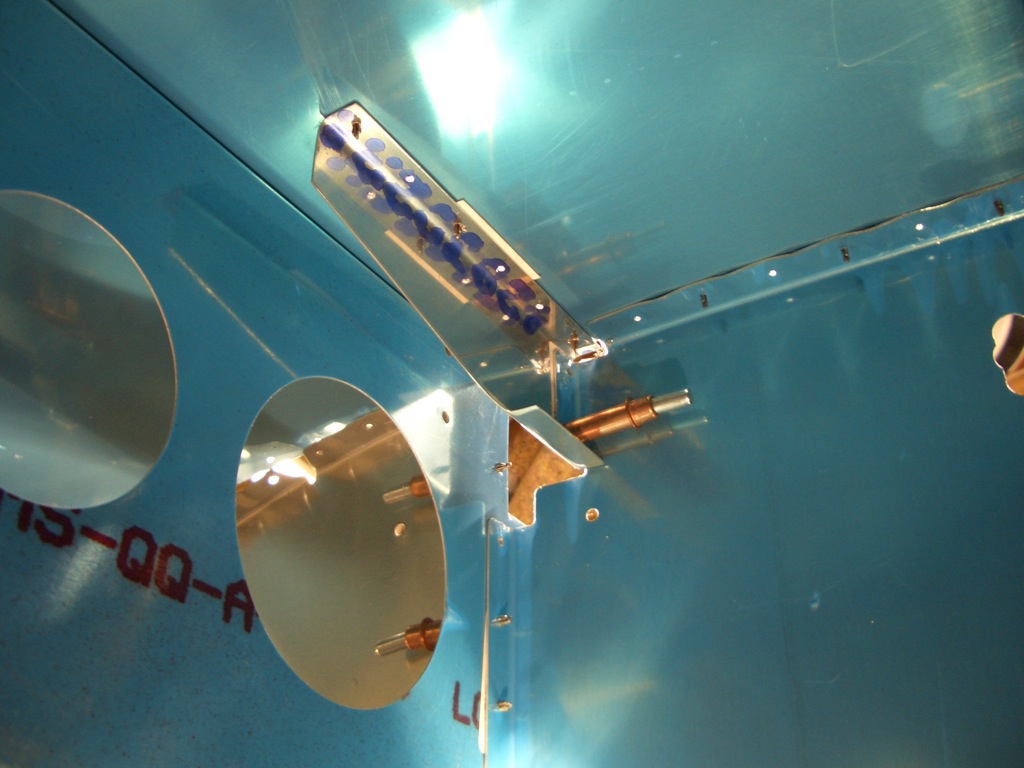

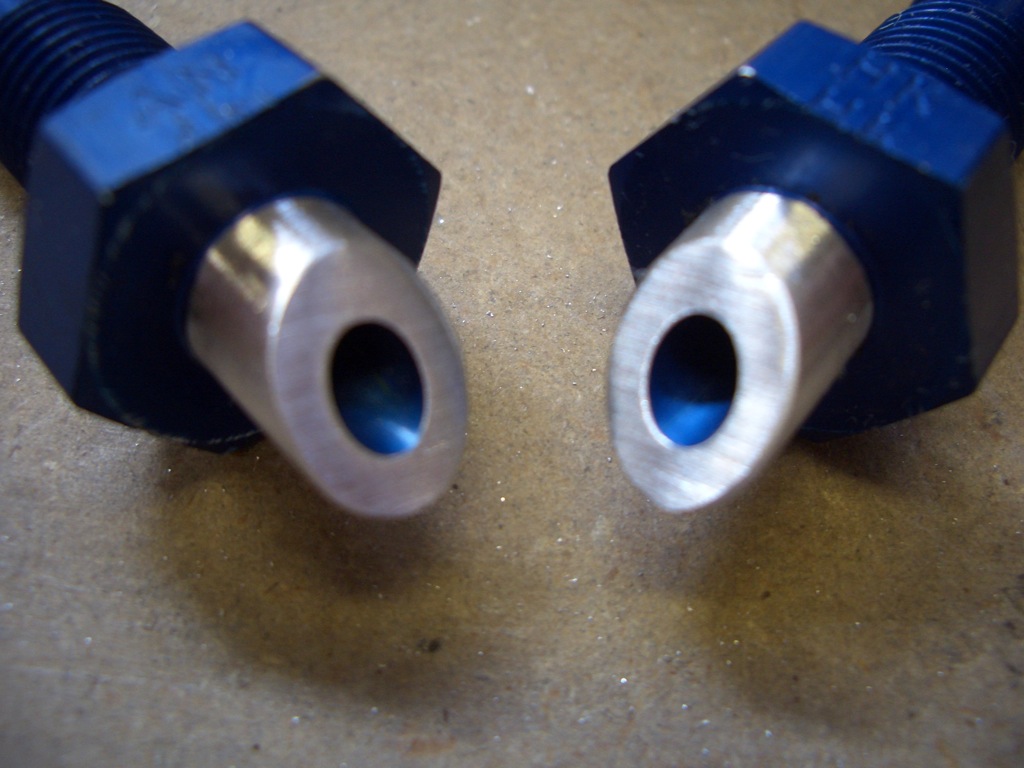

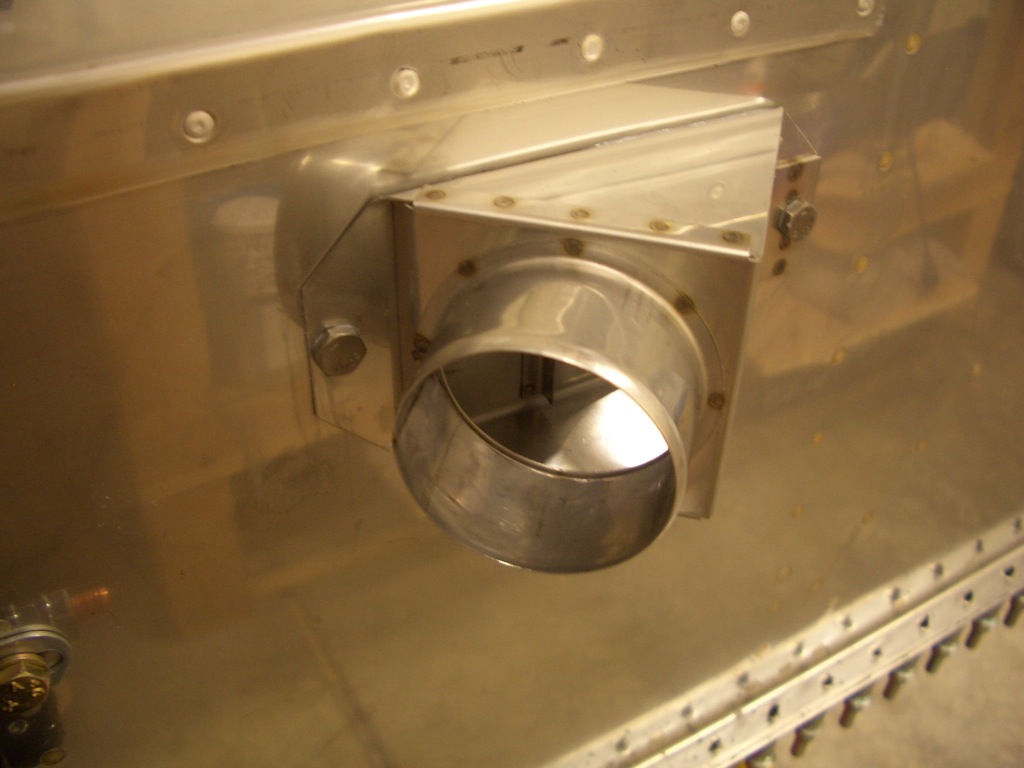

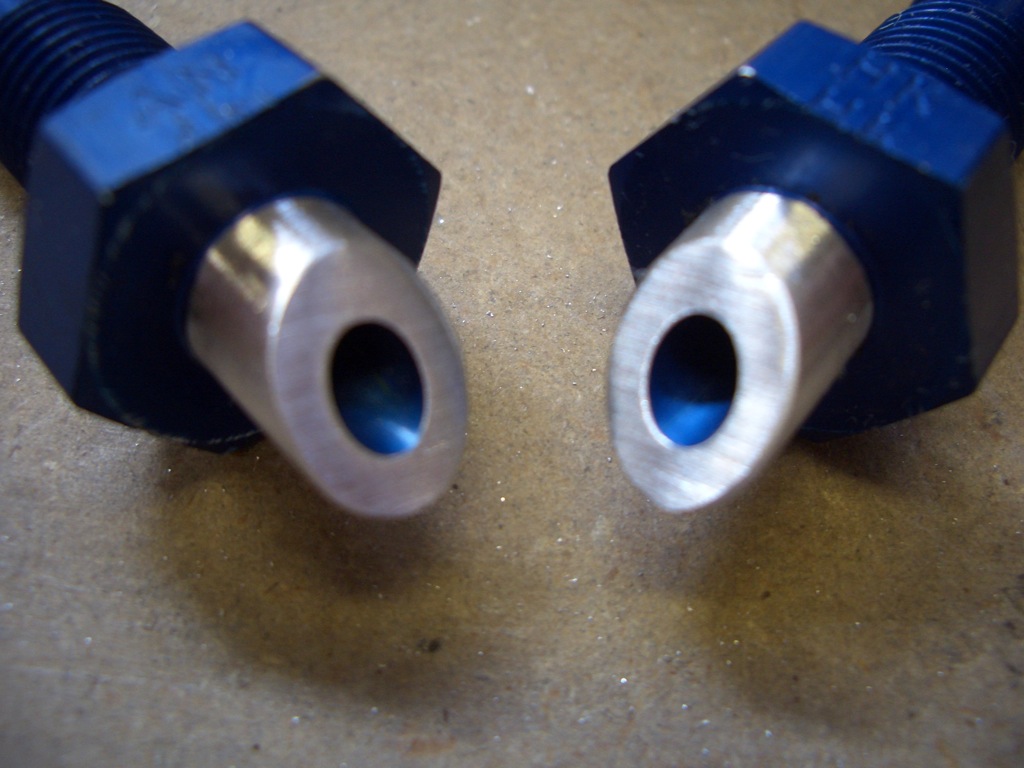

I knocked out the other fuel vent fitting this morning. For freehand work, it looks nearly identical to the one I did yesterday.

