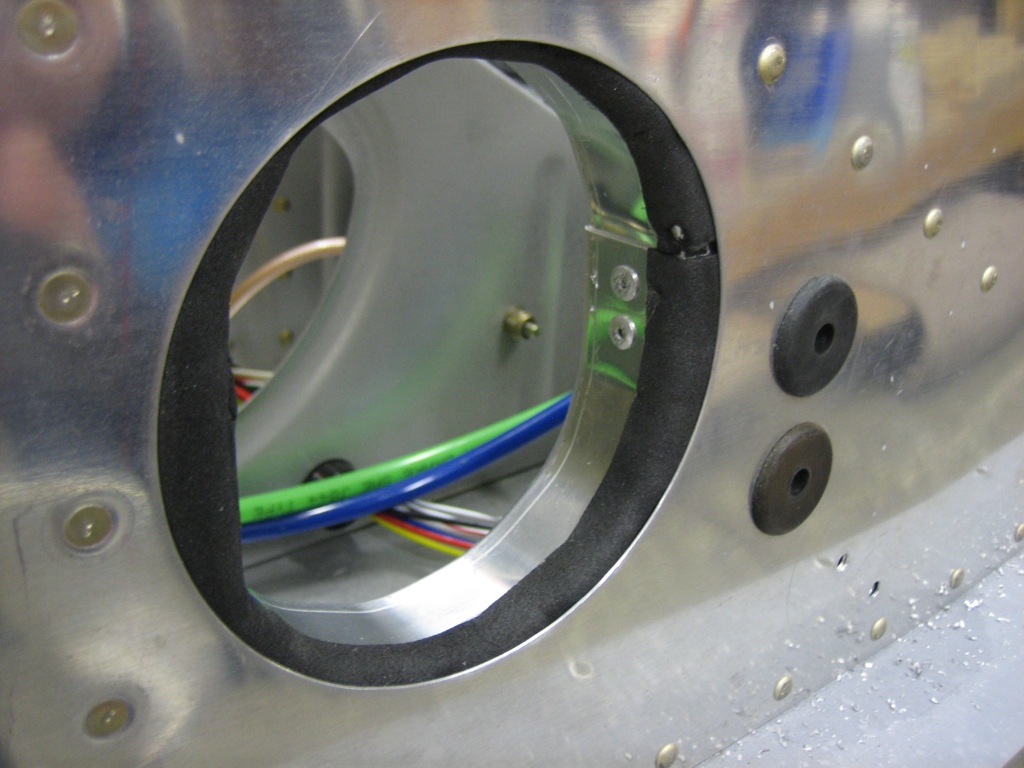

One of the biggest sources of air infiltration in the RV is the large hole in the side of the fuselage that allows the aileron pushrod to exit the fuselage. When flying at high altitudes, ice cold air comes in through this hole and then comes up through the seat belt attach holes, stick boot hole, etc. It also makes the seat pans really cold which can make sitting in the plane really uncomfortable. The solution to this is to install boots around the pushrods to block the air.

