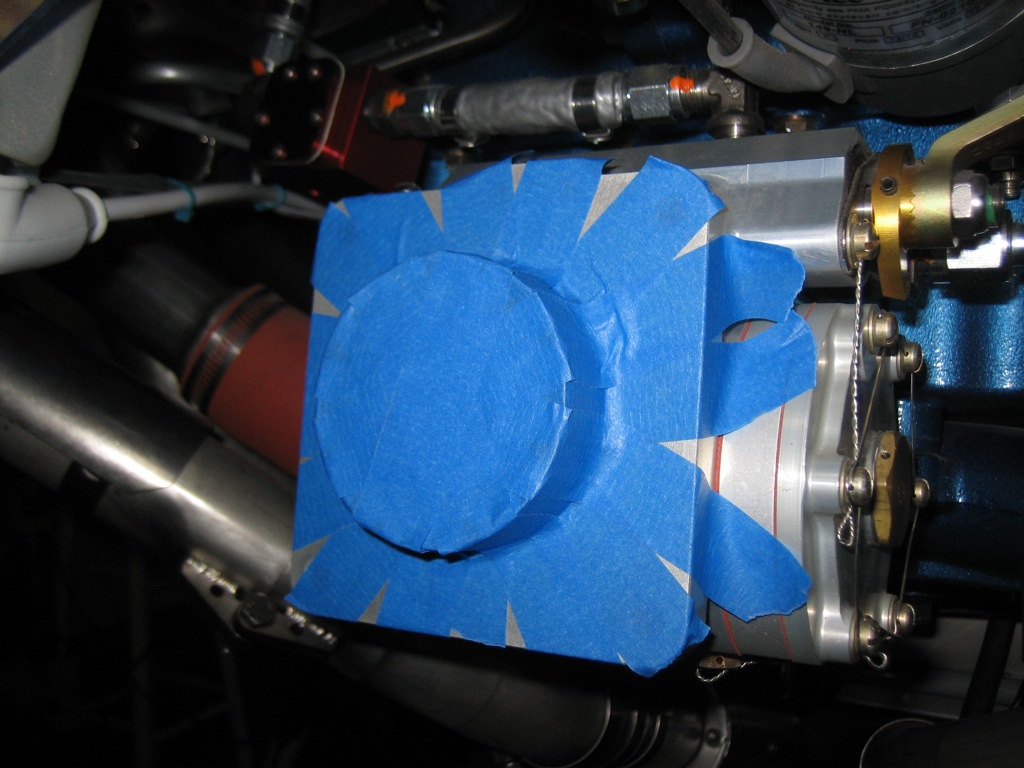

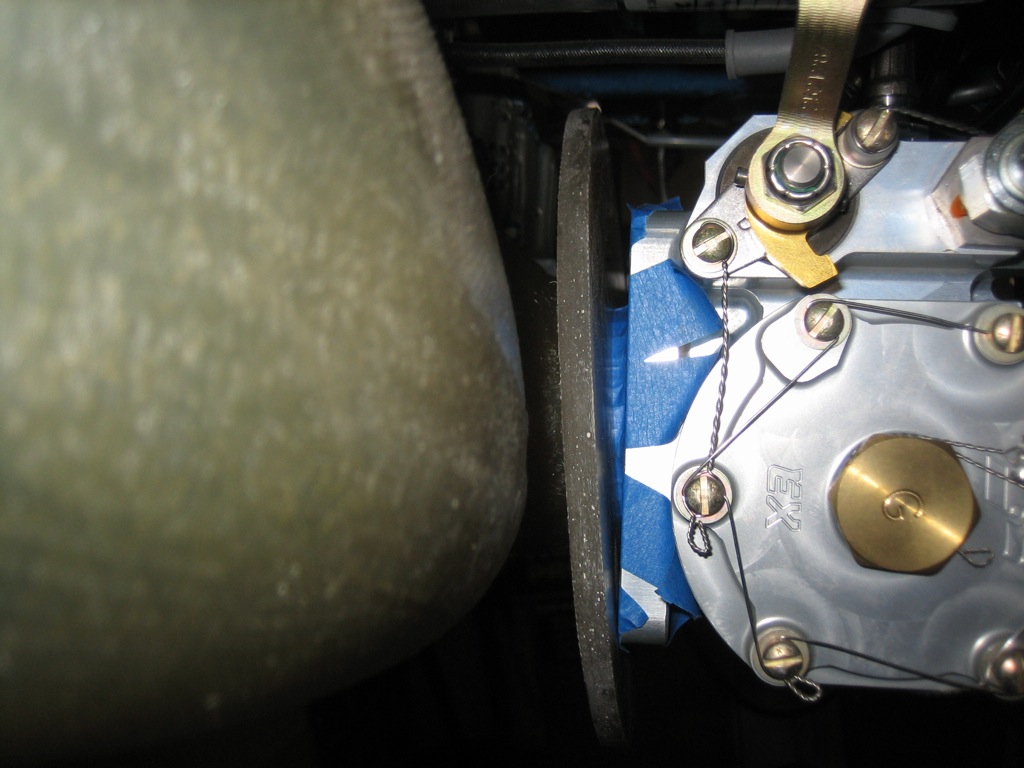

I never liked the old tach cover (see this entry). Although it was safety wired, that didn’t prevent it from unscrewing and bouncing around behind the engine. I recently found out that Andair made this nice machined tach cover with integral o-ring. I swapped it out and safety wired it to the same spot on the engine. There’s no way this is coming off.