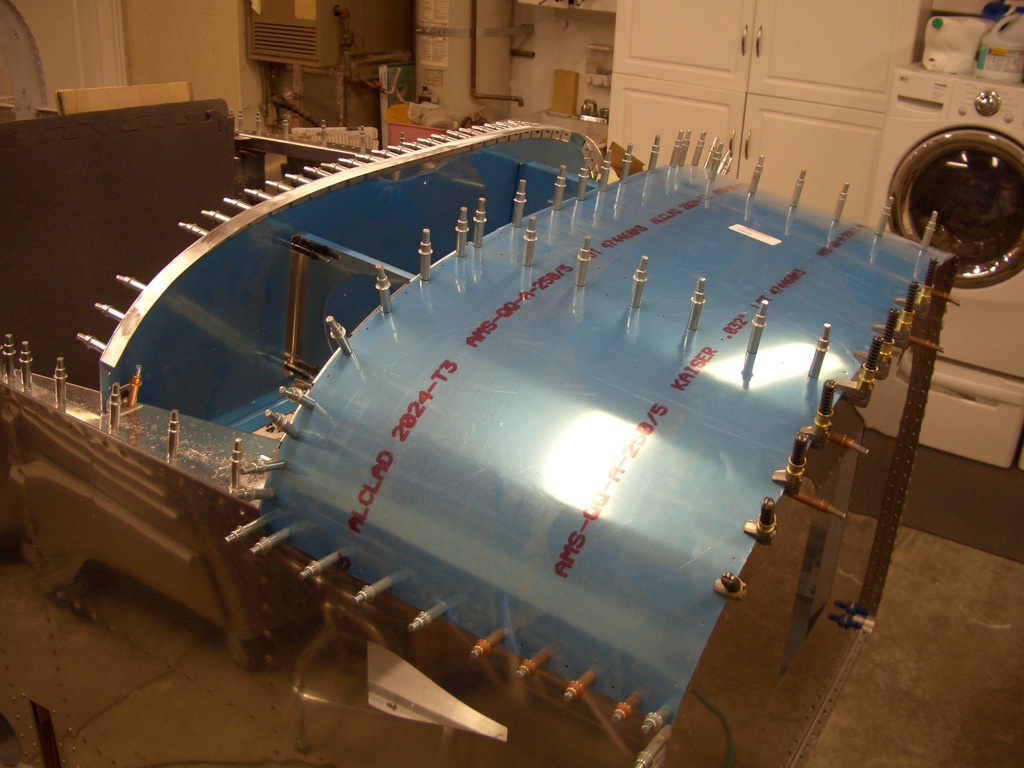

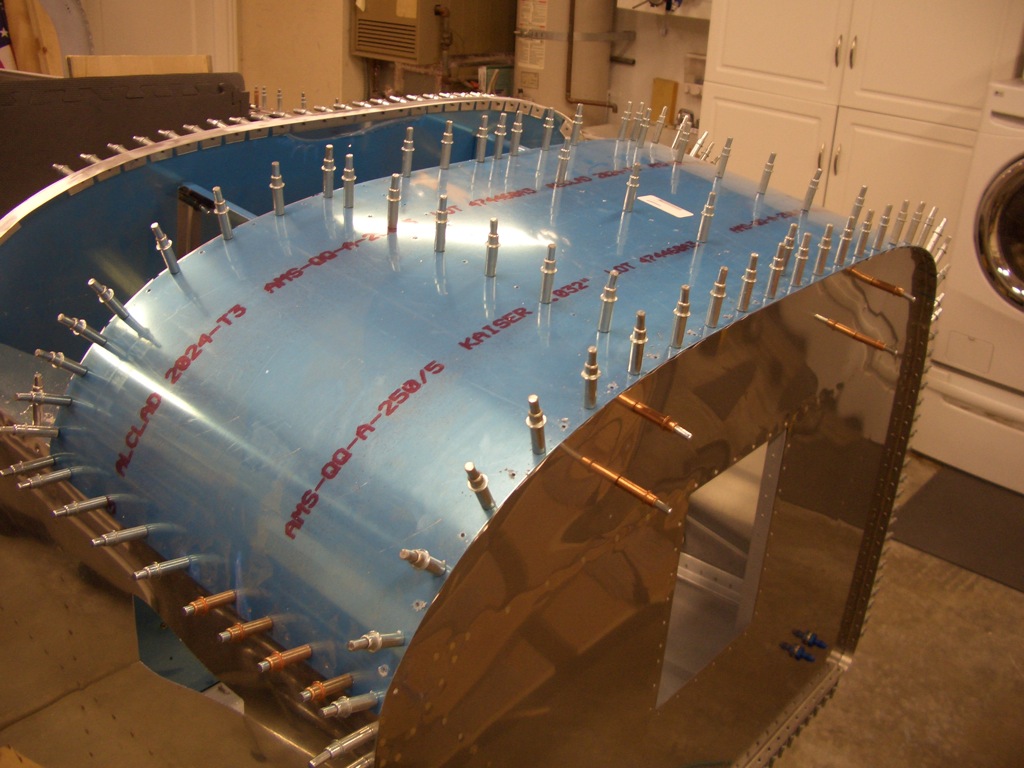

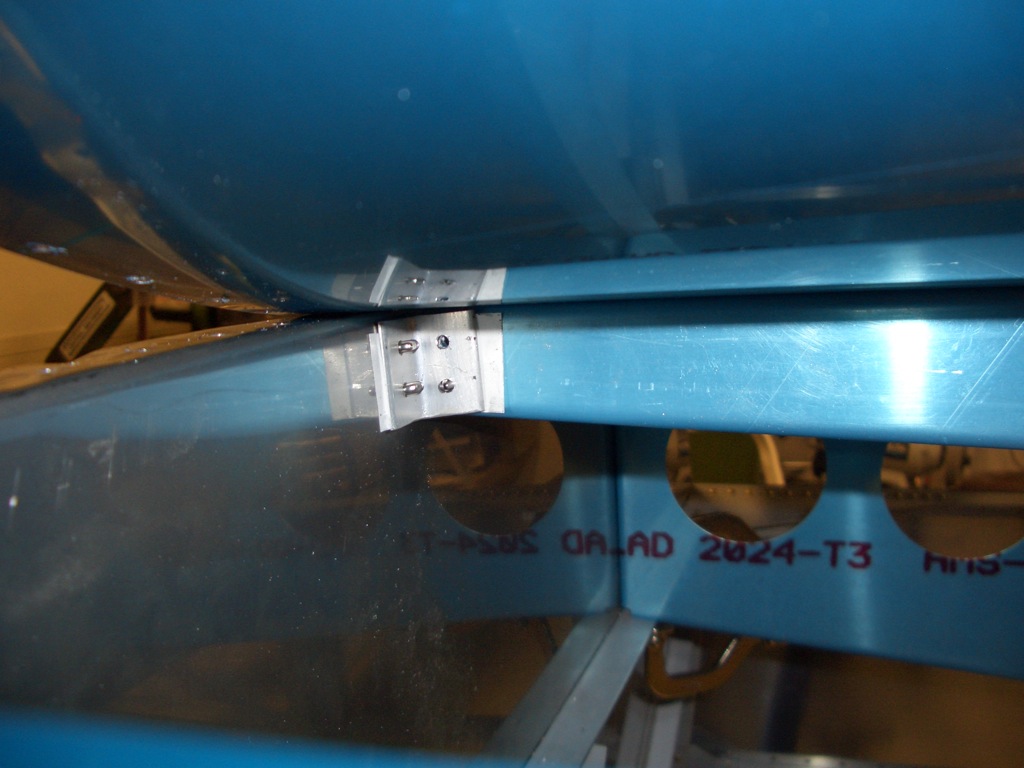

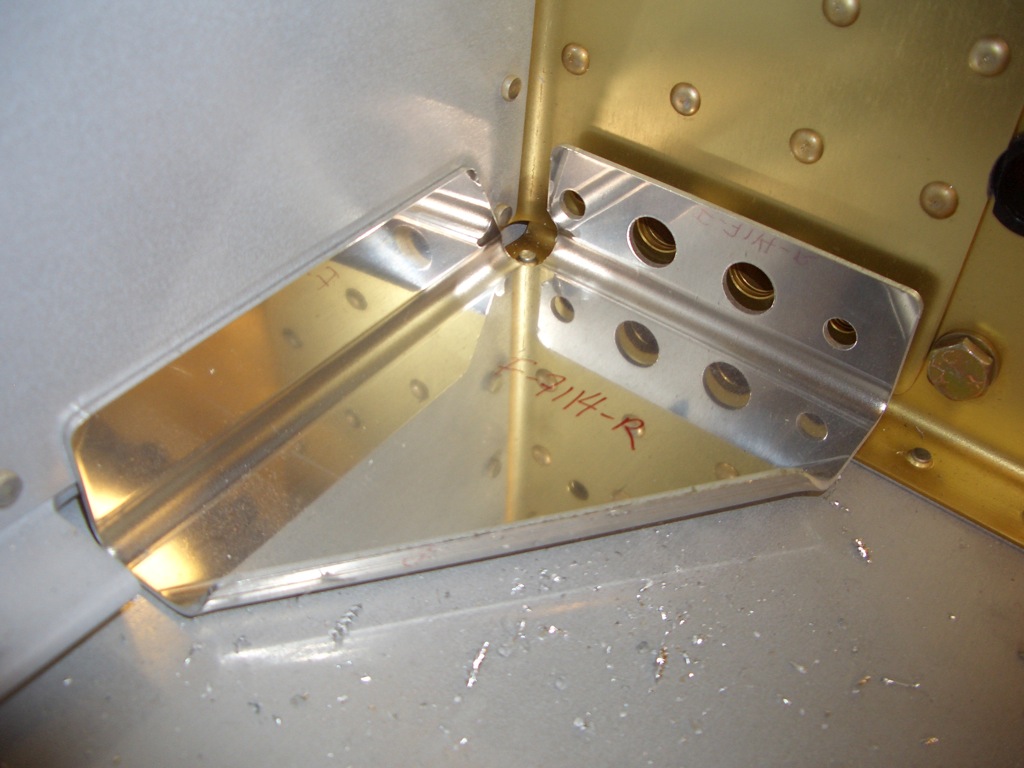

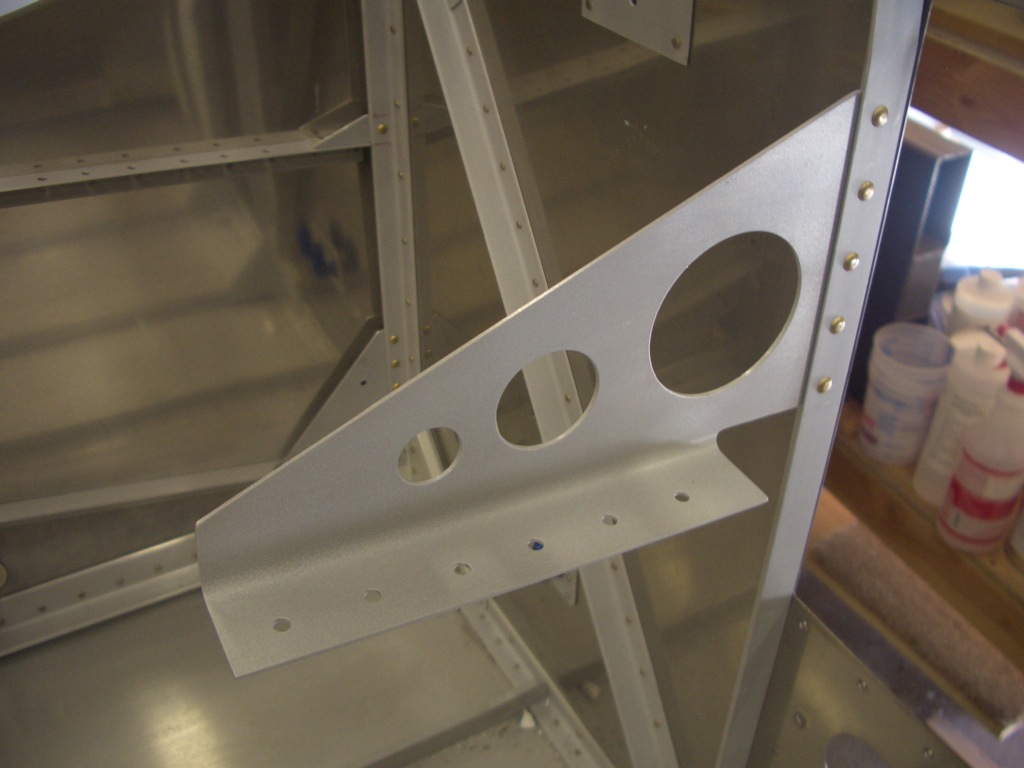

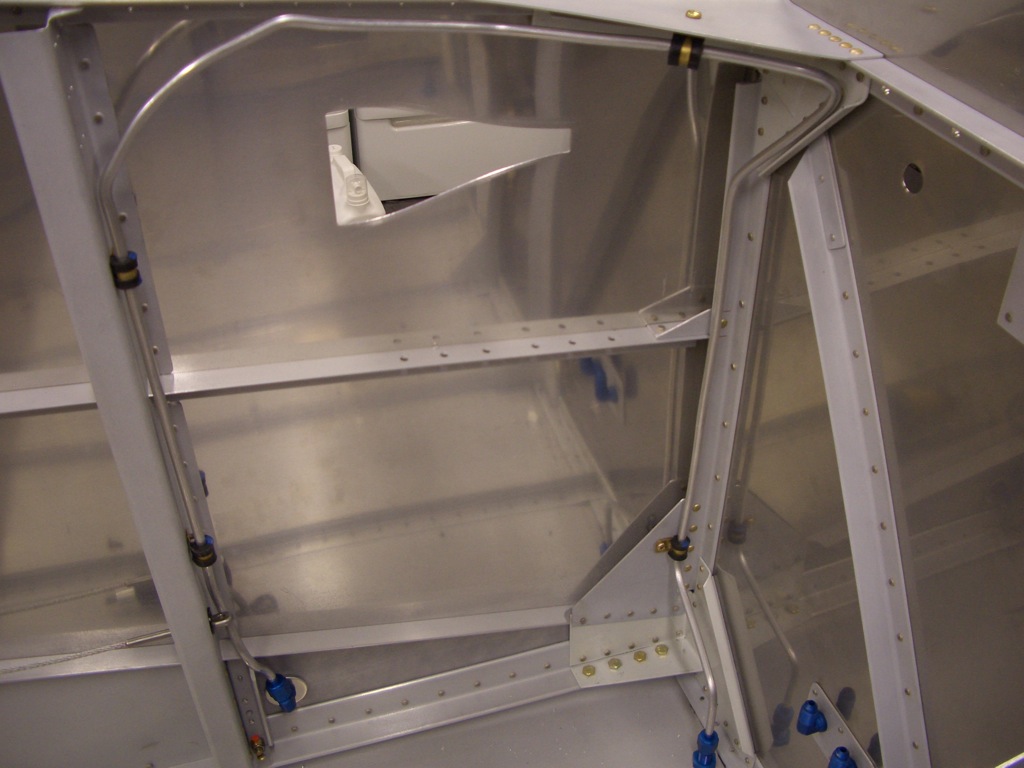

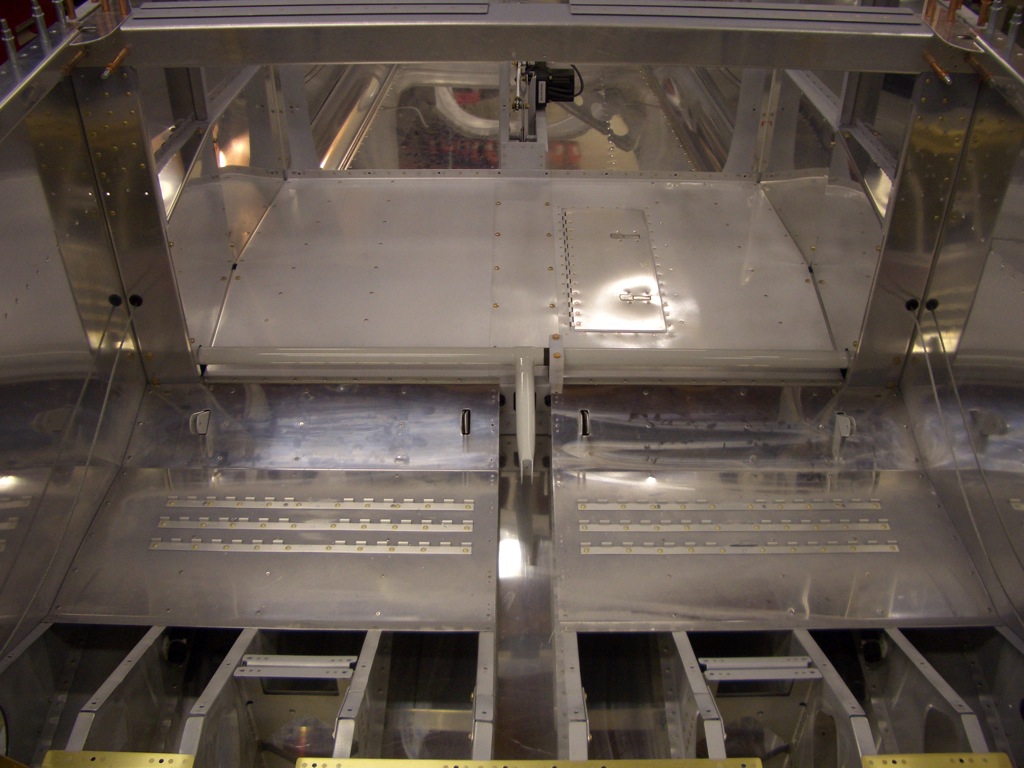

