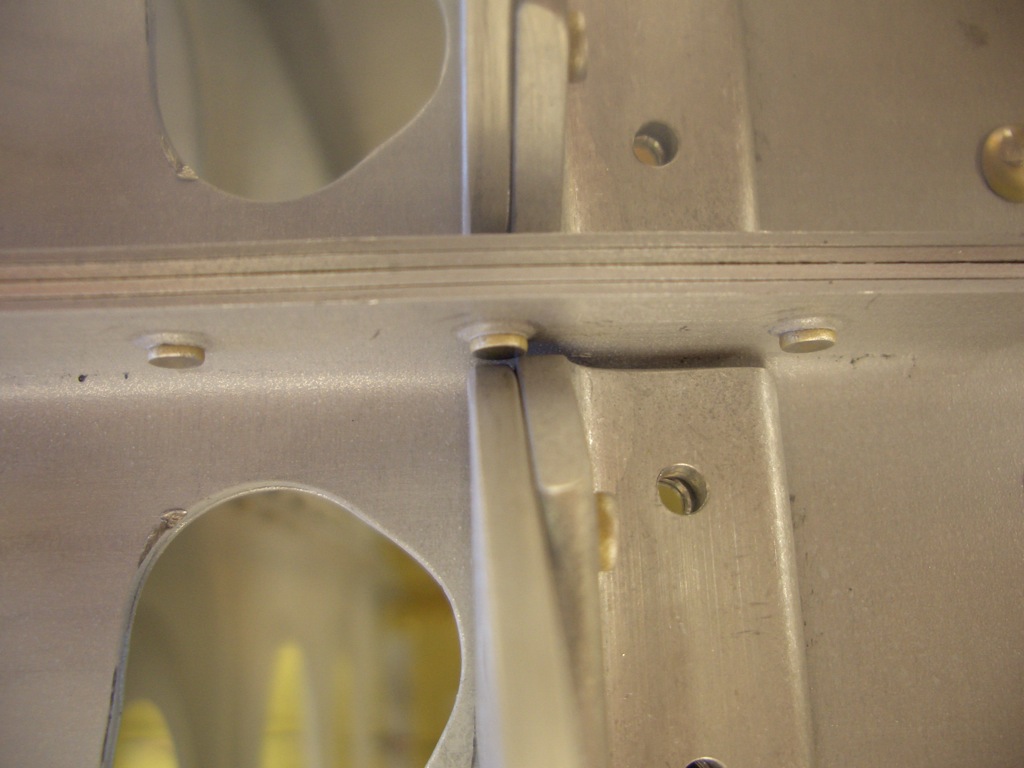

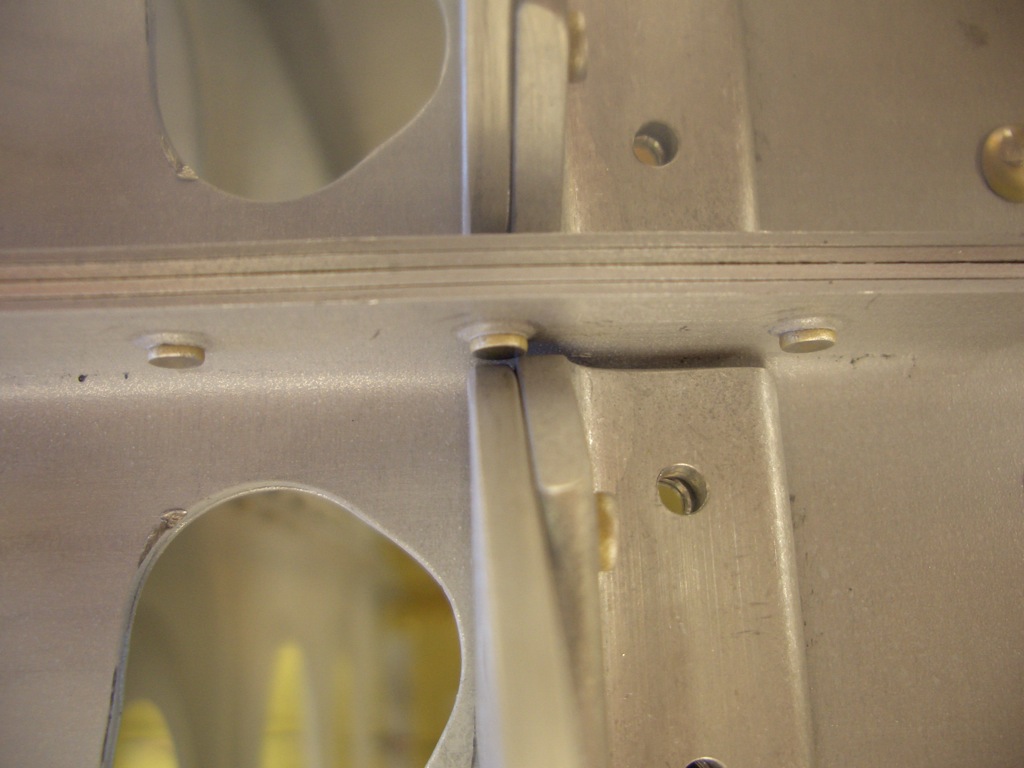

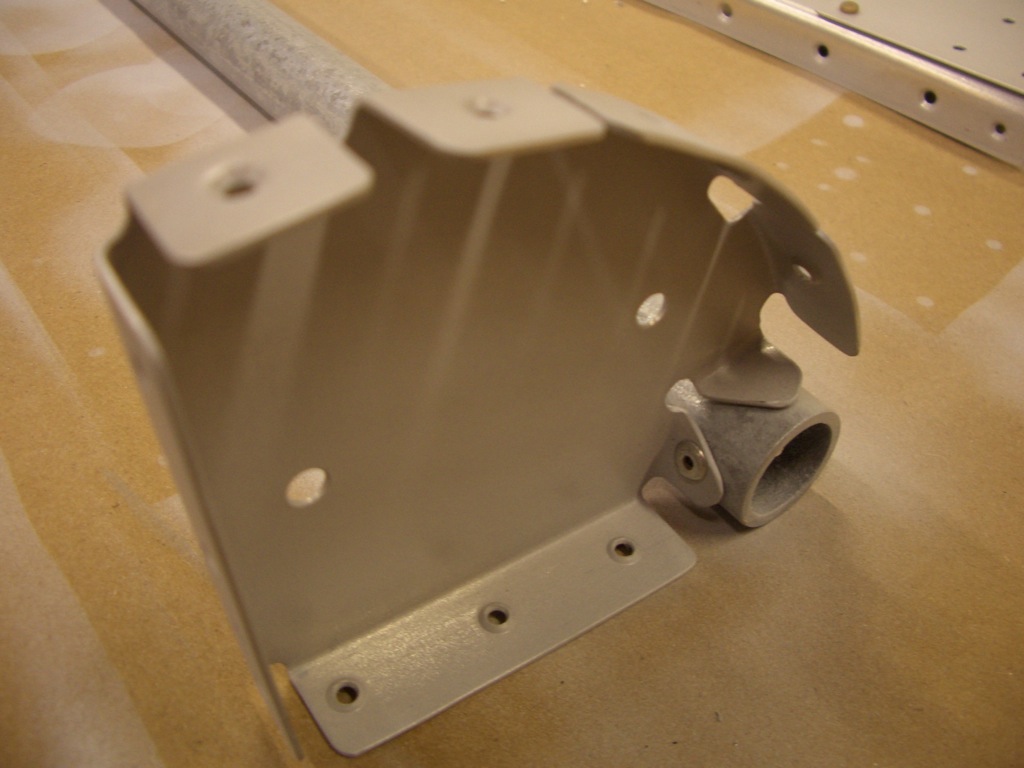

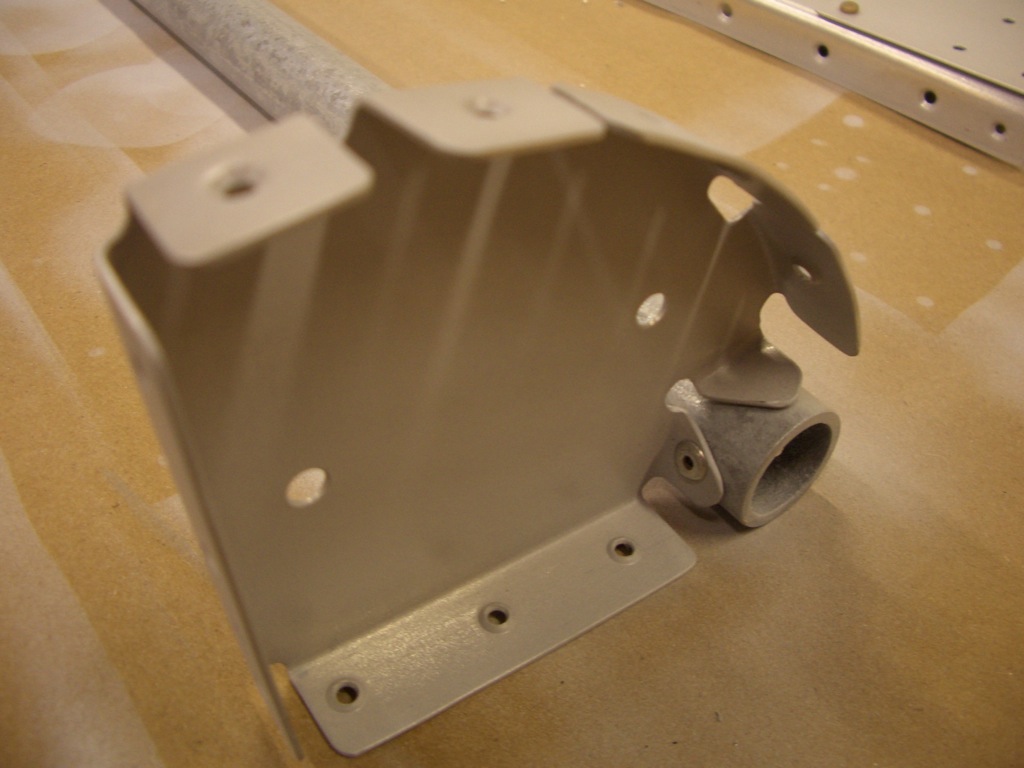

I started out by fitting the aileron hinge brackets on the right wing. One of the rivets interfered with the hinge bracket slightly. A few seconds on the scotchbrite wheel took care of that and the hinge bracket now fits perfectly.

