My brother Seth flew out from KY yesterday to help me mate the wings. The weather was spotty in the morning, so we got started a little later that I’d have liked. We pulled the plane out into the driveway and temporarily fit the wings with some hardware store 7/16″ bolts.

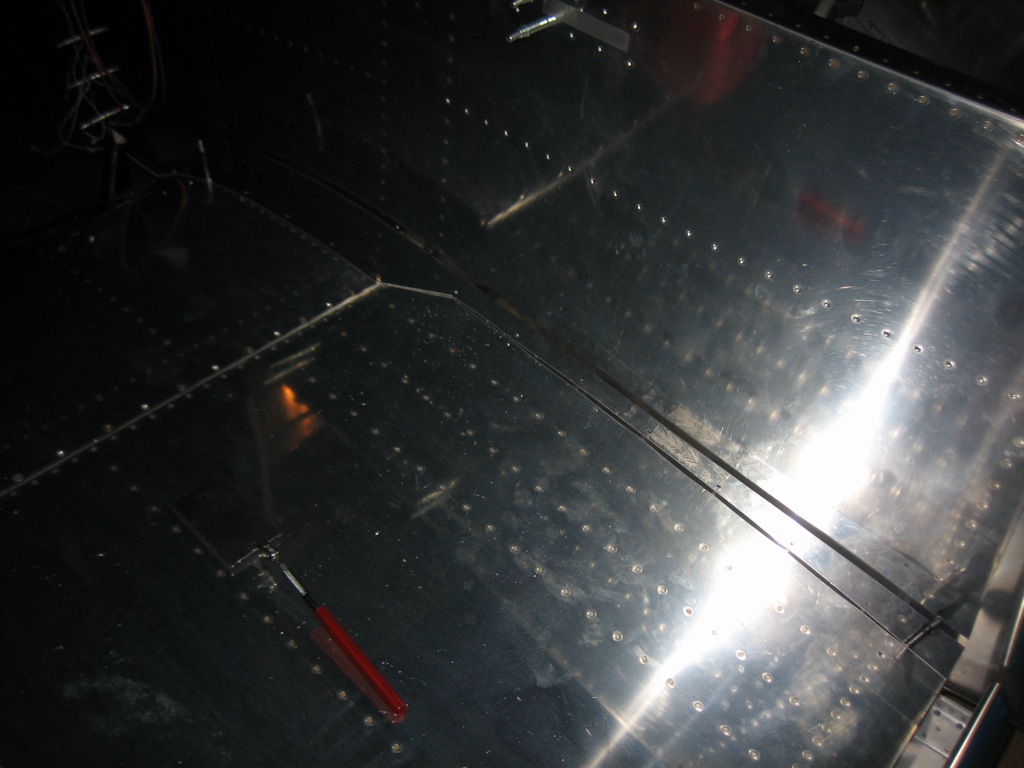

Next up, we leveled the fuselage laterally and hung two plumb bobs off of each wings. I tied a piece of fishing line to the cord on the outer two plumb bobs so that I could easily compare the position of the inner two plumb bob cords to the line to see if the wings had any sweep in them. I also took some measurements from the tail to make sure each wing had the same amount of sweep. Finally, I checked the wing incidence on both sides to make sure they were the same.

With the wings straight, I installed the flaps to see how they fit against the fuselage. The good news is that the height on both sides is perfect and the inboard end of the flap skins just kisses the bottom of the fuselage. Unfortunately, with the wings perfectly straight, the joint between the flaps and the side of the fuselage wasn’t uniform. The gap got progressively wider towards the trailing edge of the flap. I decided to sweep the wings back slightly to make the gap uniform (I probably only brought the wing tips back 1/4″ or so from straight across). This will make no discernible difference in the flying qualities, but the aesthetics of the flap/fuselage intersection are significantly improved.

