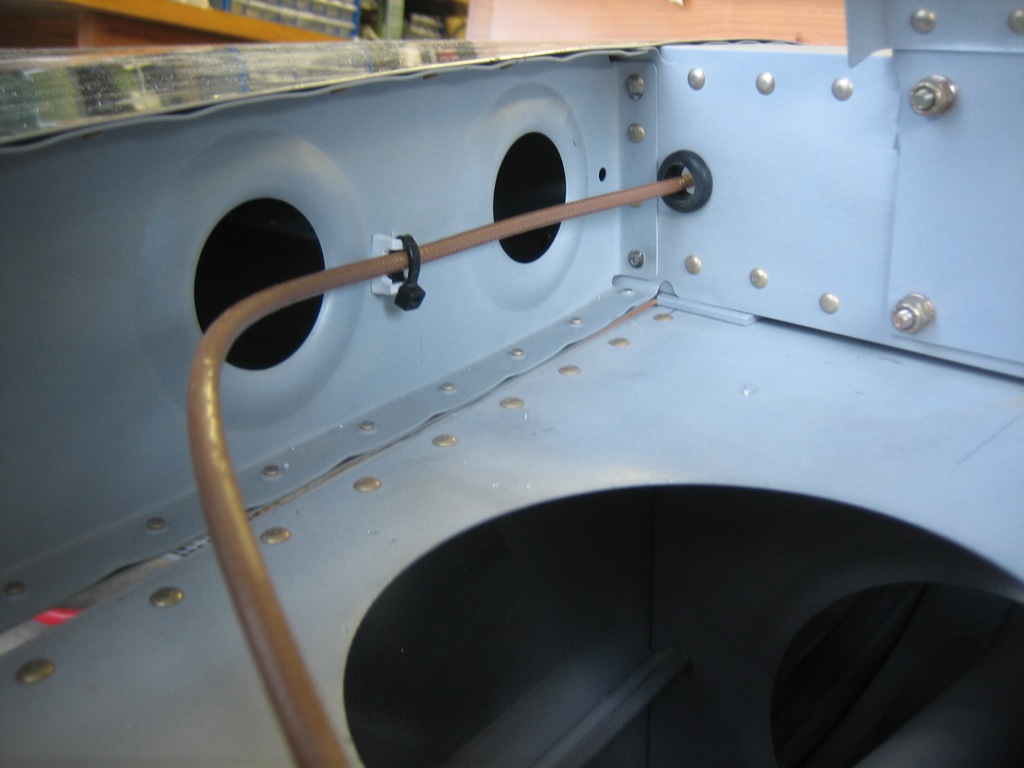

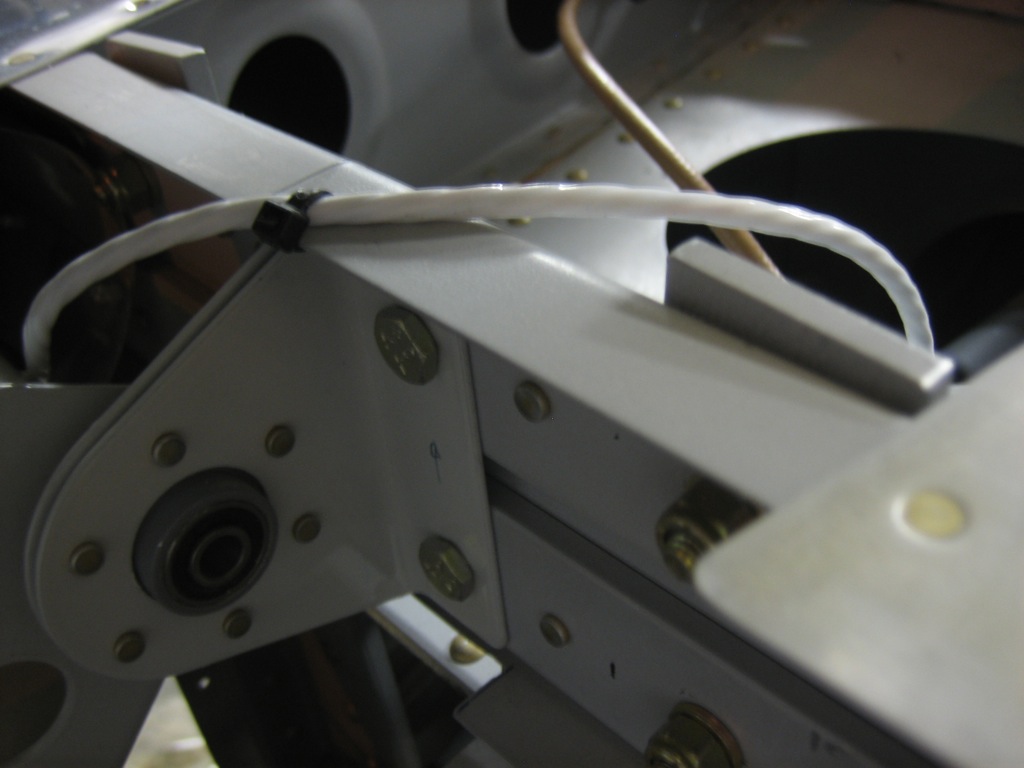

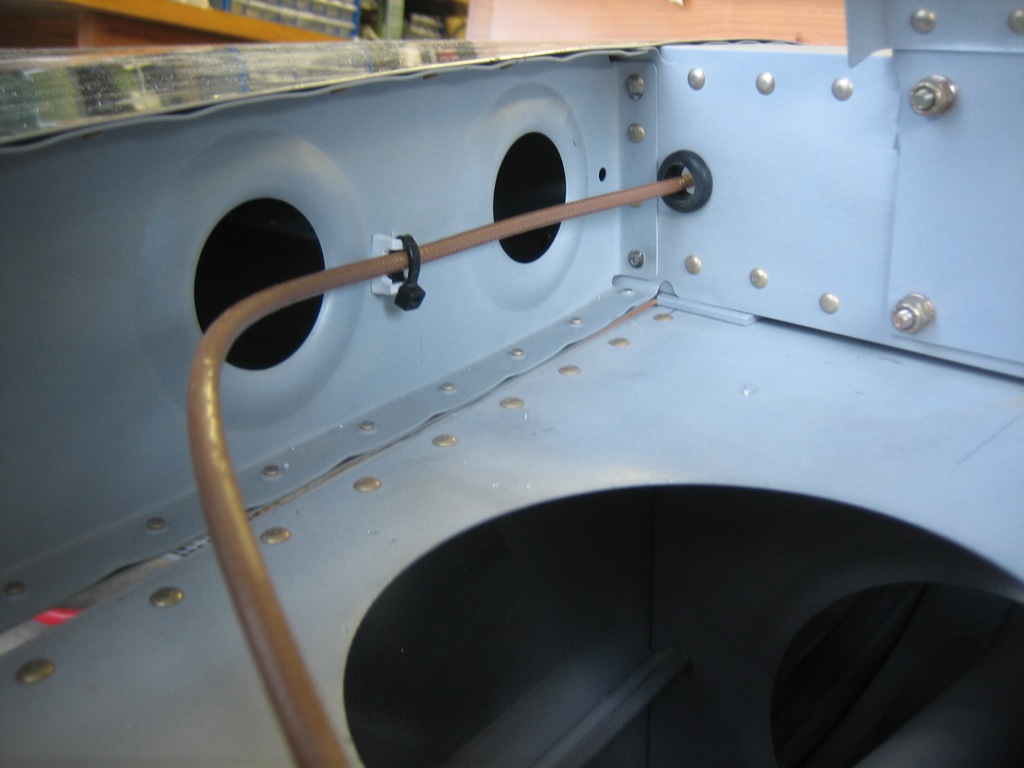

I drilled out one of the rivets on the horizontal stabilizer and installed an adel clamp to secure the aft end of the antenna. I also wrapped a bit of silicone wrap around the antenna where it passes over the forward spar of the horizontal stabilizer so that it can’t touch.