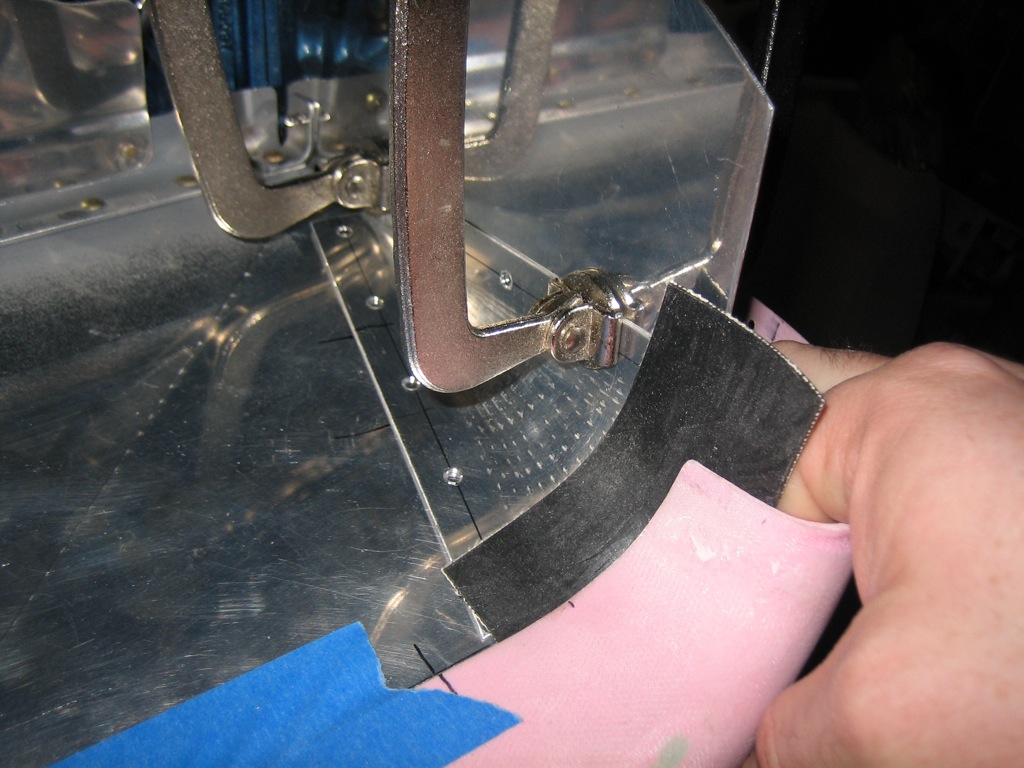

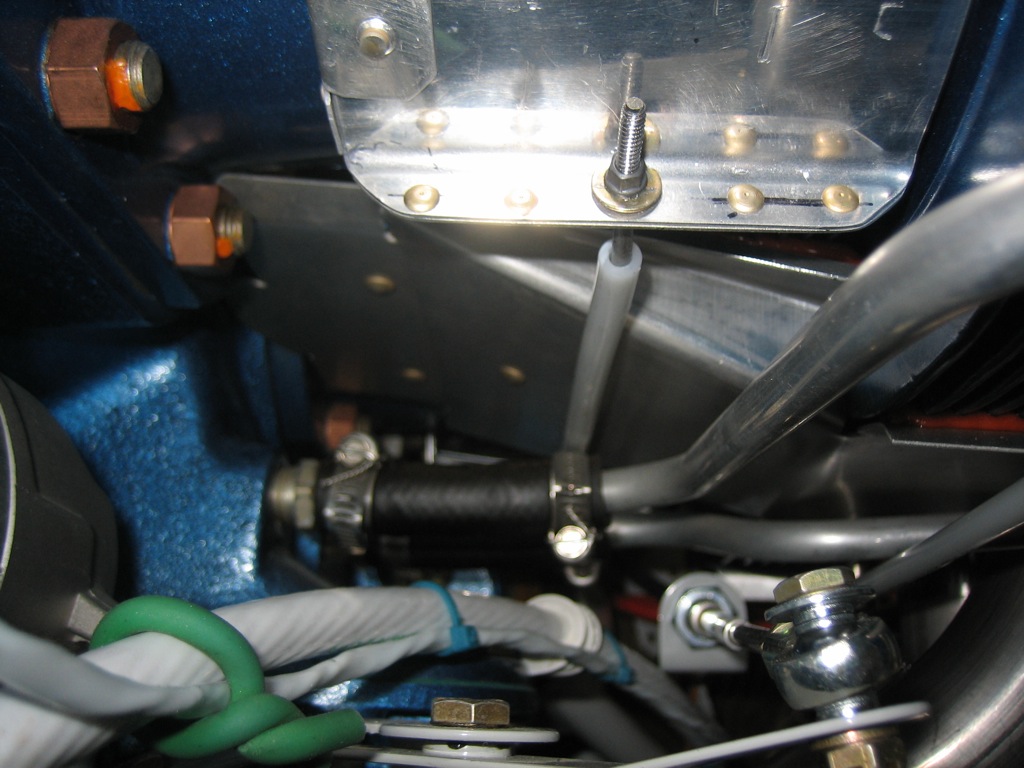

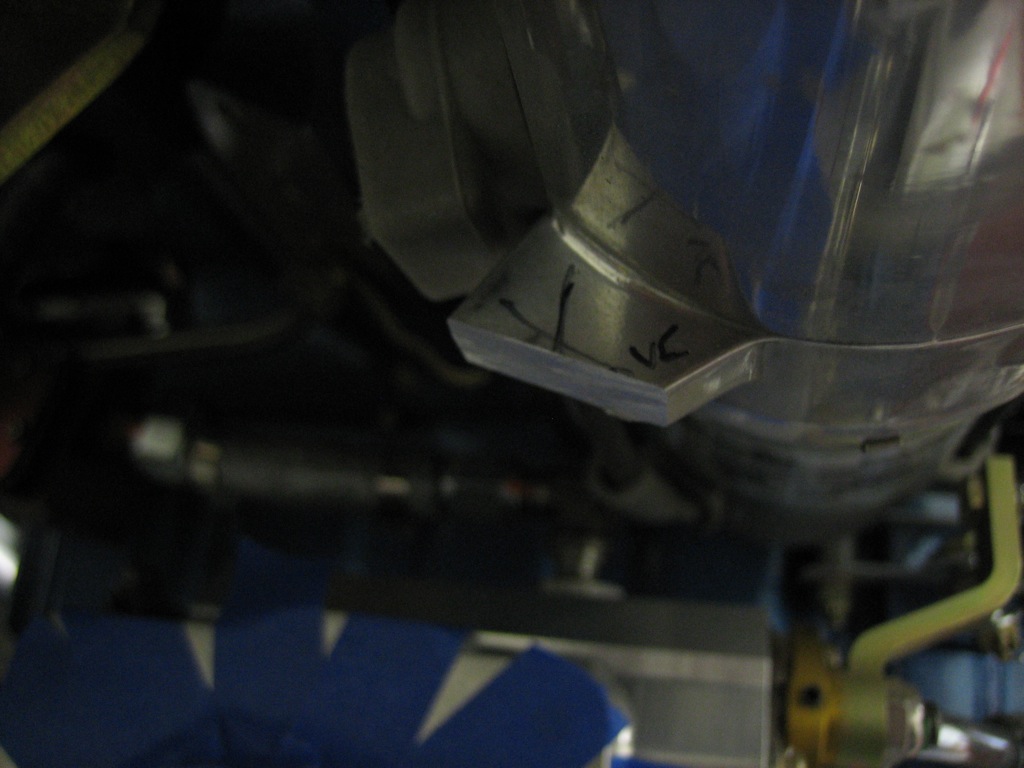

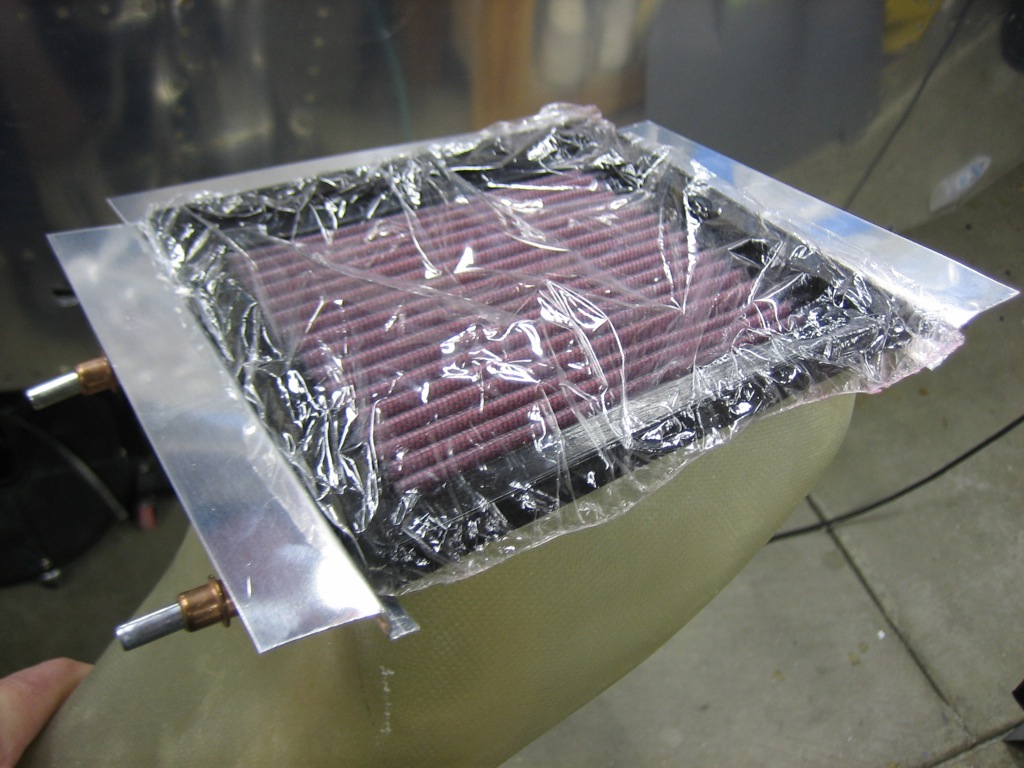

I fabricated the three front ramp support brackets. This is the one that ties the right ramp to the right center baffle. I left the bottom flange long on both ends until I know the left-right position of the vertical face. I’ll then drill this to the right ramp and cut the ends of the flange parallel with the angle on the left.