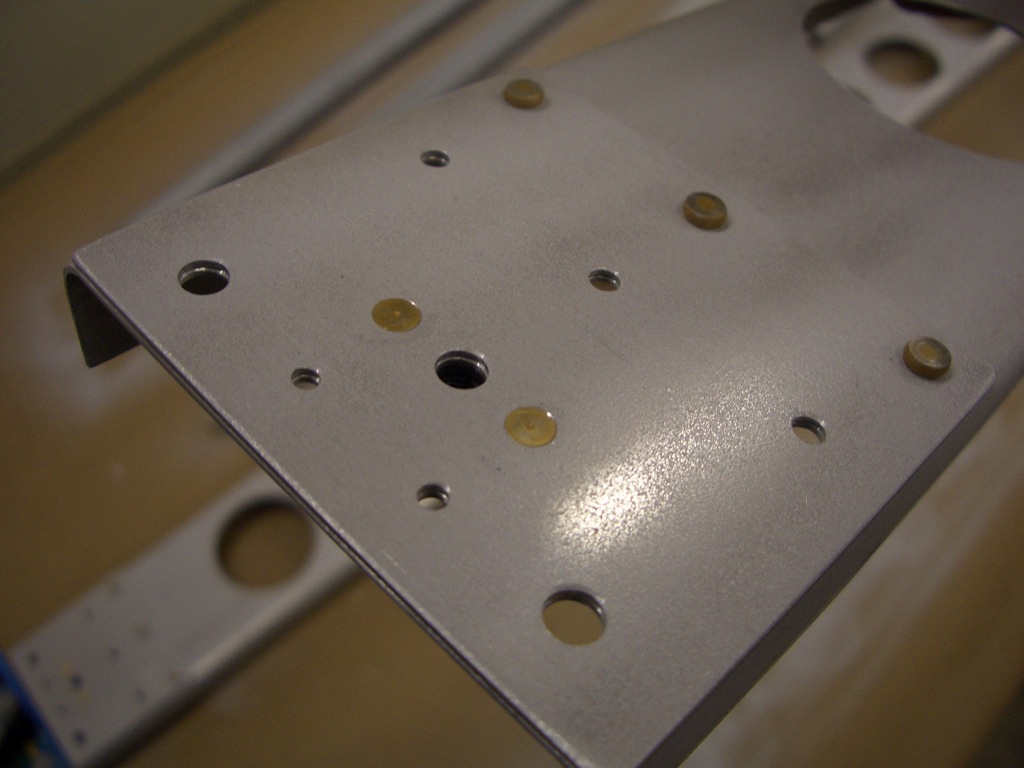

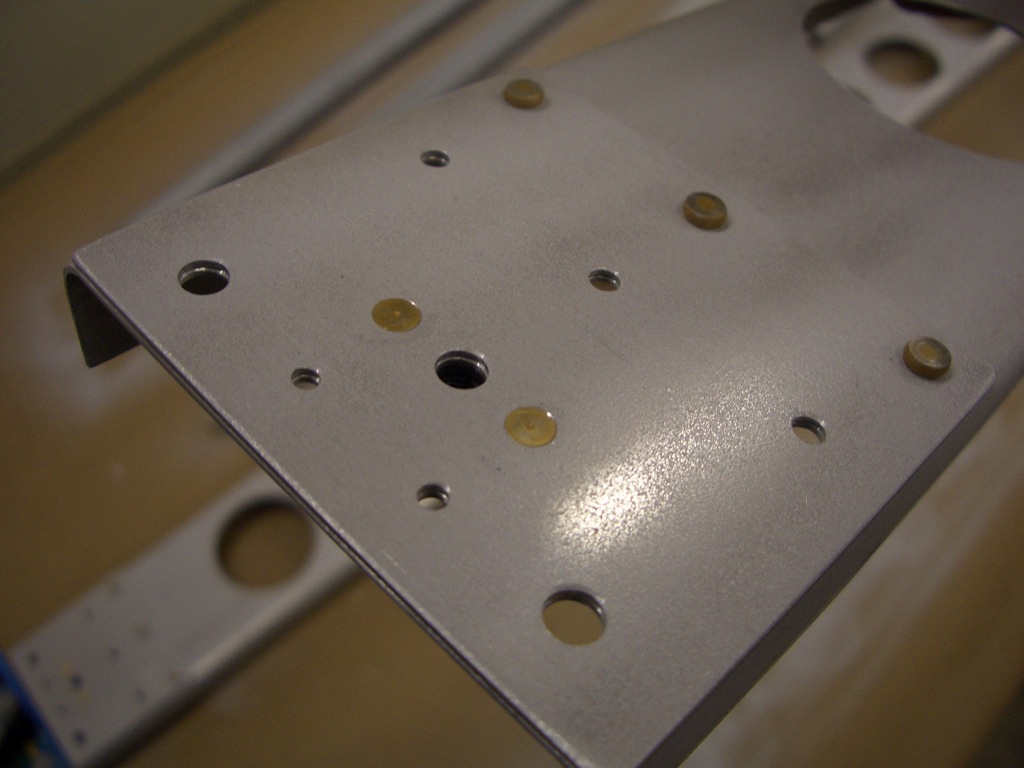

I finished up deburring the aileron components and started working on dimpling the various components. Dimpling the spar is tight, so I ground part of my 1/8″ female dimple die to allow me to fit in there.

I also ended up grinding off part of my 1.5″ yoke so that it wouldn’t scrape along the spar.

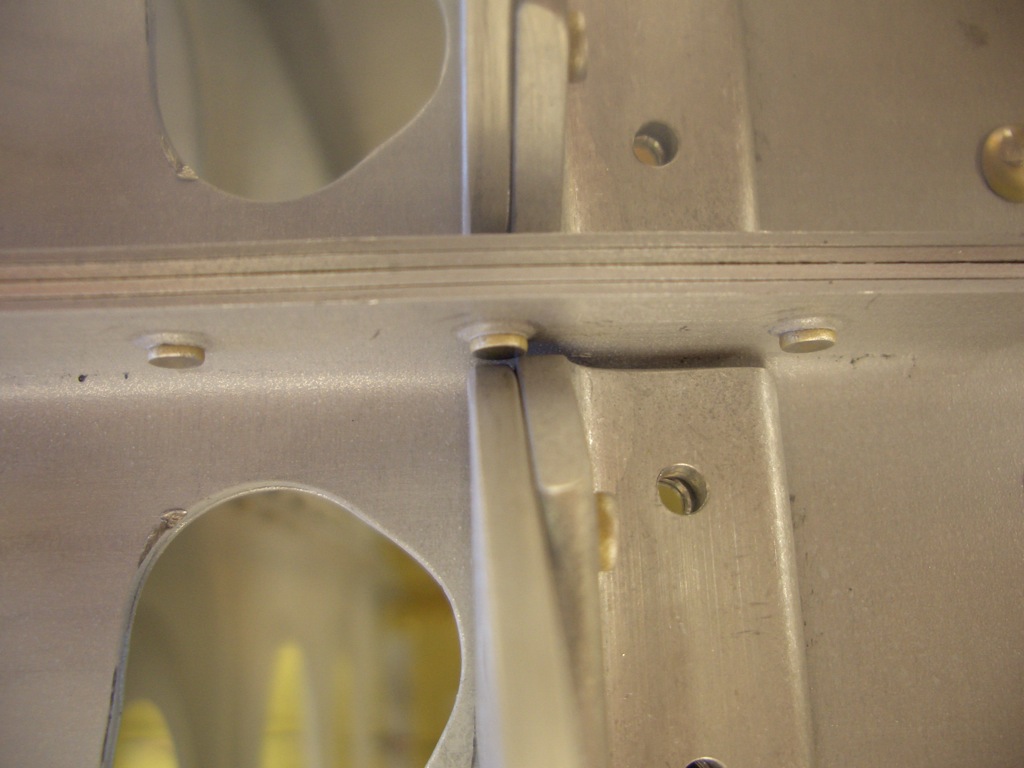

Here you can see that I can easily reach the spar dimples now without scraping the spar web or hitting the flange radius.