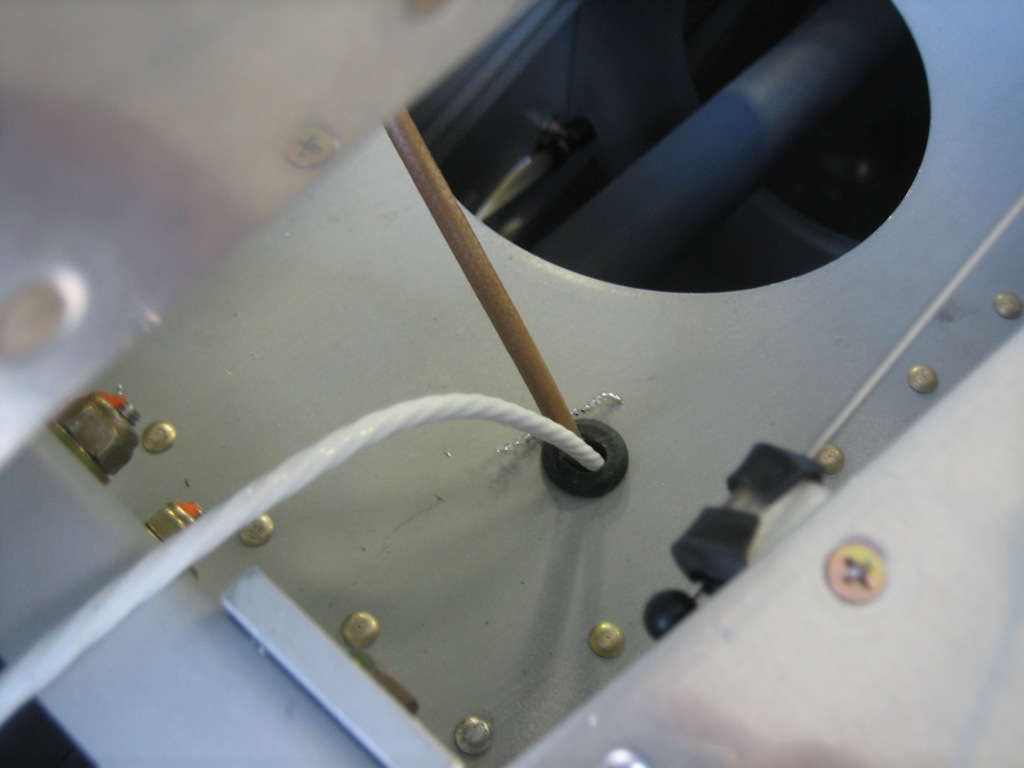

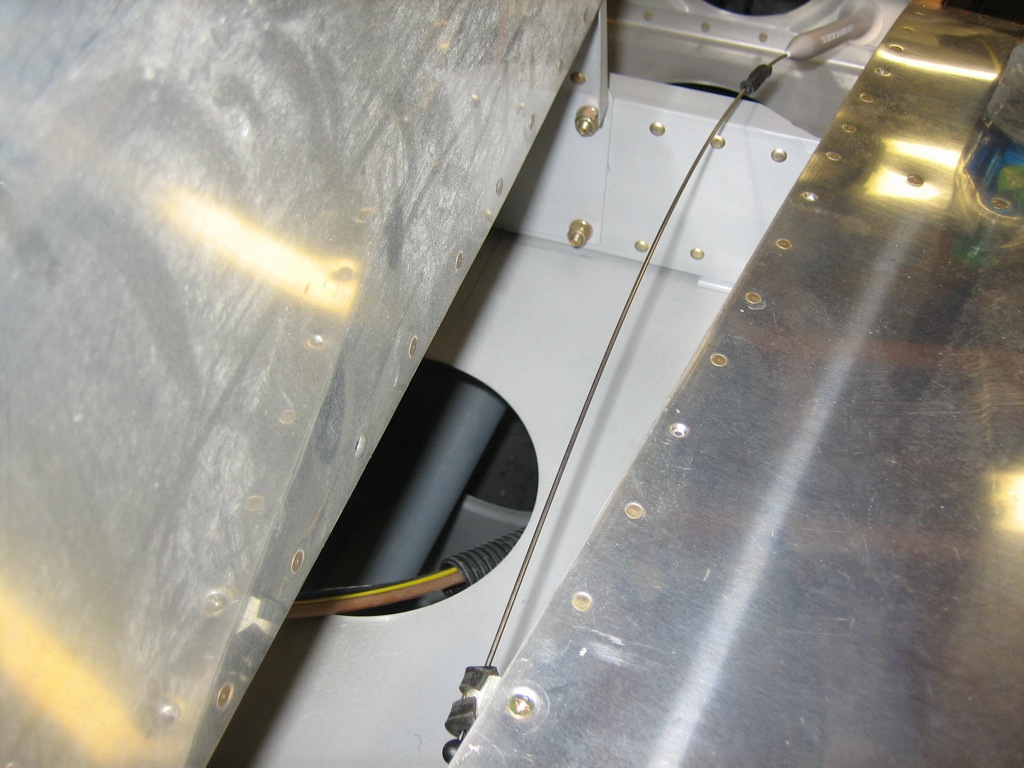

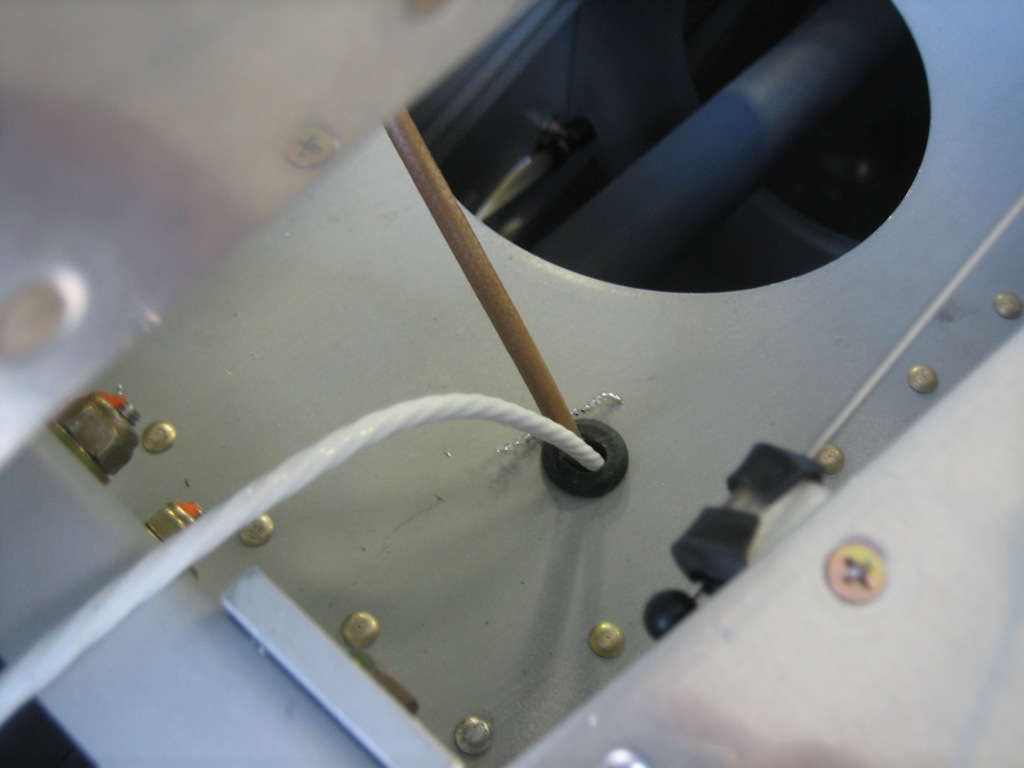

I drilled a hole for the tail strobe wiring. The material here is so thick that a single snap bushing won’t go all the way through, so I glued a snap bushing in from each side.

