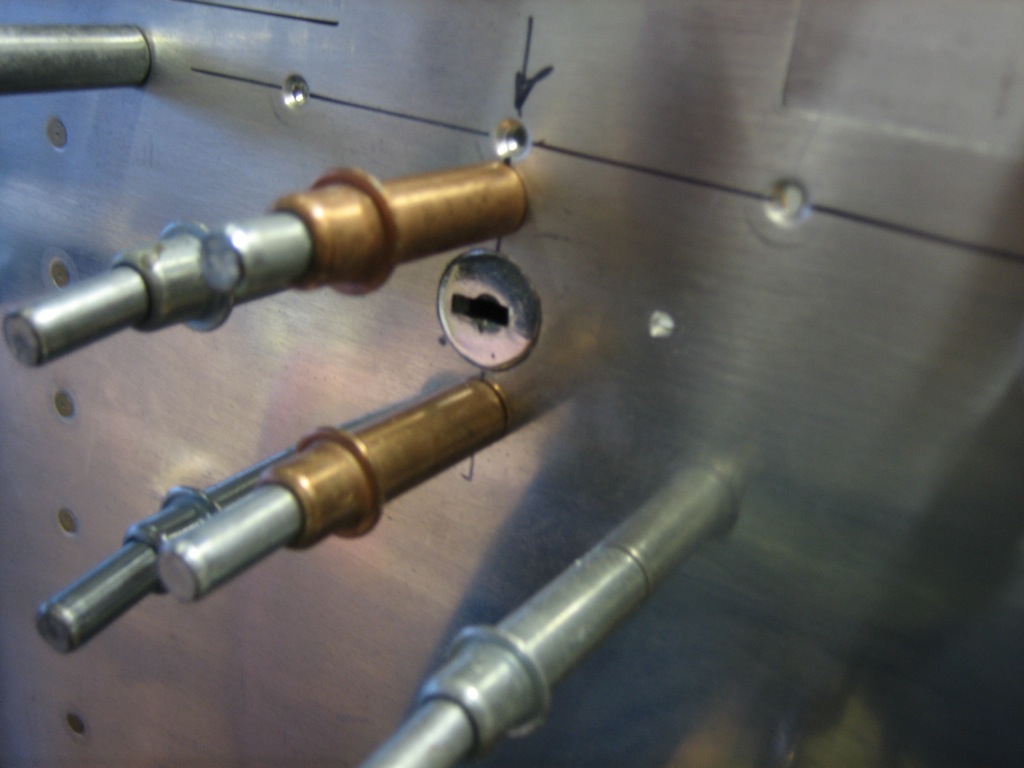

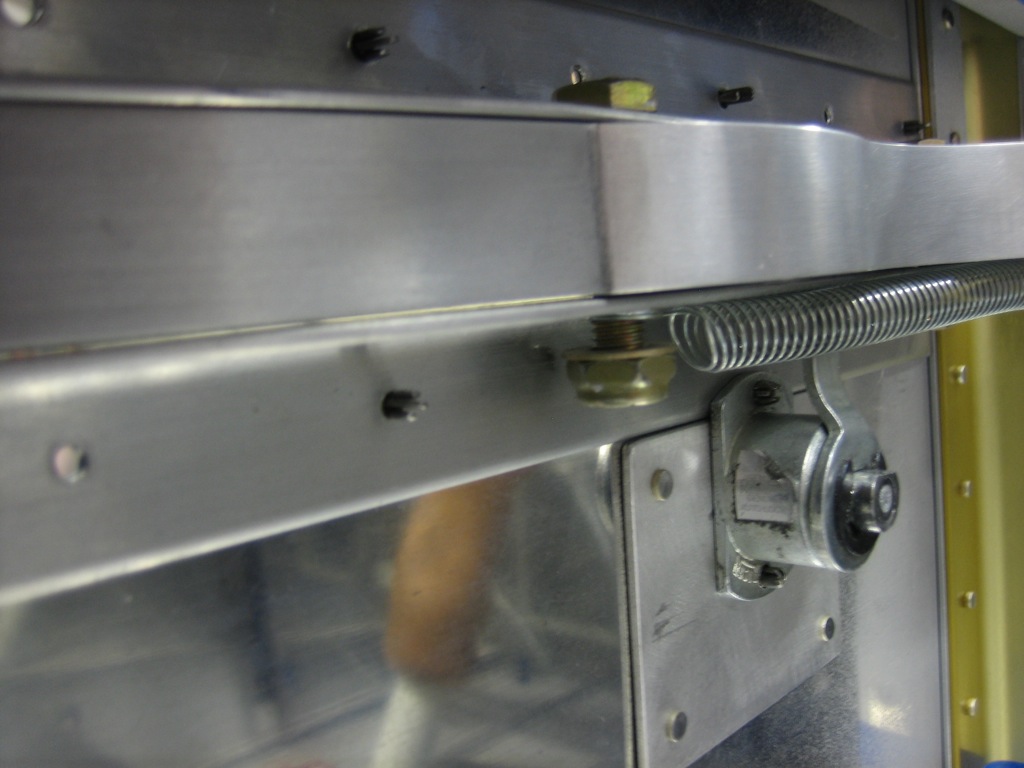

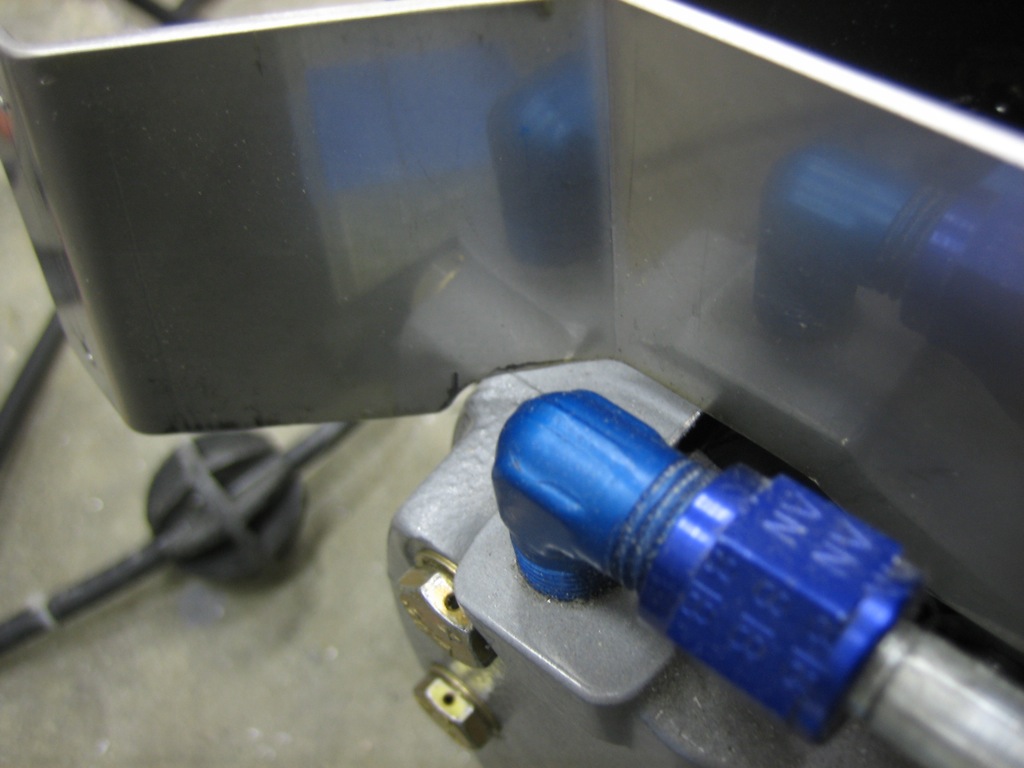

I found a great lock online that can be flush mounted against the side of the plane. Most camlocks mount through the hole, but this can be mounted from behind so that it doesn’t protrude beyond the skin. This is apparently the baggage compartment lock for a Lambretta/Scooters India Limited motor-scooter. You can find them on eBay for about $5.

