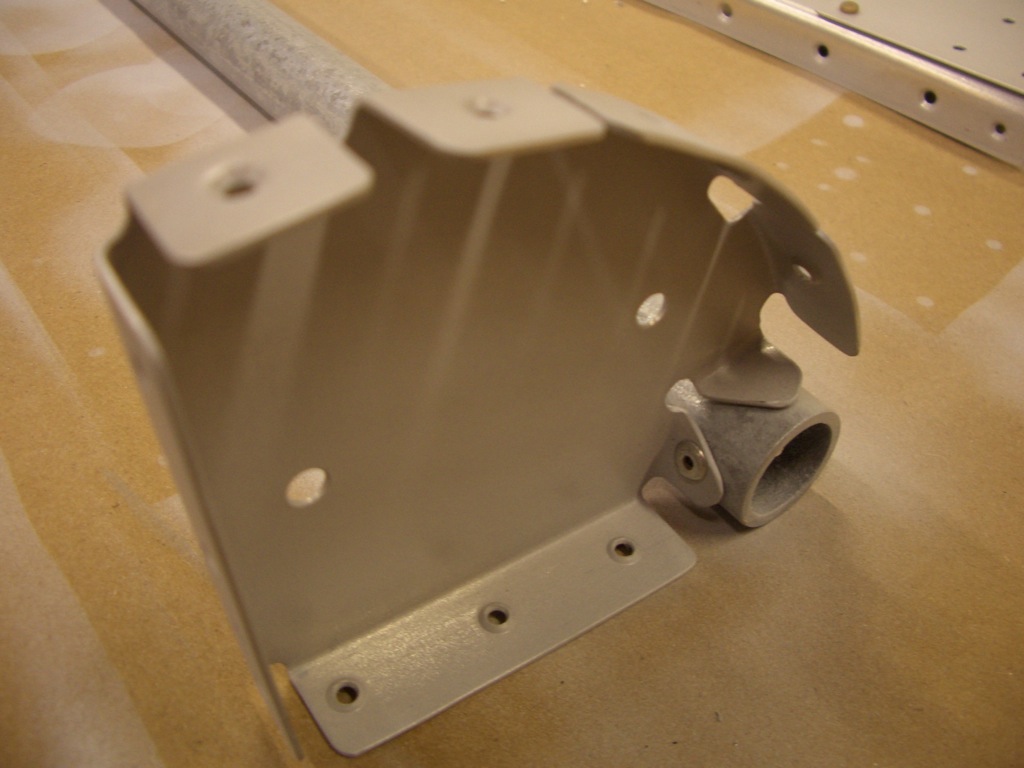

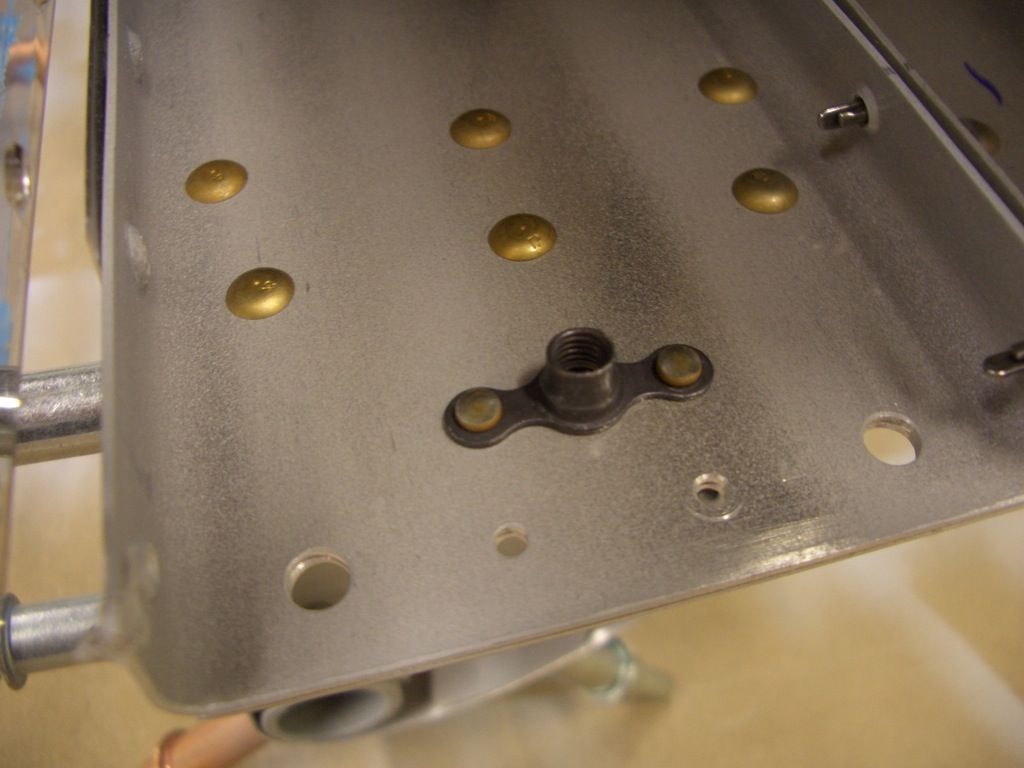

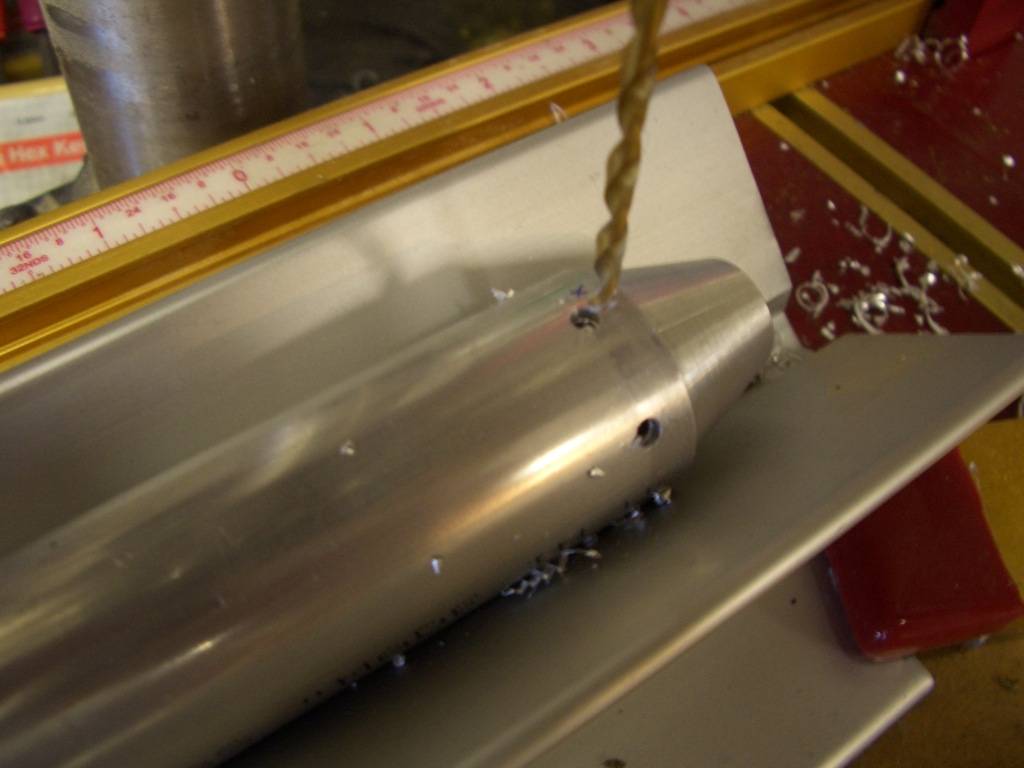

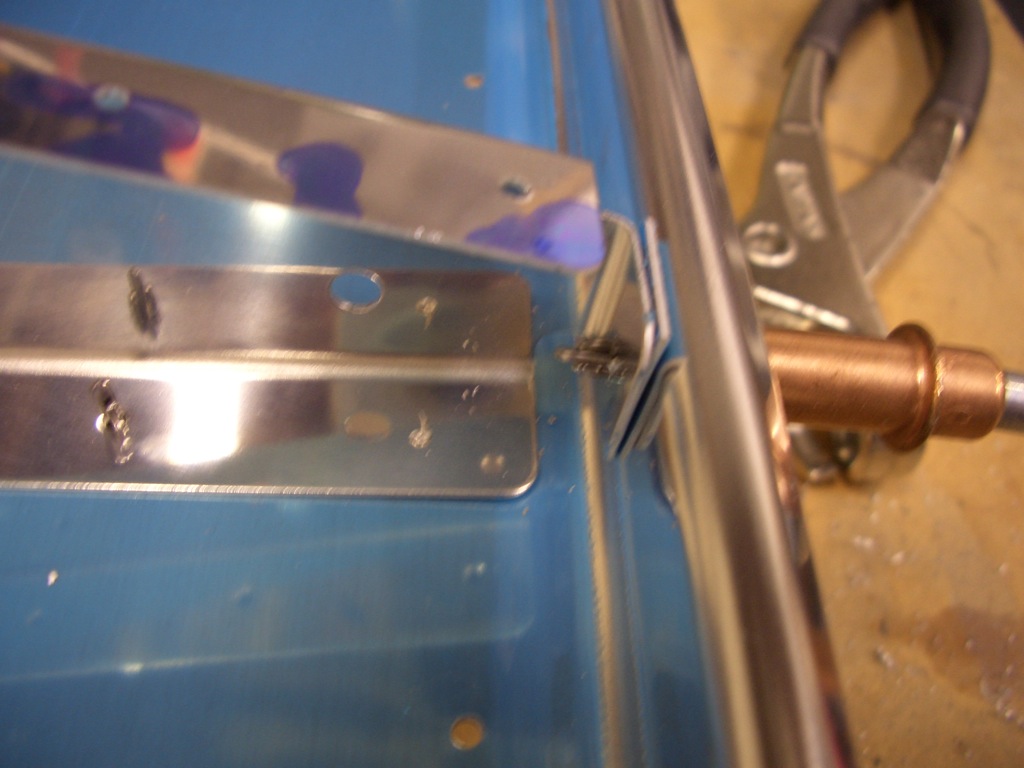

I noticed last night that the bearing in my right outboard aileron hinge bracket was binding. I called Van’s about it today, and they happily sent out a replacement at no charge. I went ahead and drilled out the rivets holding this together, which was a real pain in the ass since those top rivets are AN470AD4-9’s. Even once you drill the head off, they’re nearly impossible to drive out. I ended up having to drill nearly all the way through them before I could drive the rest out. Fortunately, I didn’t elongate any holes.

