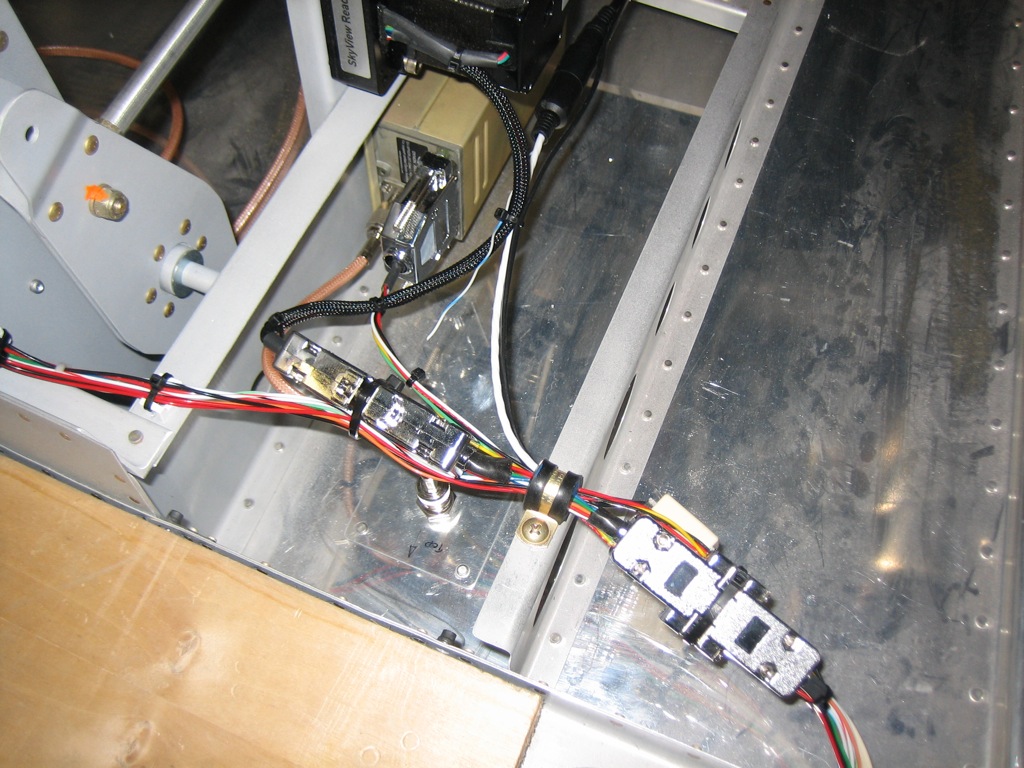

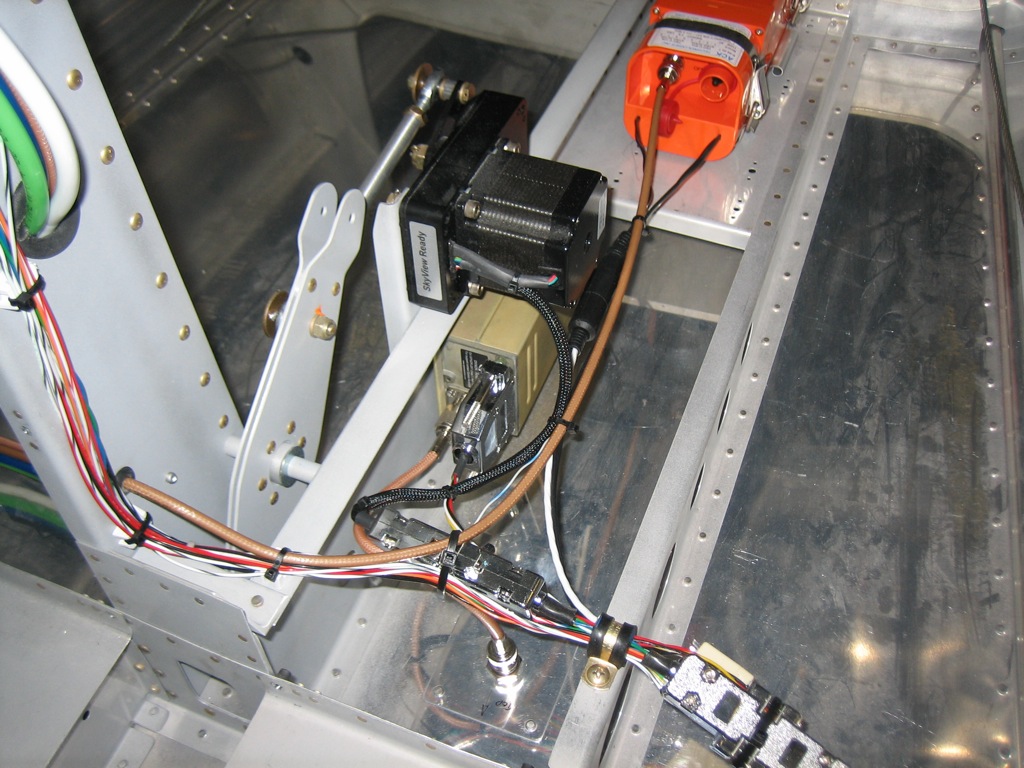

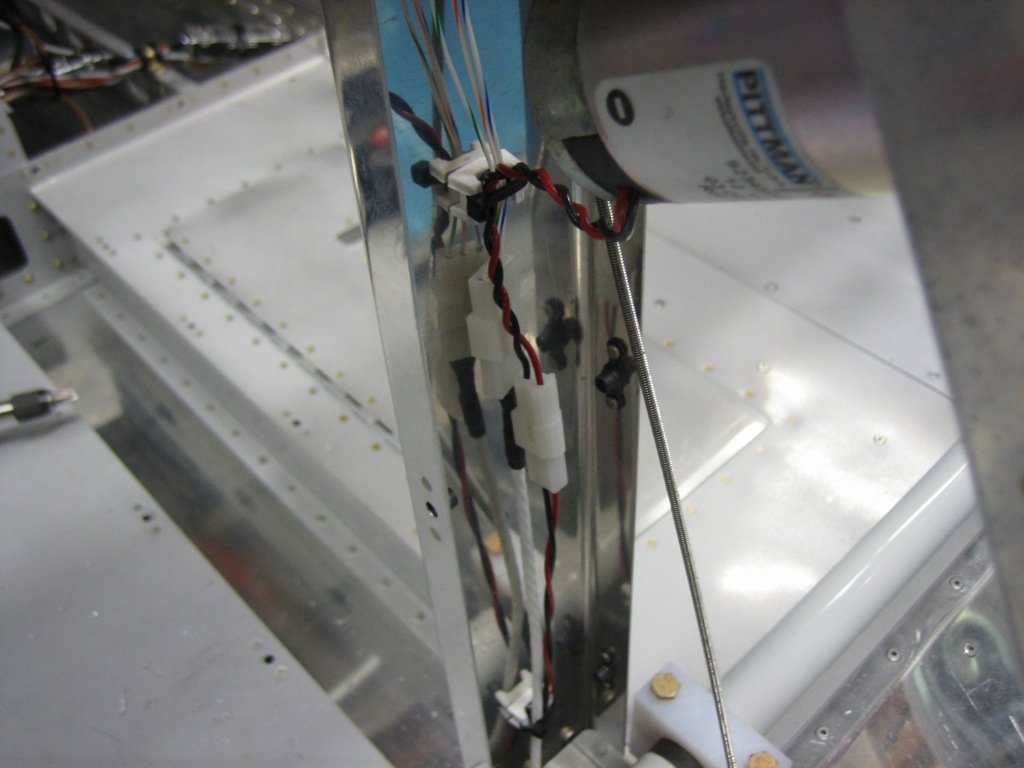

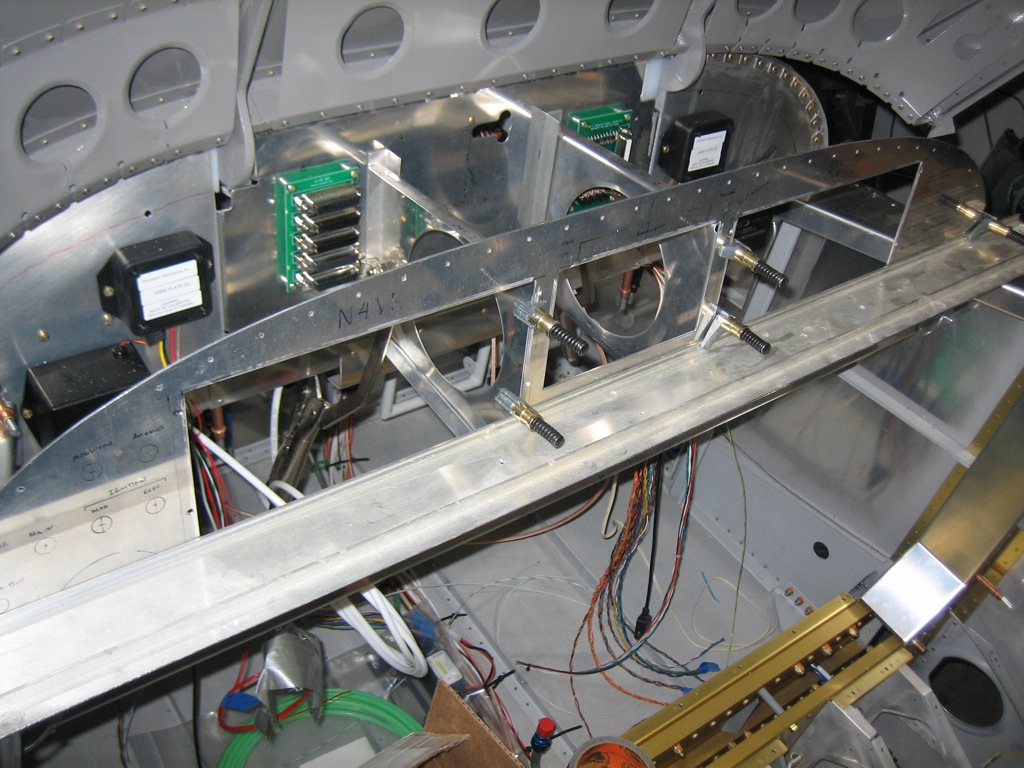

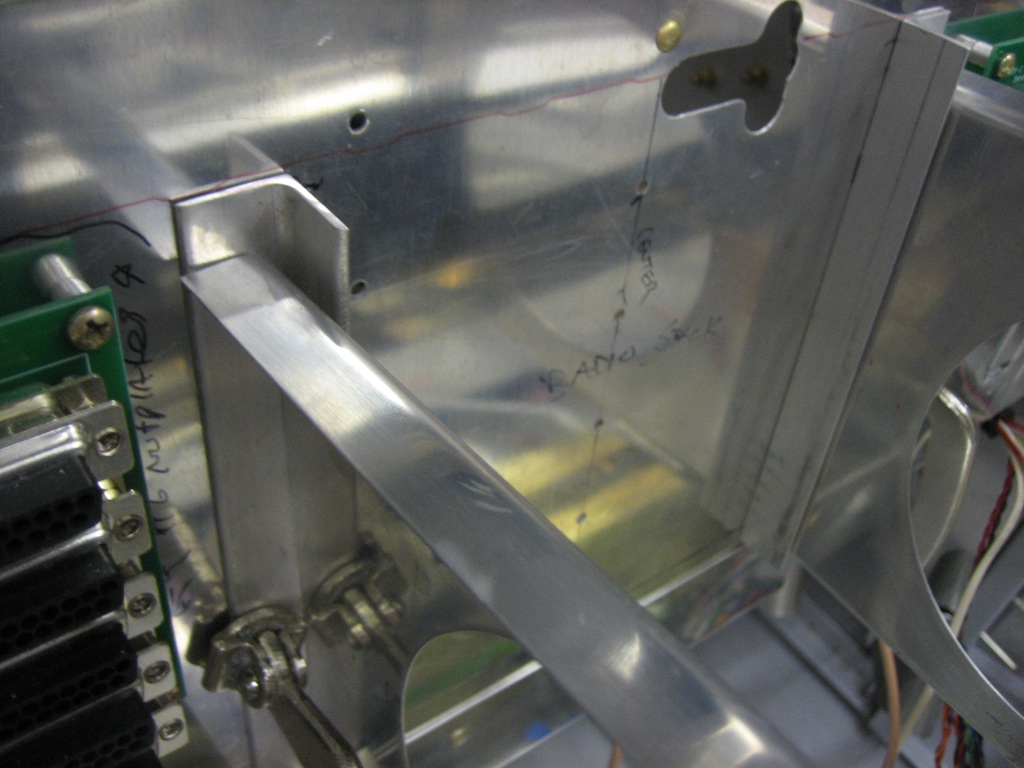

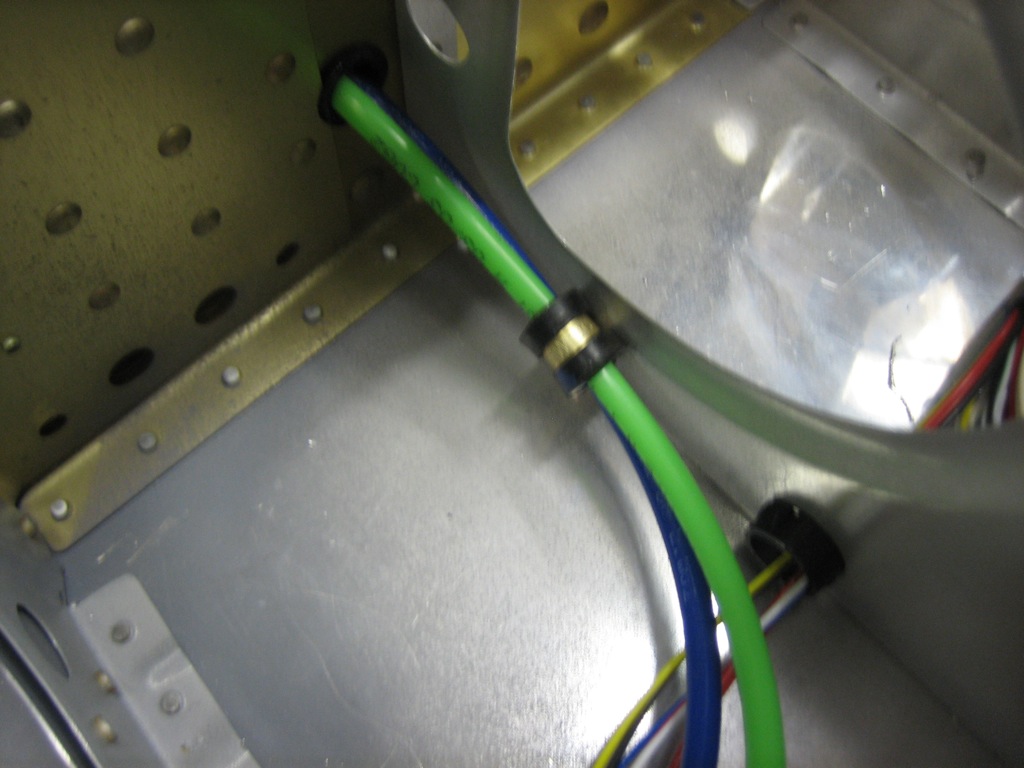