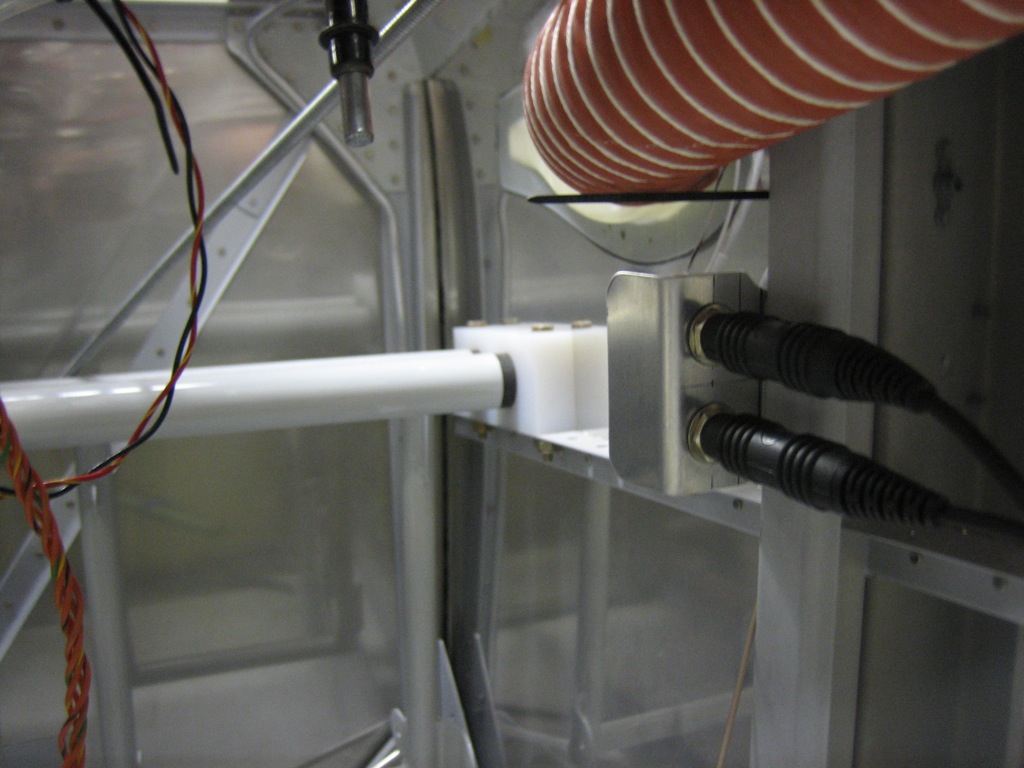

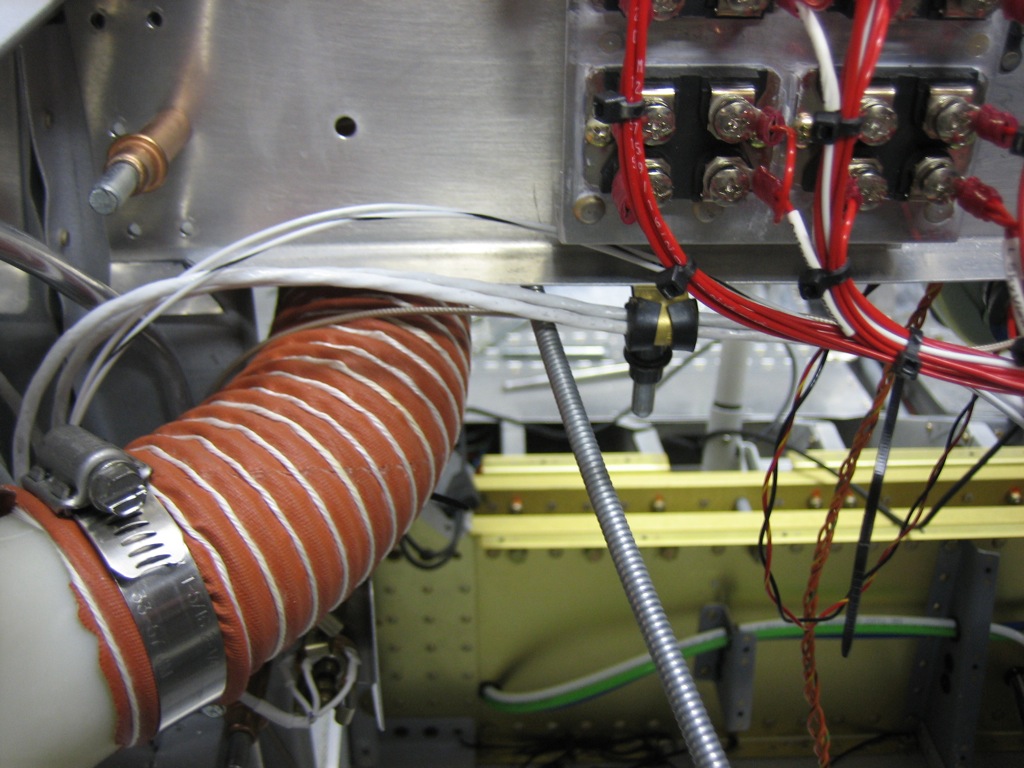

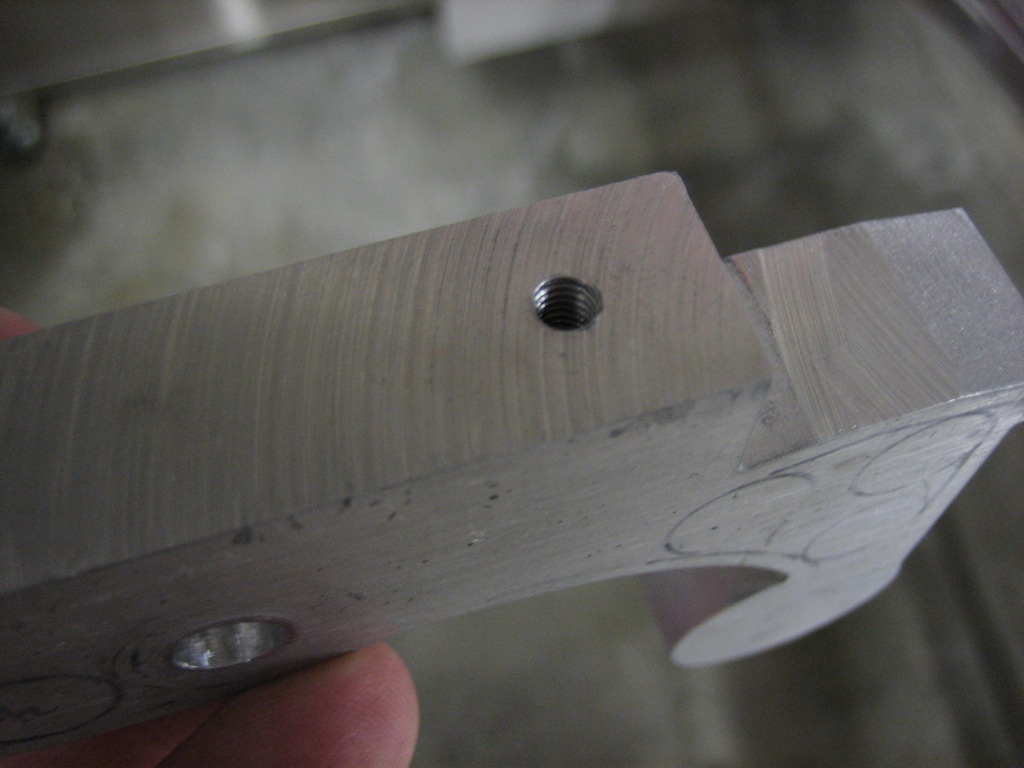

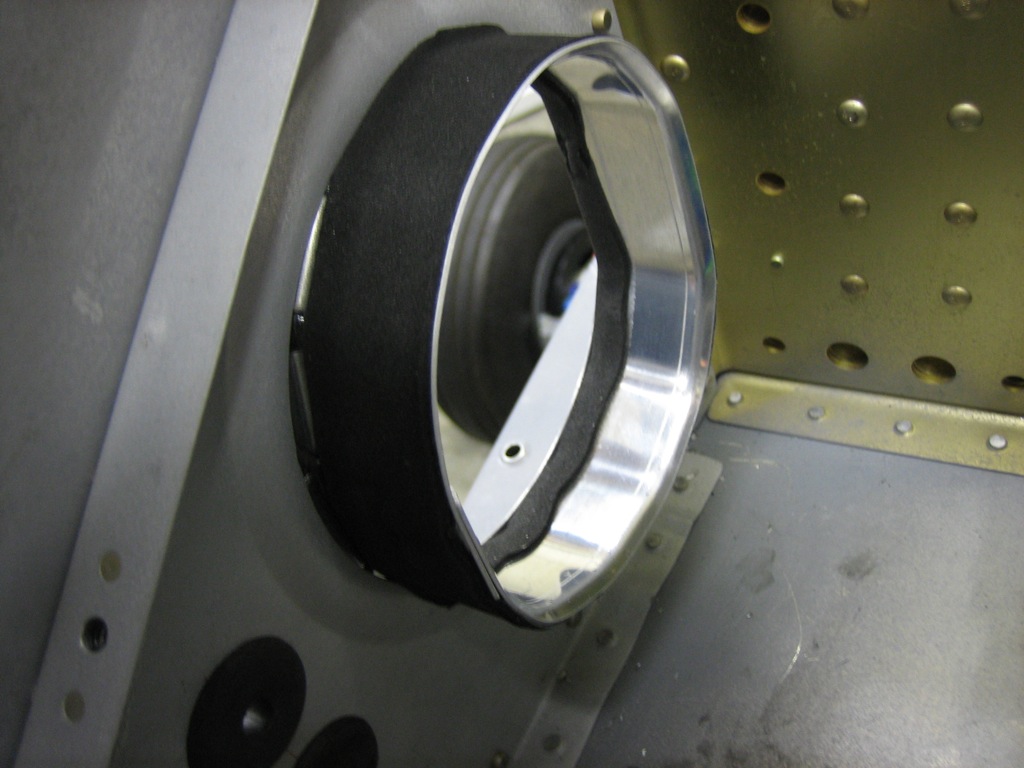

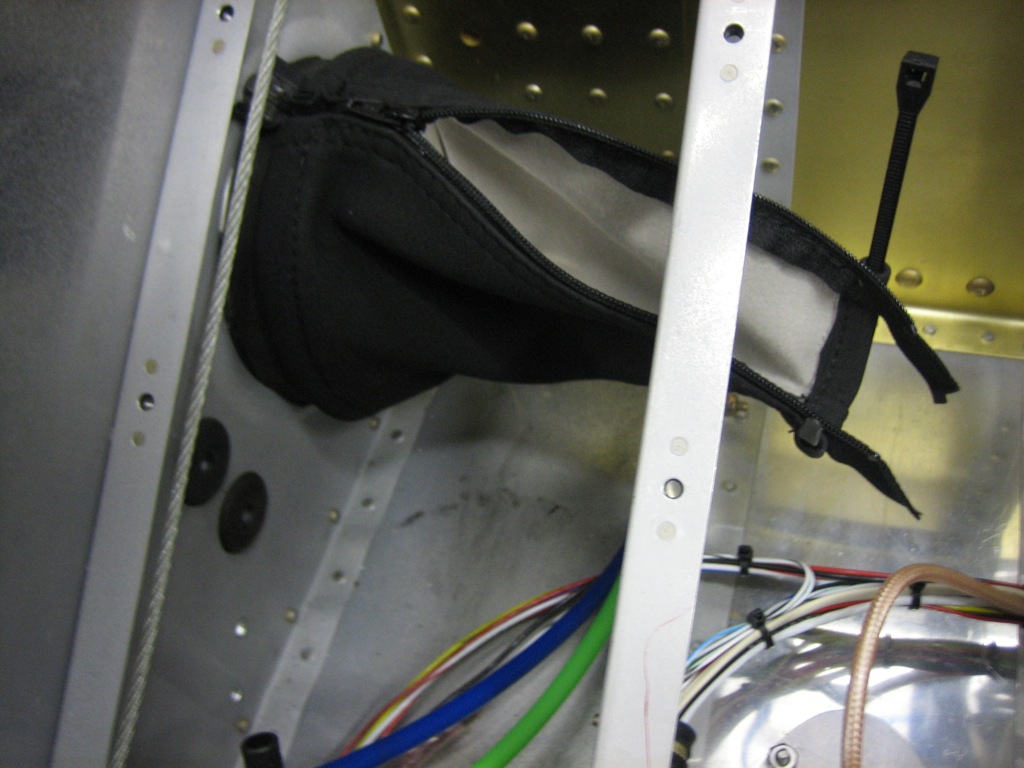

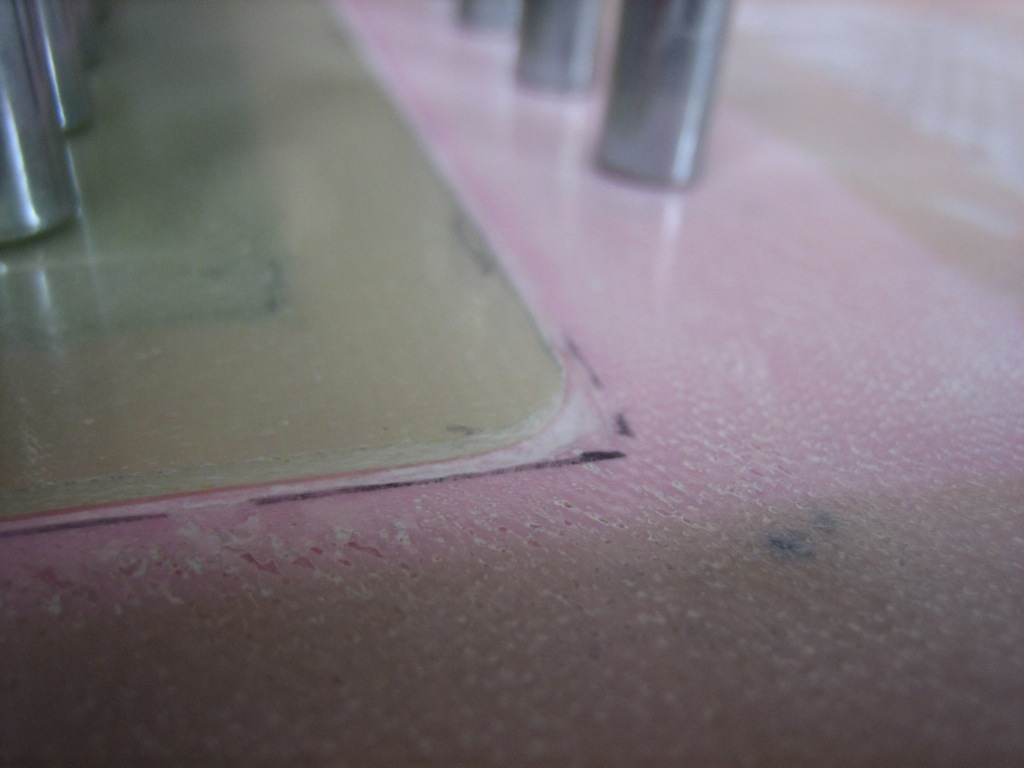

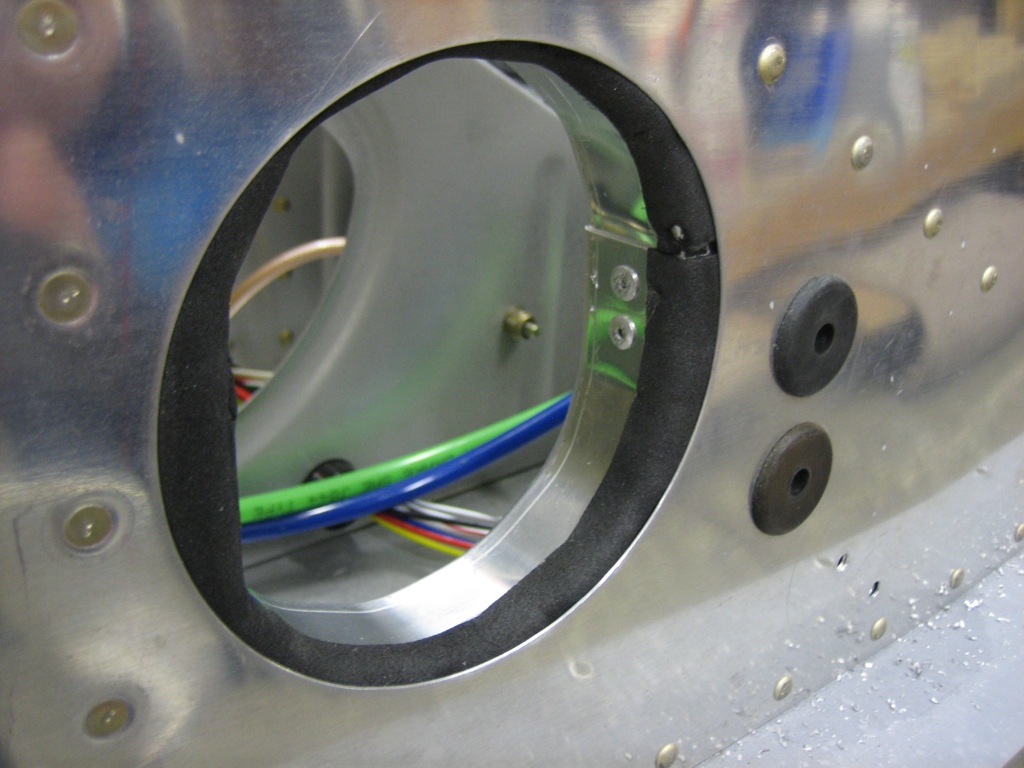