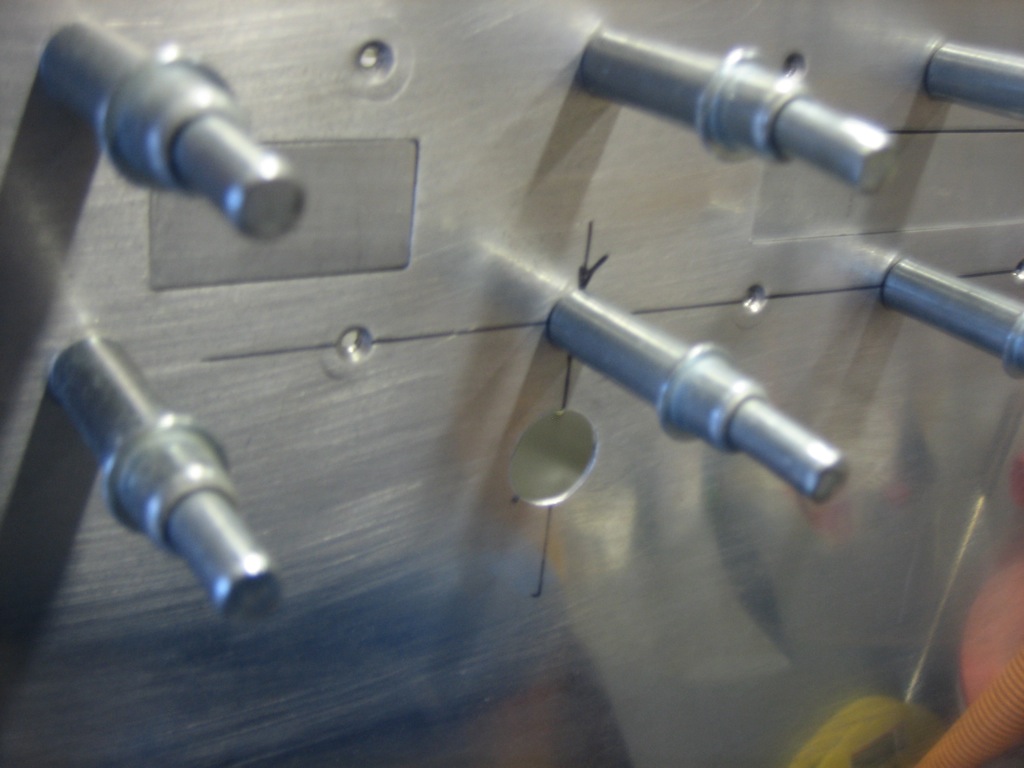

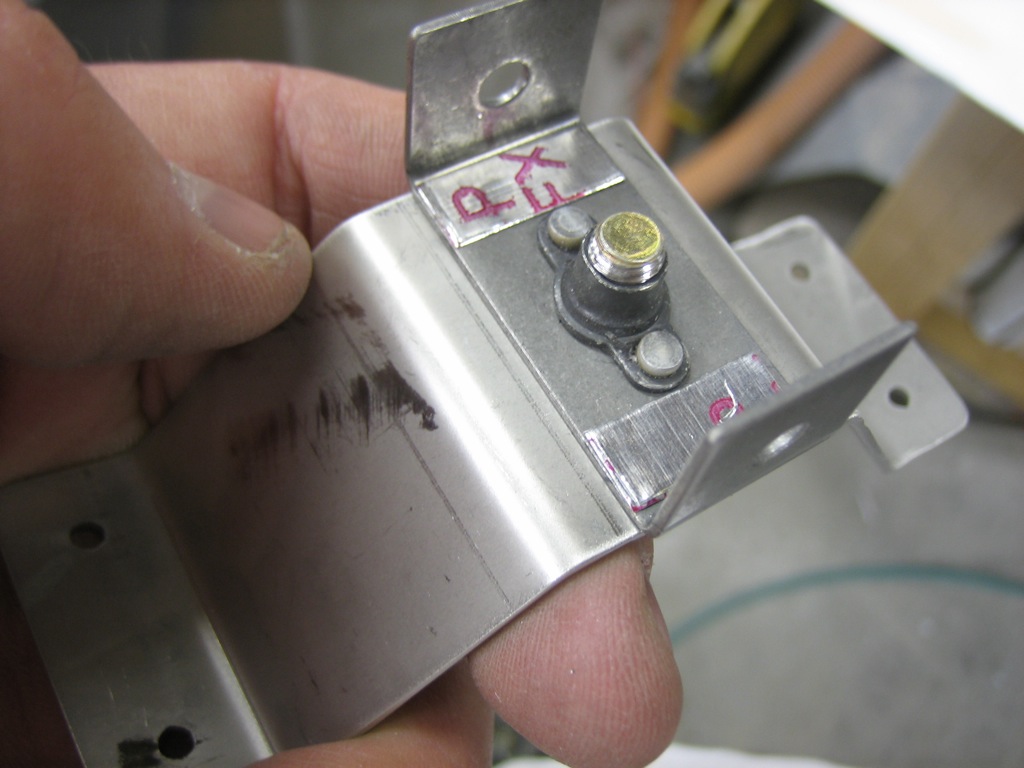

The problem is that the lock is designed so that the key will only come out in the locked position as seen here. I didn’t realize this when I ordered the lock, but it obviously won’t work since I want to be able to unlock the plane and remove the key.