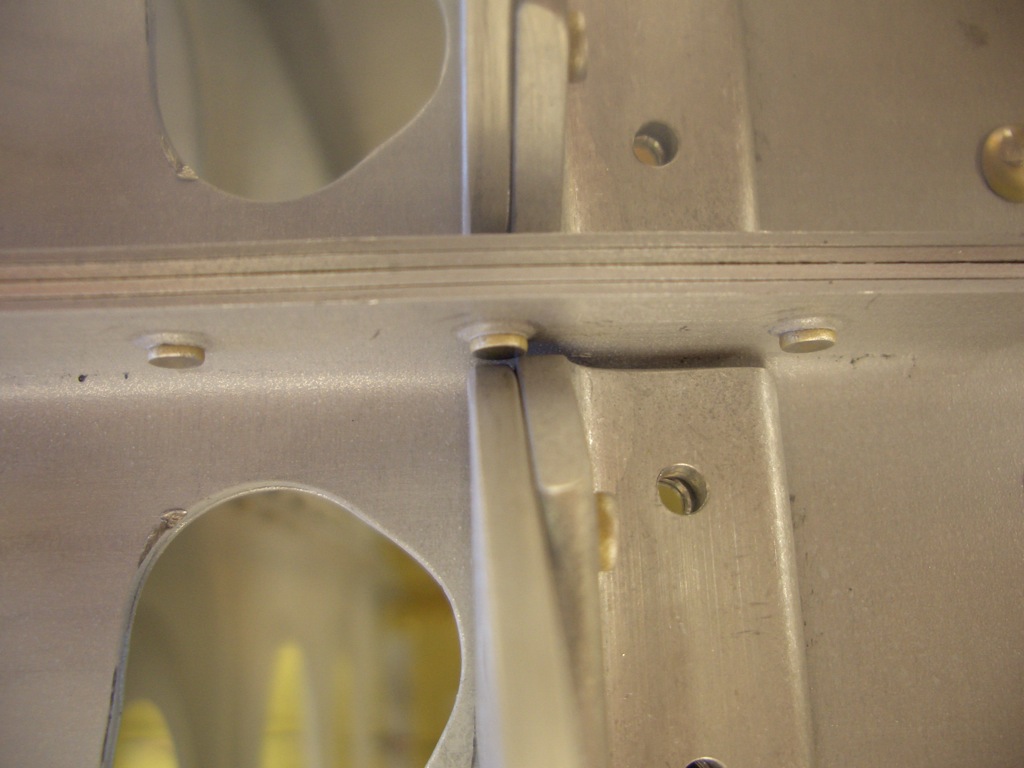

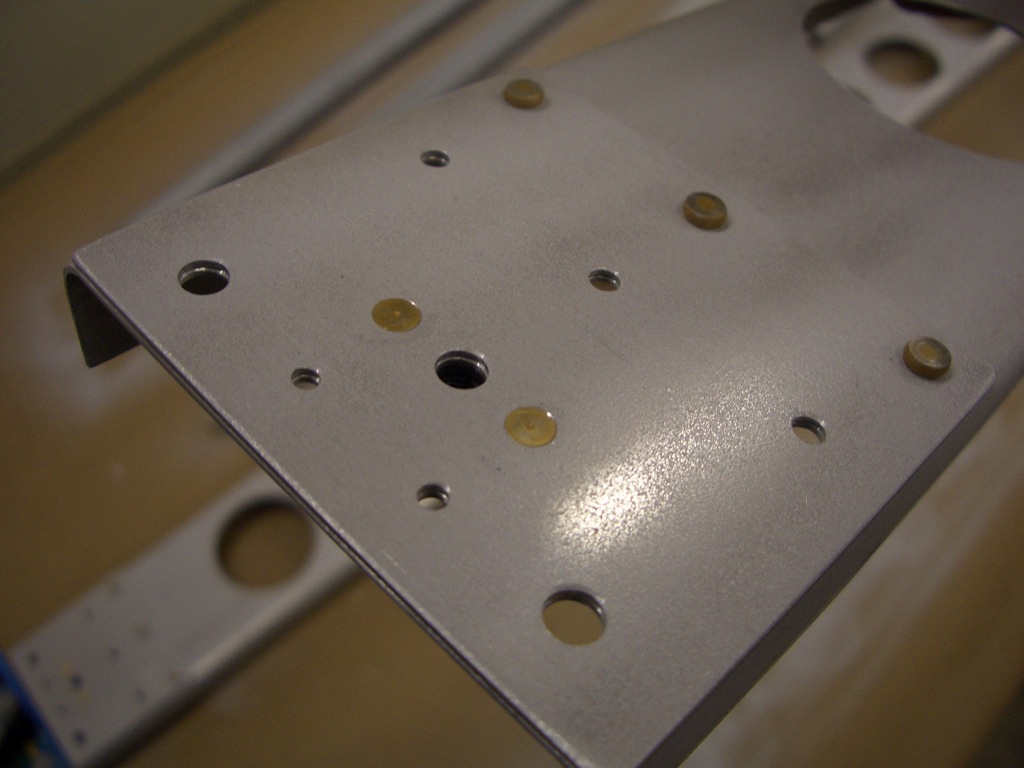

Oddly, after removing the bearing, it was no longer binding. After resqueezing the two lower AN426AD4-7 rivets (the flush ones near the bearing), it bound up again. Argh! After drilling them out a second time, I determined what was going on. Basically, the holes for those two rivets were not perfectly normal to the surface, so squeezing the rivets caused the two surfaces to shift slightly which applied a sideways load to the bearing (squeezing it out of round). I ran a drill bit back through those holes and resqueezed the rivets and the bearing now moves as smooth as silk.