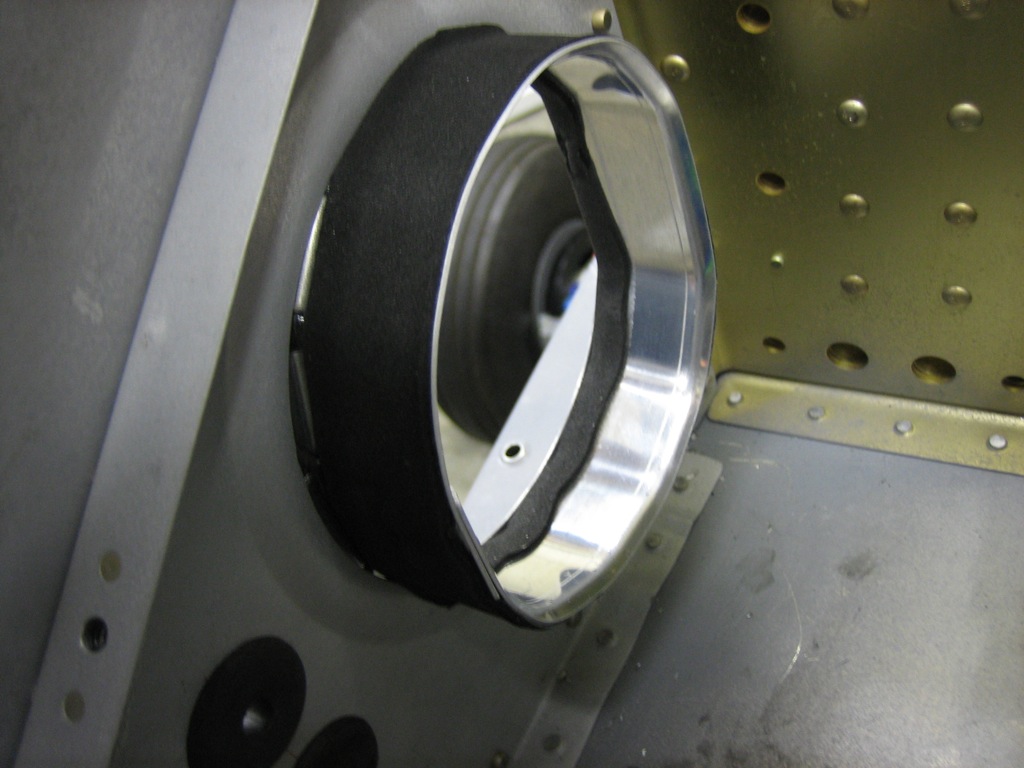

I installed the aileron pushrod boots from Classic Aero Design. These are more expensive than others on the market, but after installing them, I think the extra cost is absolutely worth it. These are very well designed and really easy to install. First up is to install the mounting ring. This is flexed into place so that the foam covered flange tucks between the outer fuselage skin and the adjacent rib. The ring is then expanded outward until the predrilled holes align. A couple of pop rivets anchors the rings in place.