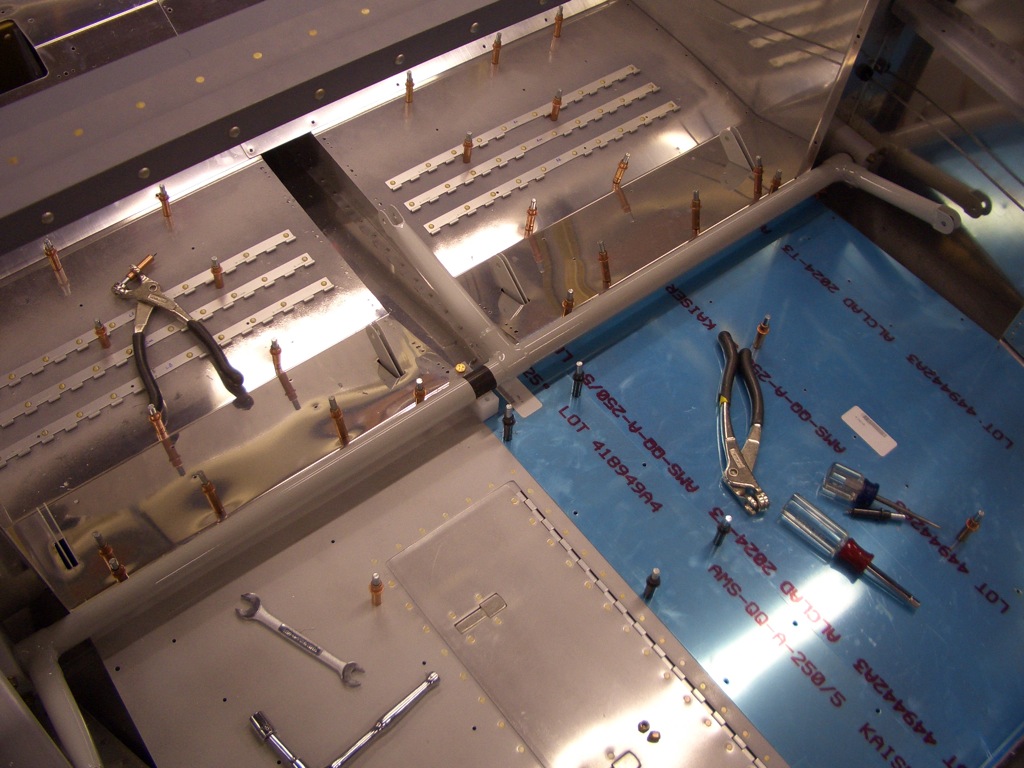

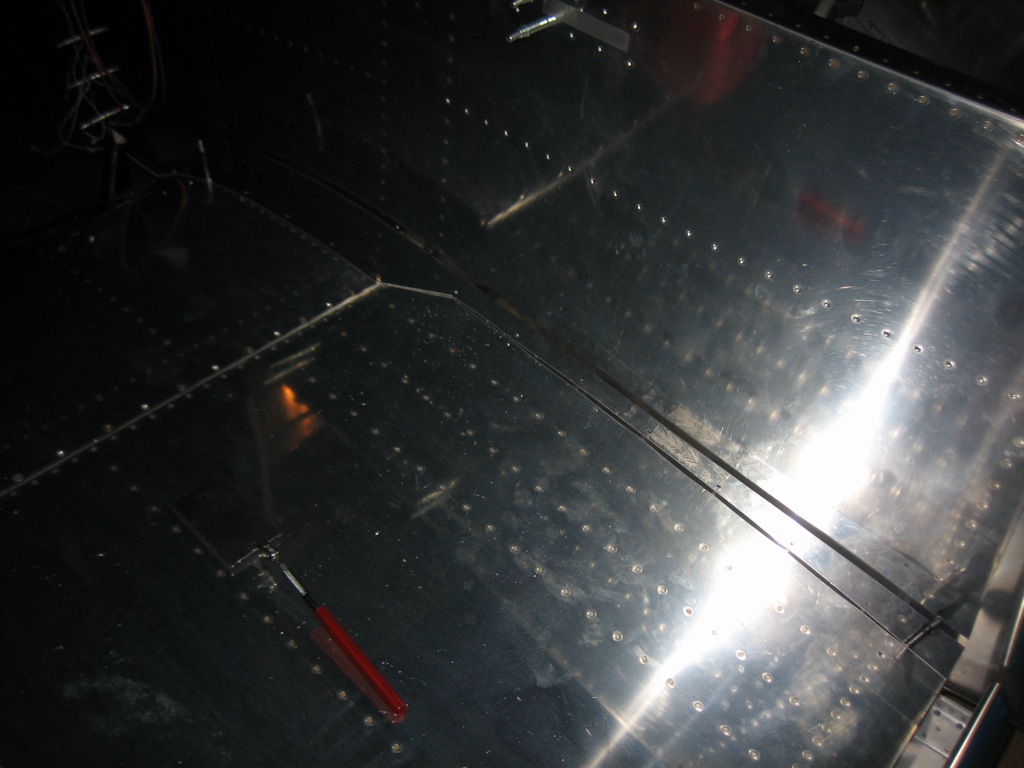

After triple checking everything, I laid out some marks to ensure that I had 5/8″ of edge distance (from the center of the bolt) in all pieces, then progressively drilled out the hole to just under the final size. I then used a 0.3115″ reamer to bring the hole up to final size providing a snug fit for the bolt. I used a drill cup on the first three sizes to ensure that I was drilling absolutely perpendicular to the material.

My buddy Andre dropped by to check out the progress, and we drilled the bottom wing skin and the wing root fairings for #8 screws and my brother trimmed them to the fuselage.