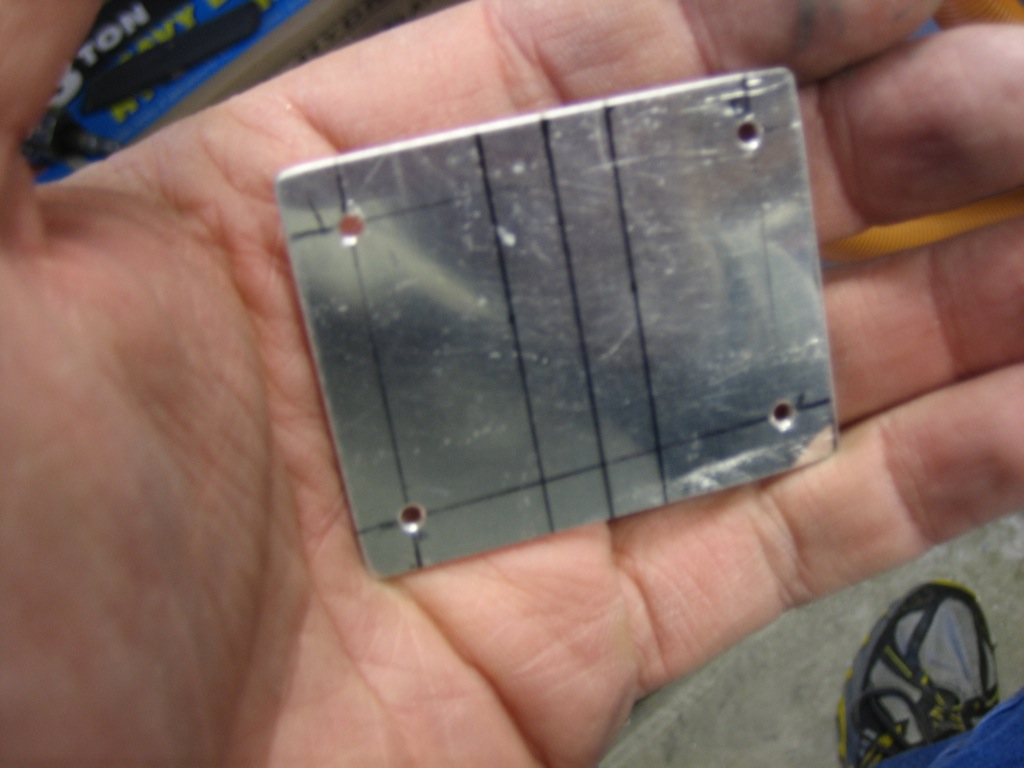

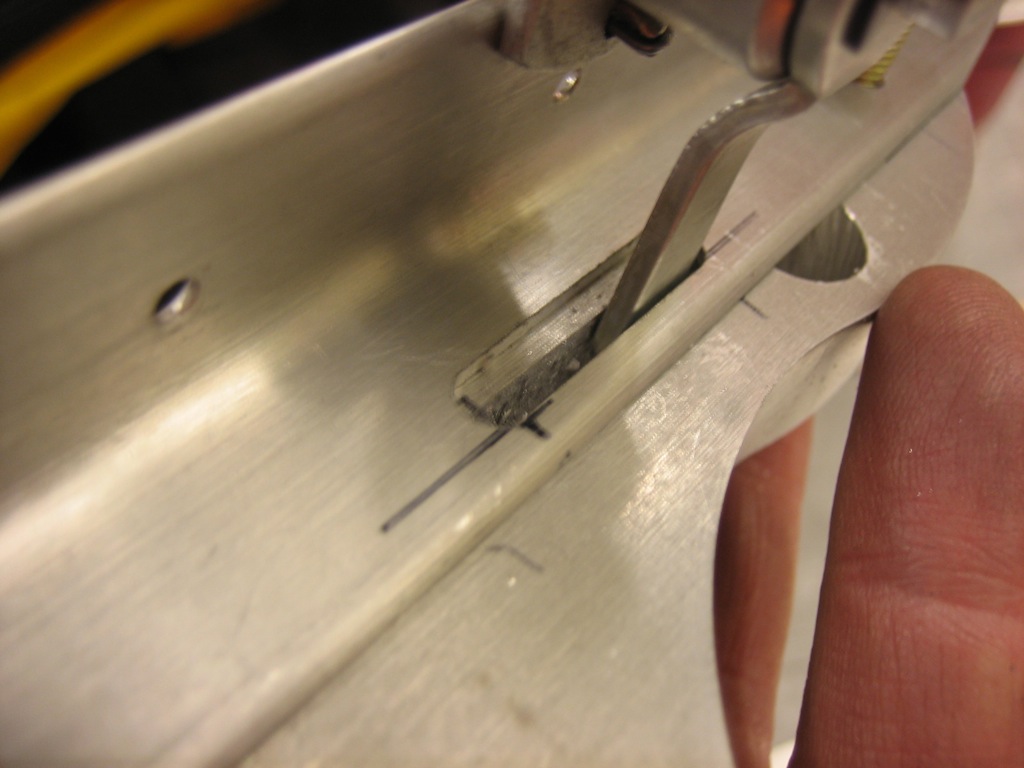

I disassembled the lock and modified it so that the key will also come out in this position. This was easier than I thought and probably took no more than 15 minutes.