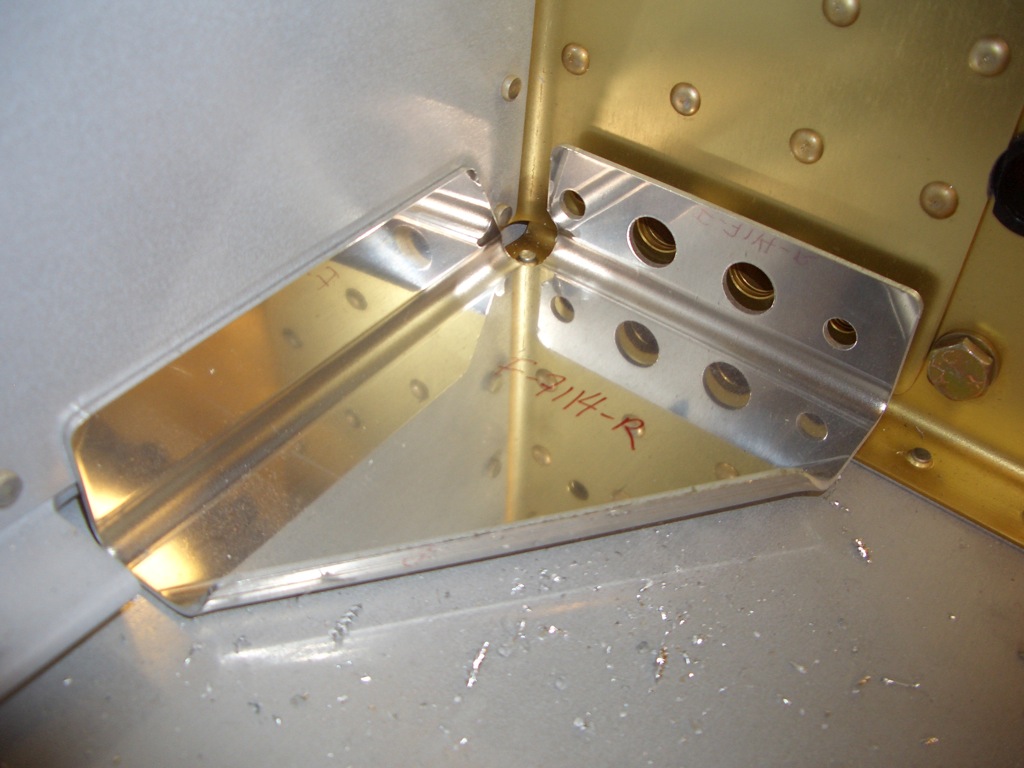

I started working on the F-7114 fuselage gussets. As other builders have noticed, one of the rivets on the side wall (on the left) interferes with the flange of this gusset, preventing it from resting against the spar.