I spent a little time tonight tidying up some wiring runs under the seats. I installed an adel clamp on the wires to the left of the center tunnel. I haven’t tightened either of these down fully yet since I want to wait until the GPS antenna cable is adjusted to length and I still need to run the wires for the control sticks.

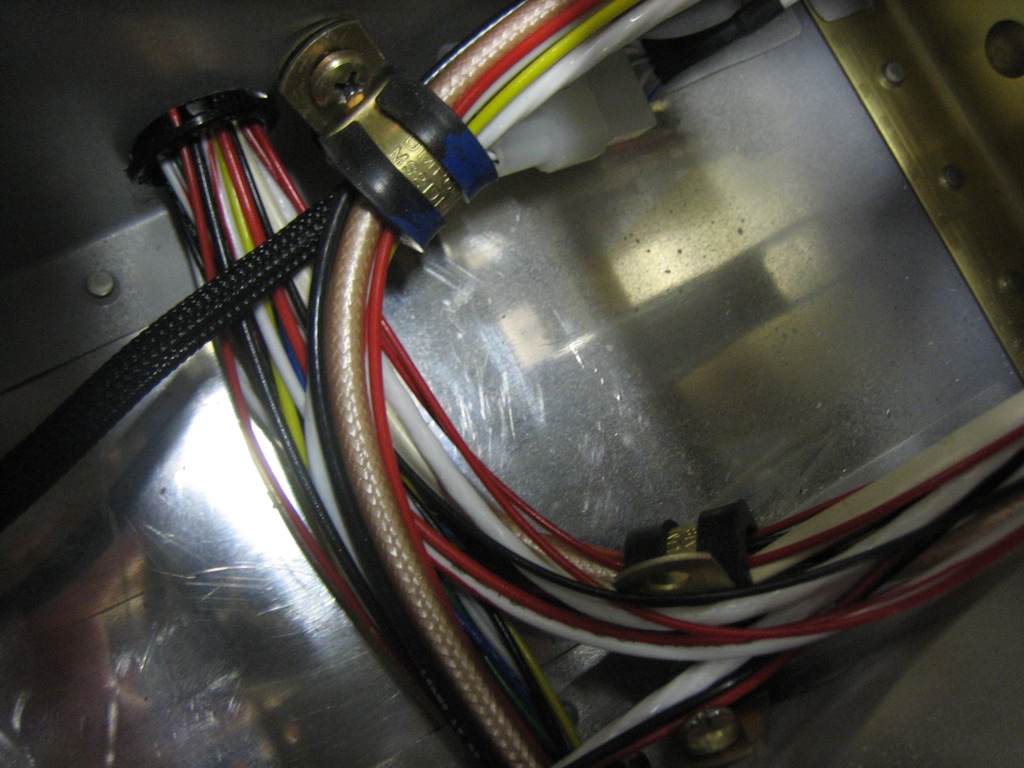

I installed the adel clamp supporting the wires coming out of the left conduit and added a couple of zip-ties to tie everything together. It’s amazing how solid these wire bundles become when zip-tied together.