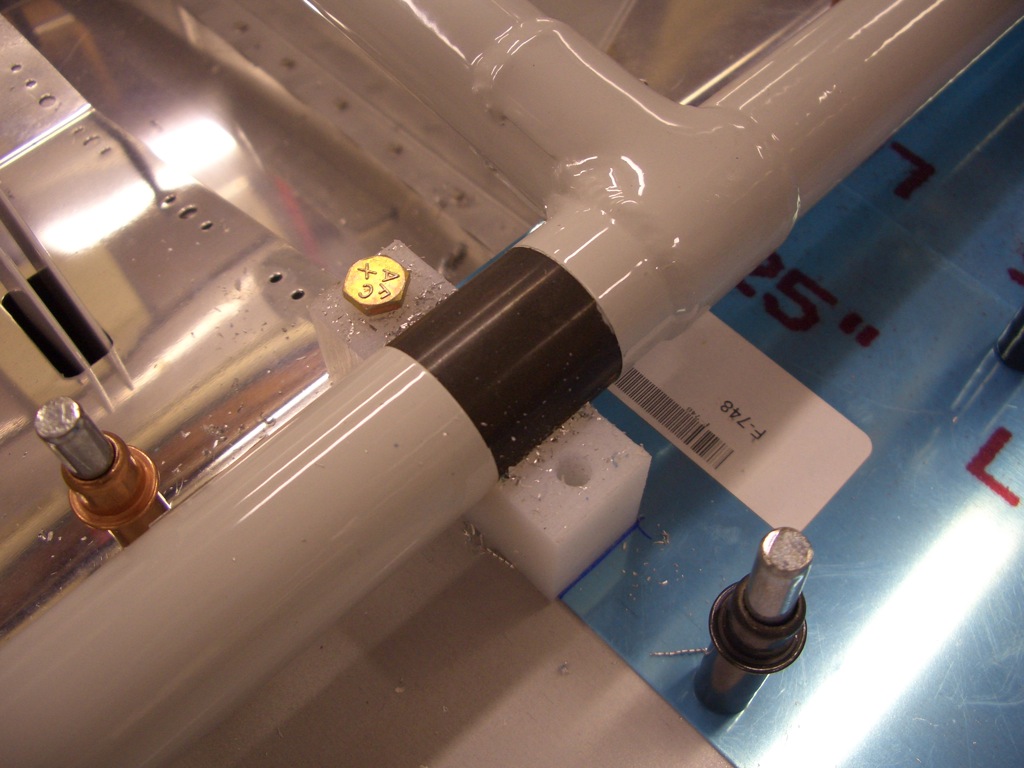

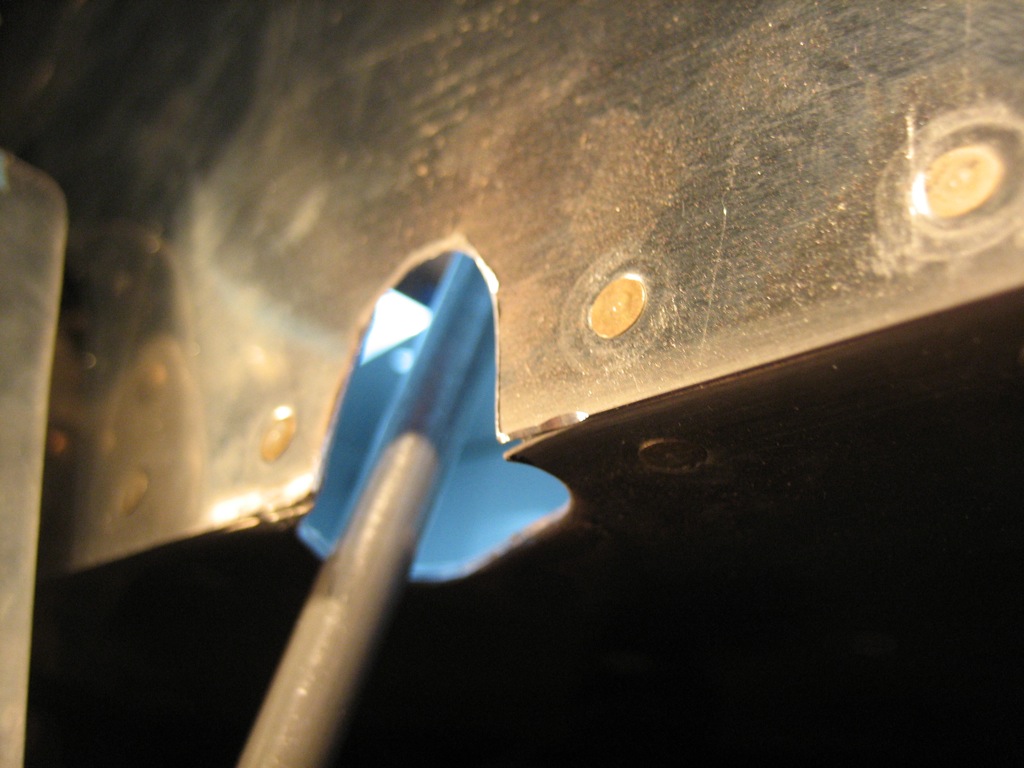

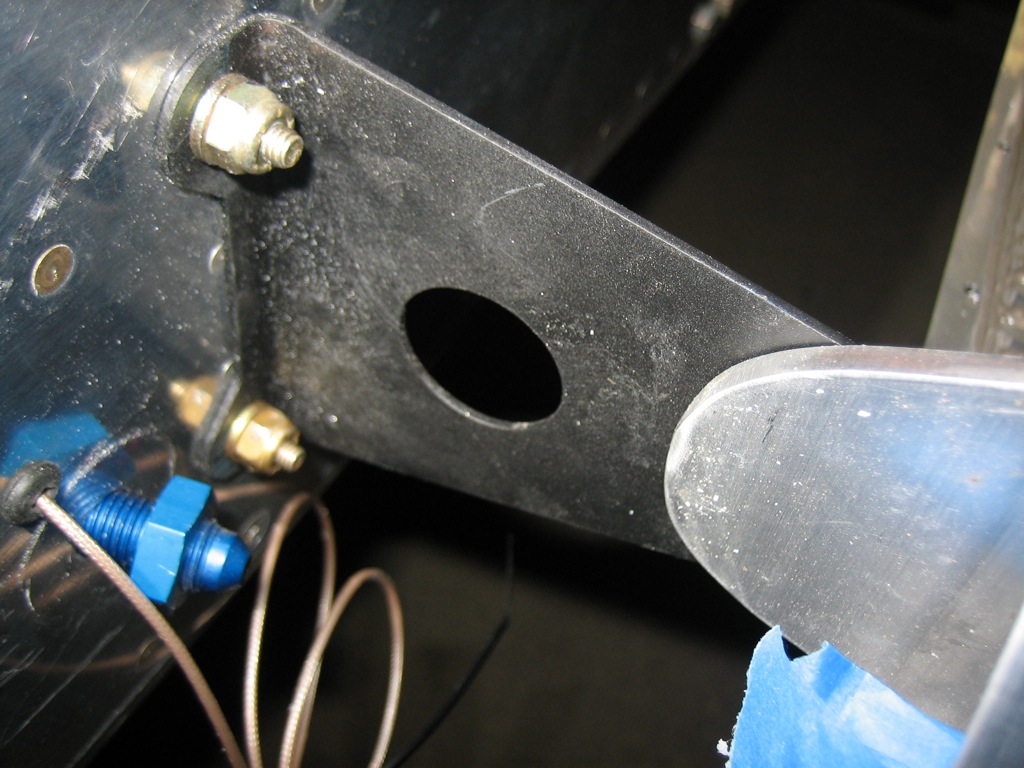

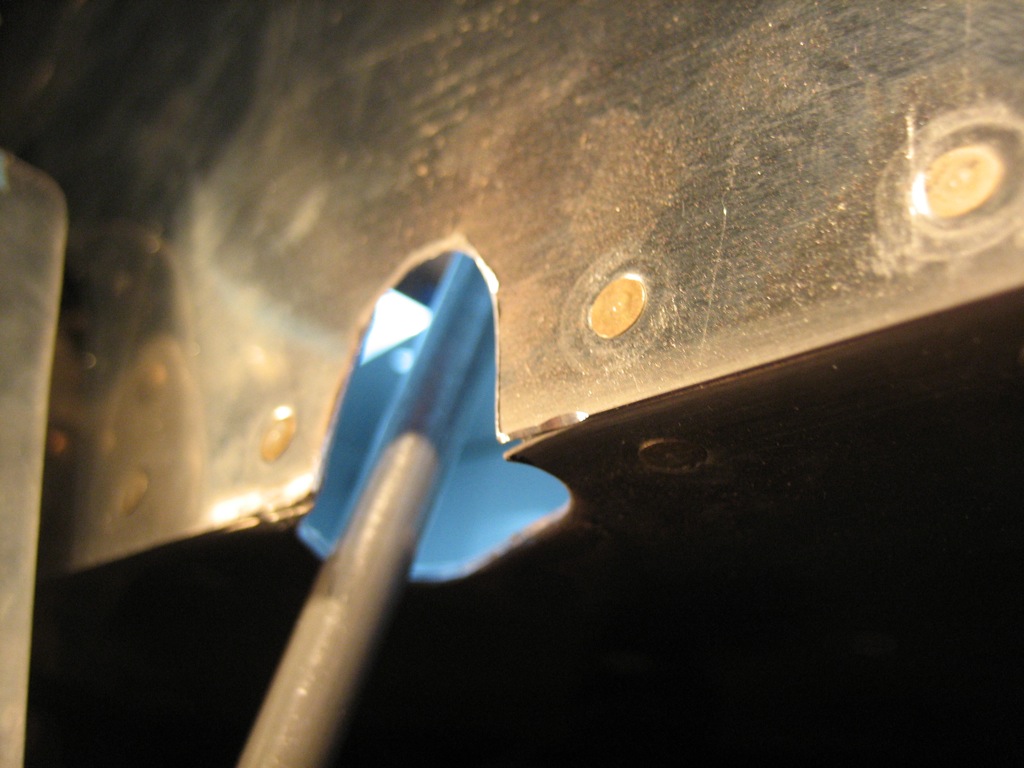

Next, I installed the flaps and pushrods and cut out the flap pushrod holes. These are odd