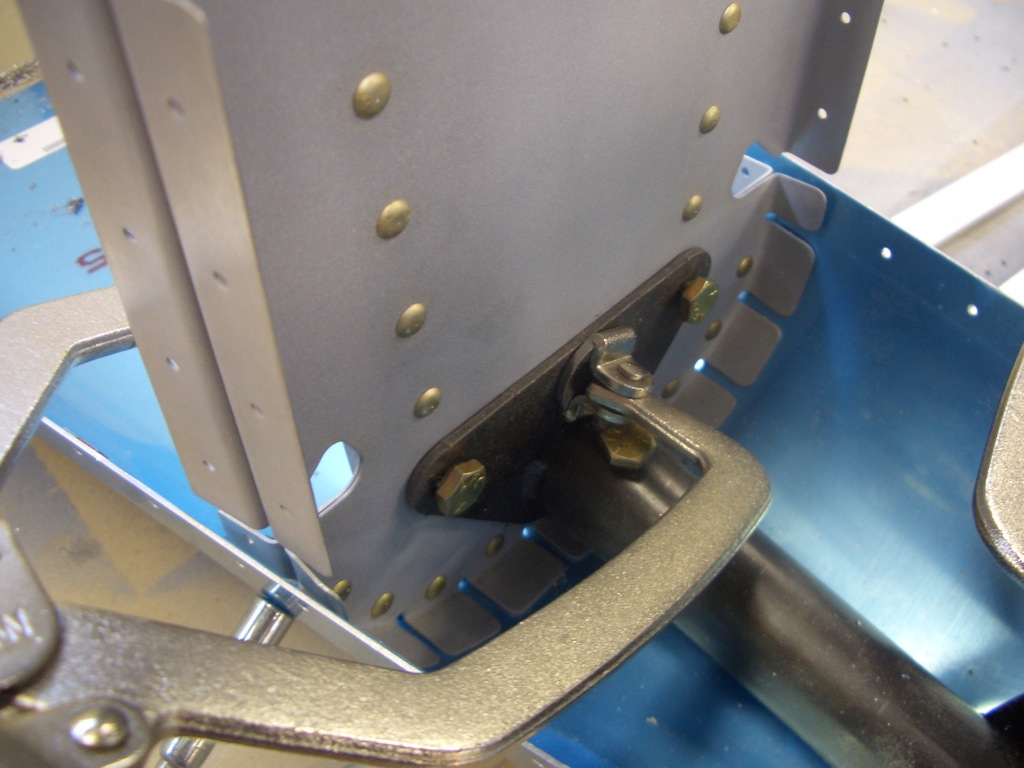

F-712 gets a couple of keeper rivets to hold the mount in place until the bolt holes can be drilled in conjunction with the vertical stabilizer rear spar.

Unfortunately, one of the holes came out slightly under the recommended edge distance of 1.5D (12/32″ in this case). I need to run this by Van’s and see if they think this is an issue.

Update: Ken Scott at Van’s said not to worry about 1/32″, especially in steel. “Build on” as they say…