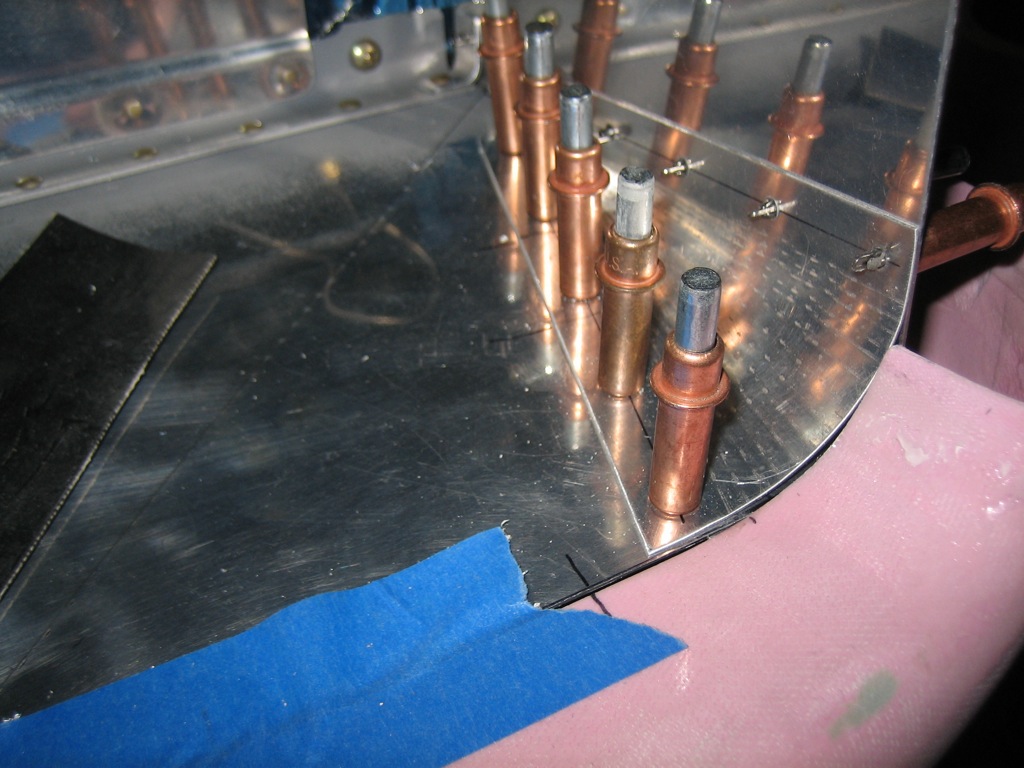

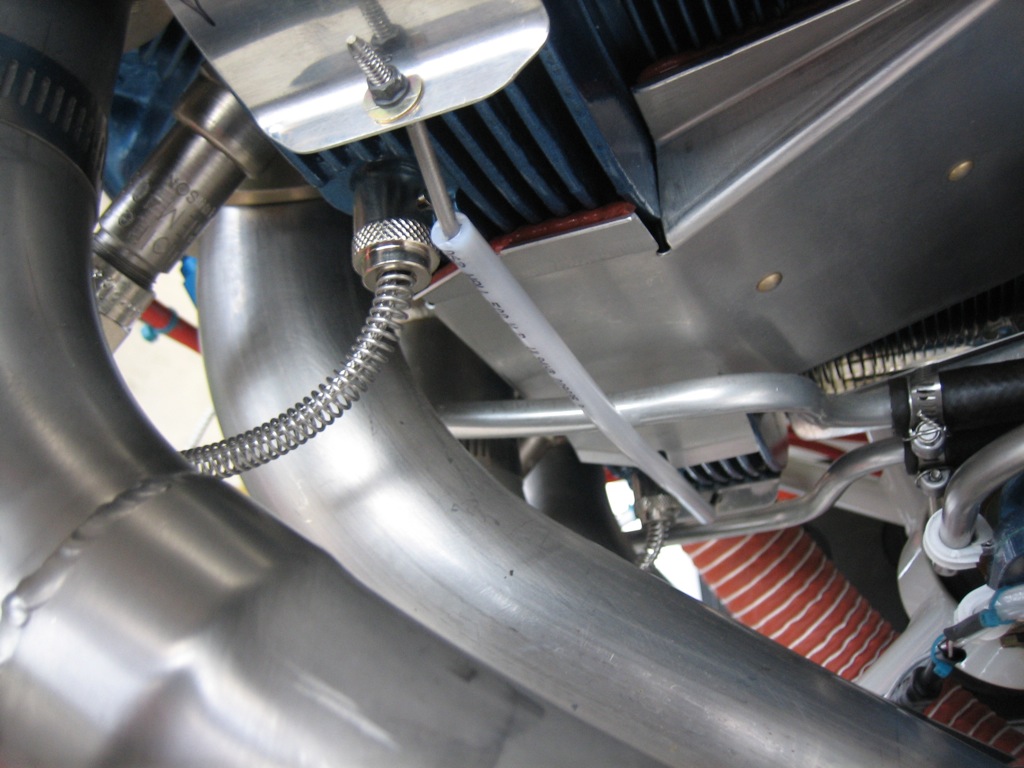

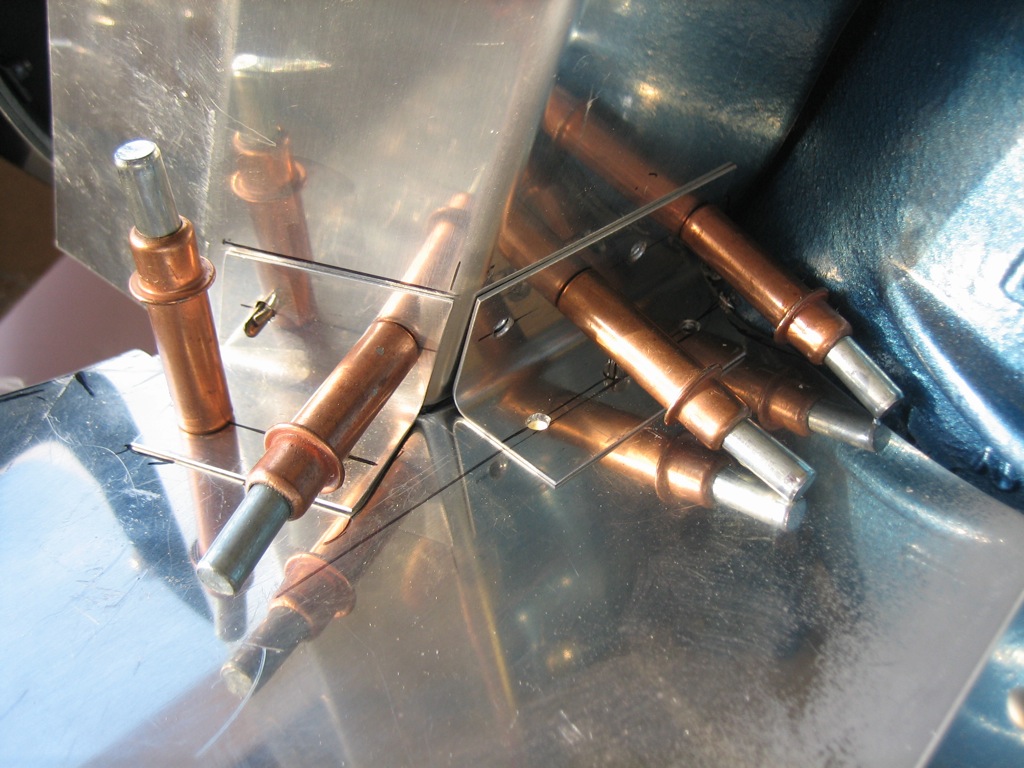

These are the brackets that tie the left ramp to the left center baffle. I positioned the vertical face against the side of the lower cowl inlet (with a piece of baffle seal between them) and then drilled the support on the left to lock in the position. I then pulled the lower cowl and back drilled the support on the right through the existing hole in the ramp and support that sits just under the ramp. I then pulled the bracket and drilled two more holes in line with that hole and then match drilled them to the ramp. Getting all of this in the right position was a little tricky until I figured out the order, but everything worked out nicely.

