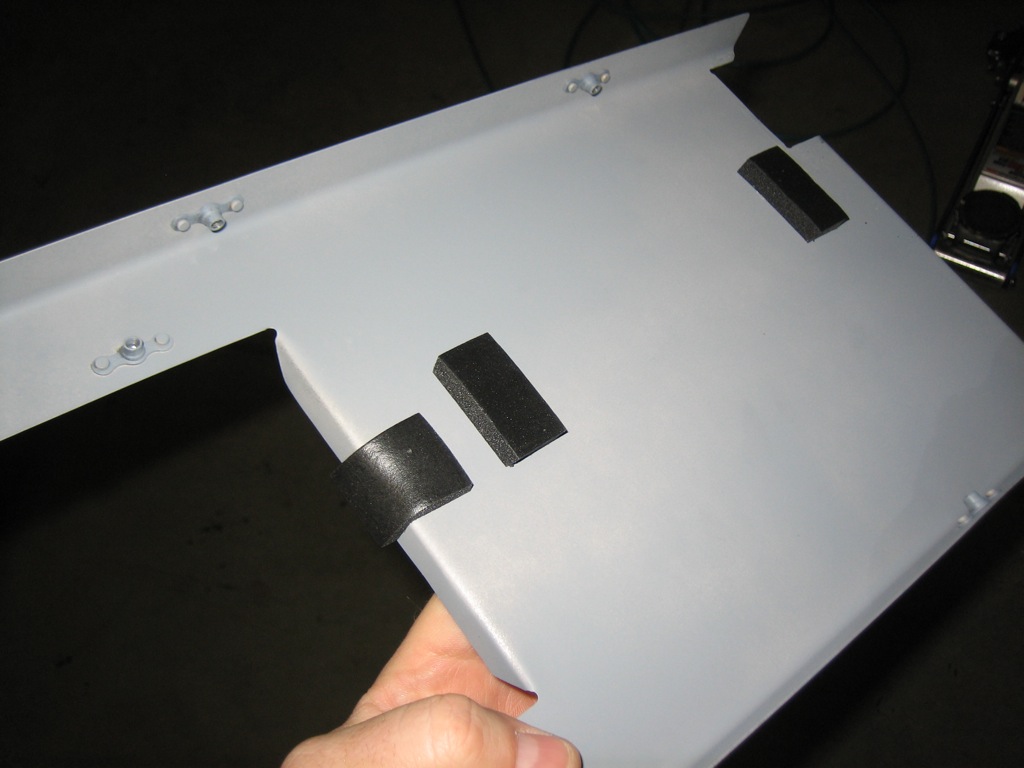

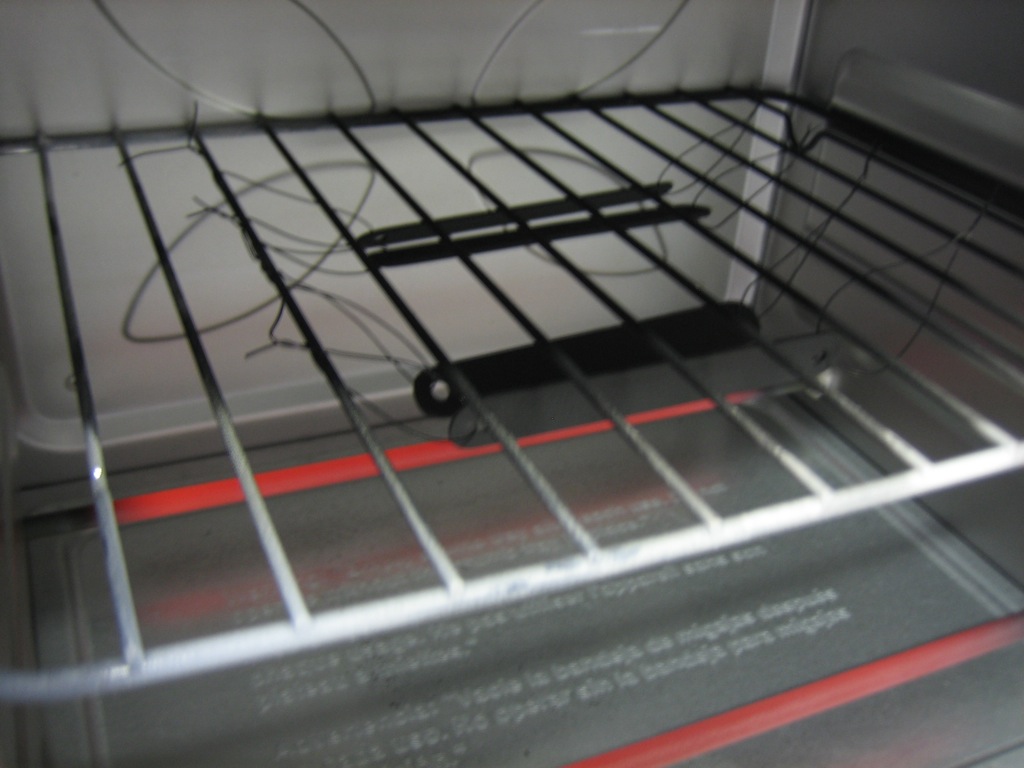

I finished fabricating the rudder pedal links and then powder coated them matte black. Here they are in my small toaster oven curing.

Finally, I installed these for good and cotter-pinned them. I didn’t get a picture of it, but I also reinstalled the cotter pins in the top mounting bolts of the brake master cylinders and tightened the jam nuts.

Here’s the right side. I tightened the rear bolt tight enough that the links won’t pivot relative to the cable fitting, so the only pivot point is at the rudder pedals. Otherwise, the weight of the links and bolt would cause the aft