Next, a strip of adhesive backed foam is adhered to the outside of the flange. Notice that the inboard edge of the flange is bent outward slightly.

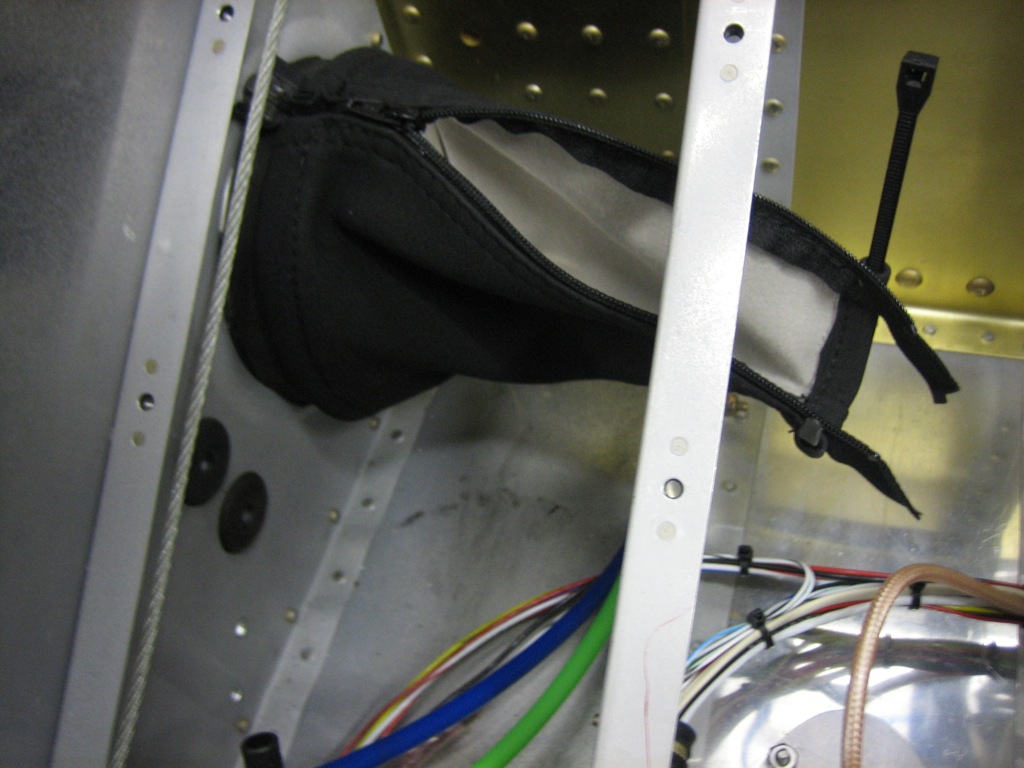

The boot is then installed over the flange and a zip-tie is used to cinch it down against the foam strip. The bent edge of the flange keeps the end from popping off the flange. Once the pushrod is installed for good, another foam strip will be adhered to the pushrod and the inner zip-tie will be used to anchor it.

