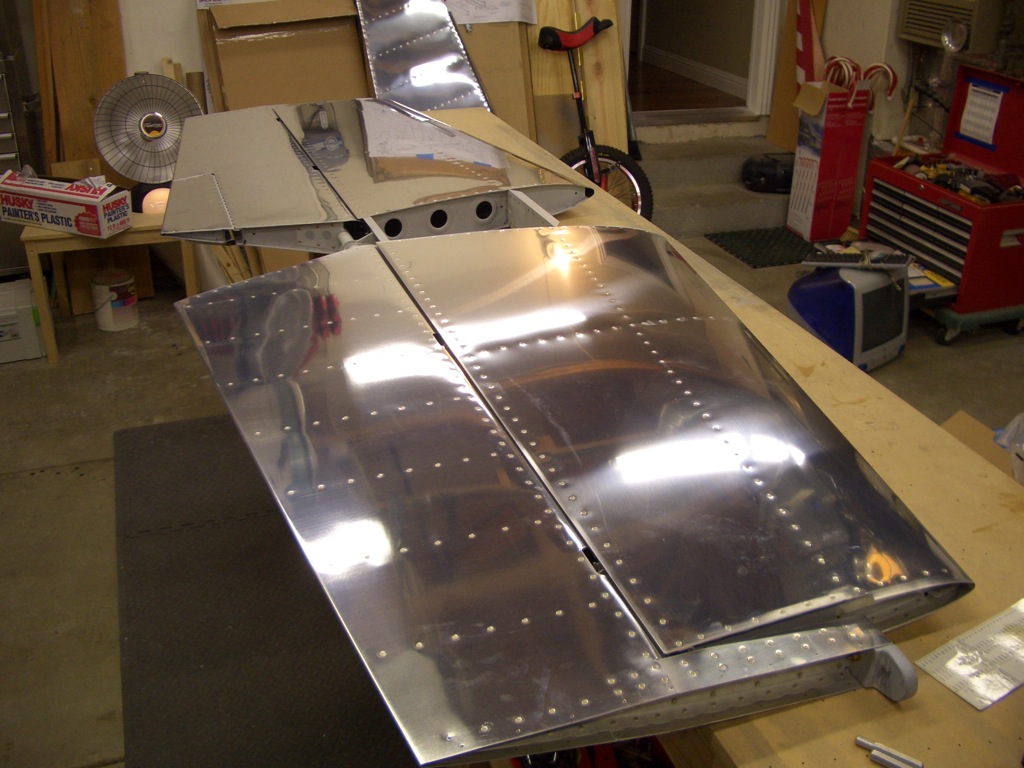

I finished riveting the trim tab with the exception of a couple of pop rivets that I need to order. I’m really happy with how this turned out. It’s not perfect, and I’m sure I could do better after I get more experience, but it turned out really well.