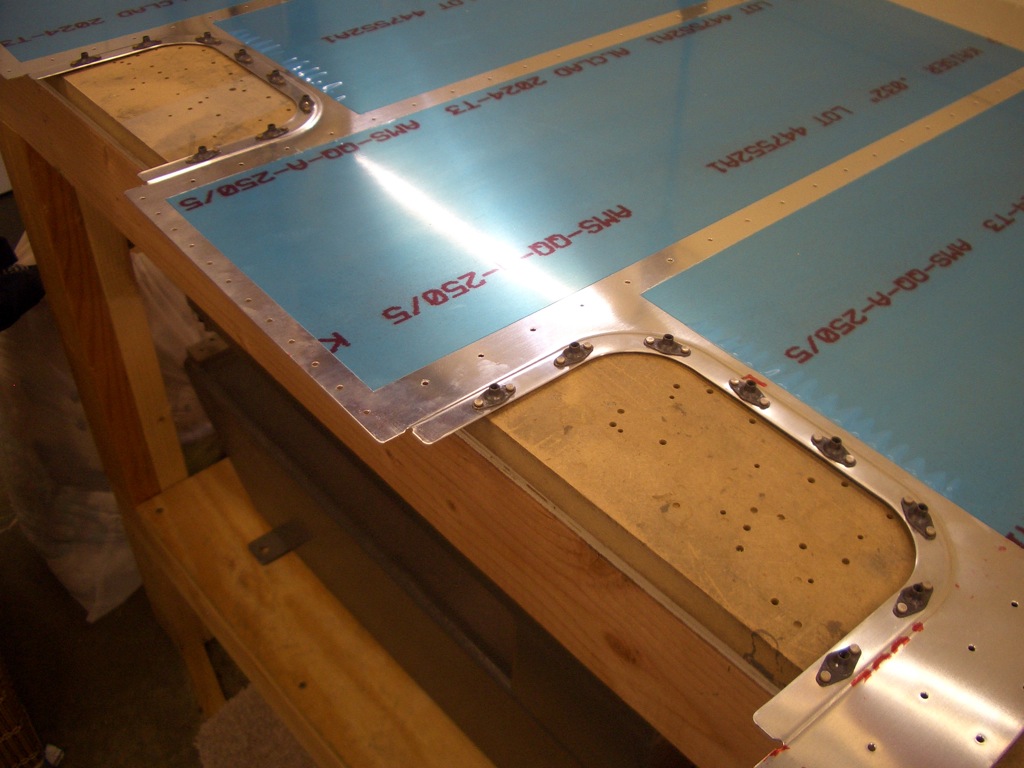

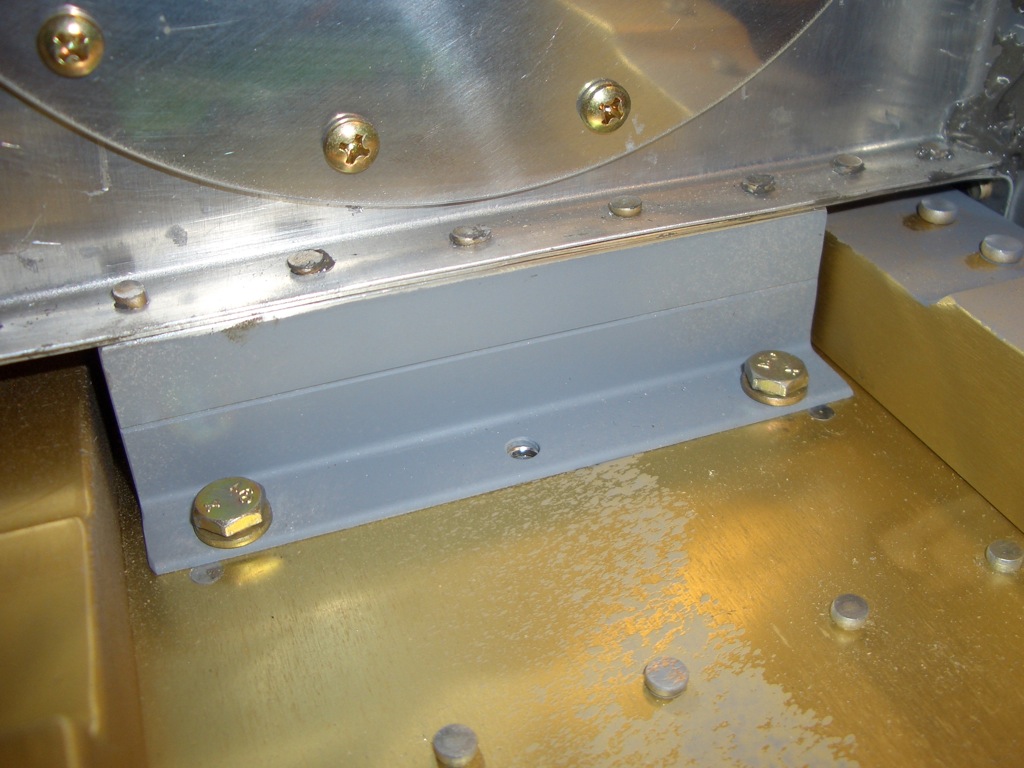

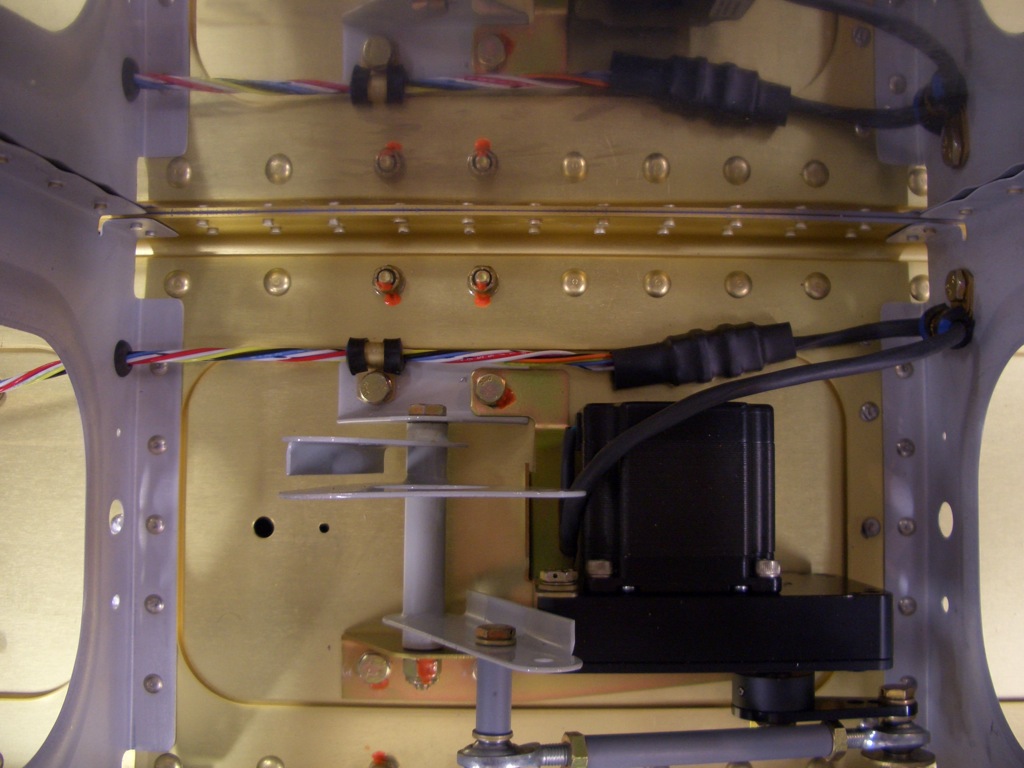

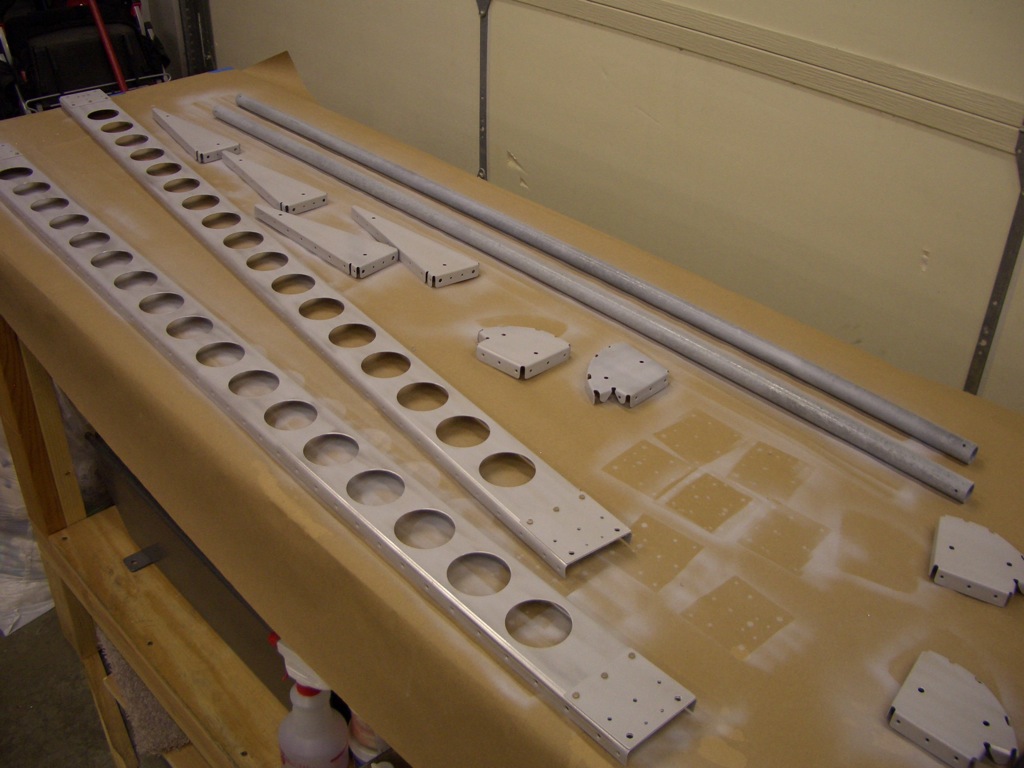