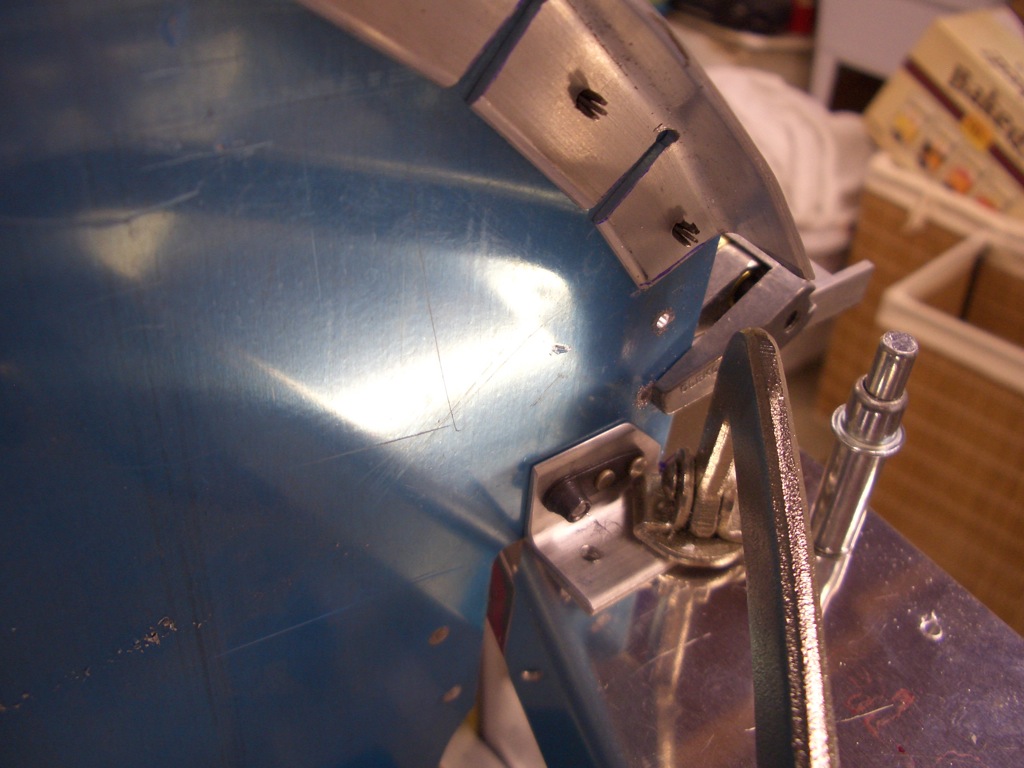

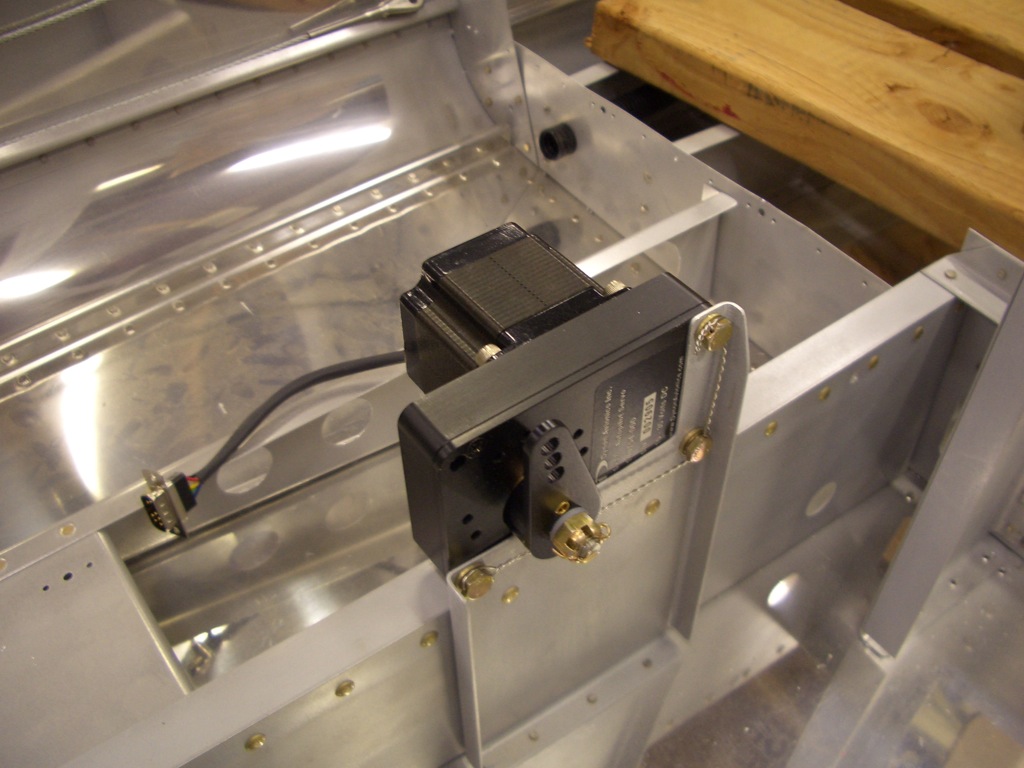

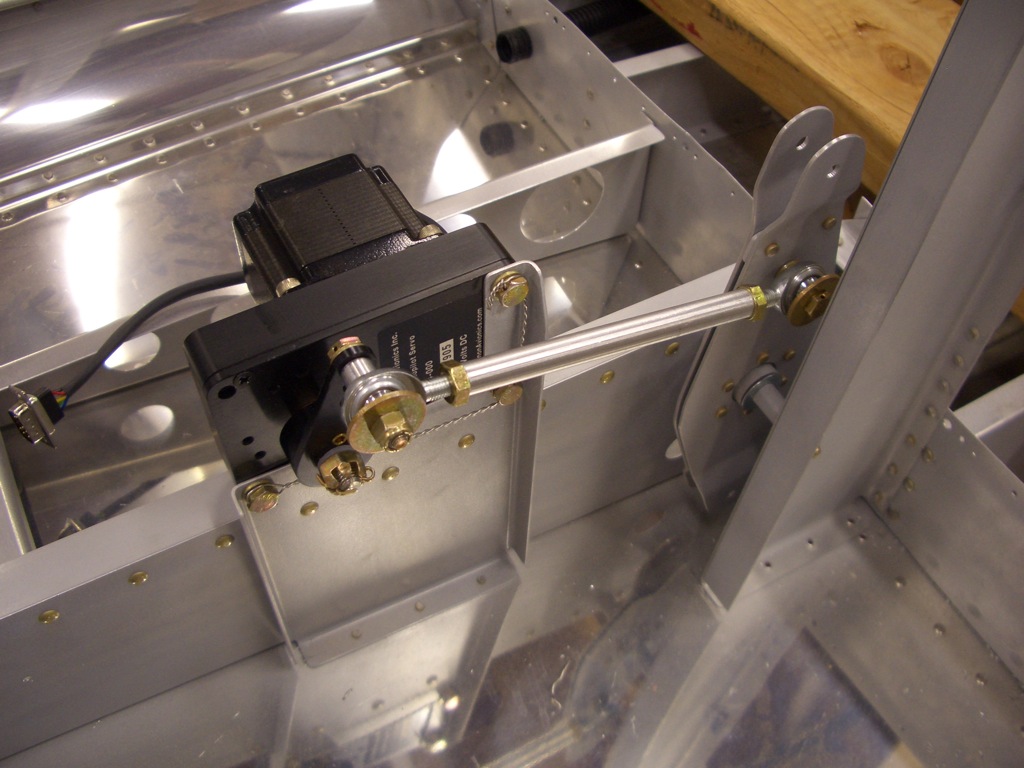

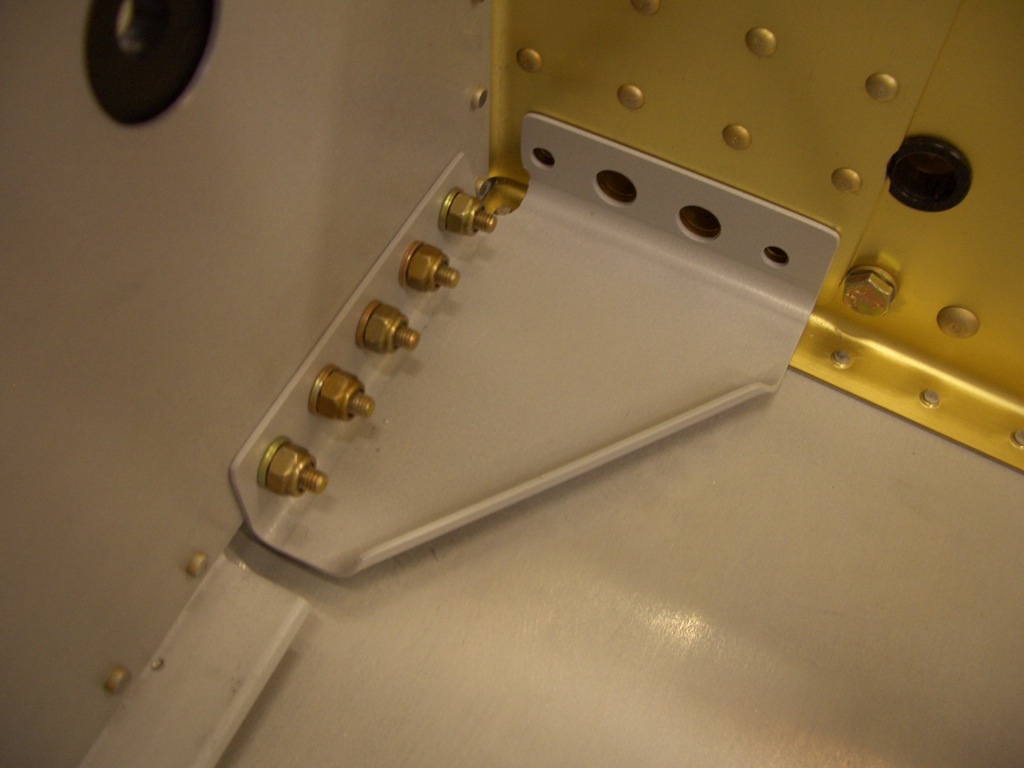

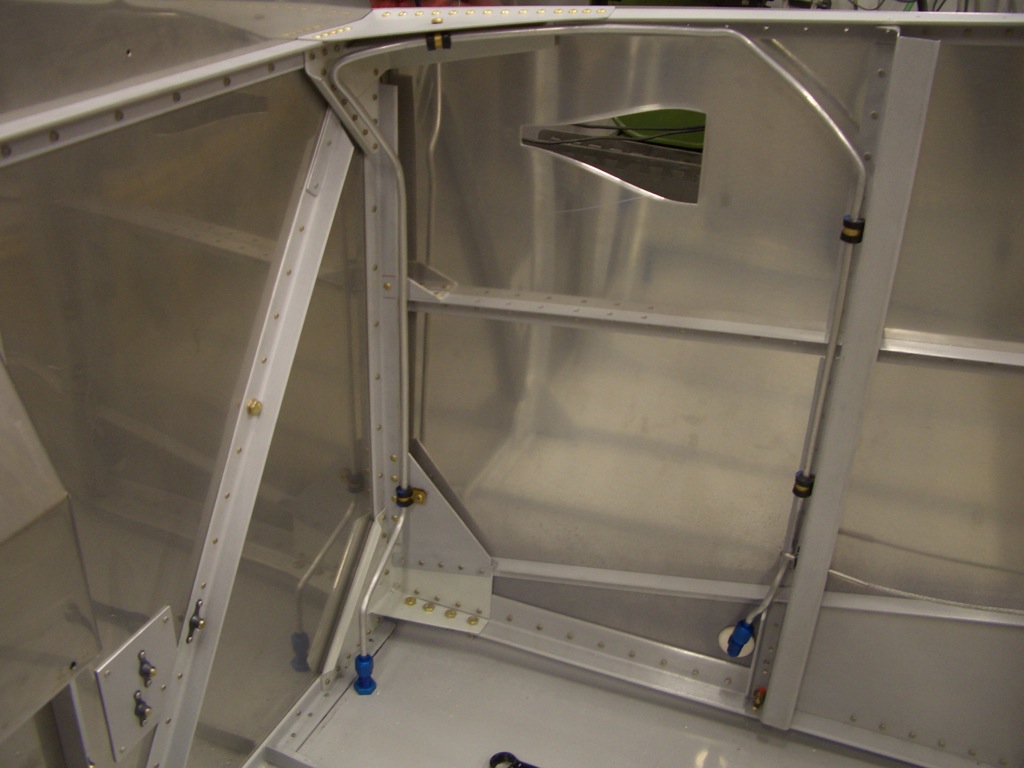

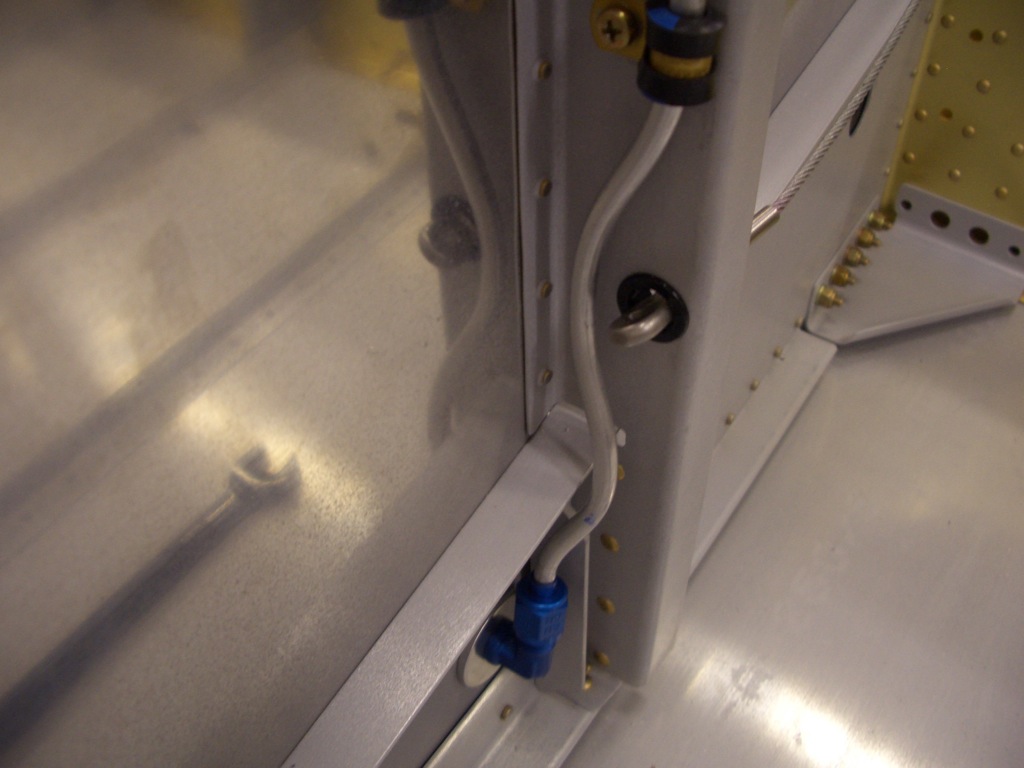

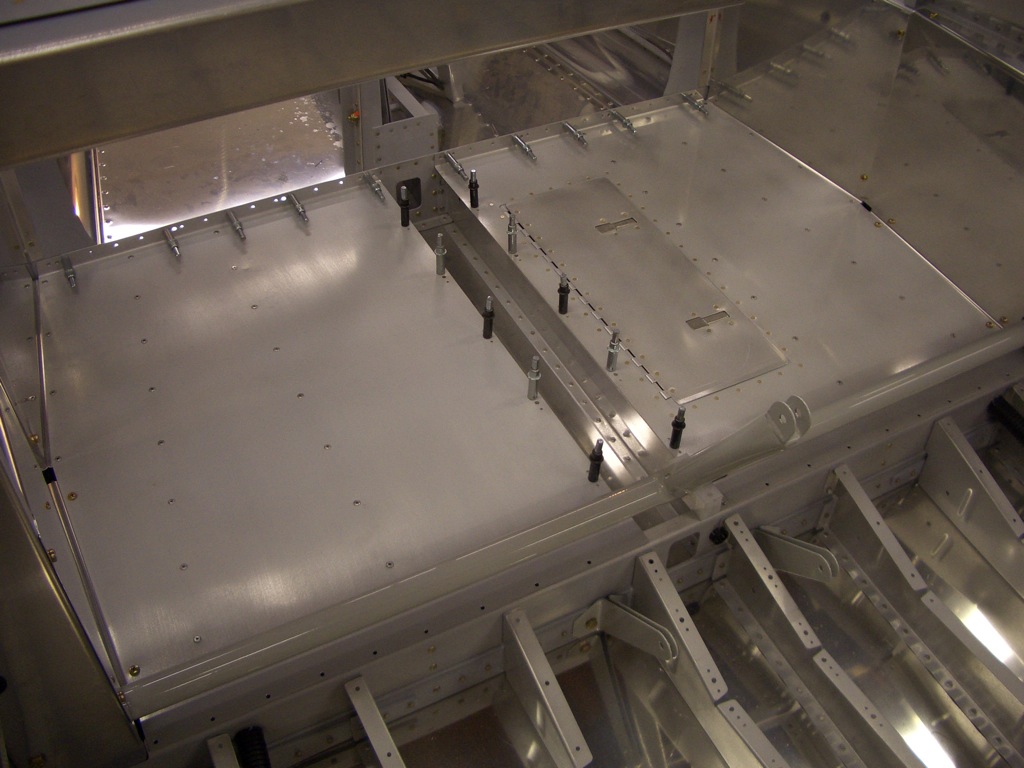

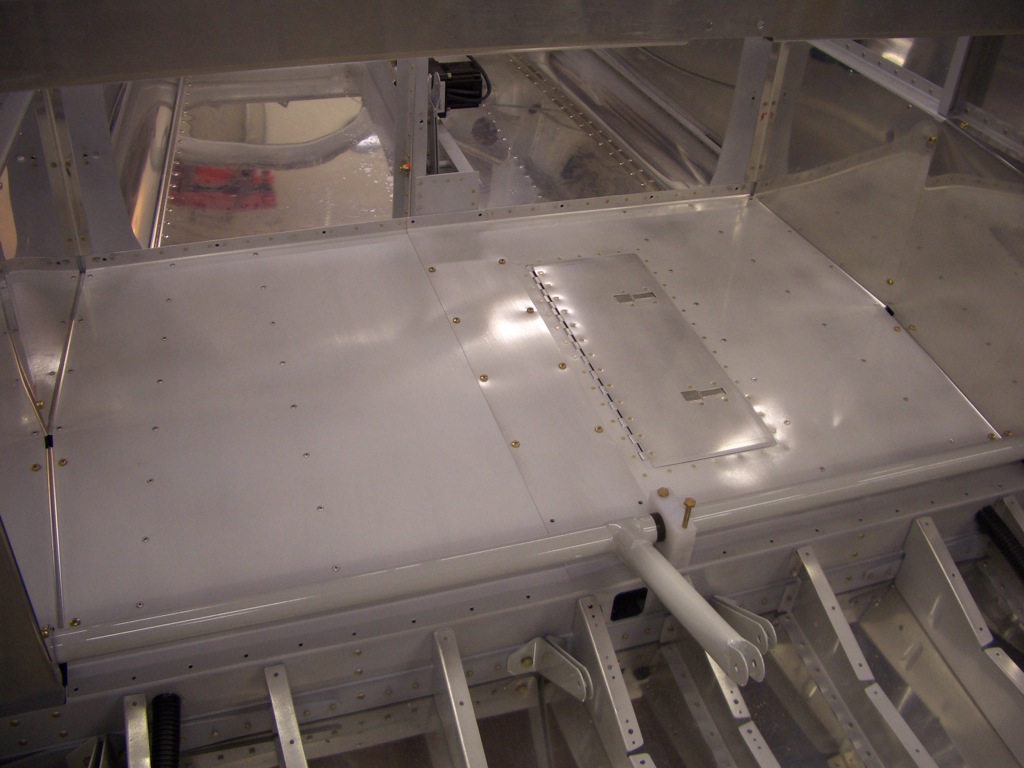

After relieving a bit of the gusset, I positioned it relative to the spar with some scrap bolts and drilled it to the side components. There are five layers of aluminum here (the side and bottom skins, the lower longeron, the gear web, and this gusset. This helps transfer load from the lower longeron to the spar.