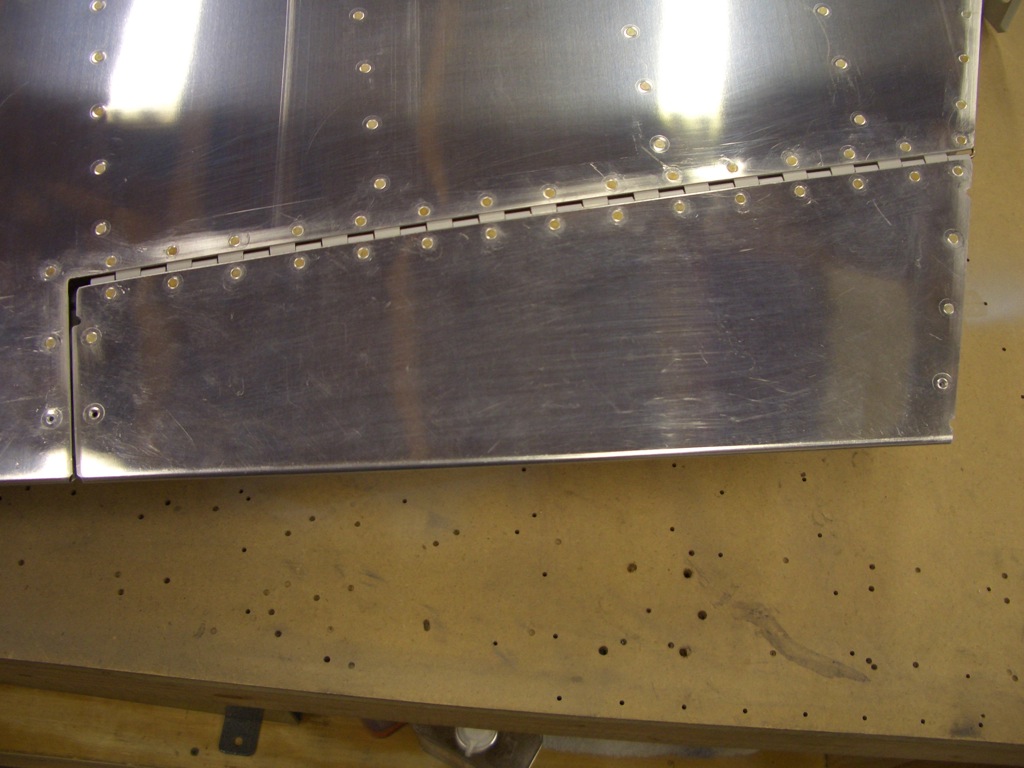

Here is the bottom side with the trim servo hooked up. I’m not getting anywhere near the +25º/-35º travel the manual states is optimal, so I’ll have to call Van’s about that, but at least it’s all hooked up and working.

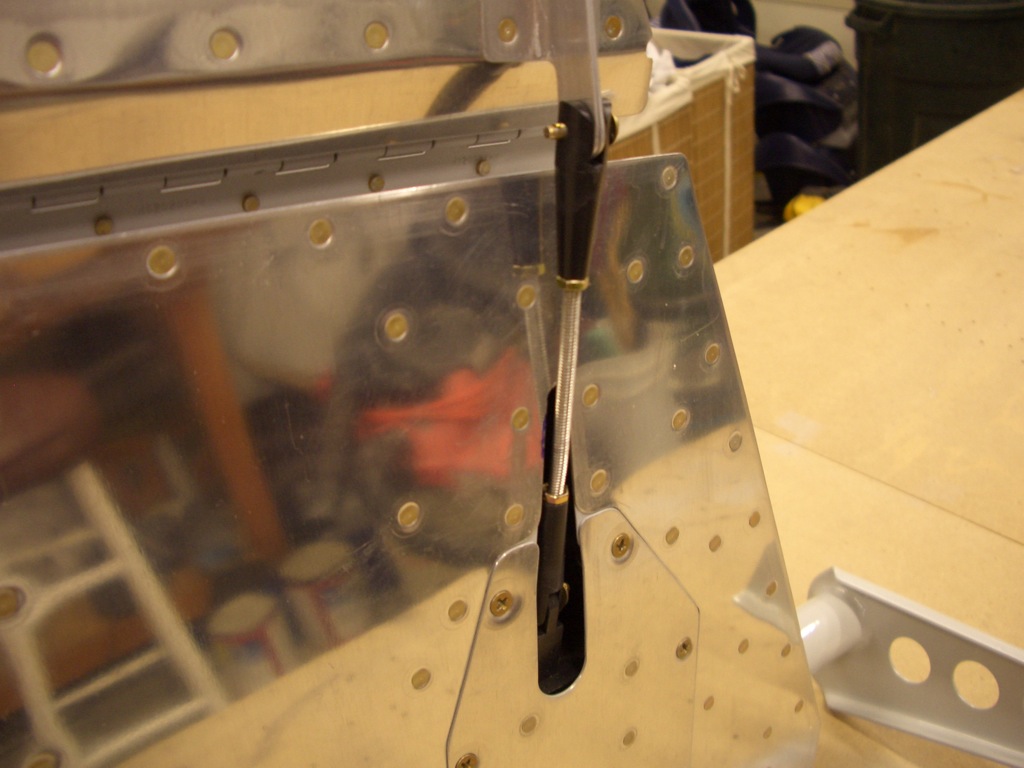

Here’s a closeup of the trim tab push rod. I’ll probably need to file the edges of the opening in the elevator to get a little more clearance, but that can wait.