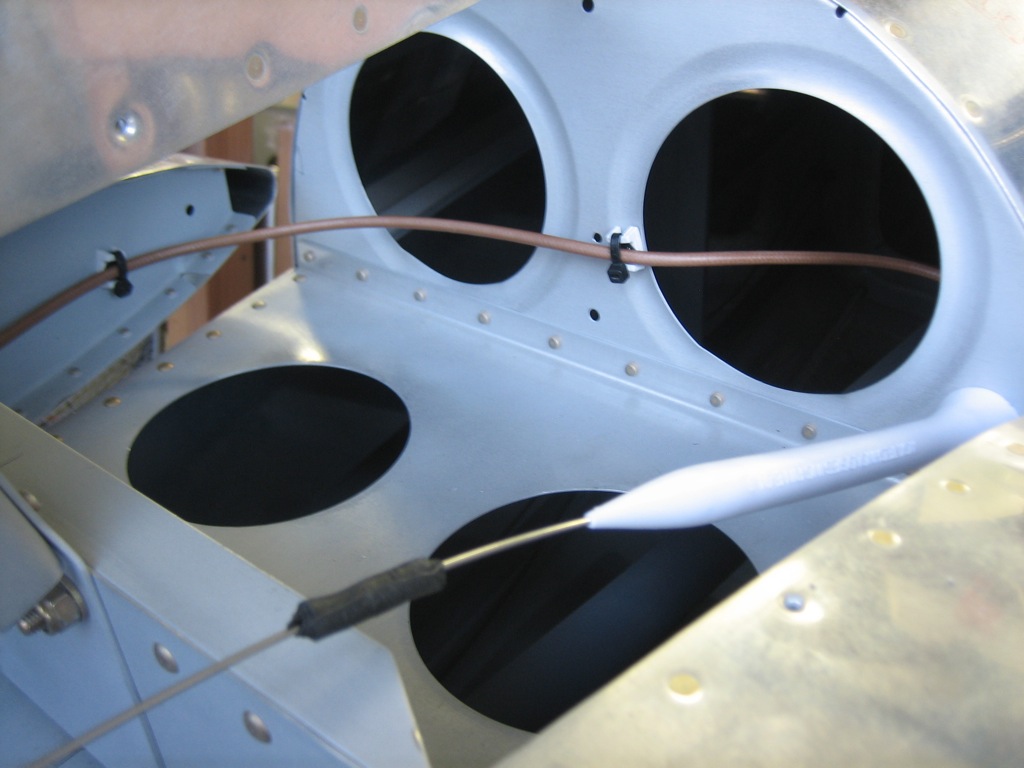

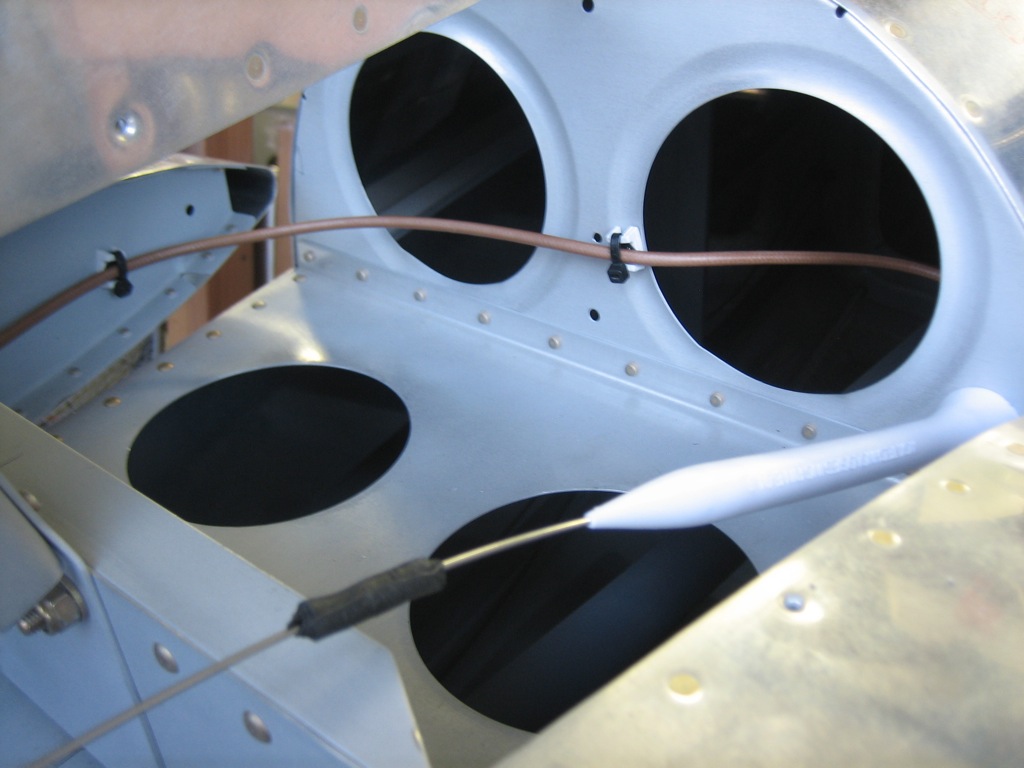

I also drilled a hole in the aft deck to bring the ELT antenna wire and trim cable through.