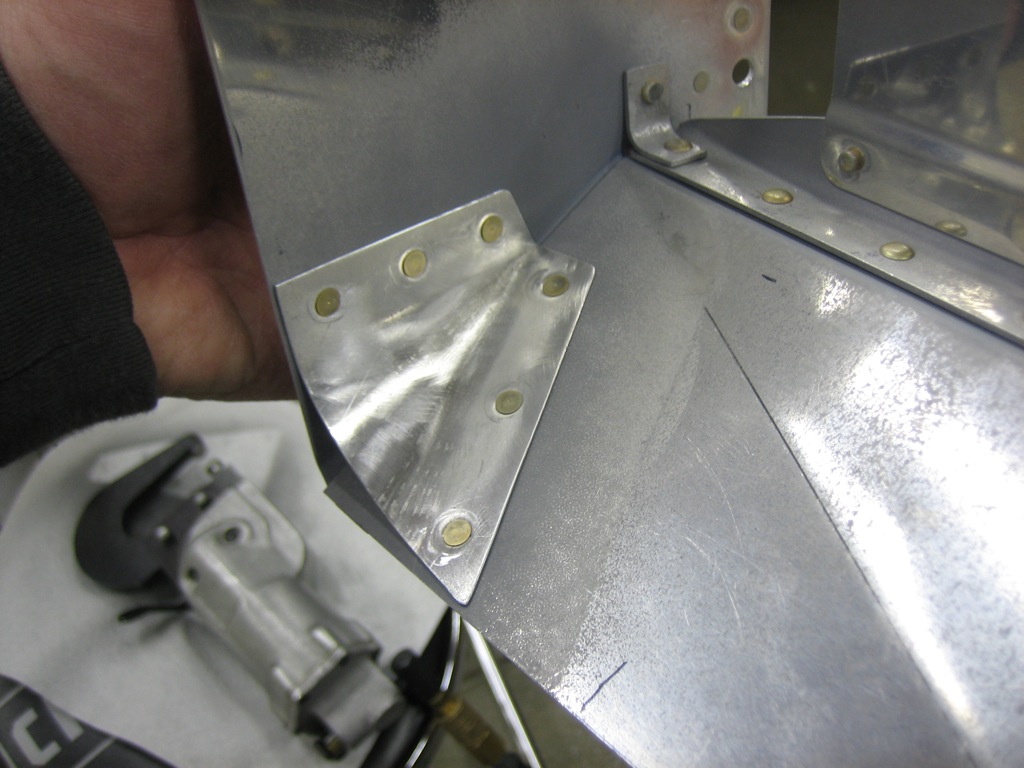

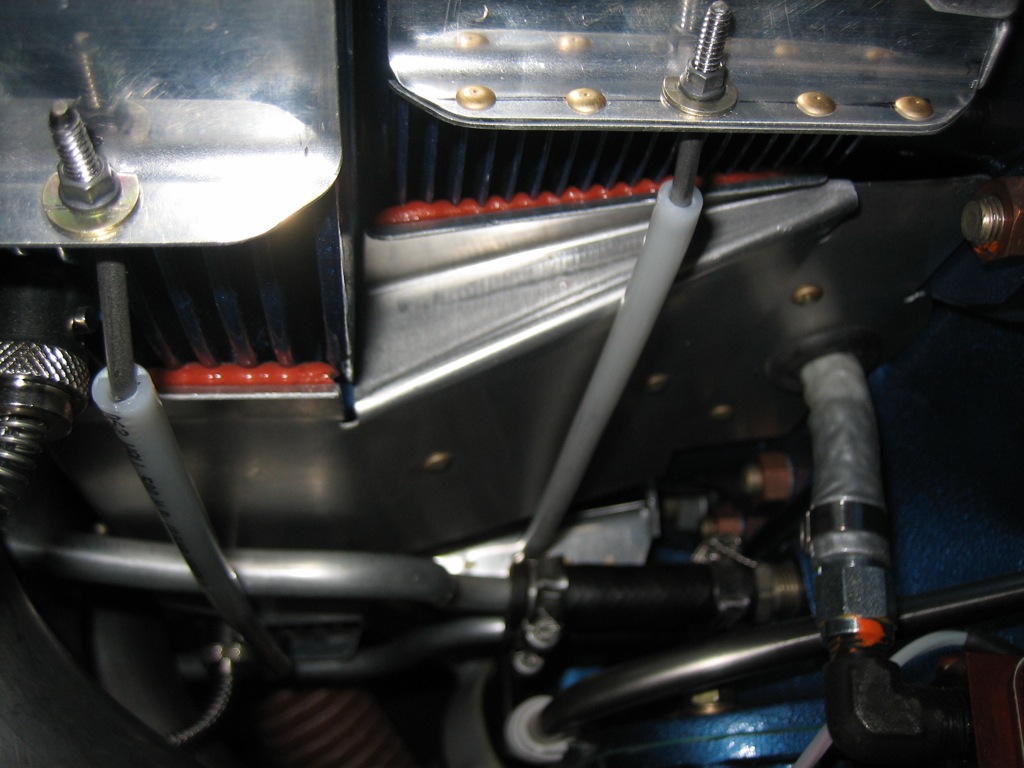

I deburred everything and riveted the support brackets to the ramps and front center baffles. The plans call for universal rivets