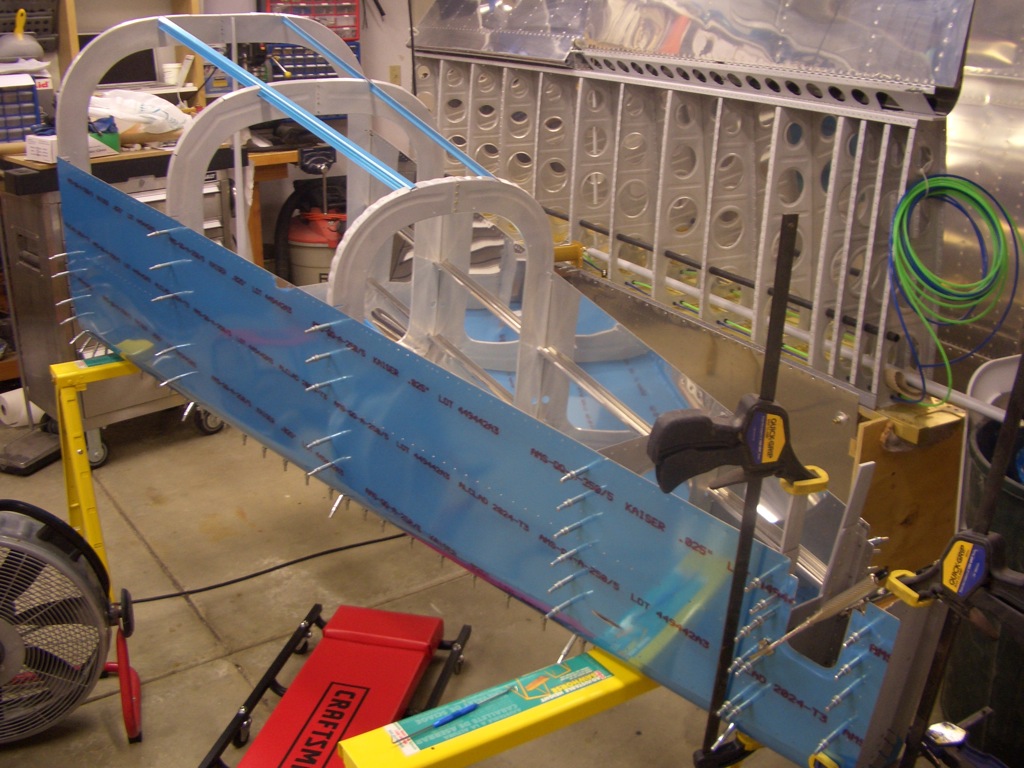

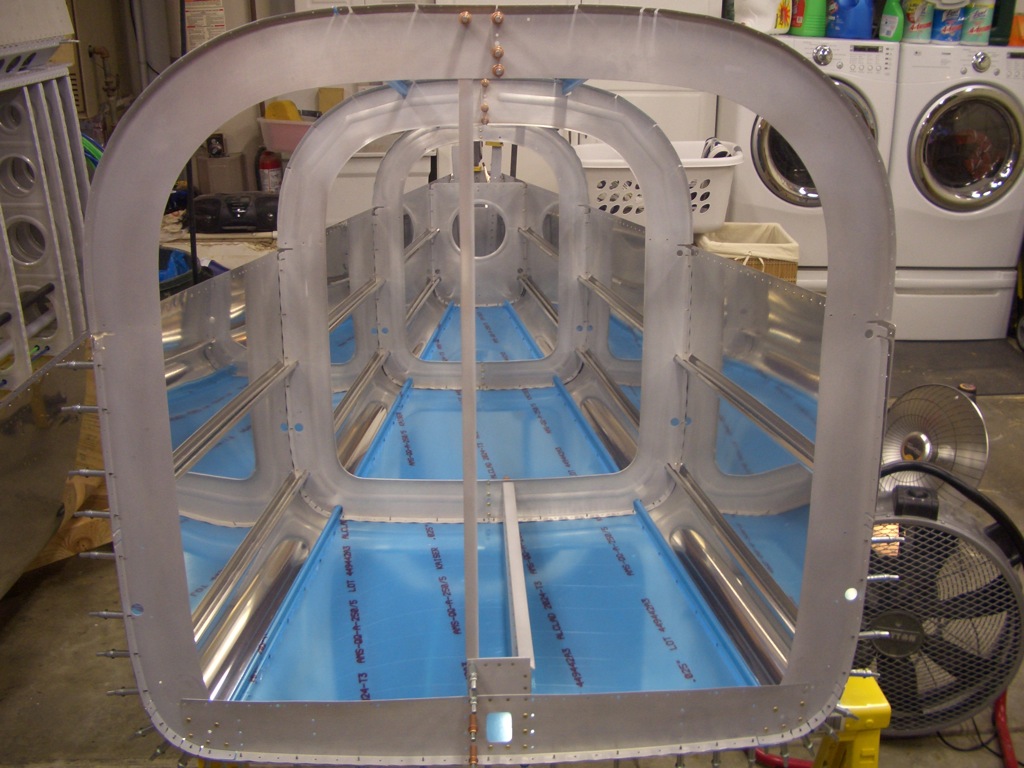

I clecoed the tailcone together. Getting the stringers in gets a little tough once all of the bulkheads are in place, but I eventually got it. The ends of the lower four stringers need notches cut in each end to clear the bulkheads.

Here’s a shot looking down the tailcone from the other end. The vertical rib connecting the top an bottom of the closest bulkhead as well as the horizontal rib that connect the closest two bulkheads are supposed to be off center.

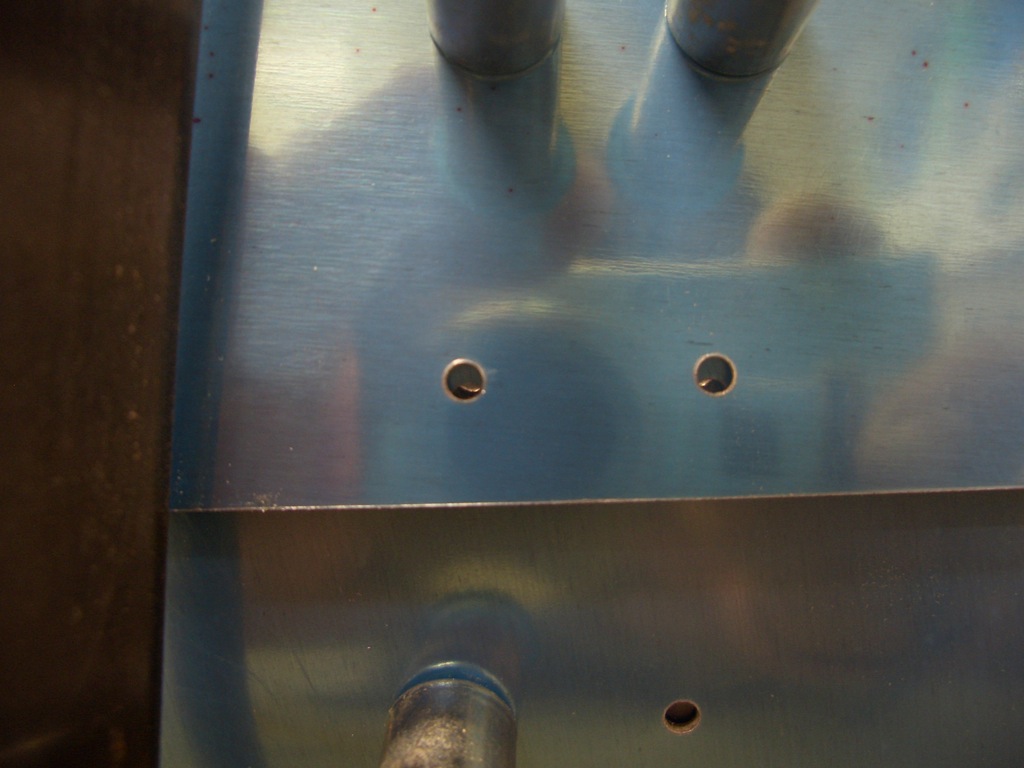

The holes in the tail skin don’t even come close to lining up with the holes in the side skin. I need to do a little research on this to see how to get these to align. I can’t just pry them into alignment since there is a stringer right on the other side of these holes that would prevent inserting a cleco through the hole after aligning.