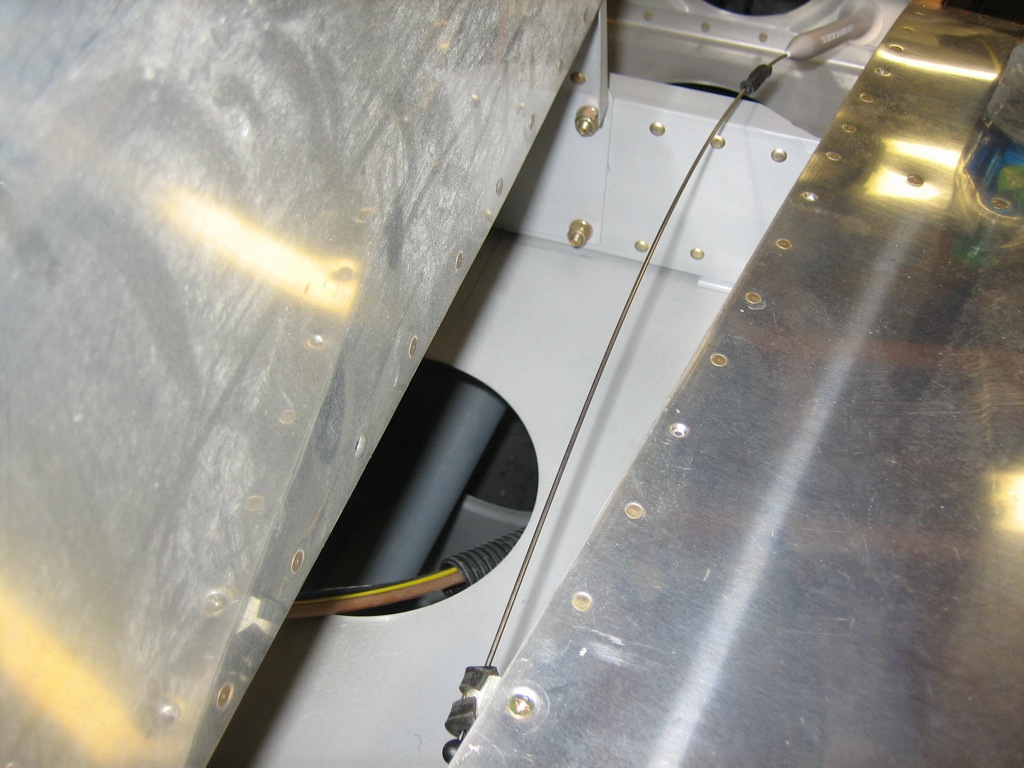

The ELT antenna cable crosses the deck and goes through the existing hole in the forward spar of the horizontal stabilizer.

From there, it crosses back across the deck and connects to the antenna.