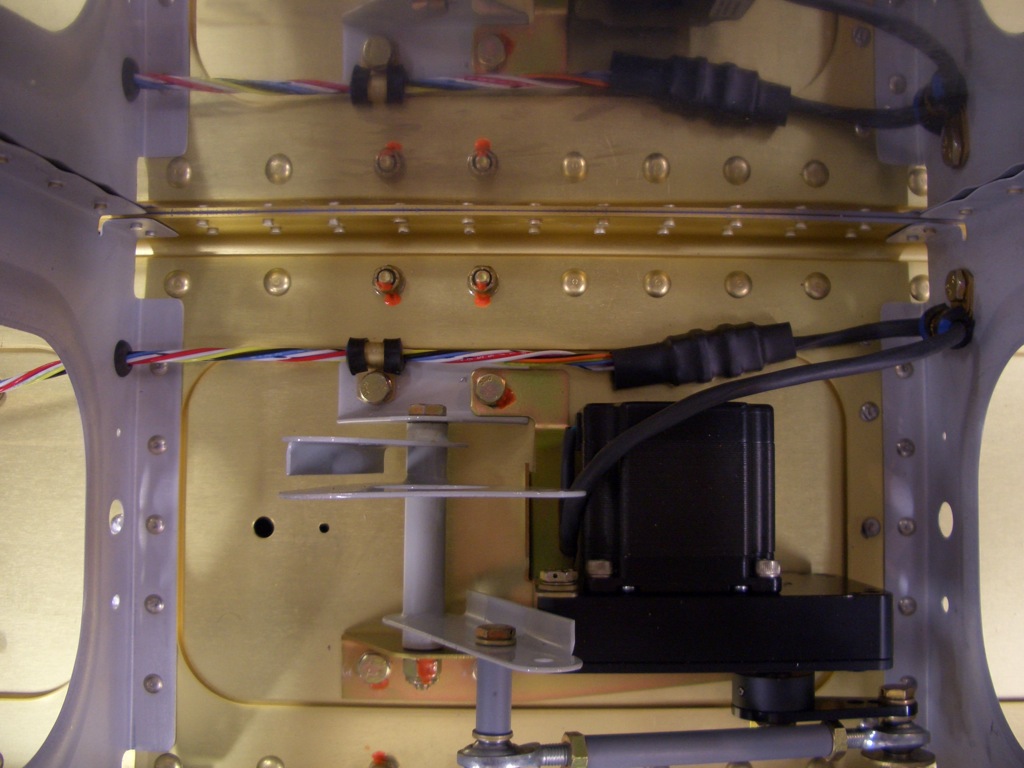

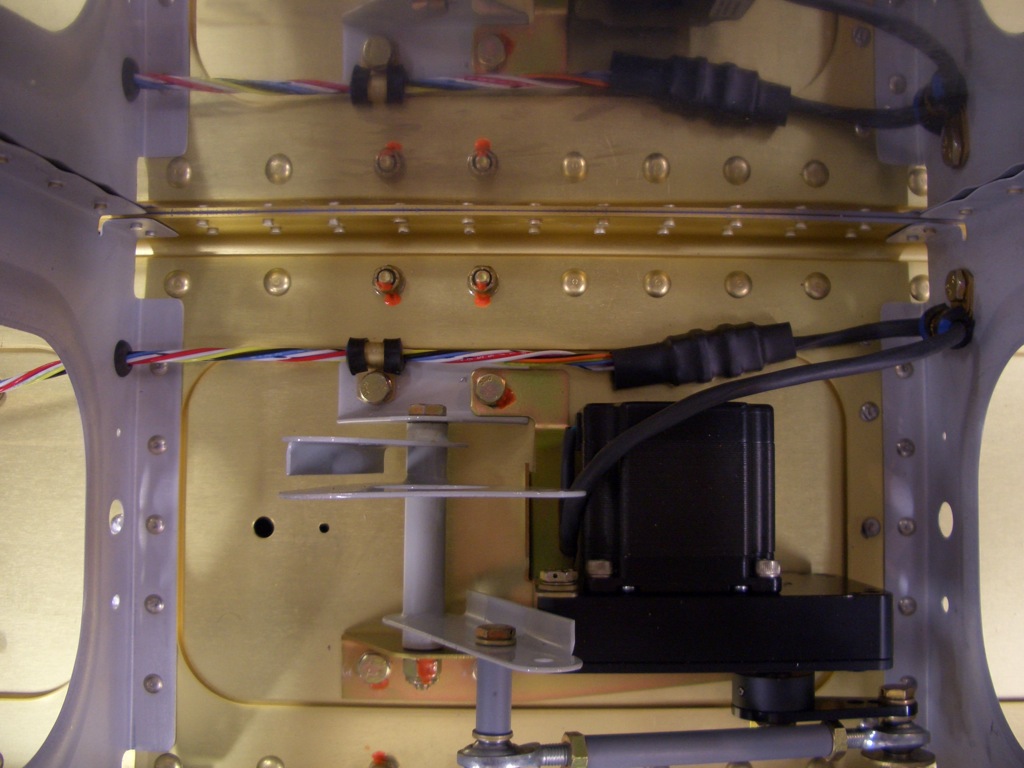

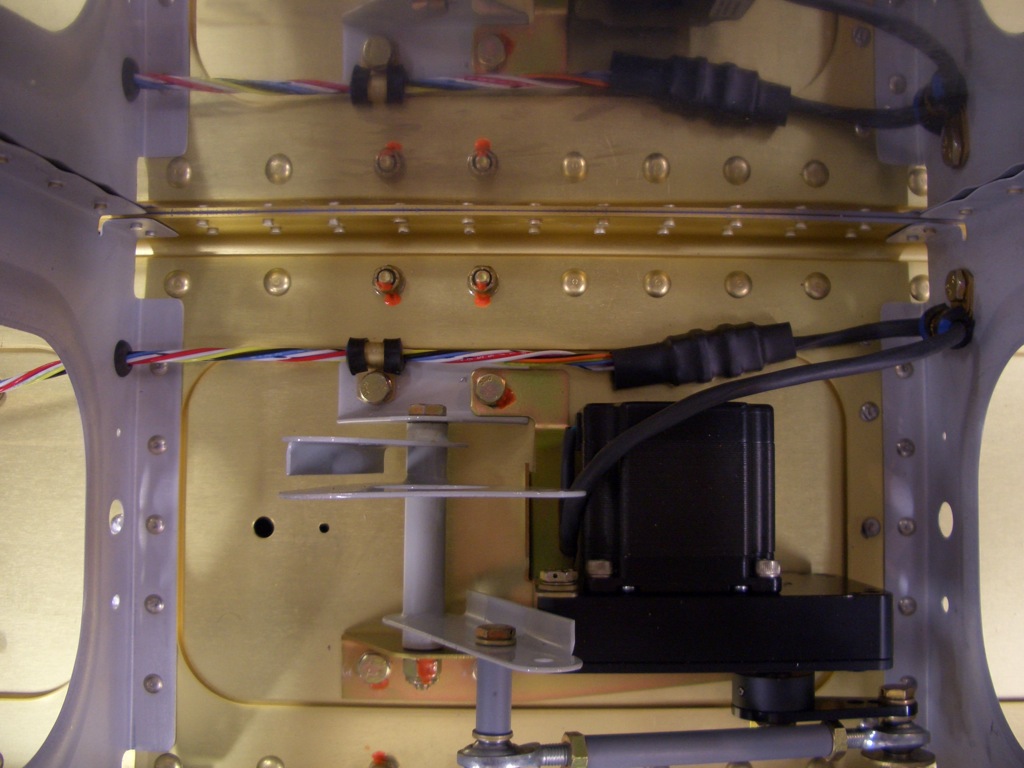

My shipment from Aircraft Spruce showed up today, so I used a couple of the adel clamps to secure the roll servo wiring harness. You’ll also notice that I added heat shrink material over the connection to not only hold it together and keep it from being exposed to the elements, but it also prevents it from scraping the spar.