shaped holes due to the changing geometry between the flap weldment and the flap as they’re moved up and down.

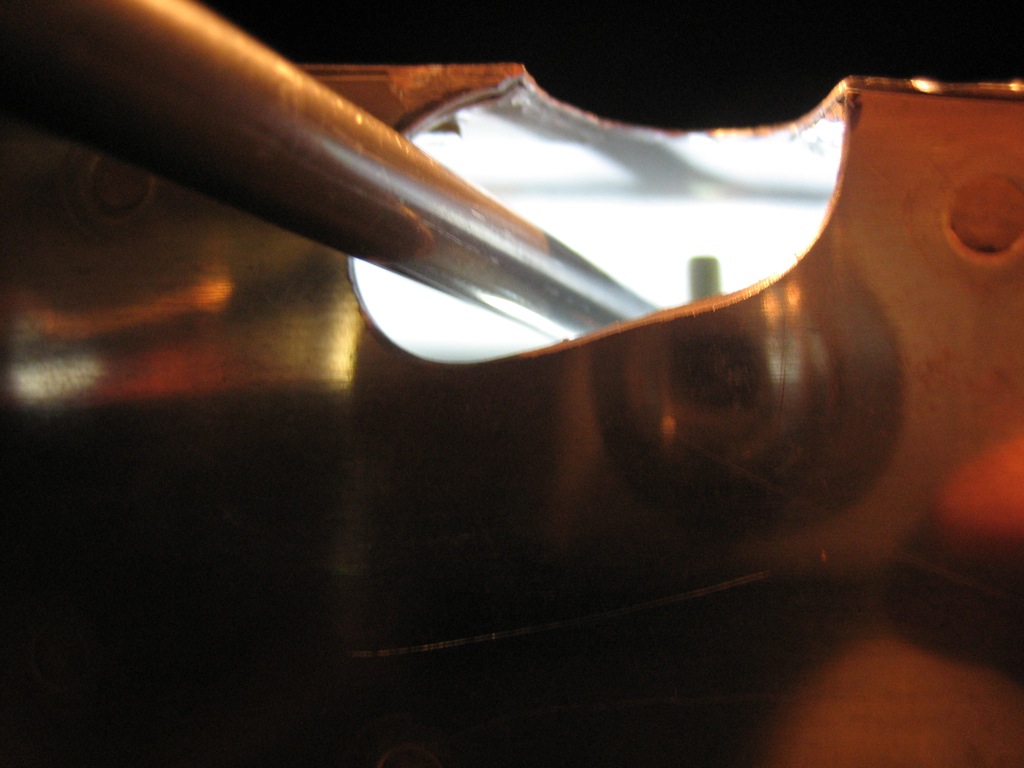

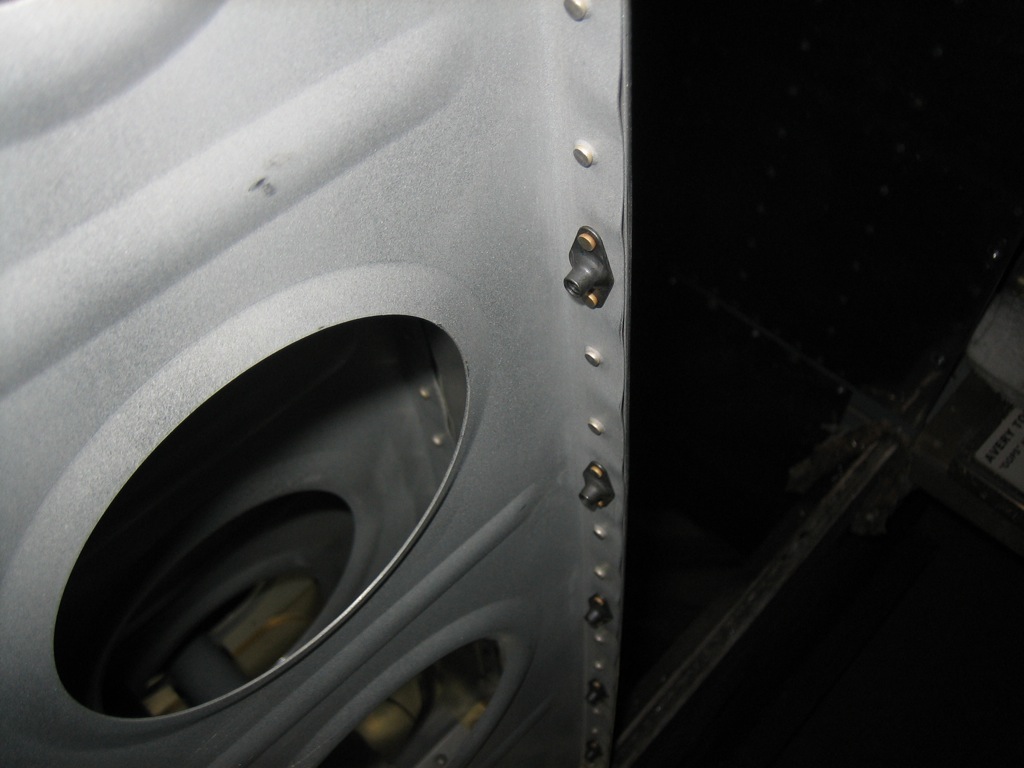

Heres a rough idea what the hole on the left side looks like.