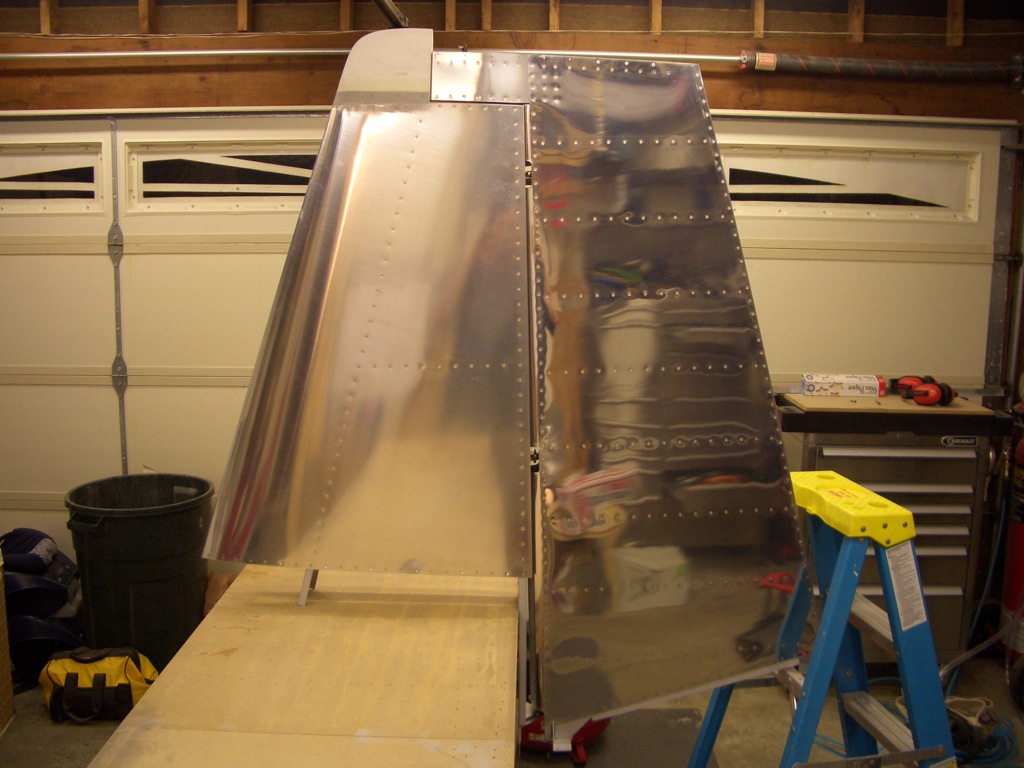

I pulled down the rudder and fit in to the vertical stabilizer. The clearance between the vertical stabilizer tip and rudder counterbalance skin is too tight right now, but I’ll open it up a bit when I do more of the fiberglass work.

The gap between the lower edge of the counterbalance skin and the upper edge of the vertical stabilizer is nice and uniform though.