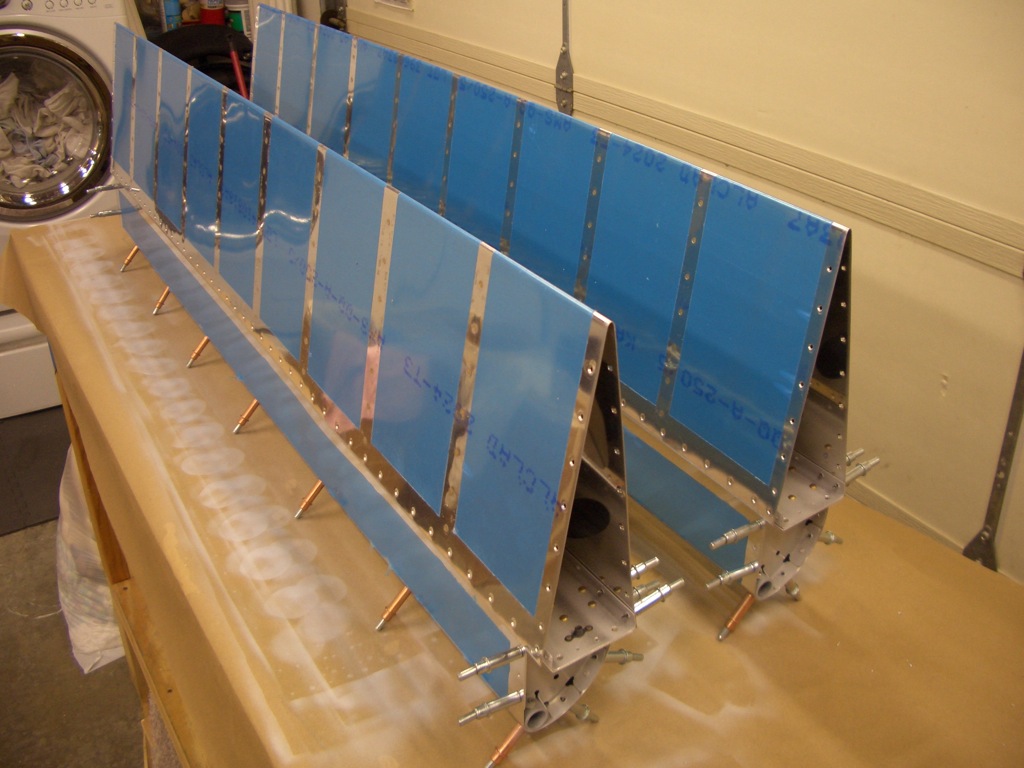

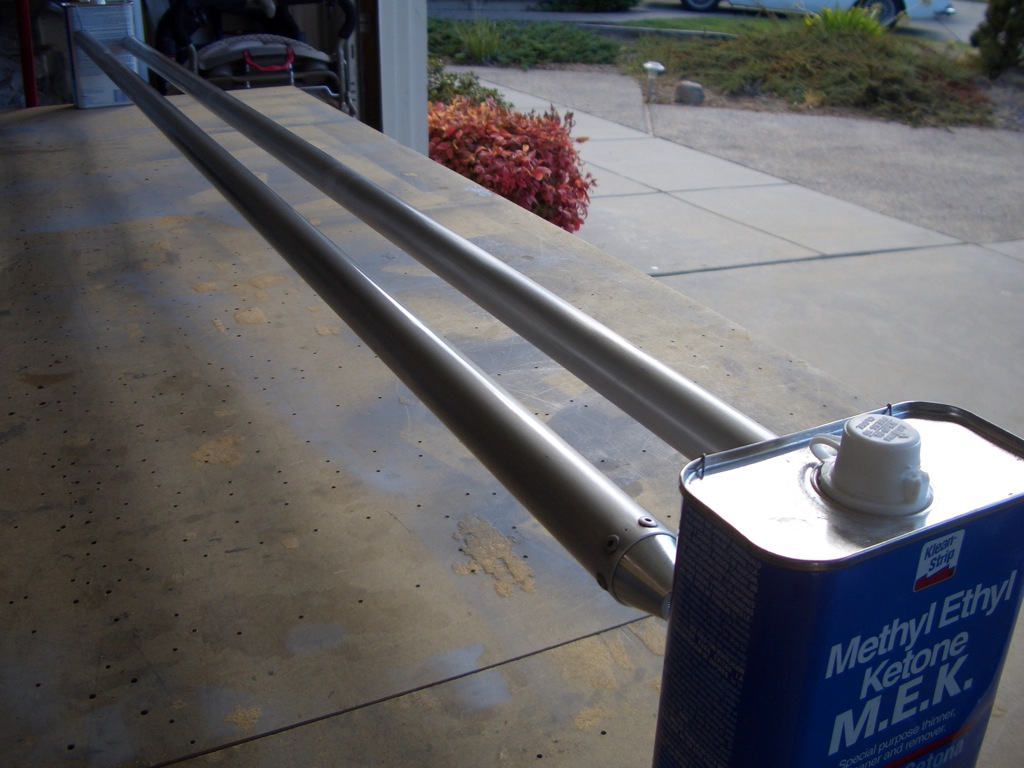

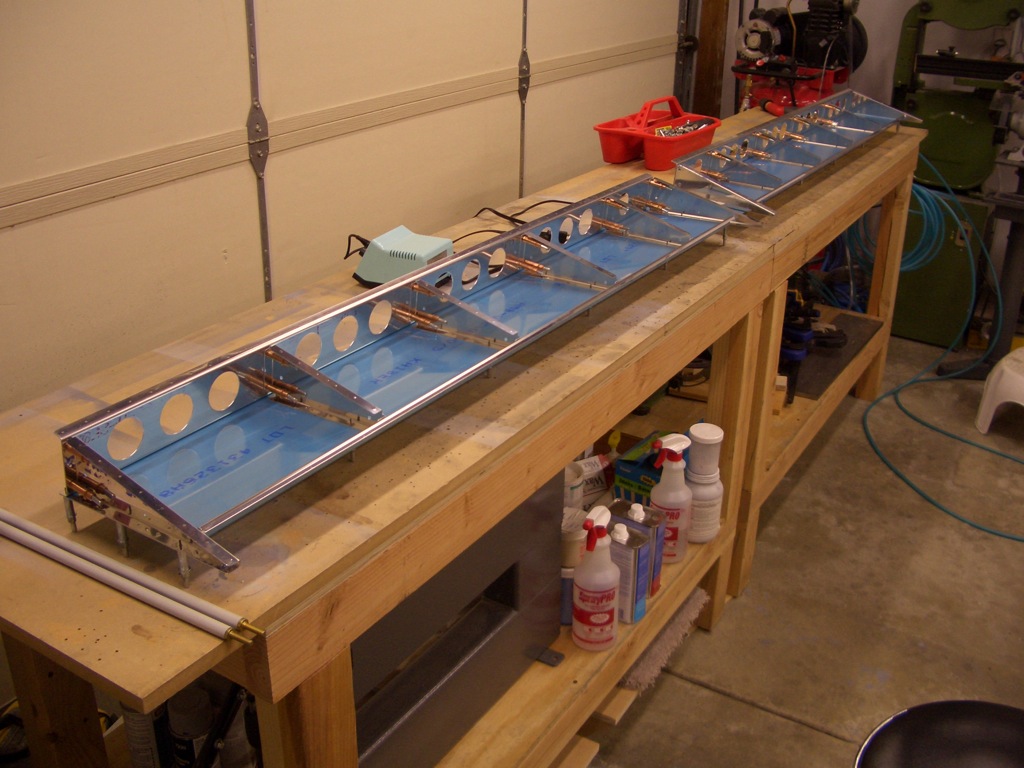