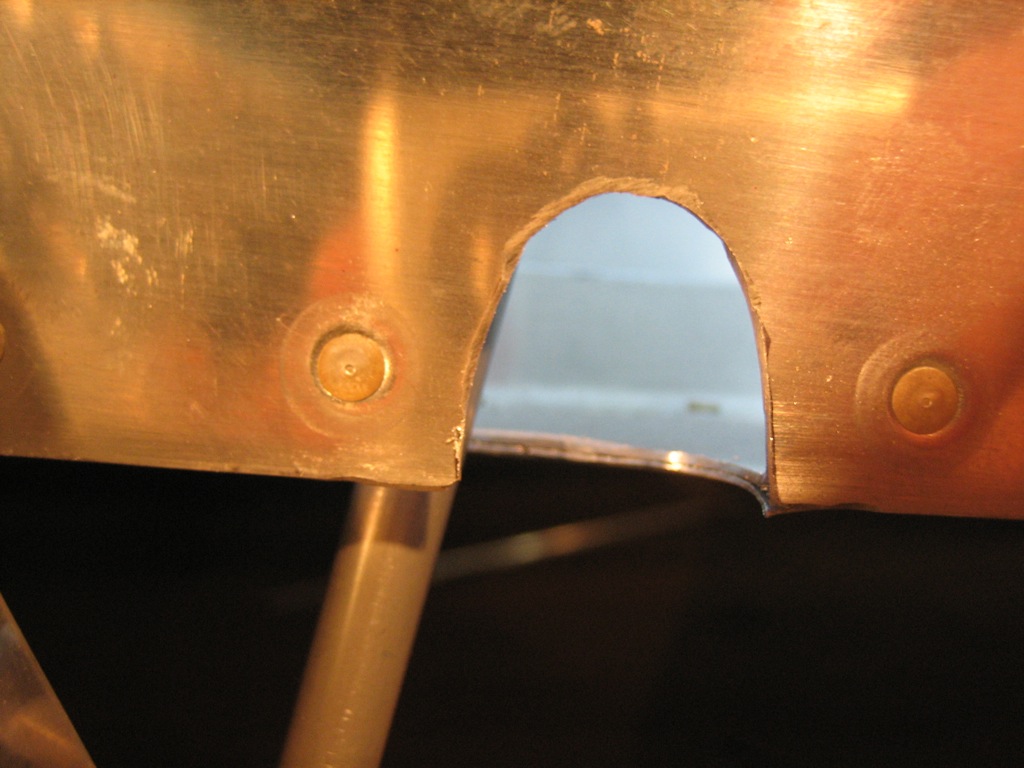

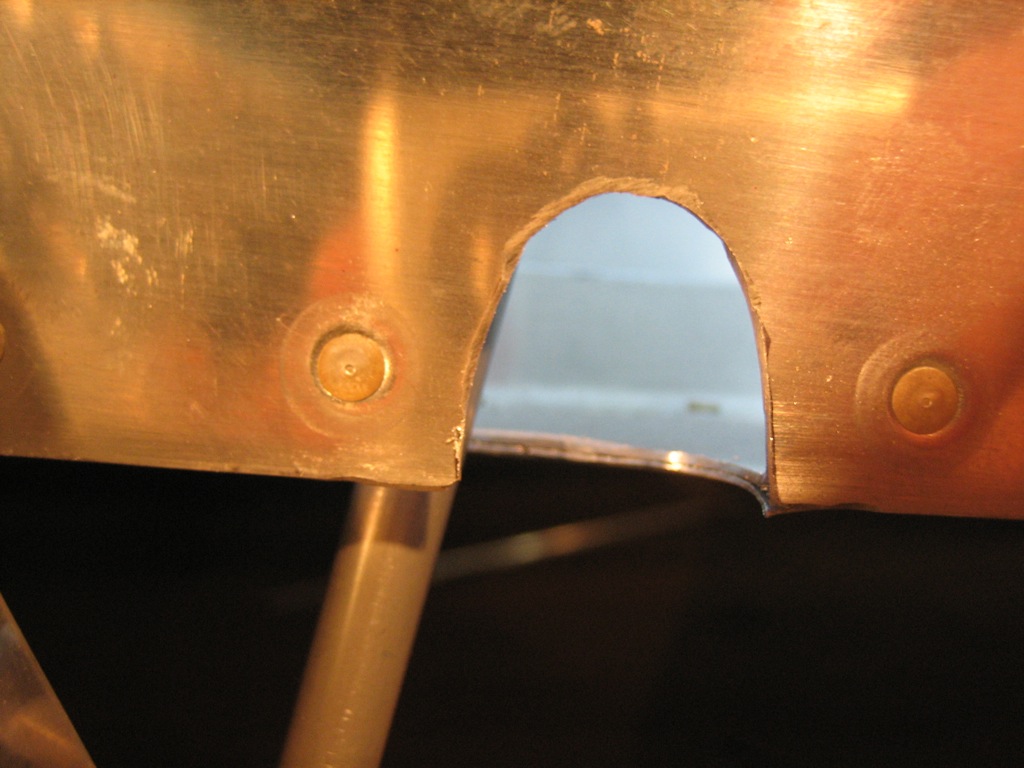

The side of the fuselage has an arch shaped hole to clear the end of the flap pushrod when the flaps are fully retracted.