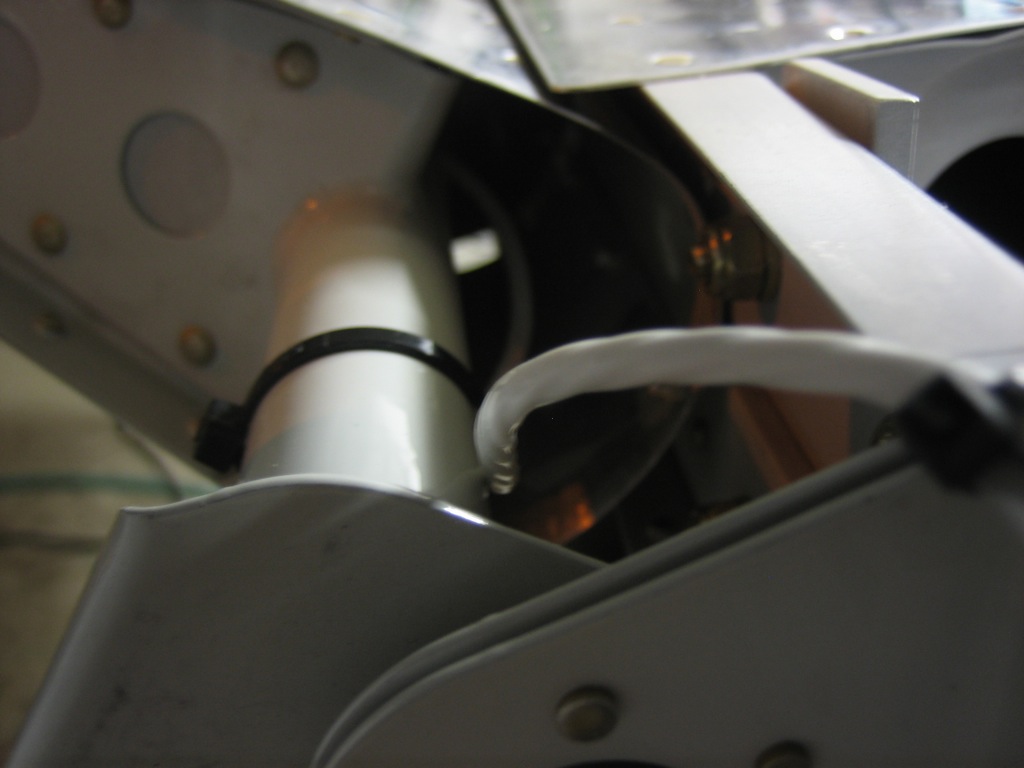

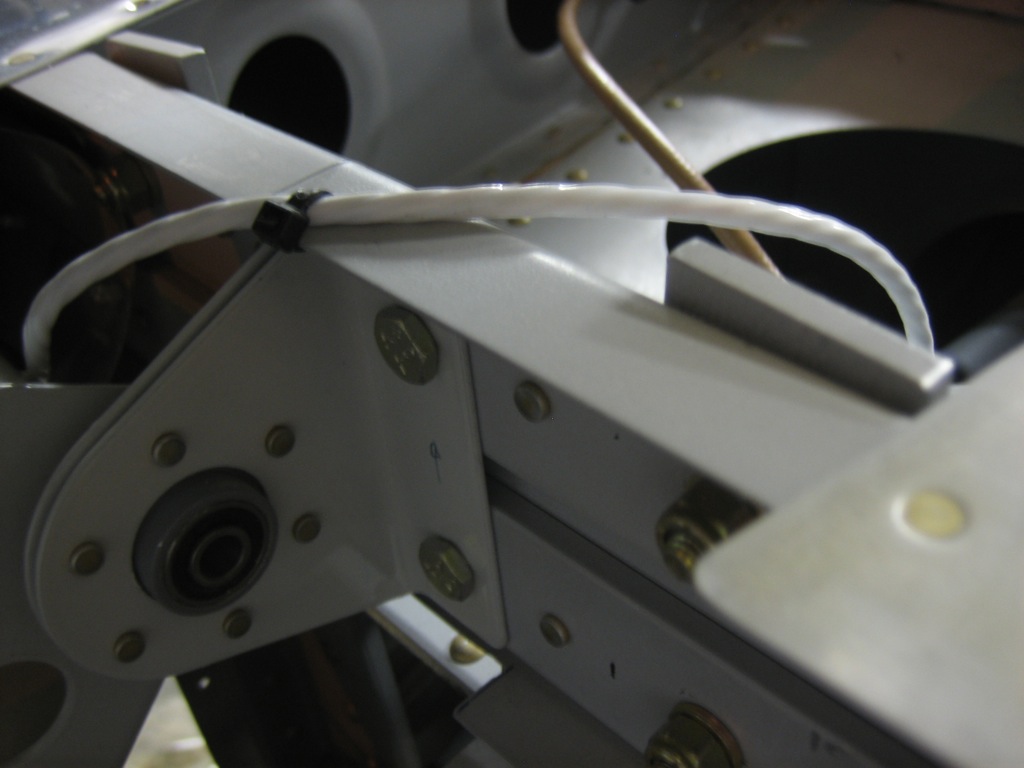

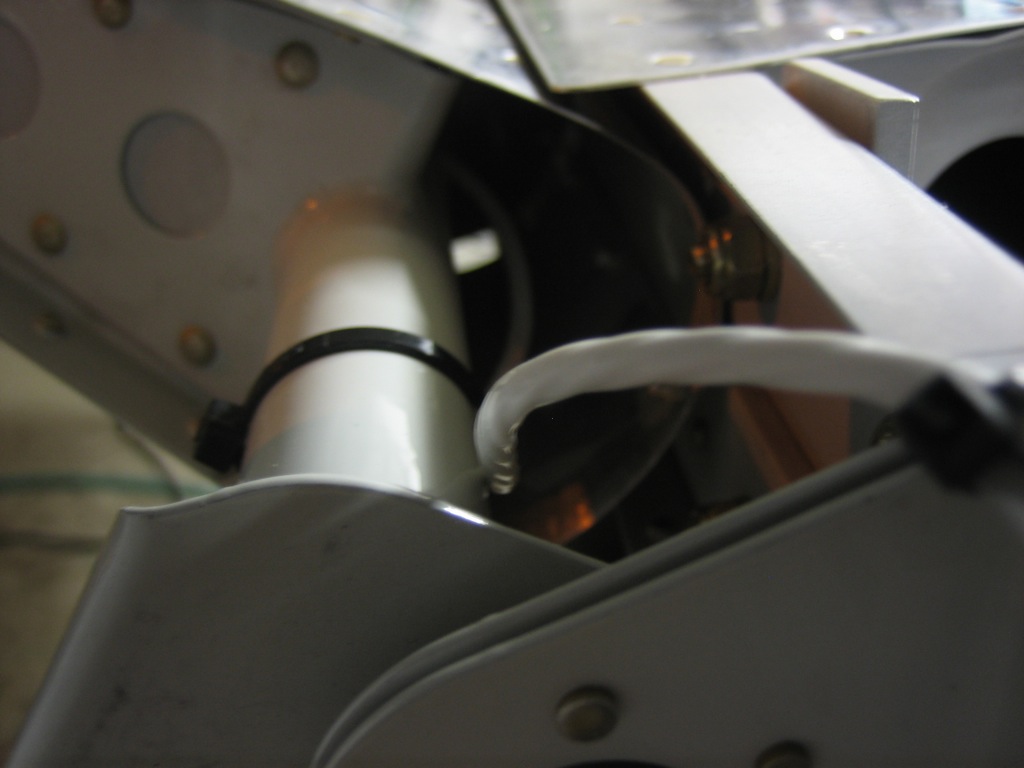

The trim cable is zip tied to the rear spar of the horizontal stabilizer and then follows the torque tube out to the left elevator.

It’s also zip tied to the torque tube and then goes through a grommet in the left elevator spar.