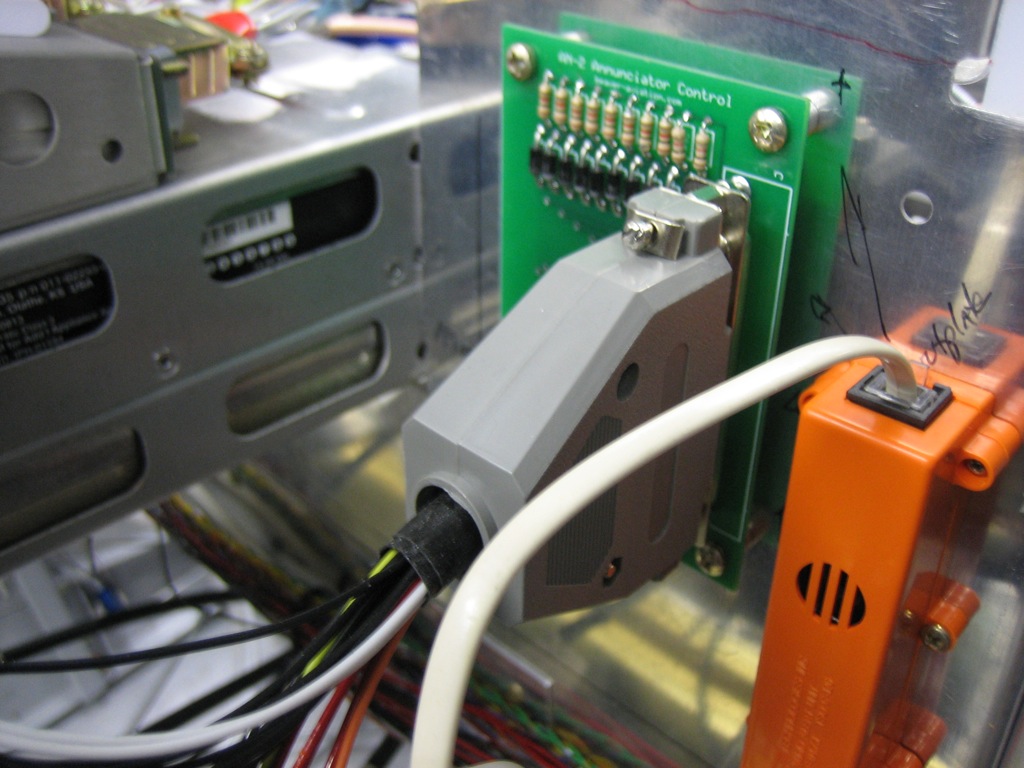

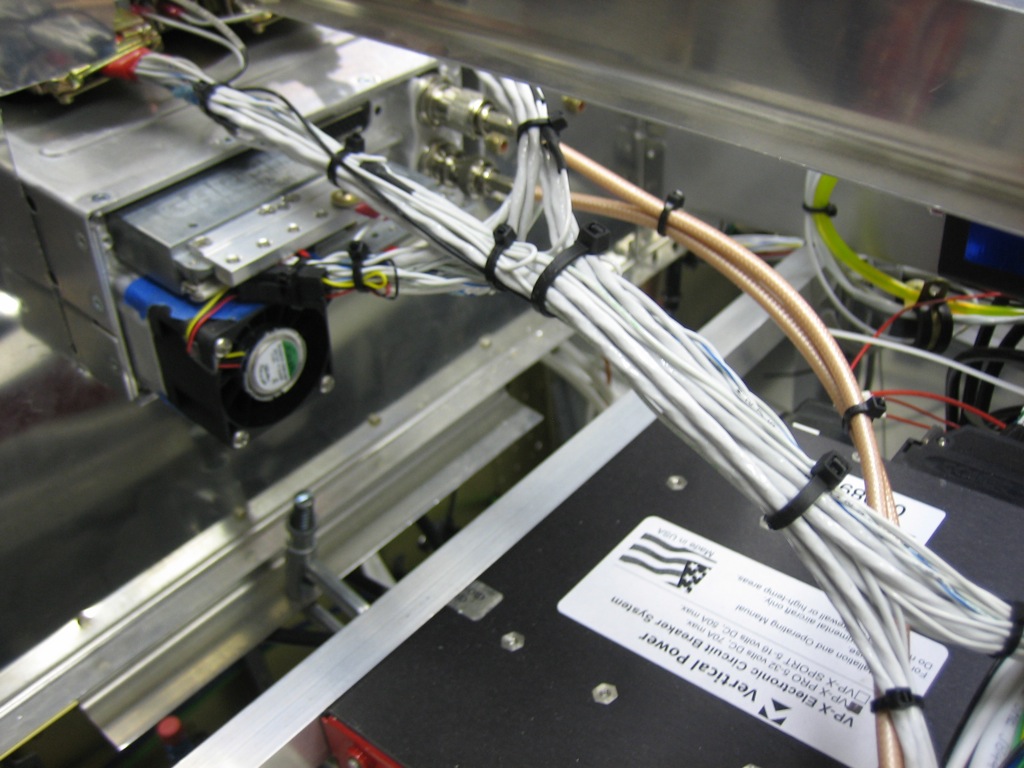

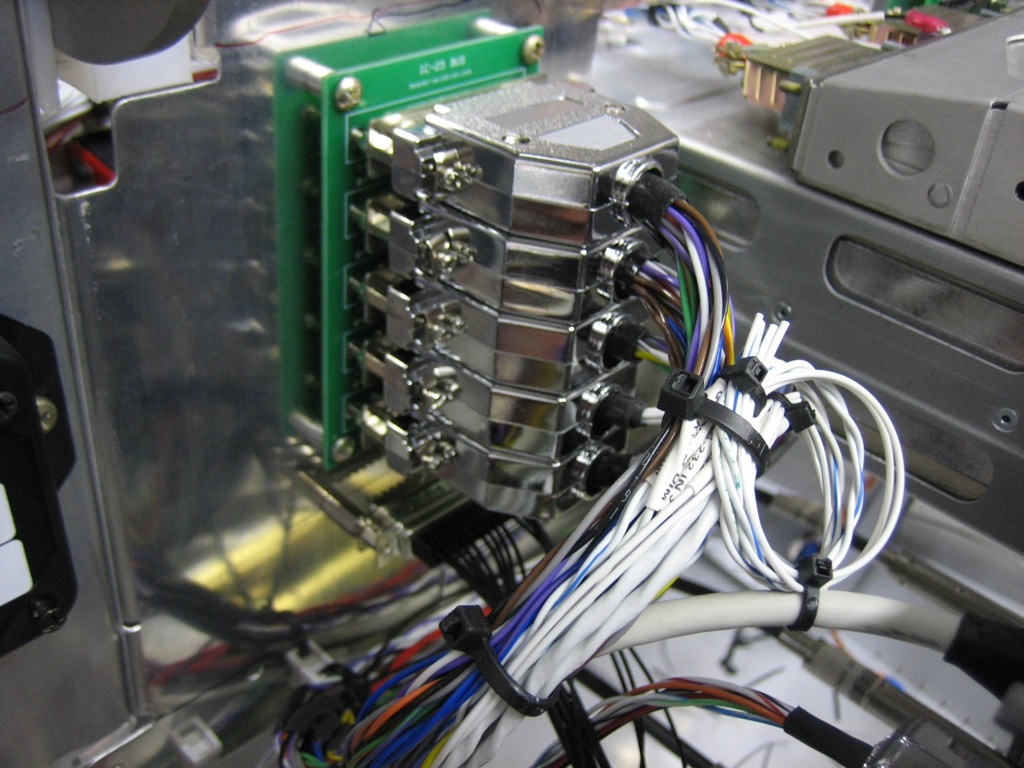

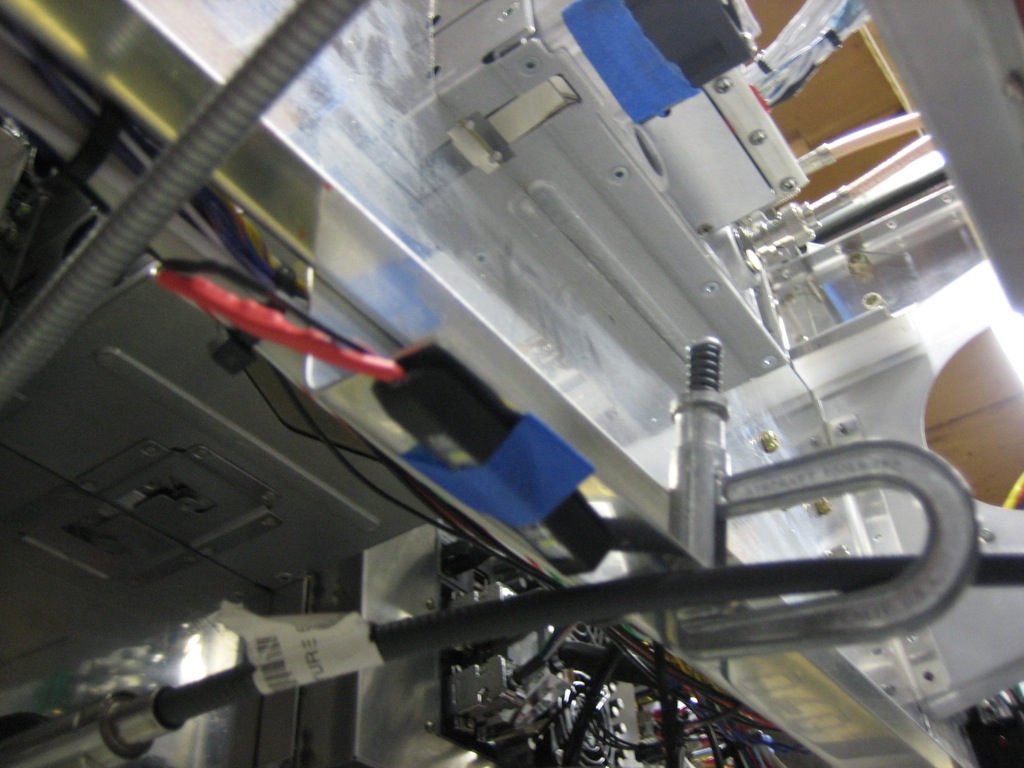

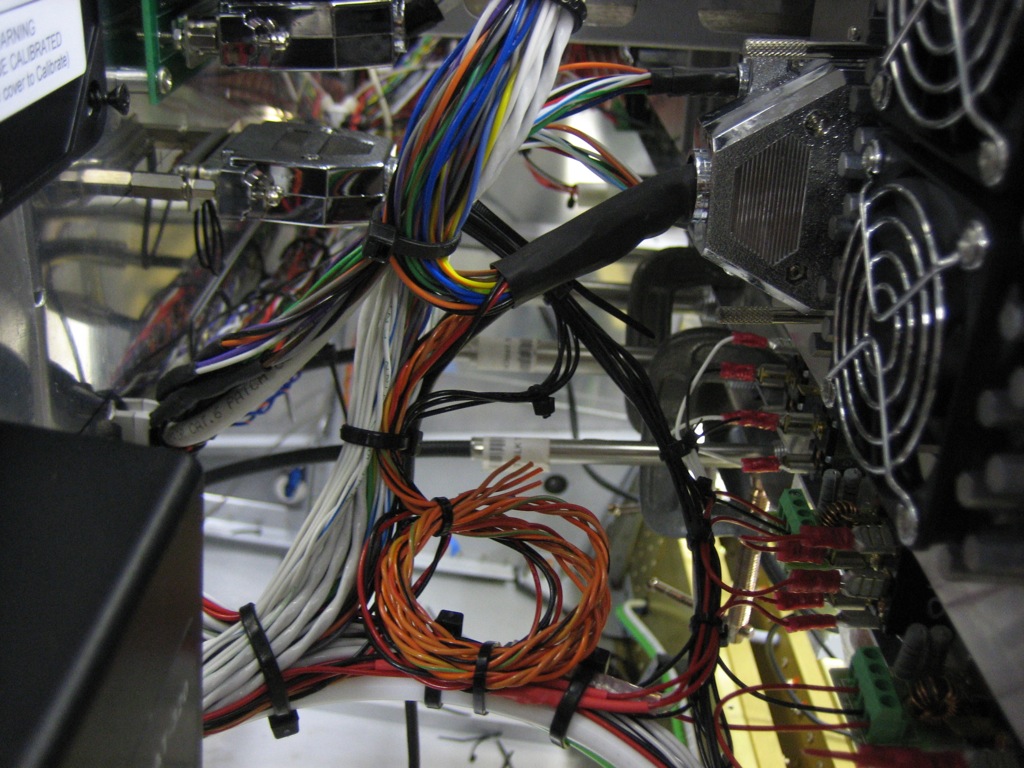