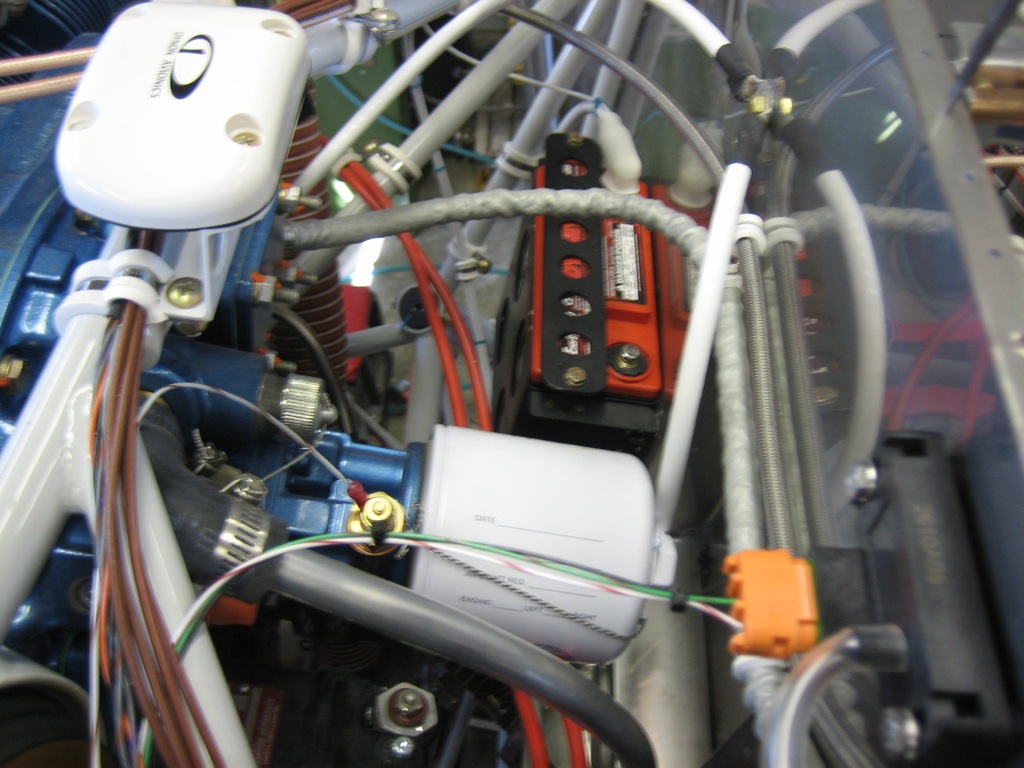

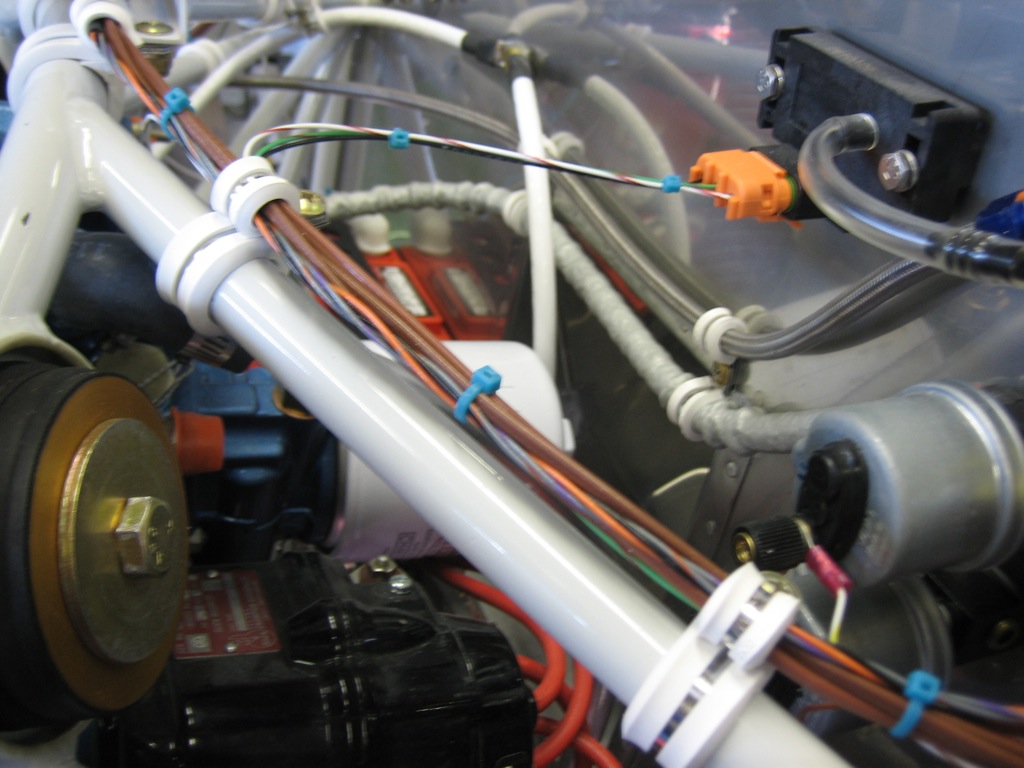

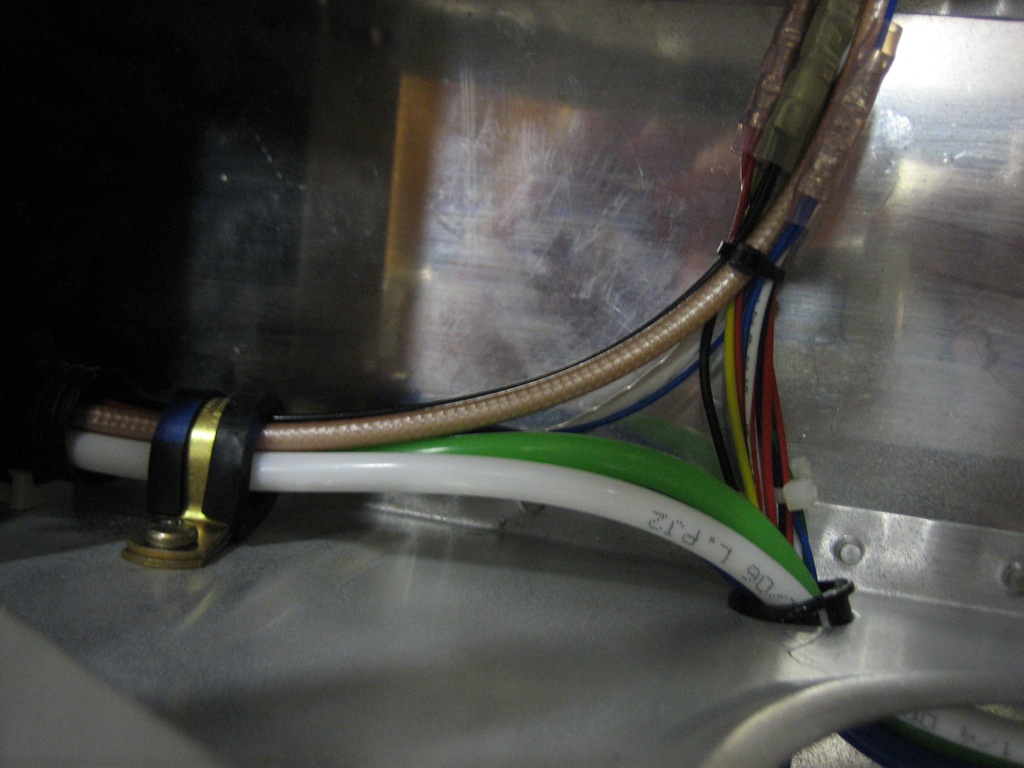

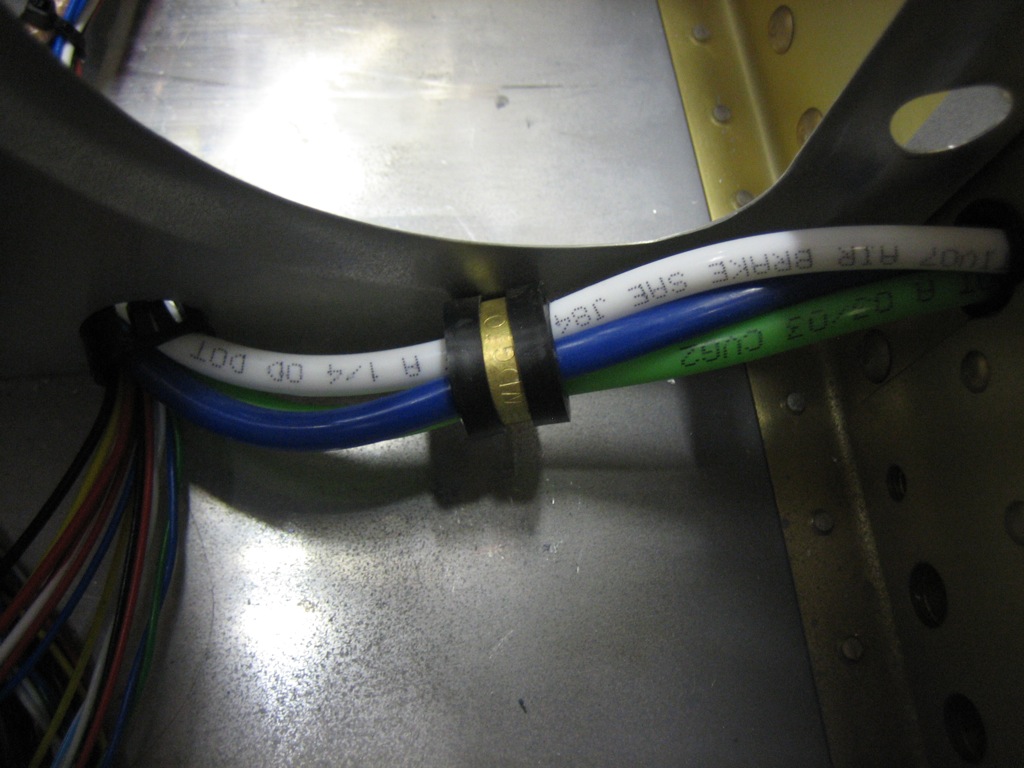

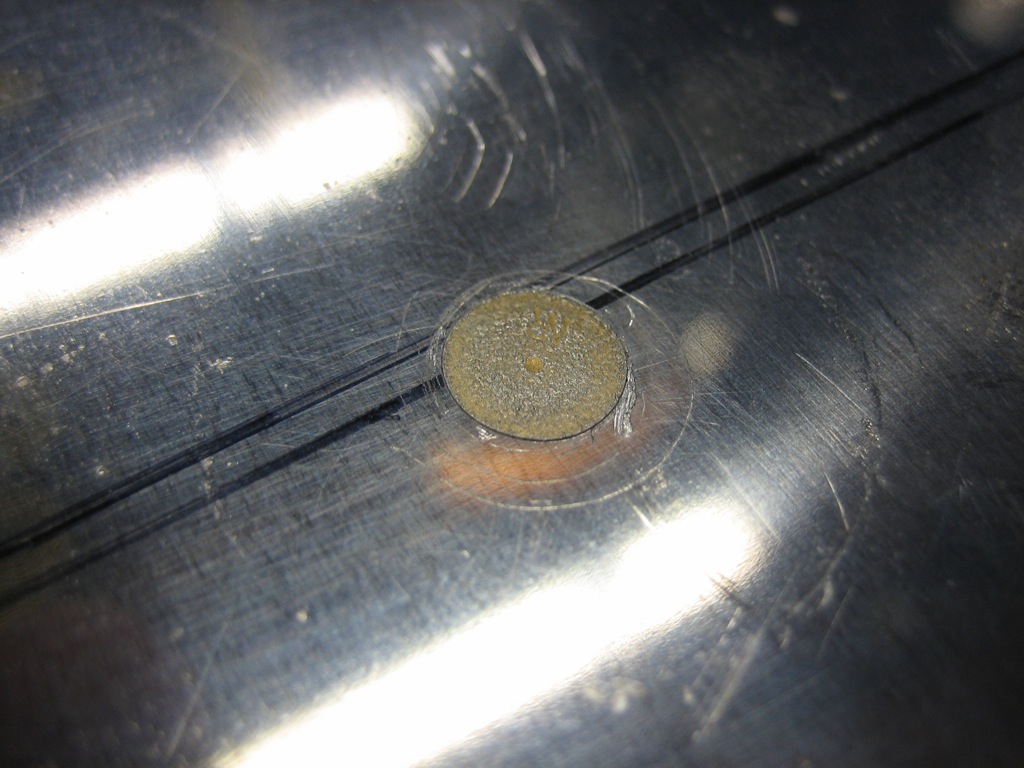

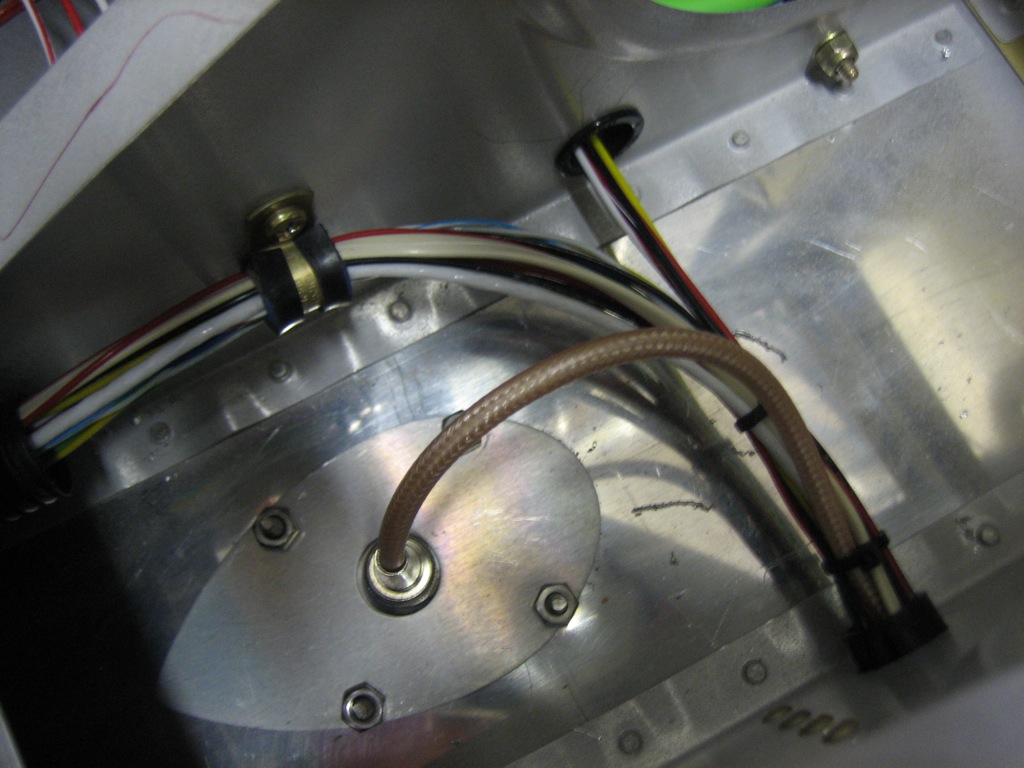

I added an adel clamp to keep the pitot/AOA lines held down to avoid interfering with the aileron push tube. I might have been able to use a zip-tie base attached with a pop-rivet, but I really don’t want there to be any possibility of anything coming loose around the flight controls. You can also see at the top of this picture that I took all of the snap bushings out of the forward holes in each seat rib. I have no idea why Van’s has you drill holes here. It’s a really poor place to put them since they’d have to snake around the control stick brackets.