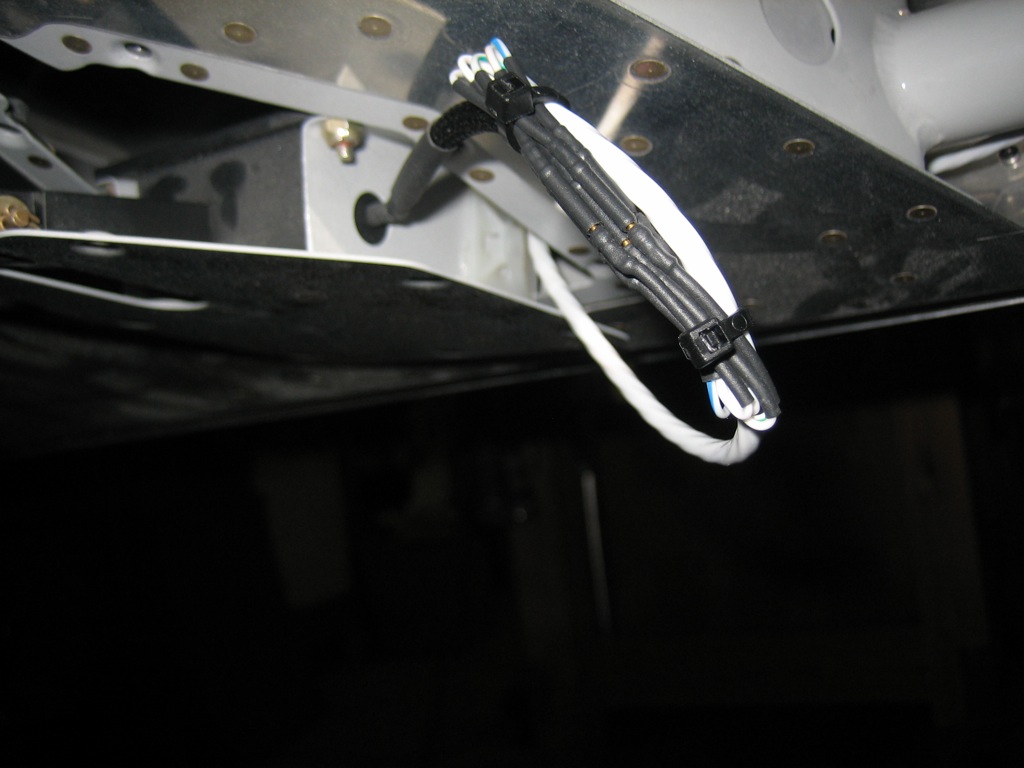

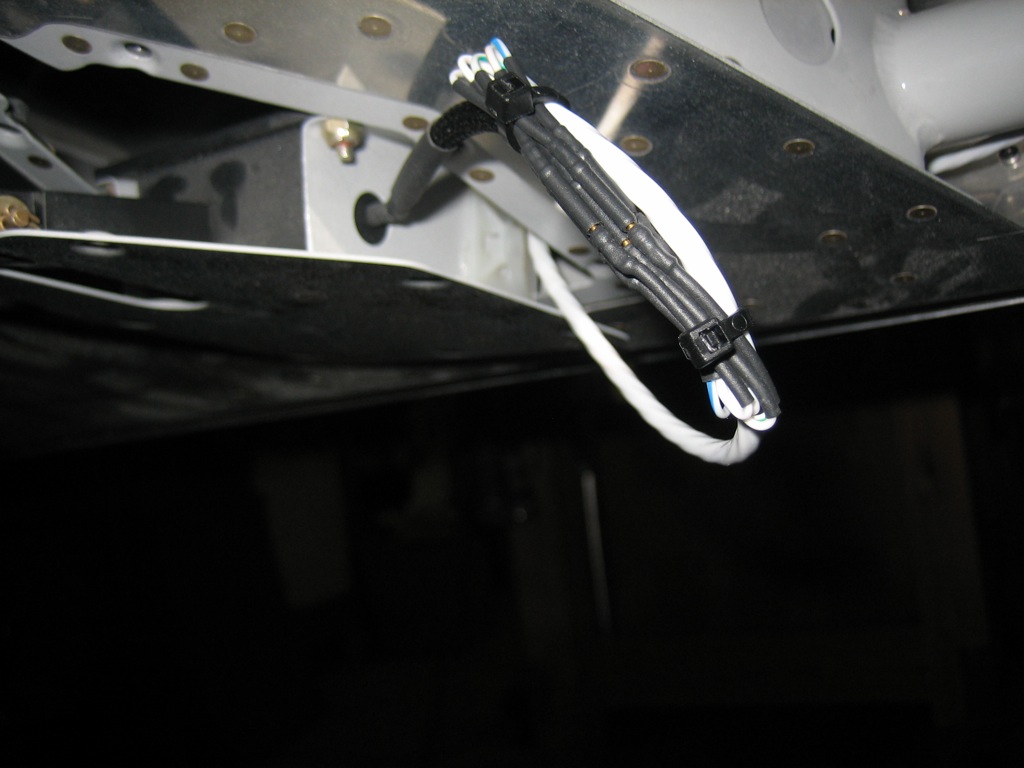

I installed some d-sub pins and sockets on the cable and trim motor to make it easy to disconnect the motor if it ever needs repair. I added some heat shrink to each side so that there will be no electrical contact between the wires. If the elevator ever needs to be removed, it’s fairly easy to fish the cable out through the hole in the spar.

By doubling the wires back on themselves and zip-tying them together, the d-sub pins can’t pull out of the sockets. This bundle can easily be tucked along side the trim motor.