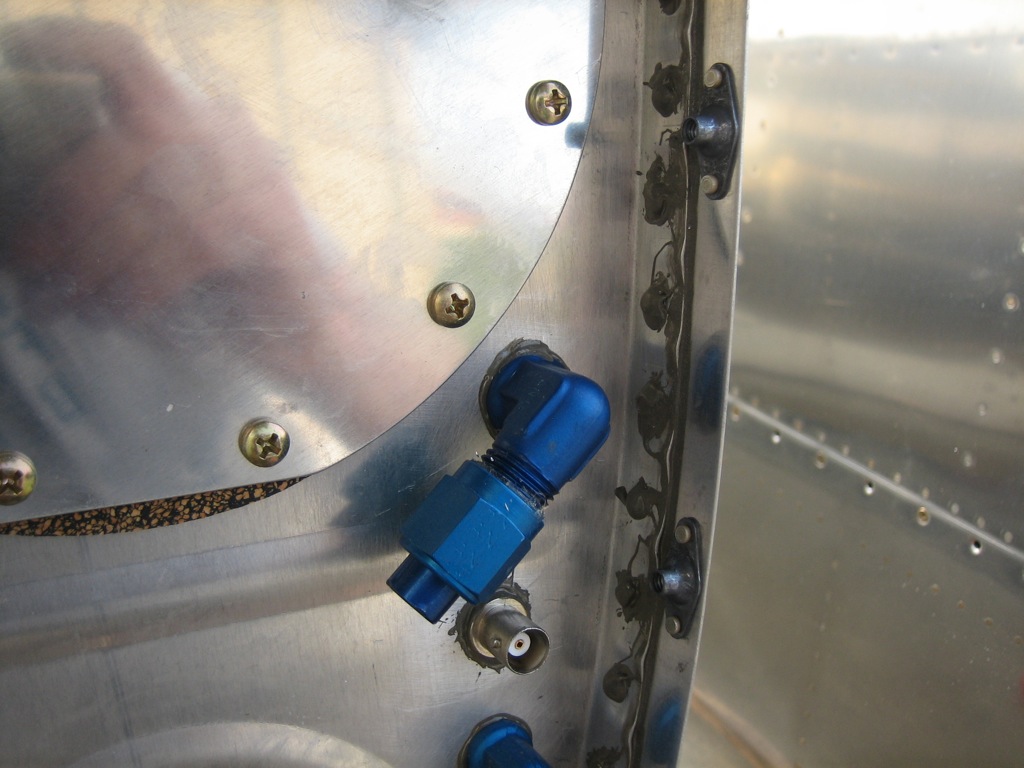

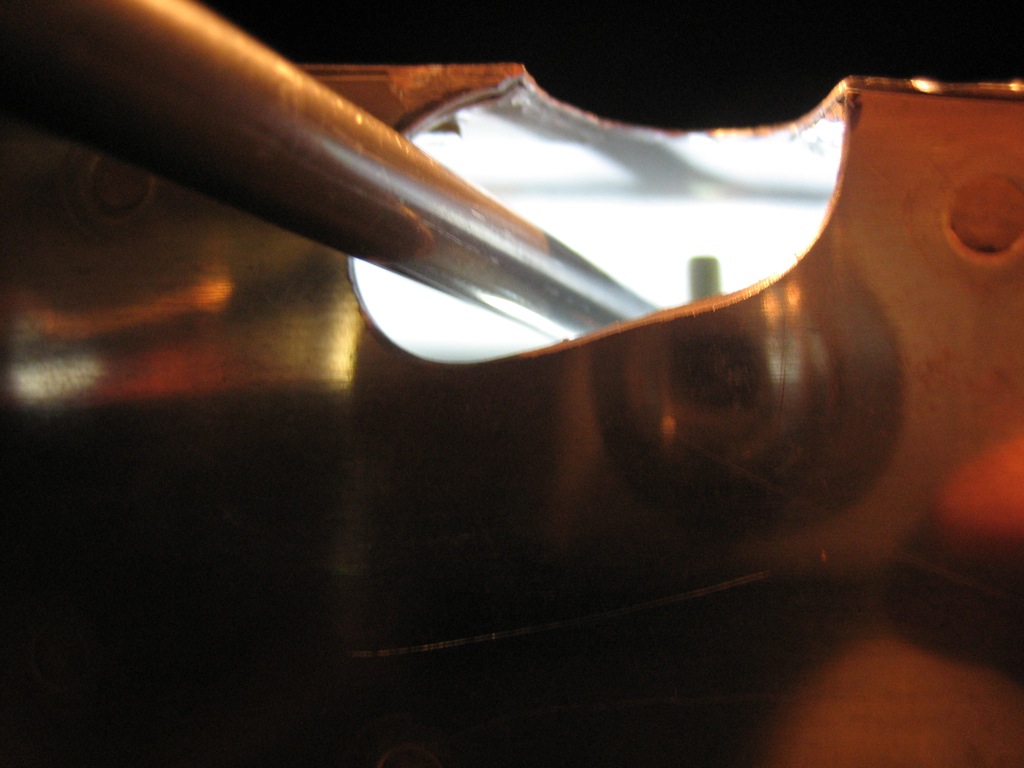

The bottom of the fuselage has a slanted and tapering hole to provide clearance for the pushrod and it moves through its range of motion. I have about 1/8″ all around the pushrod in all positions.