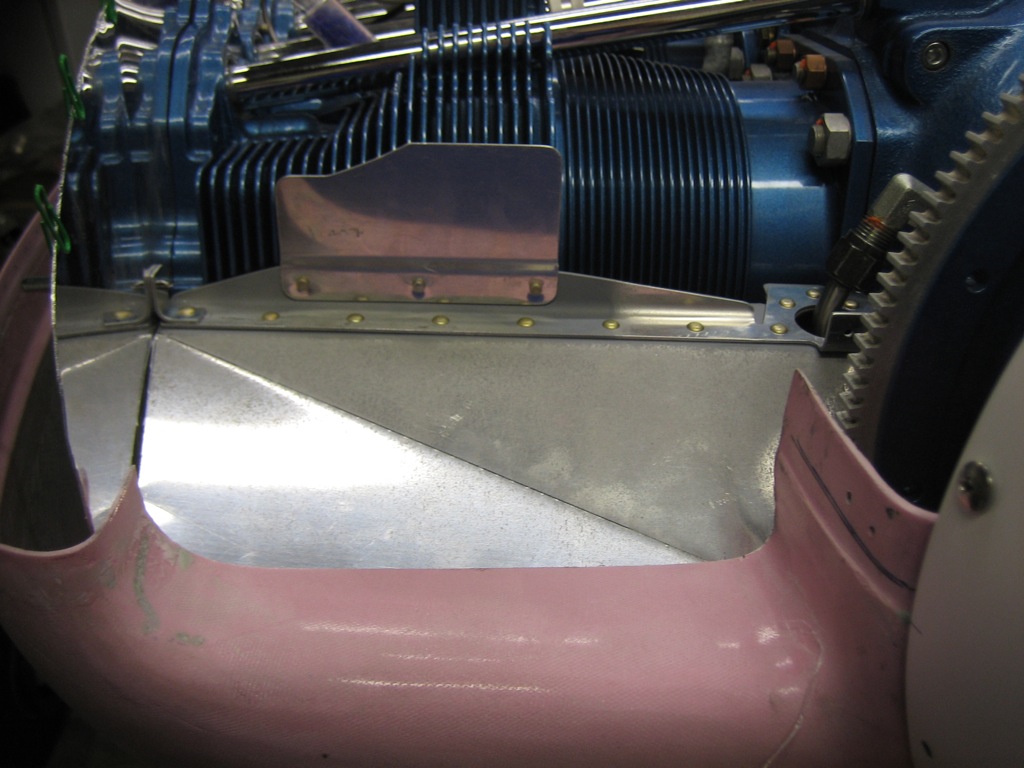

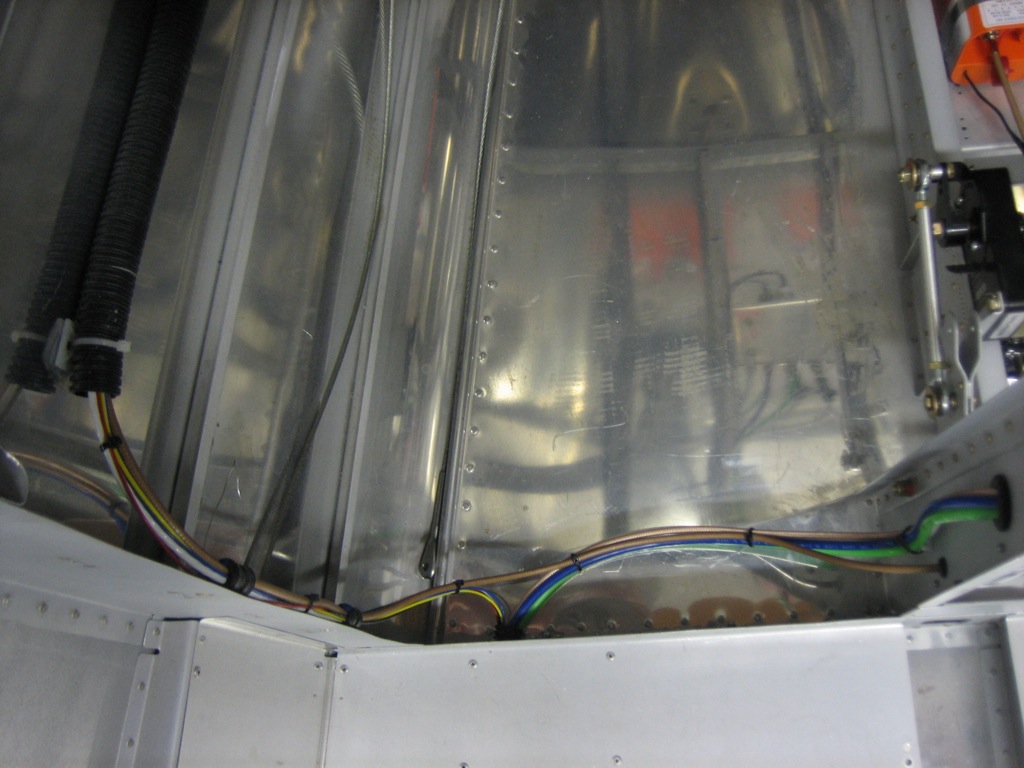

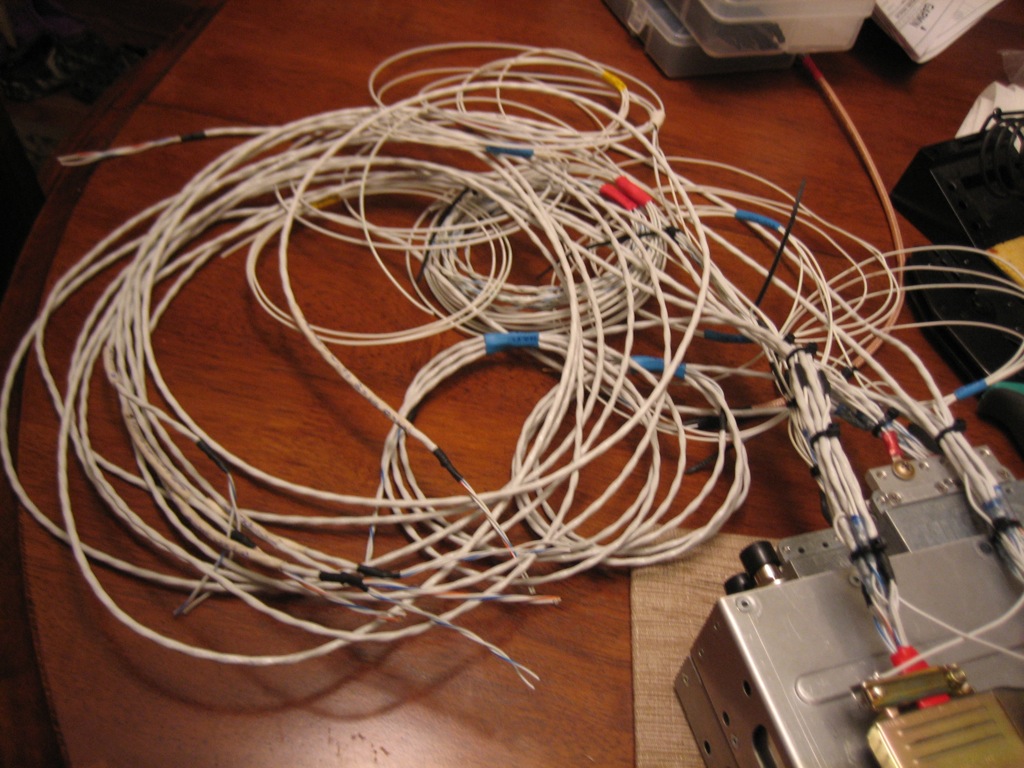

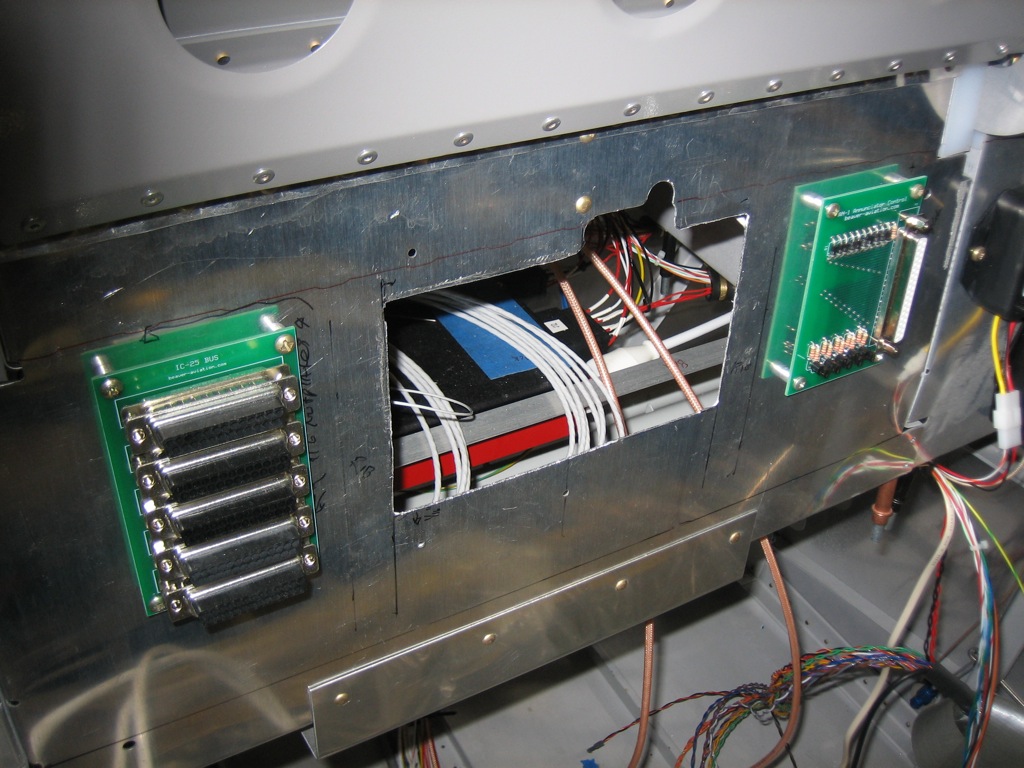