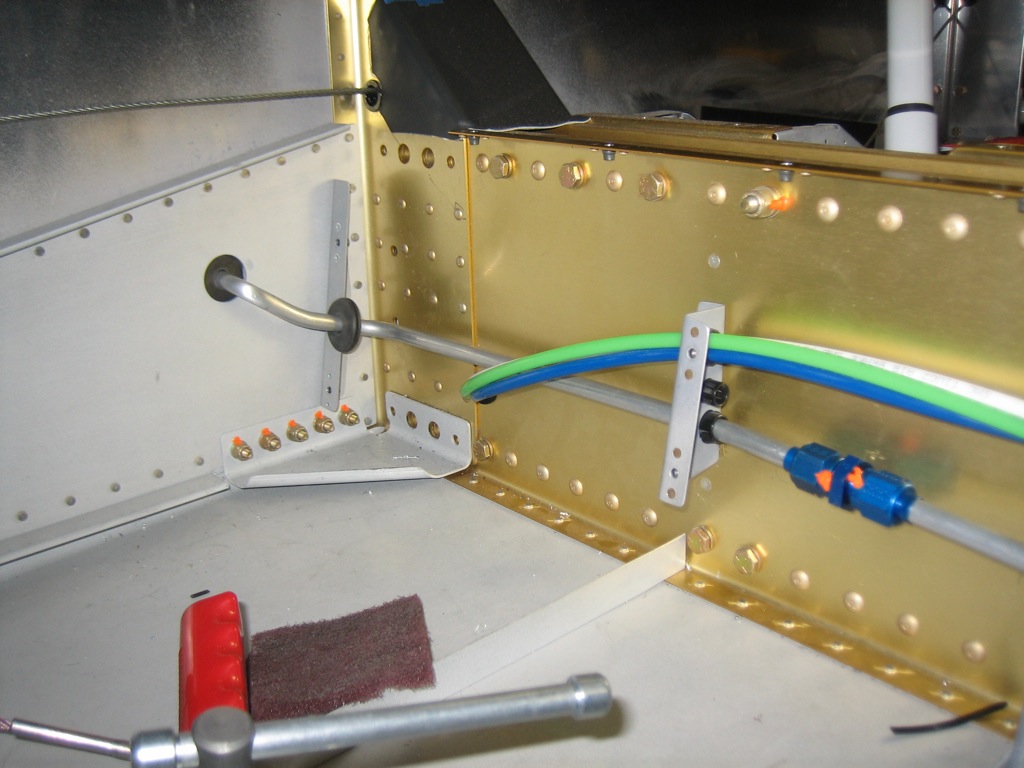

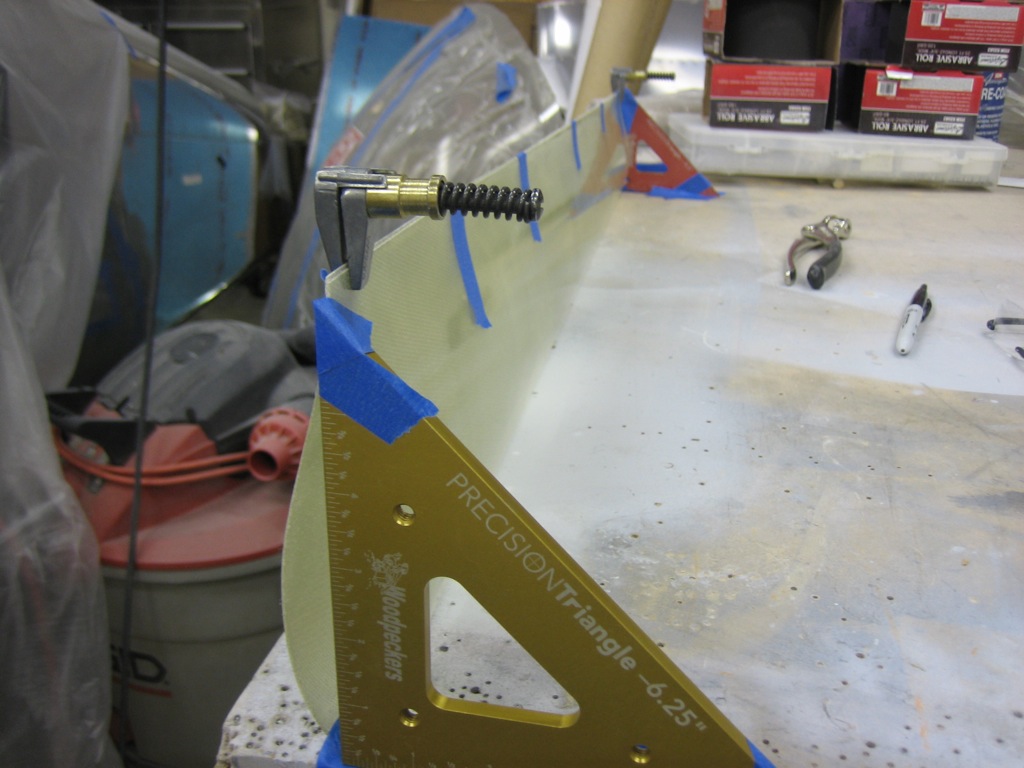

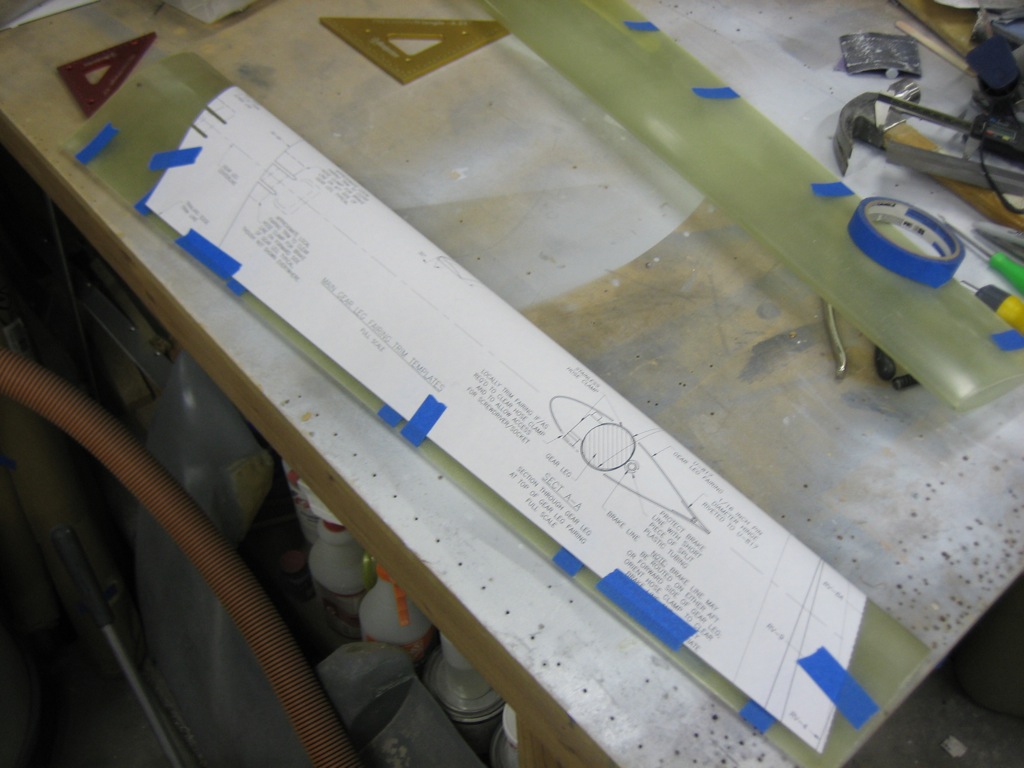

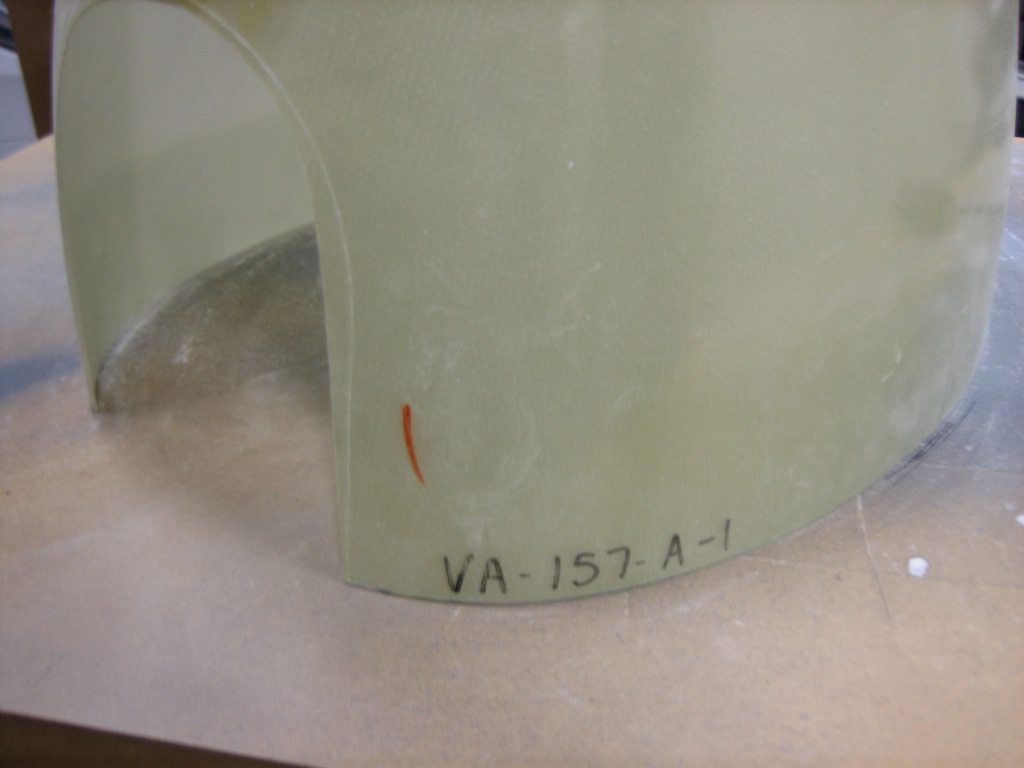