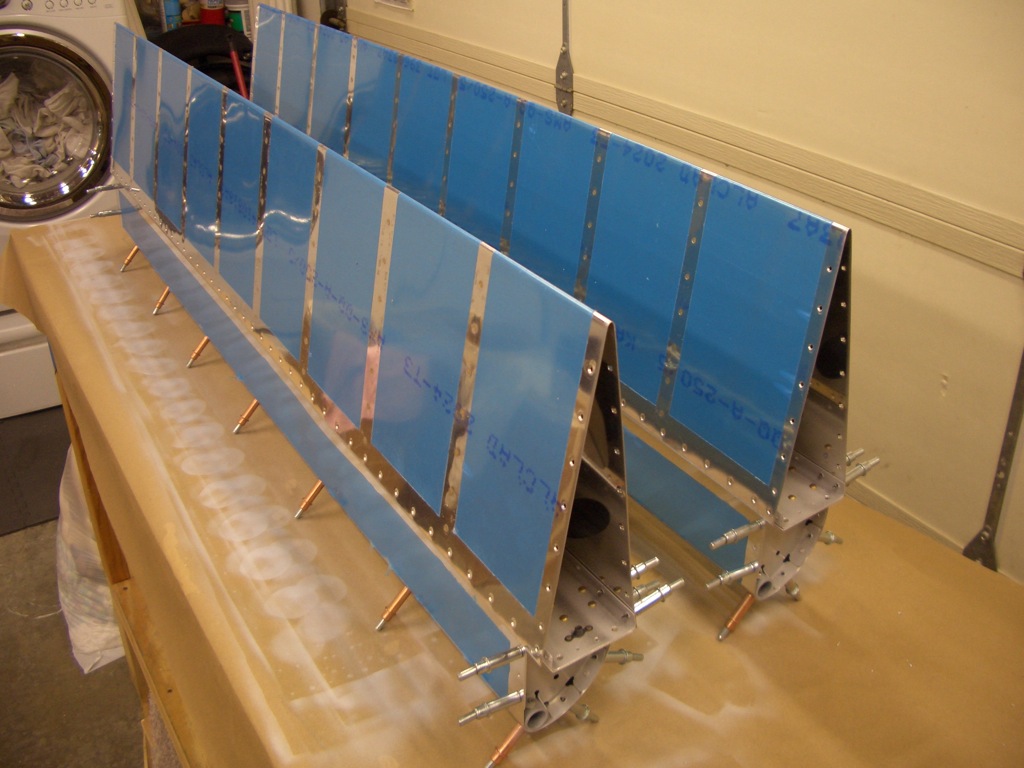

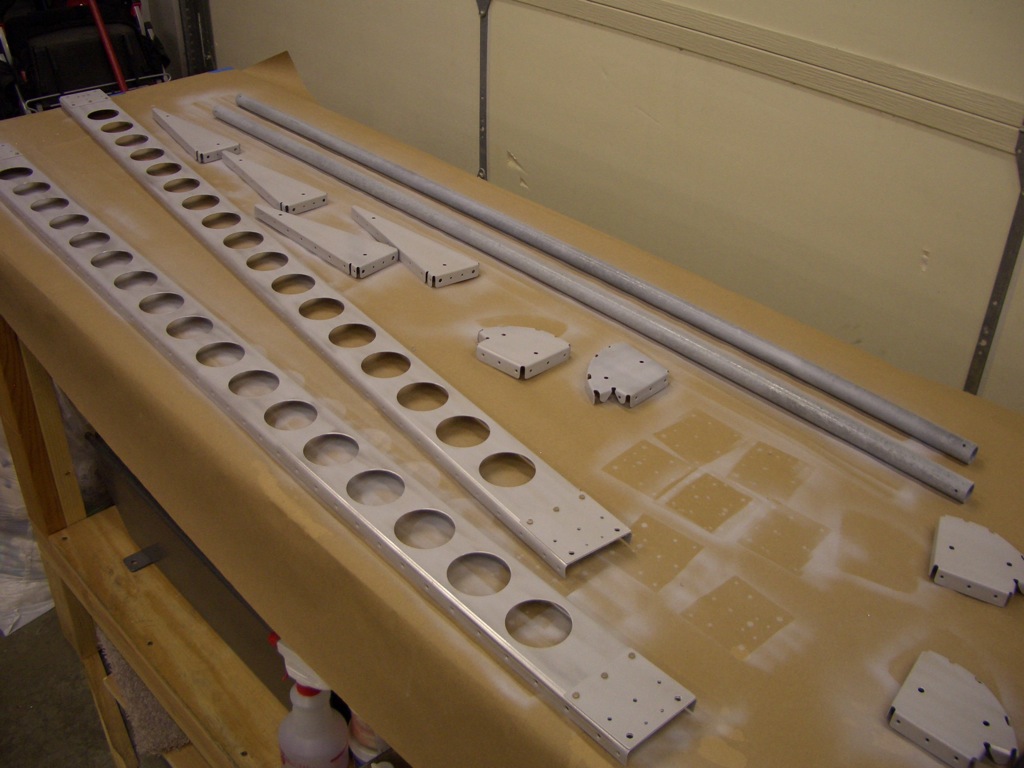

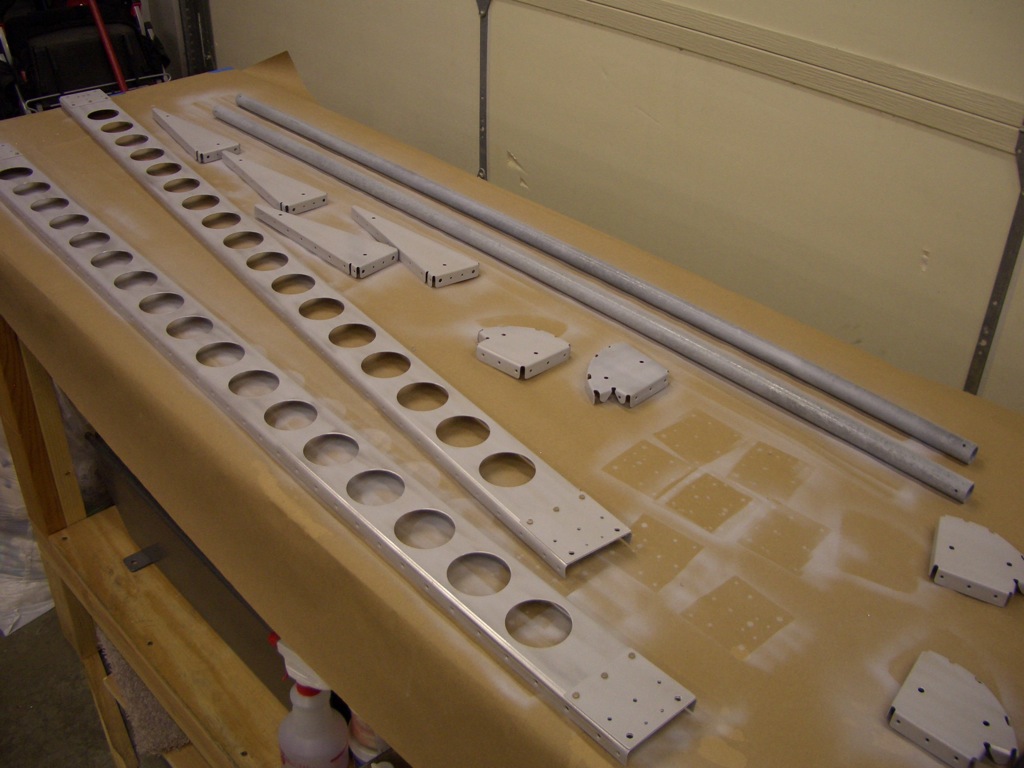

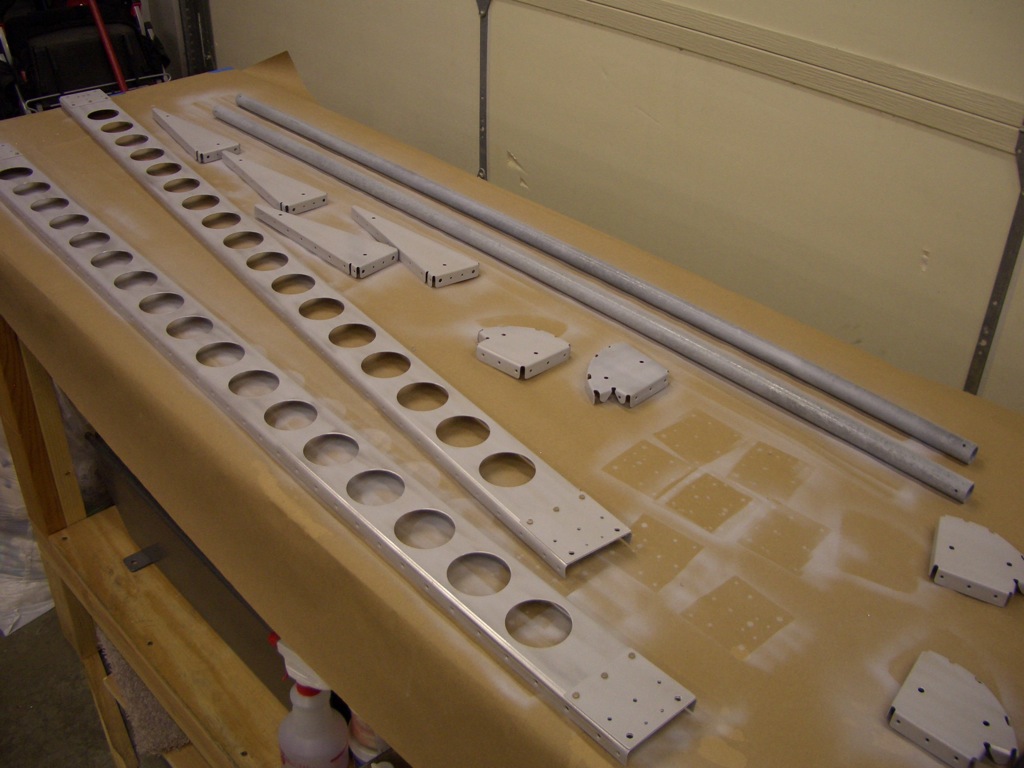

I cleaned, etched, and primed all of the aileron components.