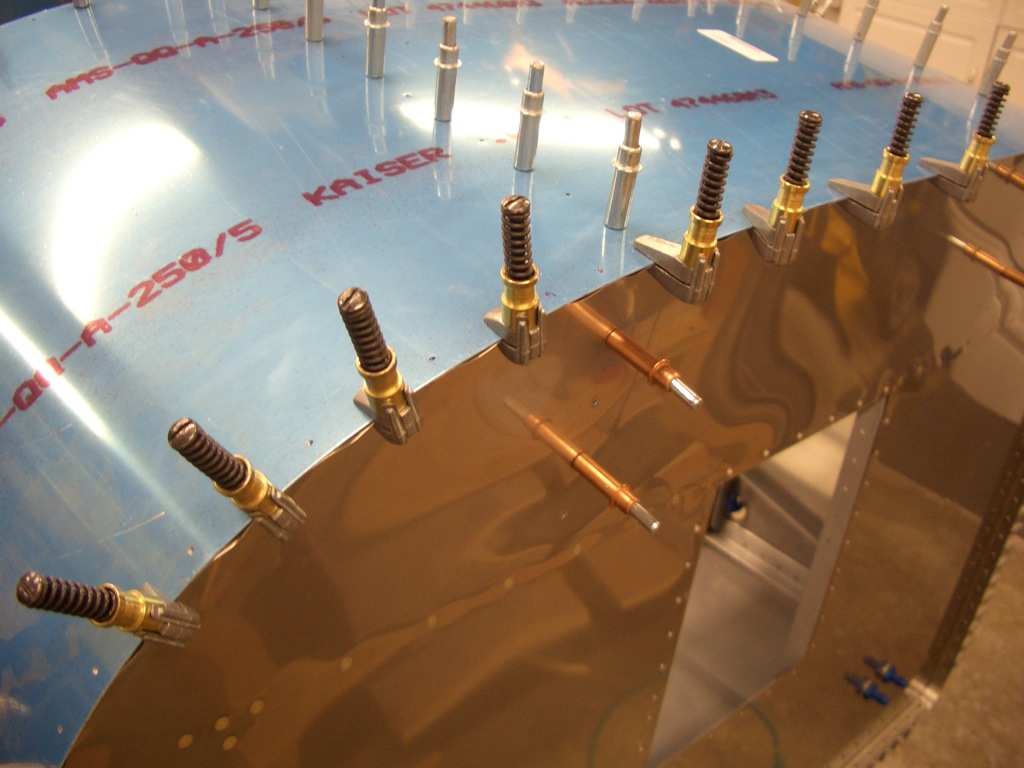

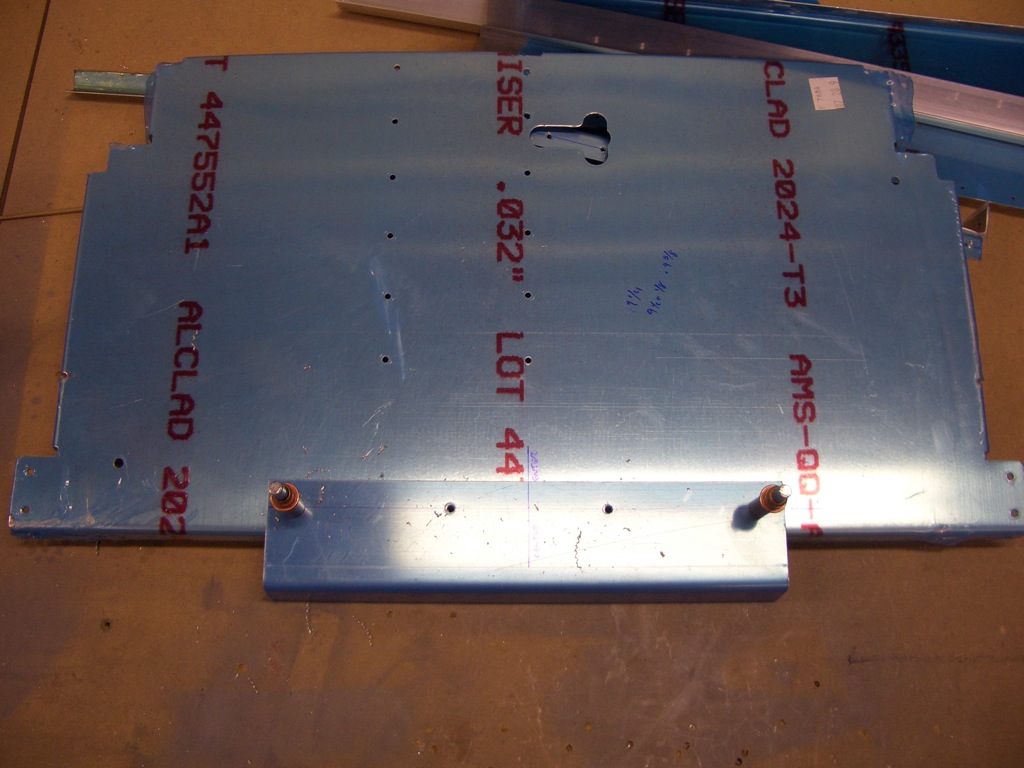

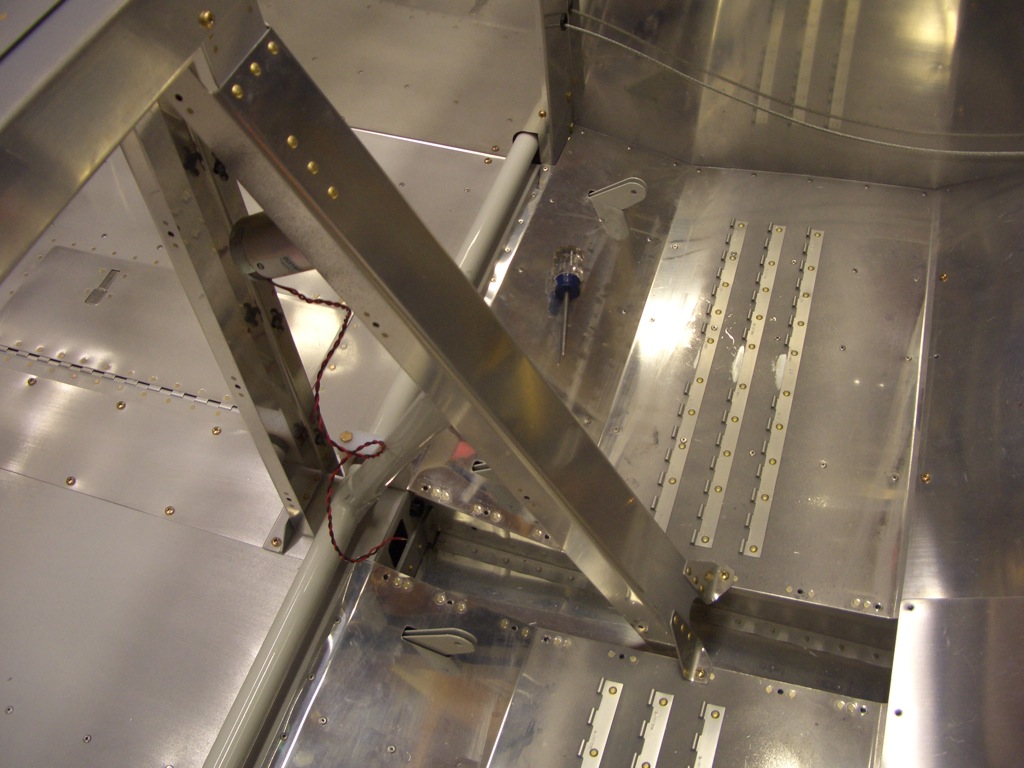

Here are these holes from the outside. I’ve only drilled them to #40 so far so that I could cleco the parts together to keep anything from shifting.

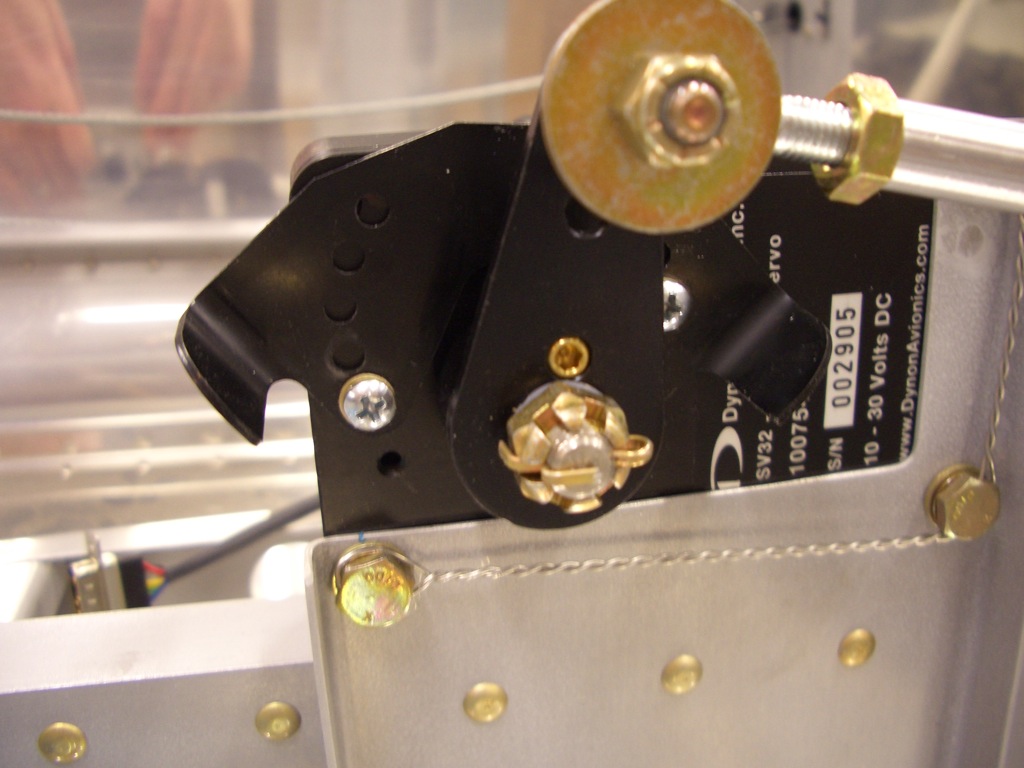

I then drilled/reamed the holes for AN3 bolts.