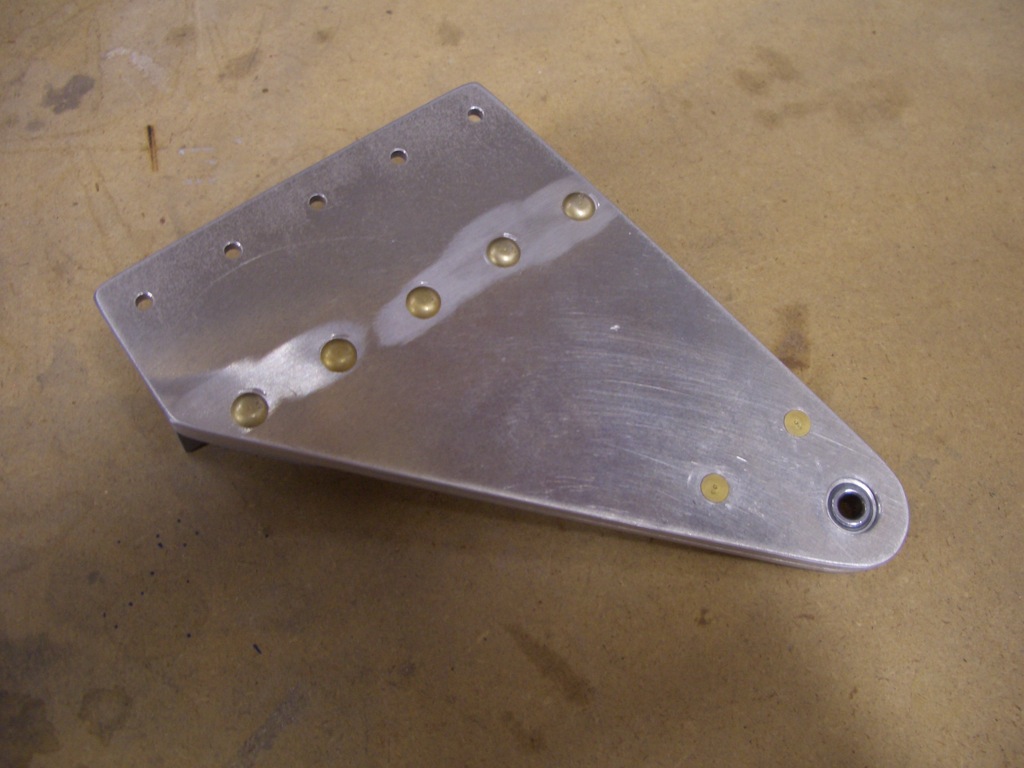

I also clecoed on the bottom skins on the left wing so that I could match drill the flap brace to the skin. The flap hinge will also rivet along here, but I can’t do that until after I build the flaps.

While I was at it, I went ahead and clecoed on the aileron brace, and match drilled it to the skin. I still have to match drill it to the rear spar, but I’ll wait until the bottom skins come back off so I have easy access.