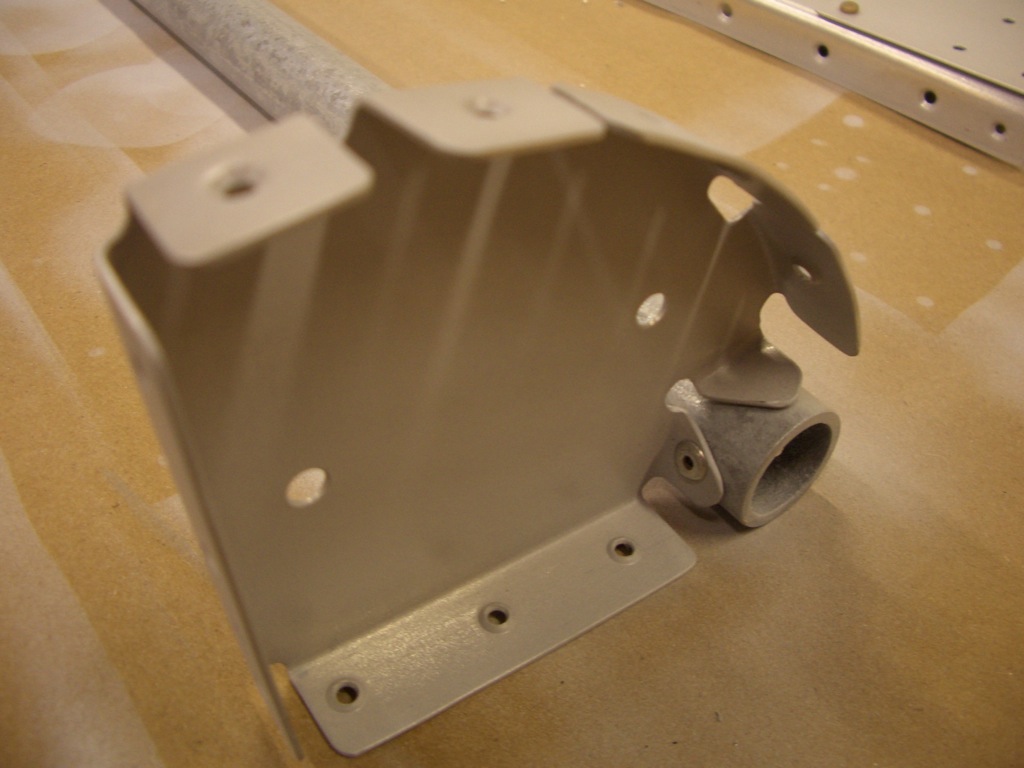

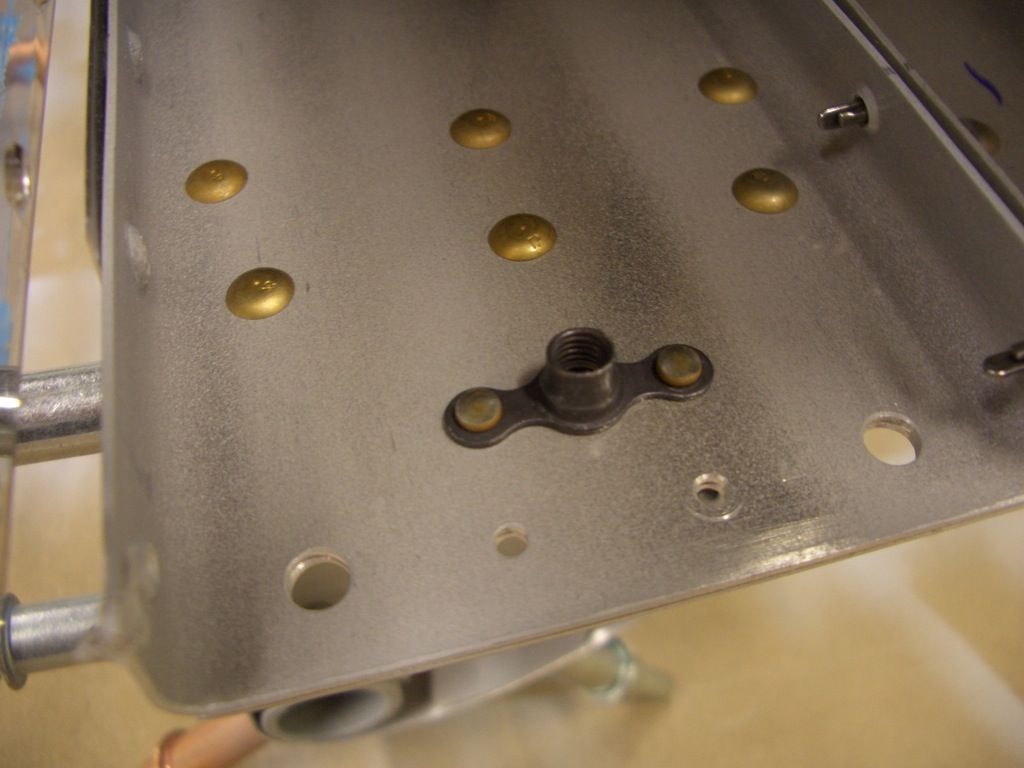

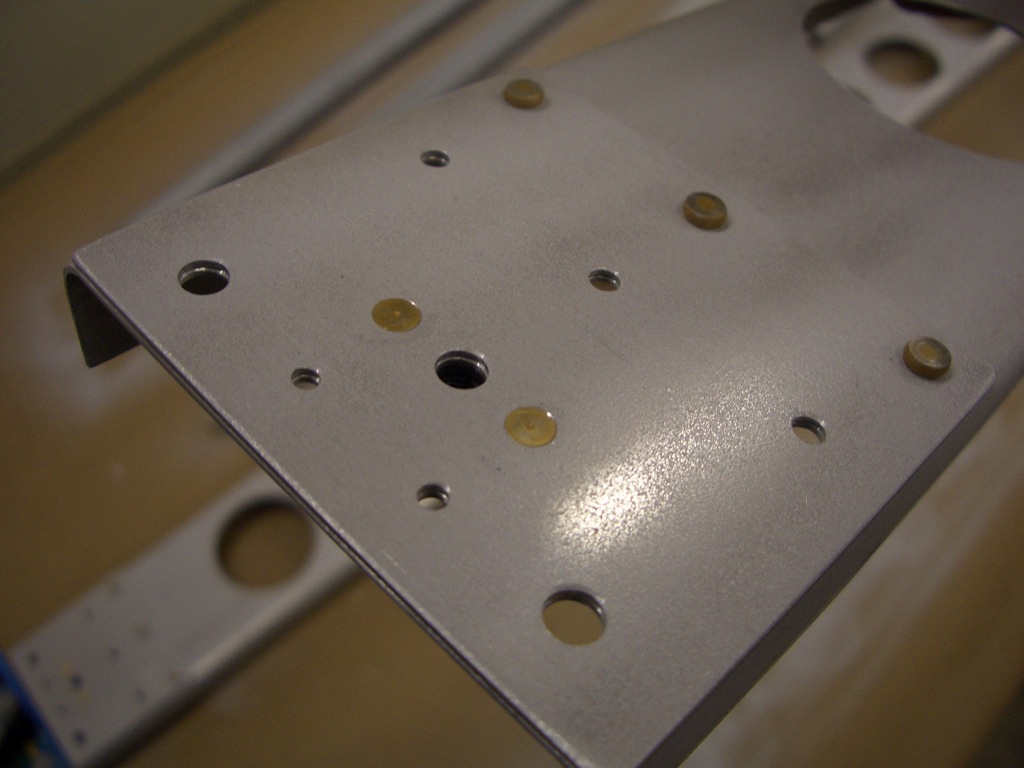

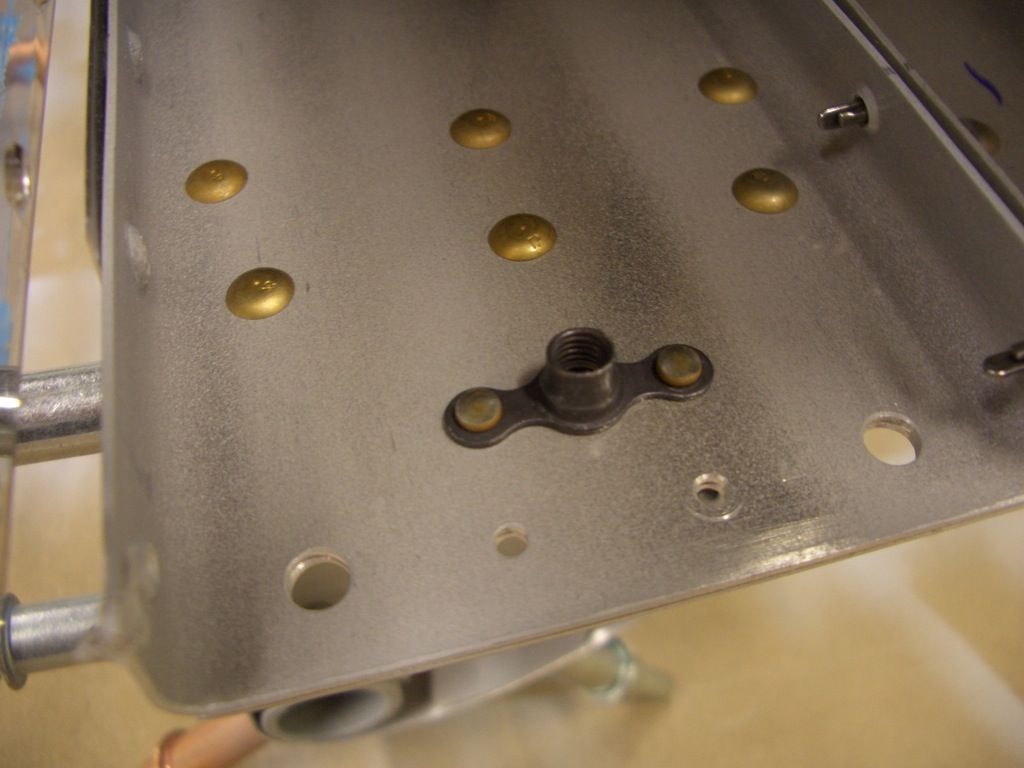

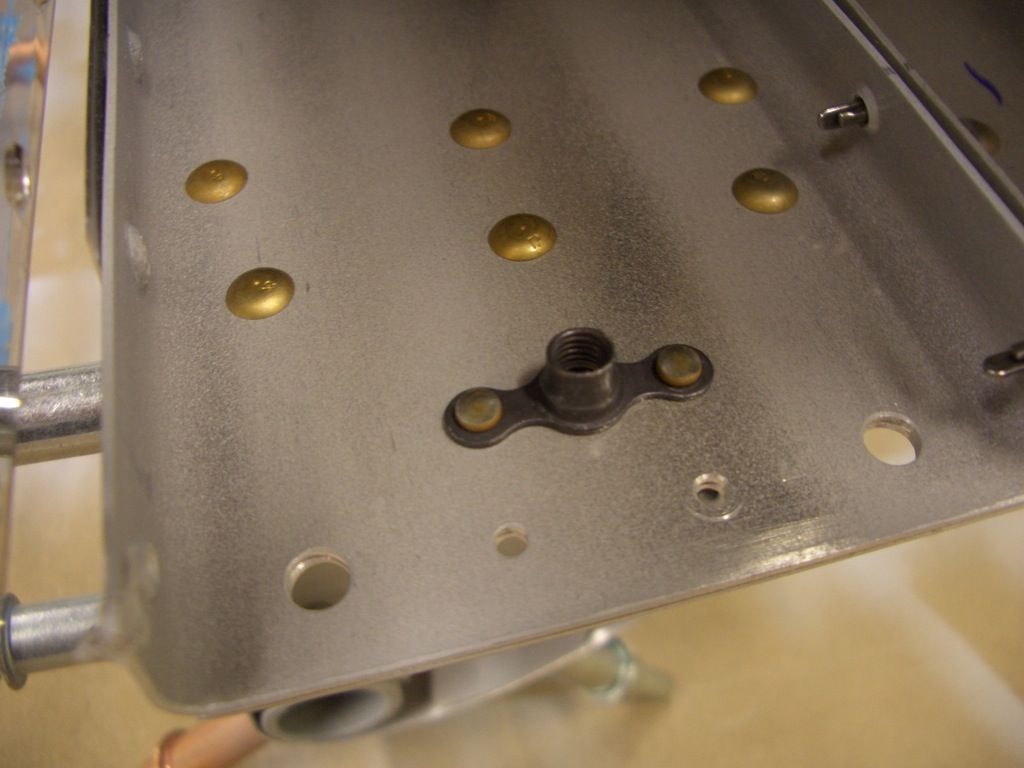

First up is to rivet on the spar reinforcing plates. The inboard ends each get a K1000-03 nutplate riveted