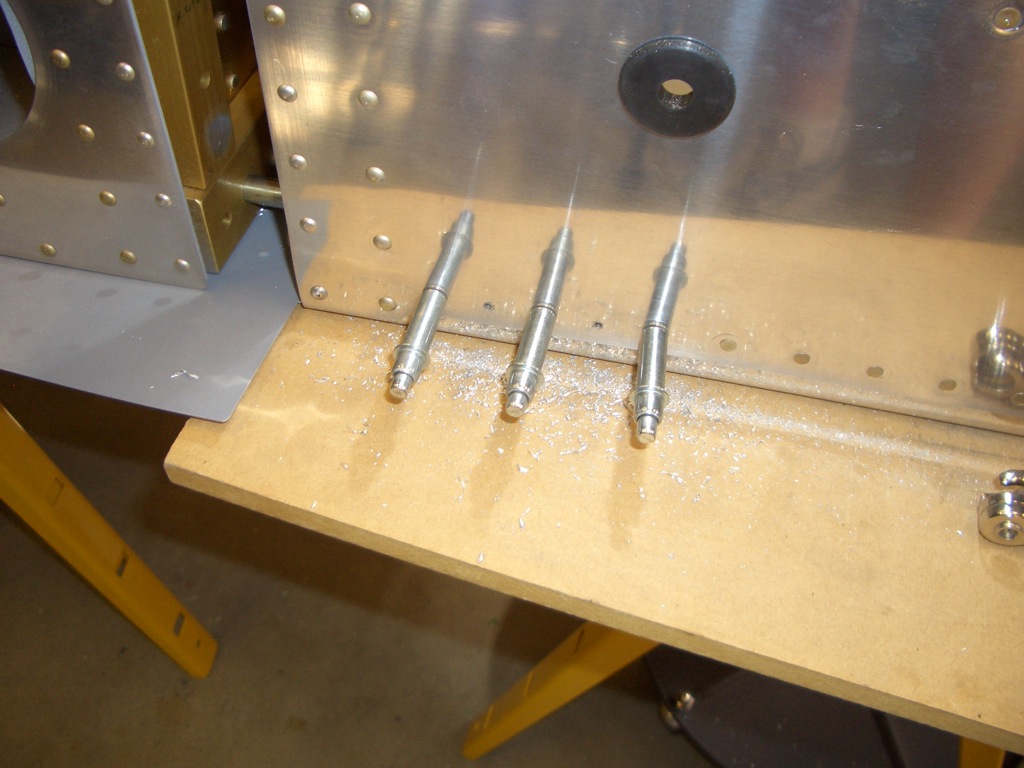

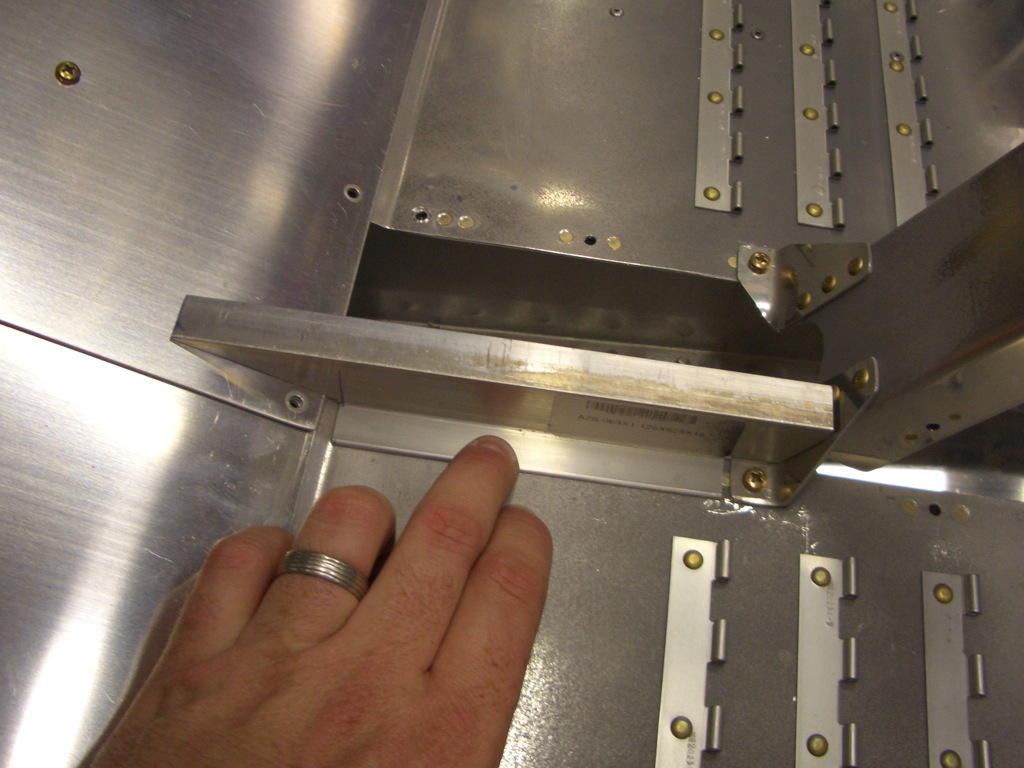

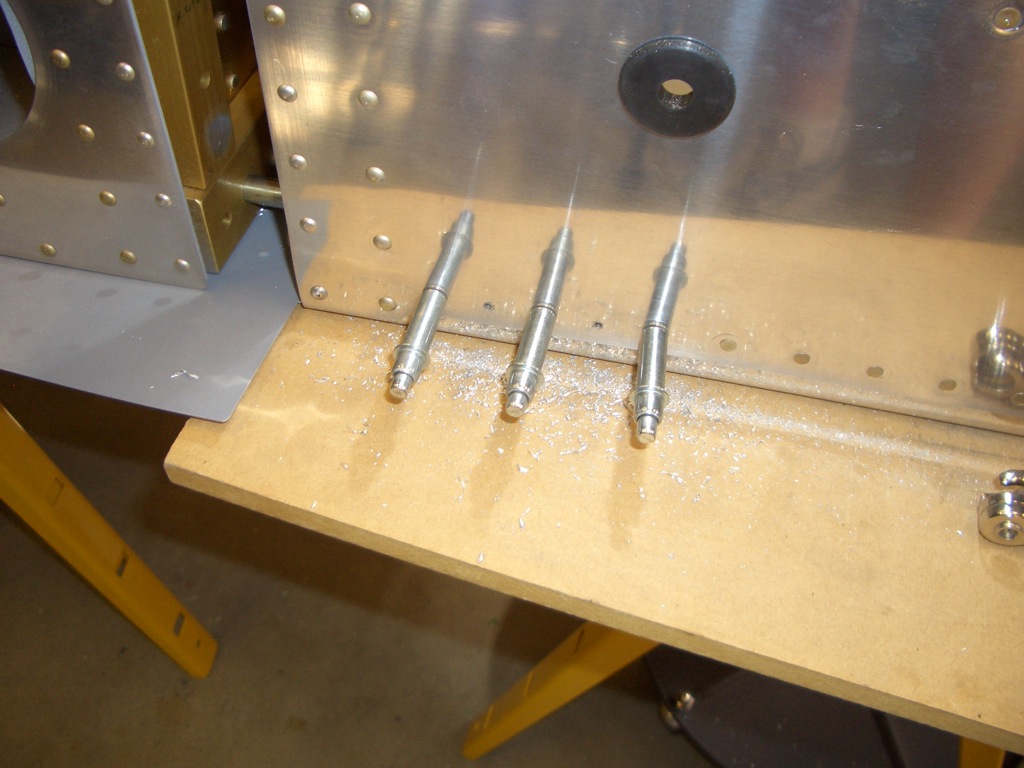

I purchased a long hardware store 7/16″ bolt a long time ago to make a drift pin to use when installing the wings. For some reason, I decided to do that tonight. I ground down the threads and