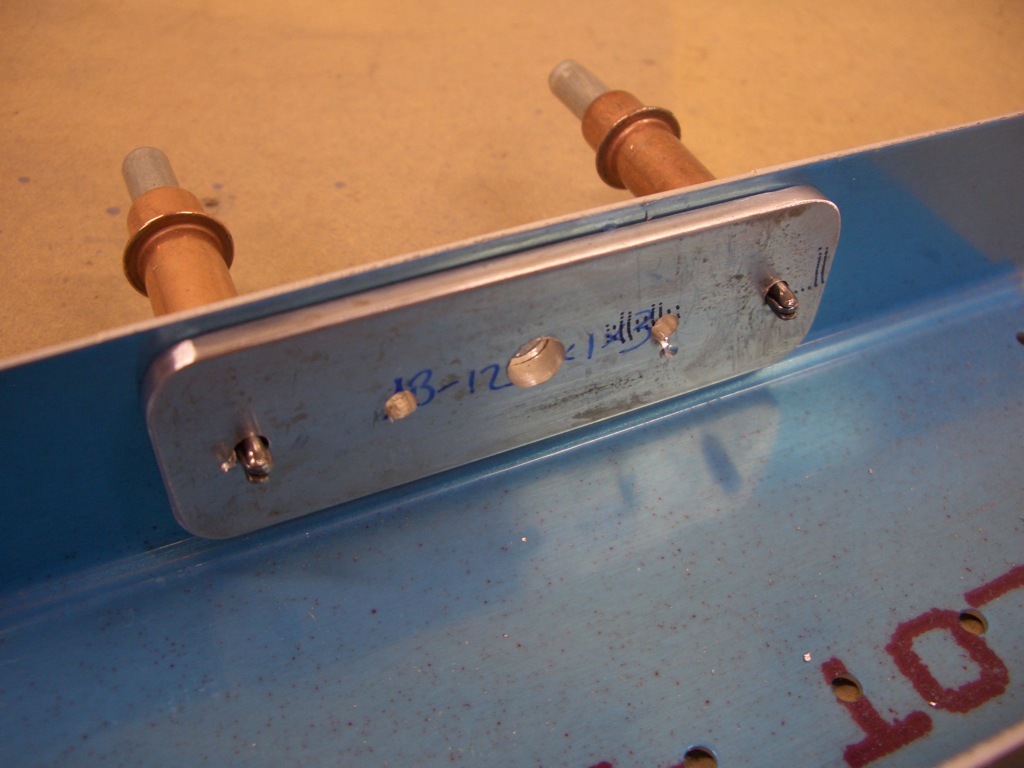

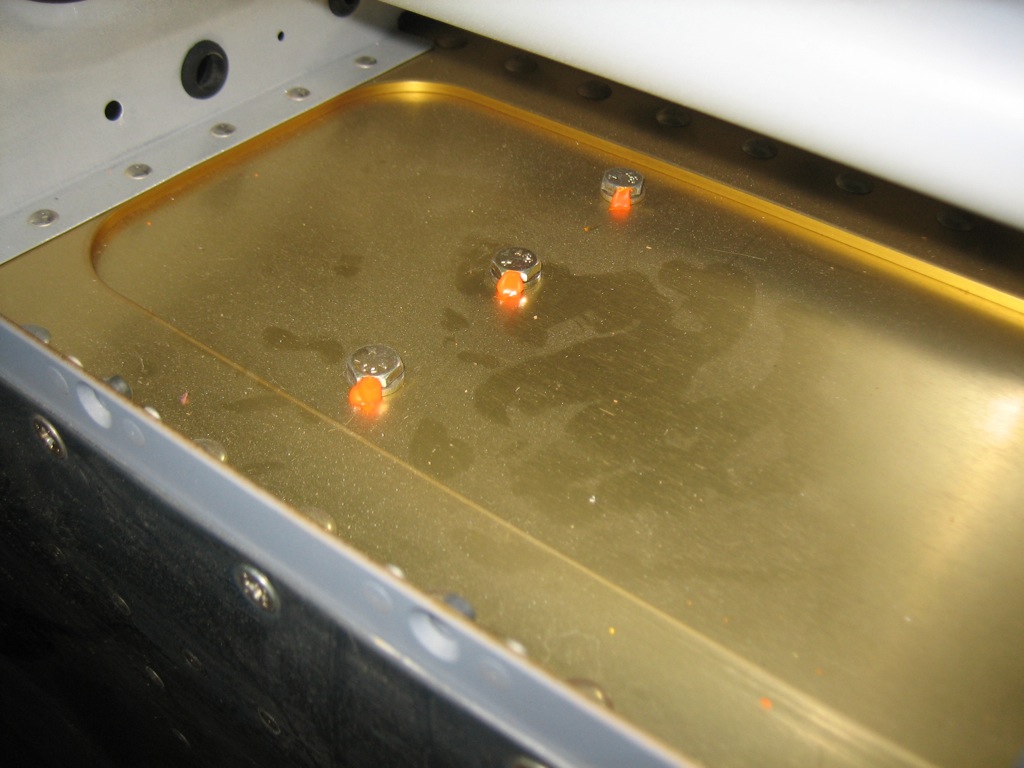

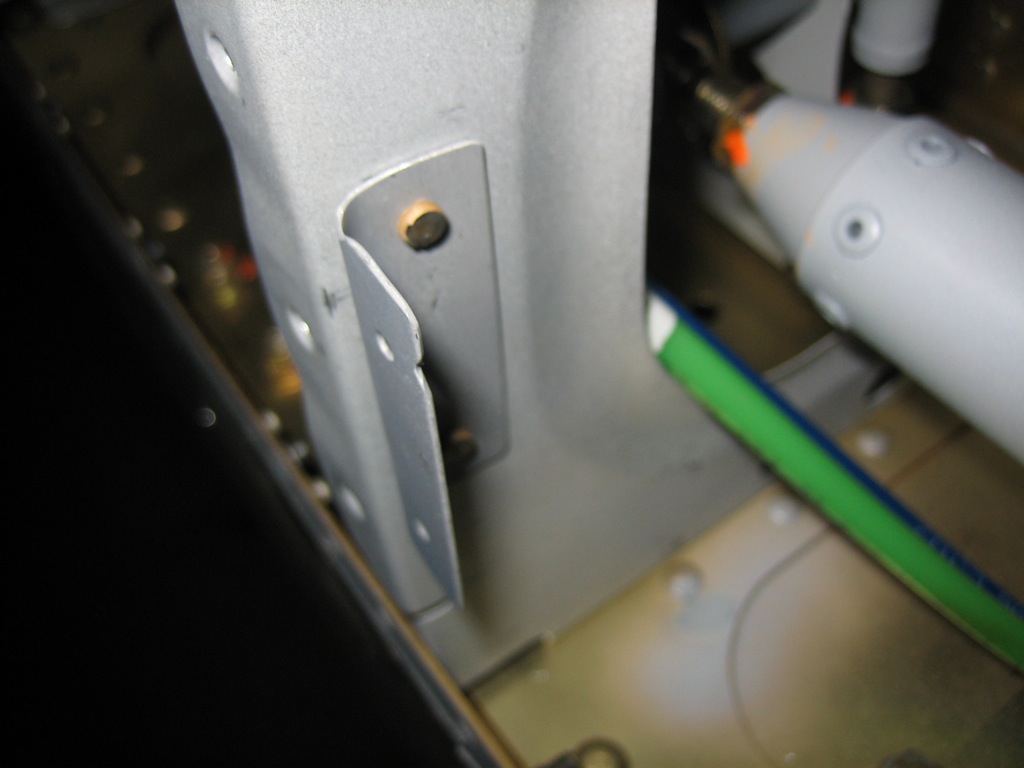

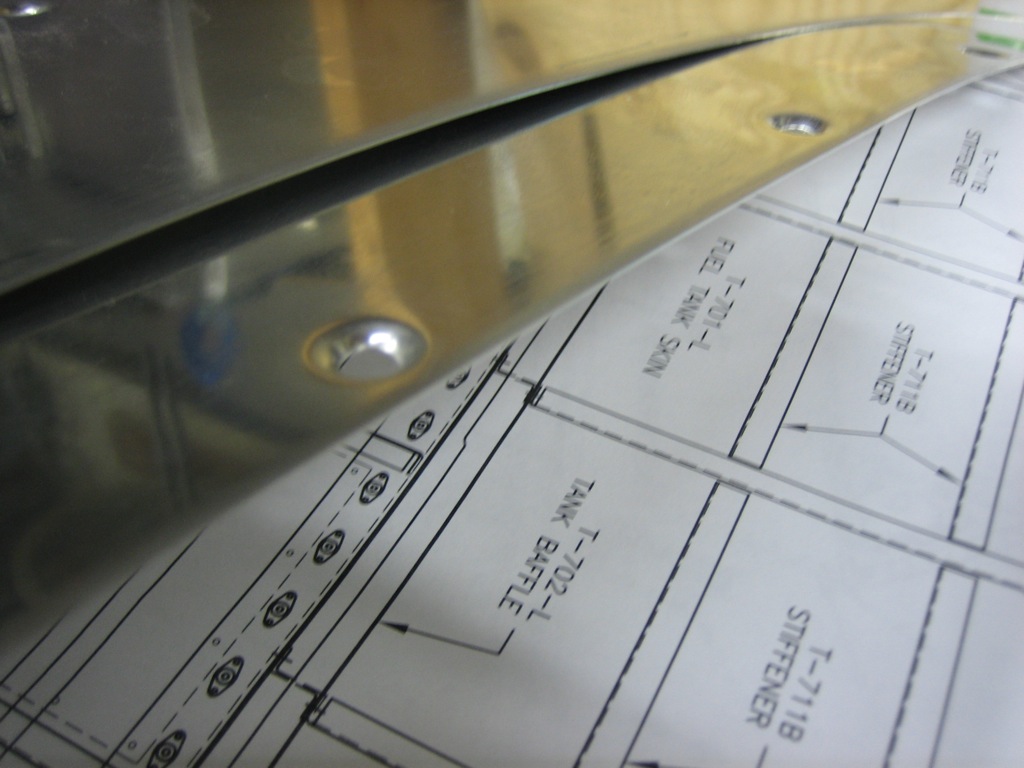

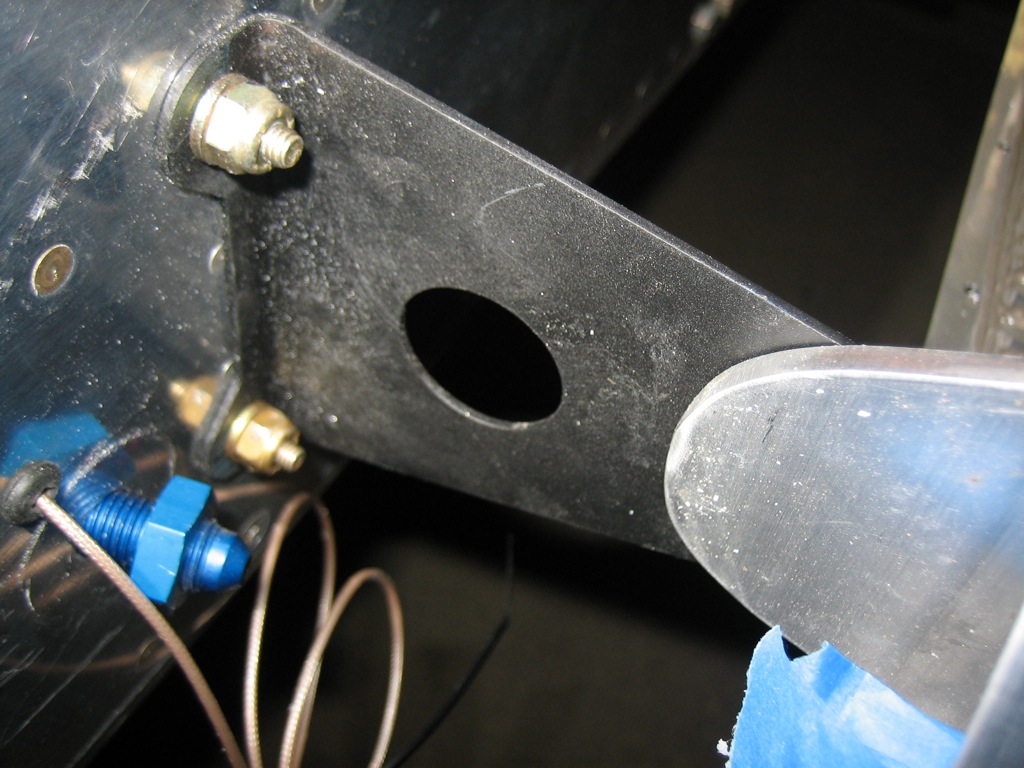

Seth removed the tank attach brackets and bent them so that they’re flush against the side of the plane and flush with the back of the fuel tank attach bracket. Afterward, I drilled the fuel tank attach bracket for the bolt that ties these together. Once the wings are back off the plane, I install a nutplate on each bracket to allow these to be screwed together.

I was getting really damn cold. I was still in shorts and a long sleeve t-shirt, and it had dropped to 46º before I gave up and decided to call it a night. Hopefully I can rig the ailerons tomorrow morning pretty quickly.