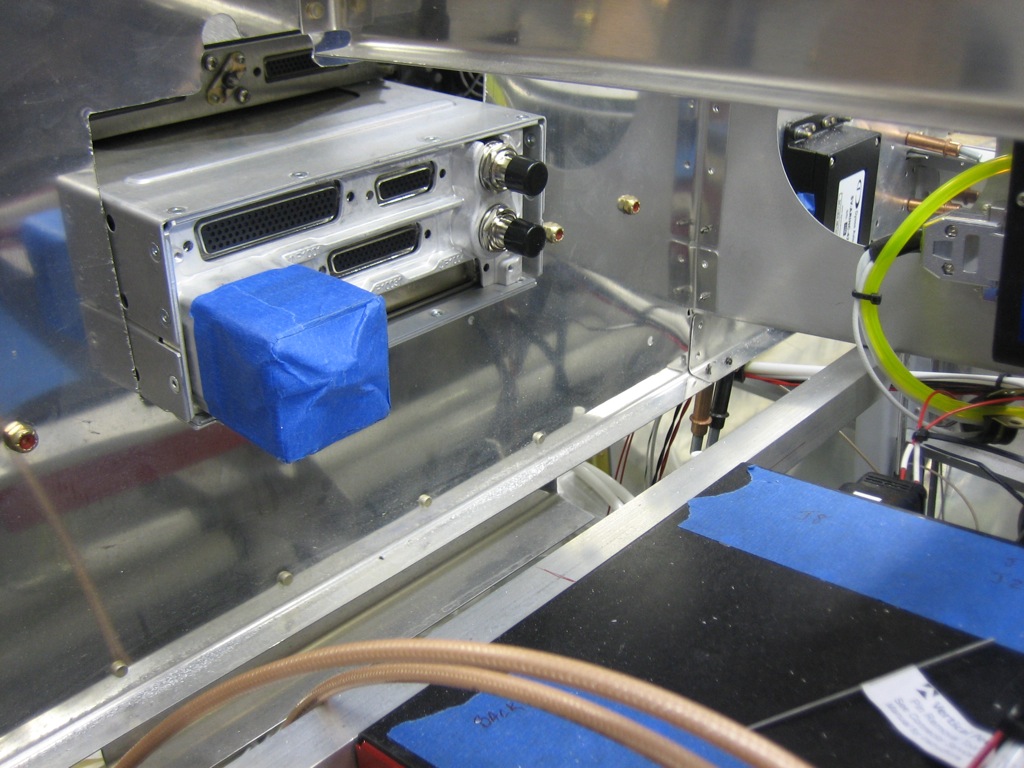

I also tidied up the wiring aft of the baggage bulkhead. Everything is firmly secured and well supported.