on with flush rivets. The inner row of holes on each reinforcing plate get riveted now as well since there is nothing else that attaches there.

The nose ribs get blind riveted to the counterweight.

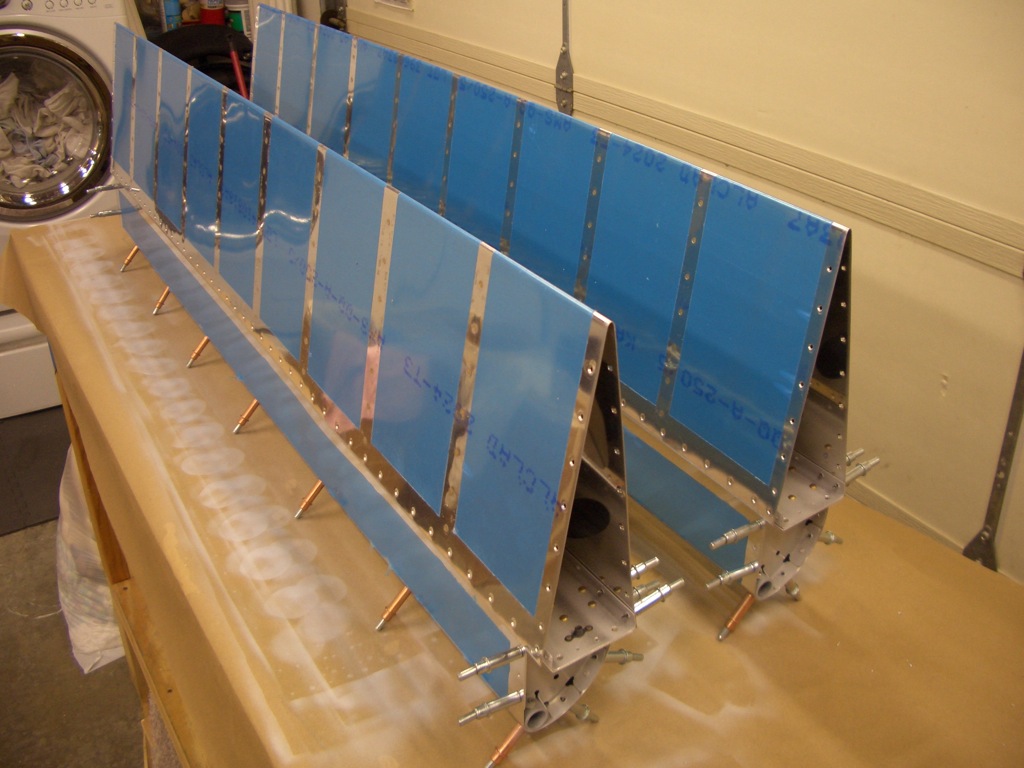

Then the nose ribs get dropped into the leading edge skins and the spars