beveled the shank in a couple of spots. When the wings are installed, this can be lubricated and hammered into place to pull the holes into alignment.

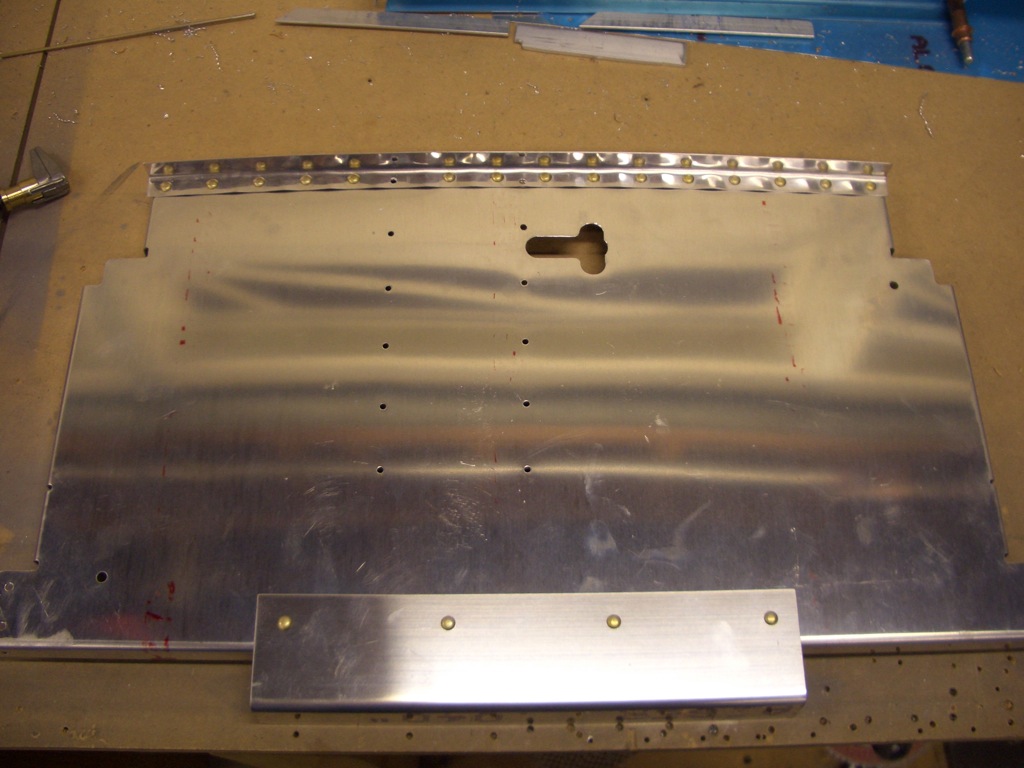

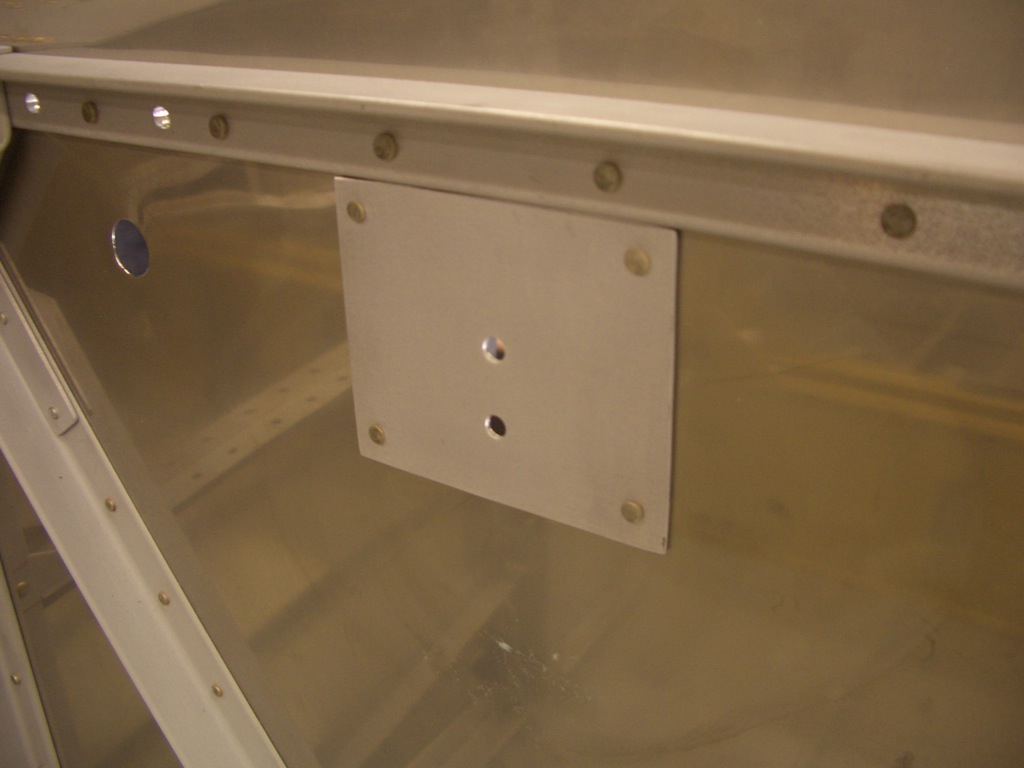

I finished the night by priming a small stack of parts that has been piling up.