joint to sag which would make it more likely to catch on something. This way, it’s essentially just an extension of the cable fitting.

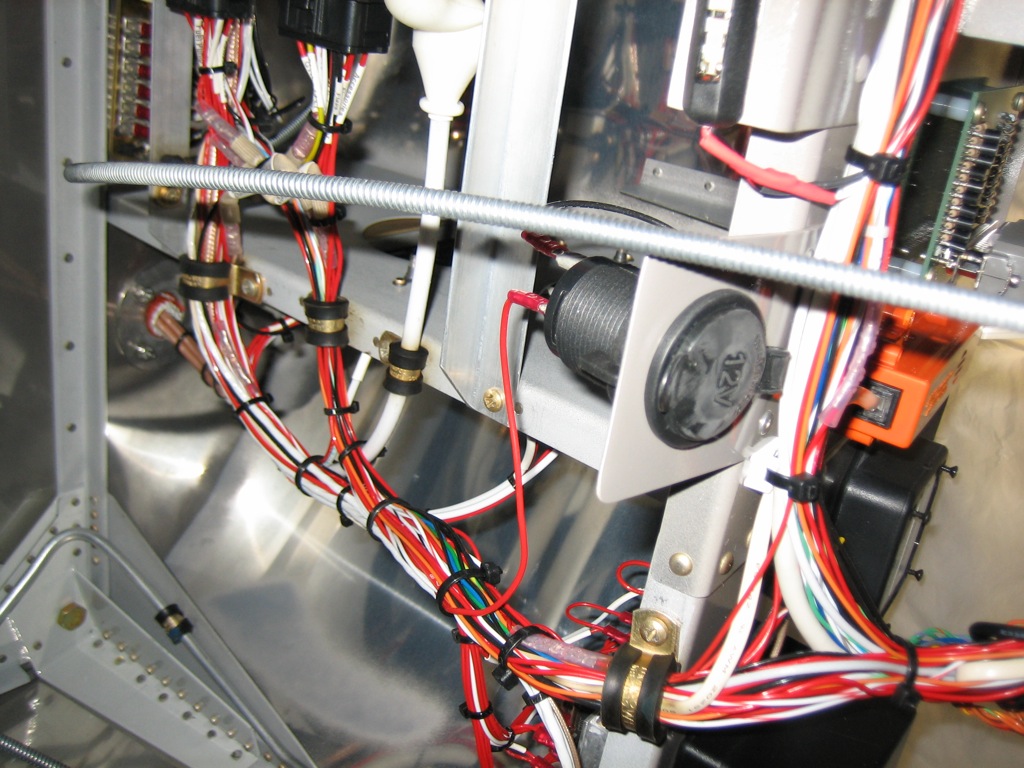

Before wrapping up for the evening, I installed the adel clamps that anchor the fuel tank vent lines to the bracket that ties the firewall angle to the longerons. You can see the adel clamp in the lower left corner of this picture. Getting these on was more of a pain than I expected. I had to remove almost all of the padding on the footwell floor and lay across the spar on my back with my head pressed into the rudder pedals. It took me nearly 30 minutes to install these two screws!