are riveted to them (the closer row of three rivets here just above the nutplate).

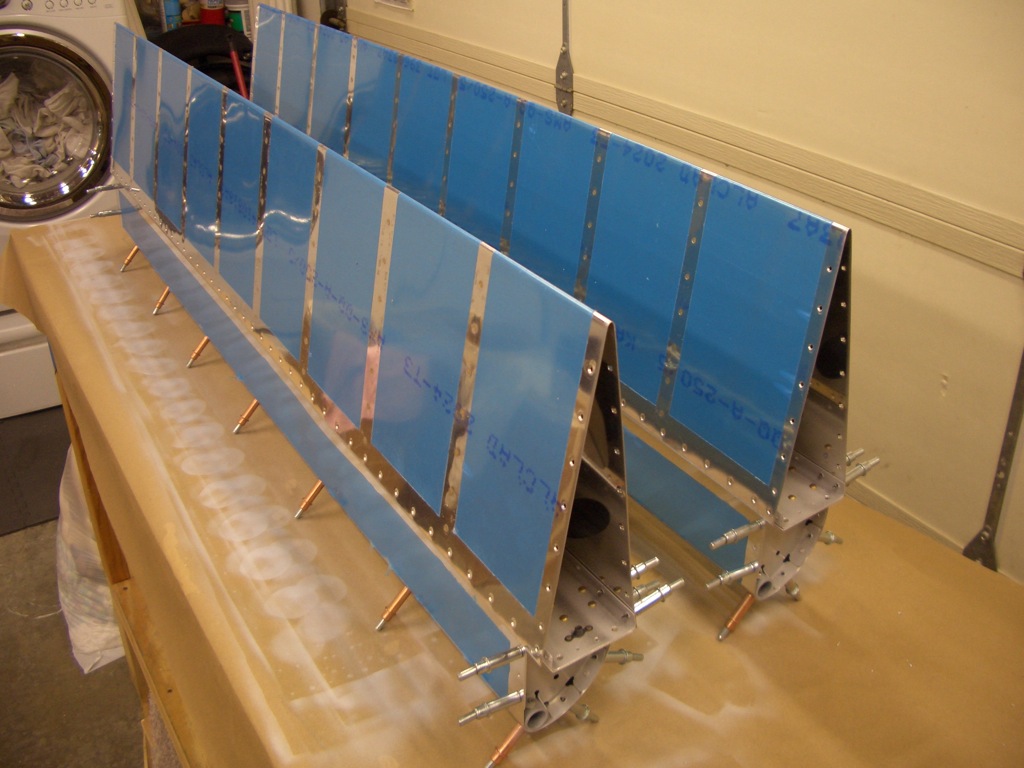

Finally, the trailing edge skin is clecoed along the top side of the spar. It’s far too late to think about riveting this tonight (almost 2 am as I’m writing this), so I’m done for the night.