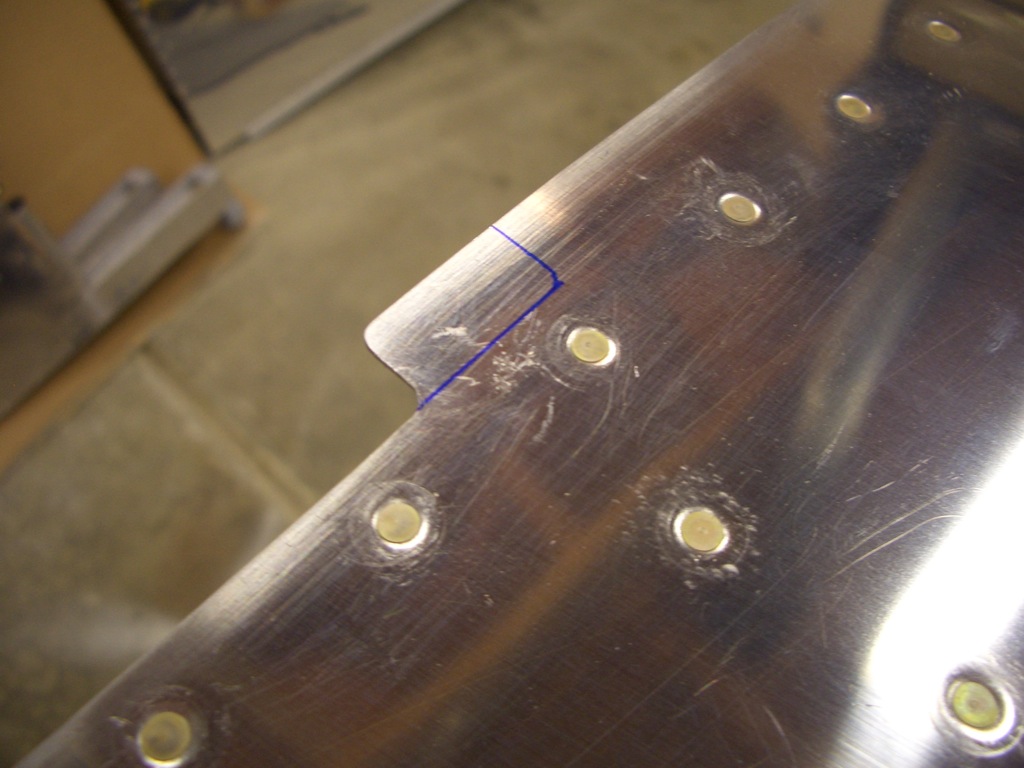

Next I got started on fitting the elevators to the horizontal stabilizer. The horizontal stabilizer skin needs to be trimmed a bit to allow the elevator counterweights to clear, so I marked and trimmed the extra off.

The lower portion of the rear spar flange also has to be trimmed to clear the elevator horns. This is tricky because you really don’t want to nick the spar reinforcing bars just behind the flange. I stuck an extra strip of 0.032″ aluminum under there when using the dremel tool to give me a little insurance. Worked great; clean cut and no nicks on the reinforcing bars.

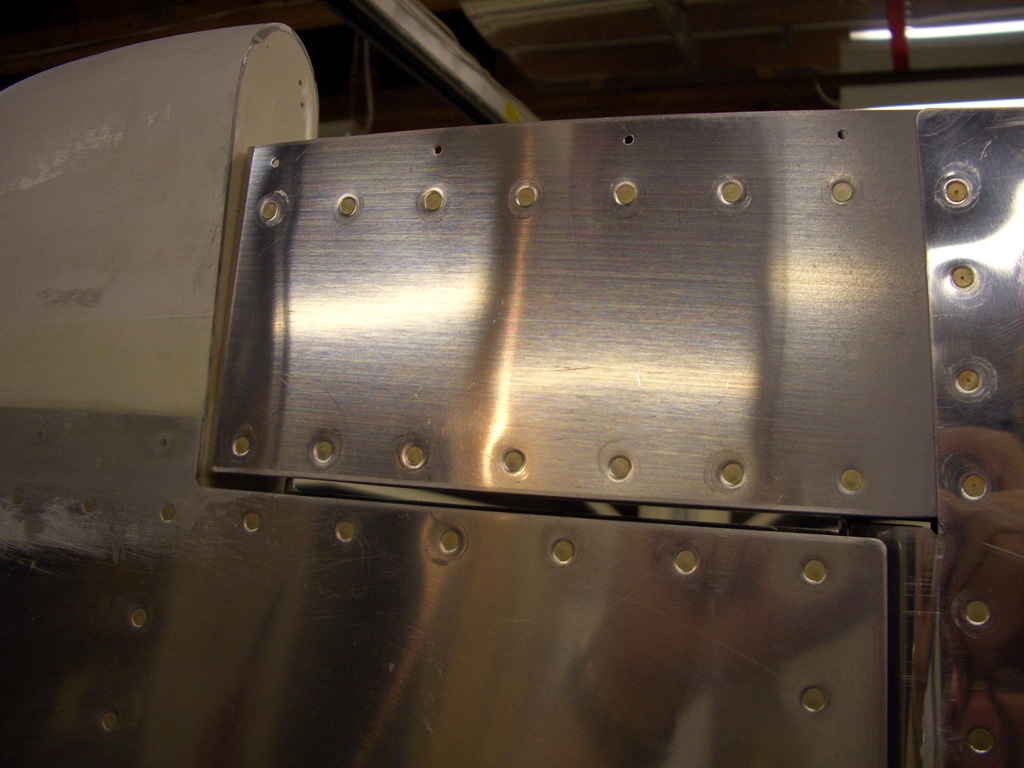

Here are both elevators fit to the horizontal stabilizer. It looks so cool to finally see some big parts taking shape.