Finally, I adjusted the length of the pushrod to give me 25º of down movement (up elevator) and 20º of up movement (down elevator).

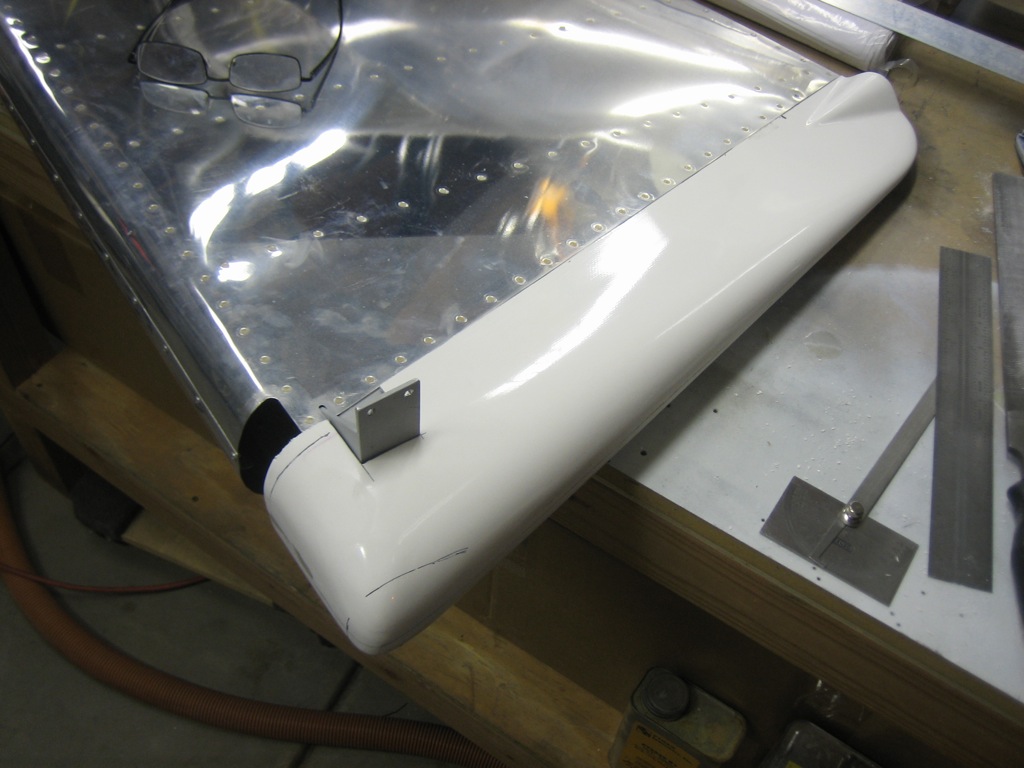

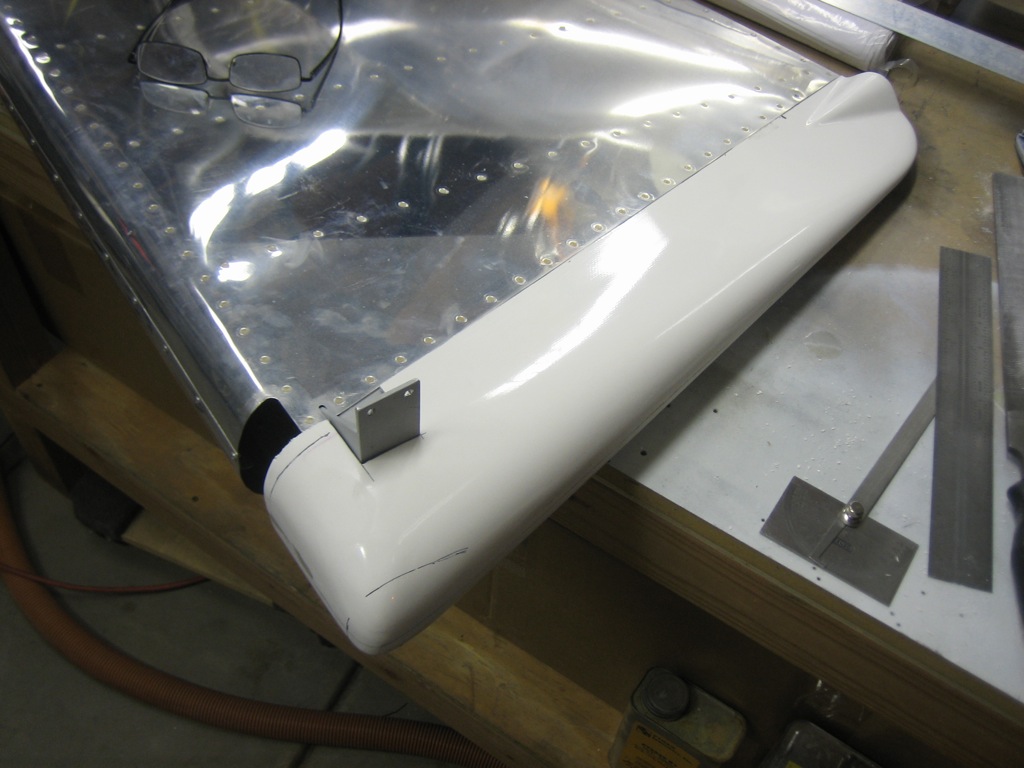

Afterward, I started fitting the rudder bottom fairing. This is going to have to move up a bit more, but it’s been a long day and I’m exhausted.