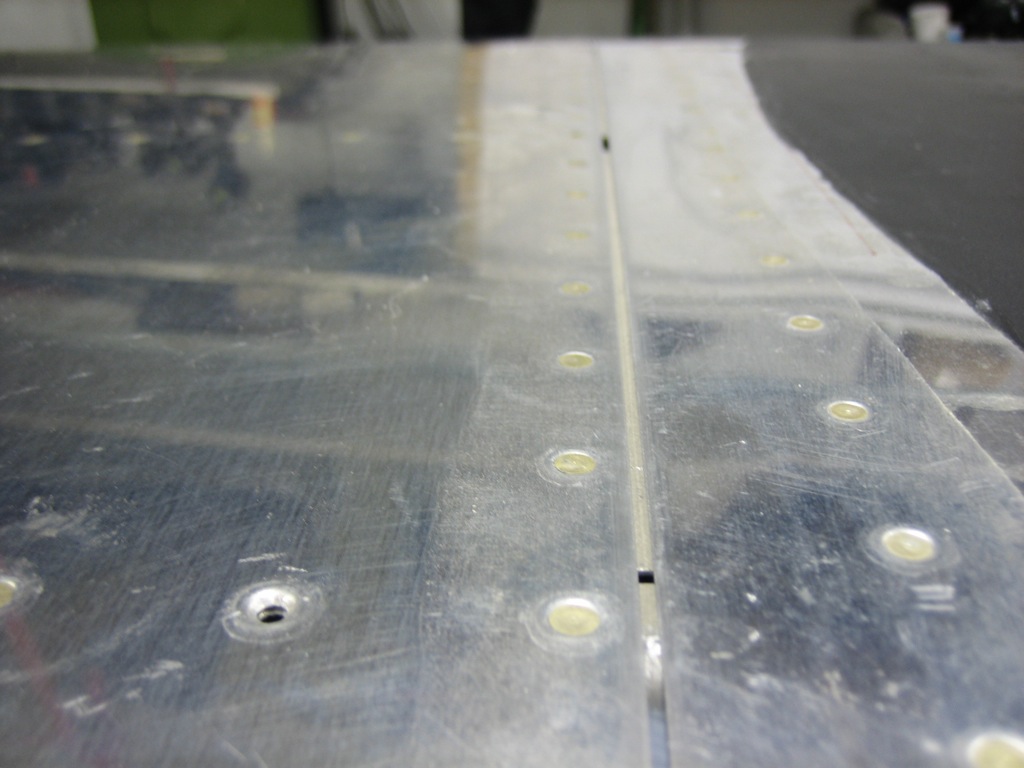

Afterward, I got started on the cowl again by riveting one of the side hinges on with epoxy/flox. This was substantially easier than the other hinges because the eyelets protrude beyond the edge of the cowling. This made it far easier to clean up the excess epoxy since it didn’t squeeze into the area between the eyelets.