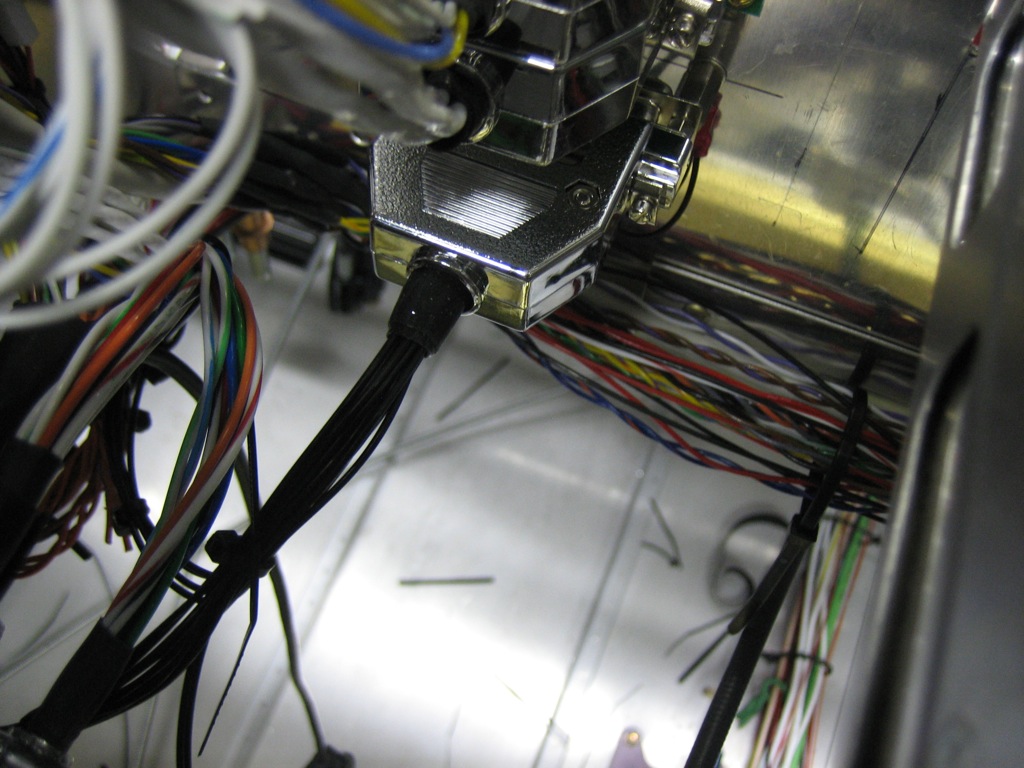

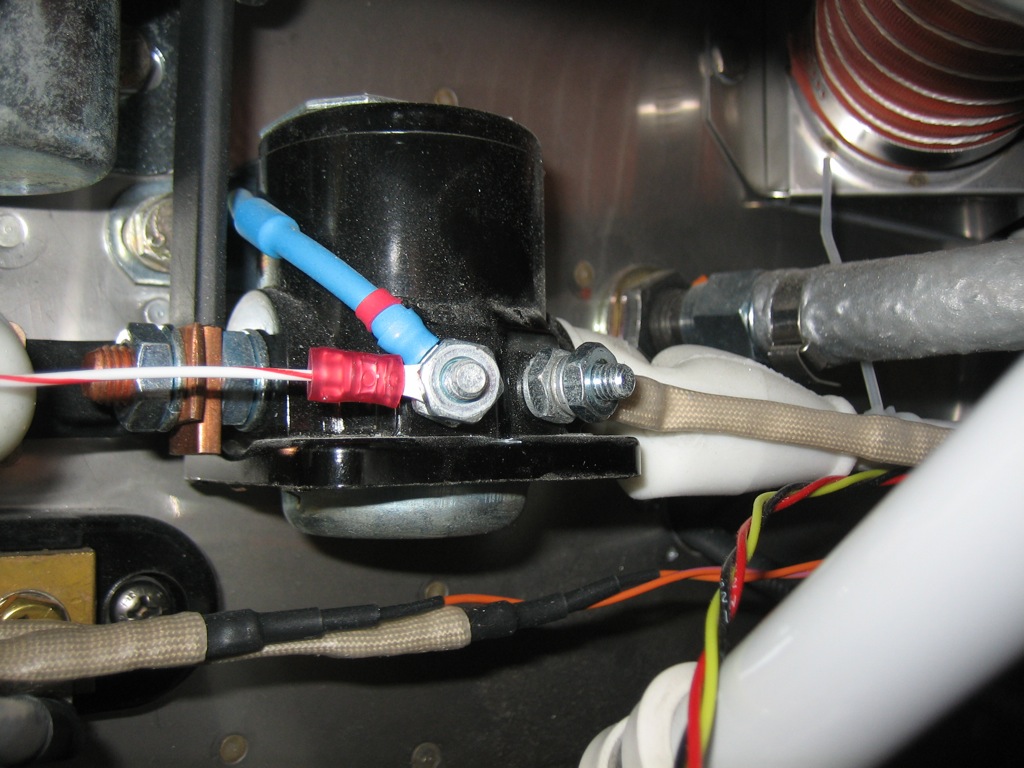

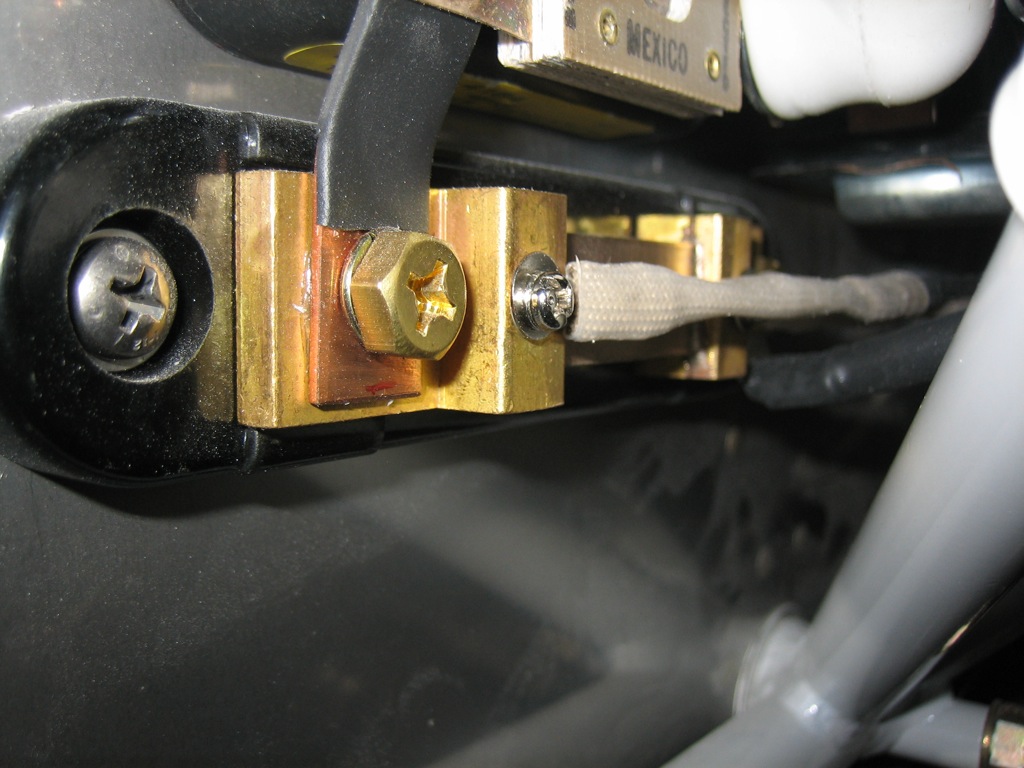

Finally, I tapped into the pitot tube to run a line up to the Gemini. I spoke with TruTrak yesterday, and the Gemini PFD has been delayed a couple of months, so they’re going to send me the Gemini ADI which has the exact same mounting holes and wiring/plumbing connections. Once the PFD is available, I’ll swap the ADI out for it.