here, but I might have to swap the rivets on the left bracket out for a flush head since the baffle seal material will rest here.

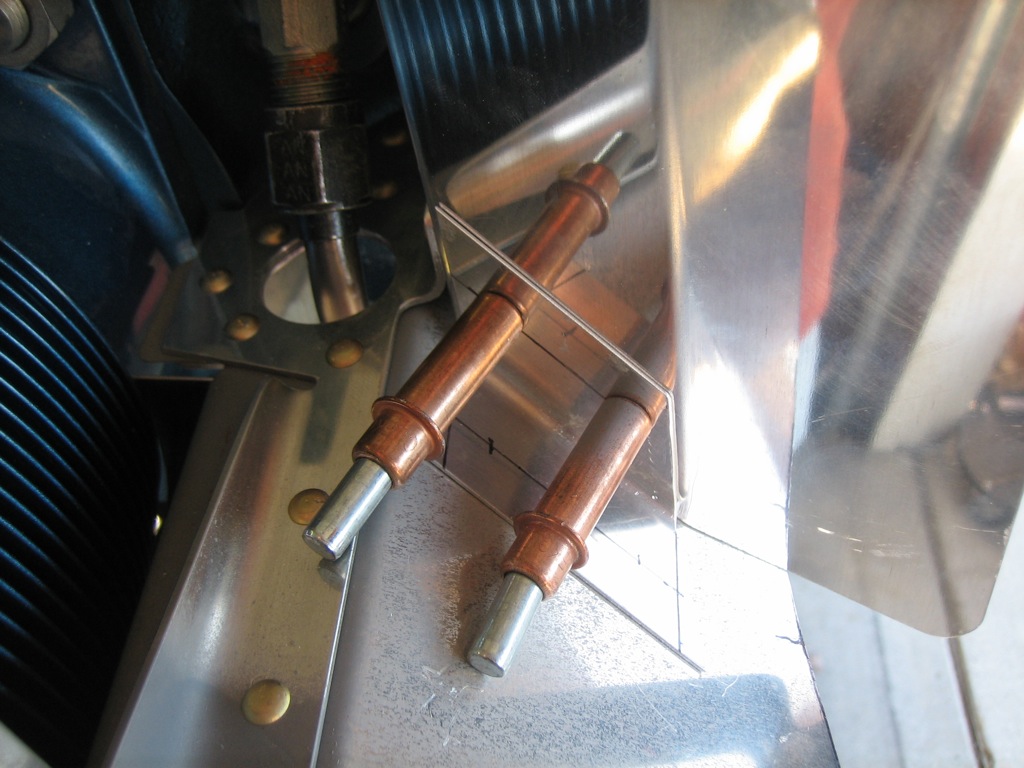

Here’s the bracket for the right ramp.