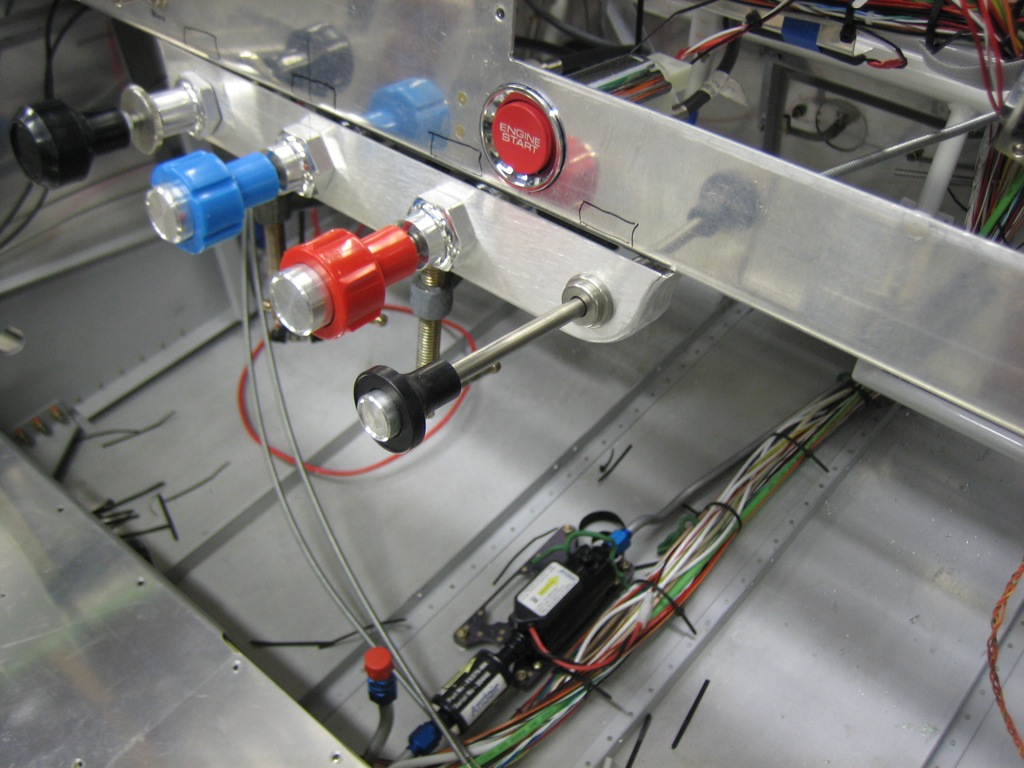

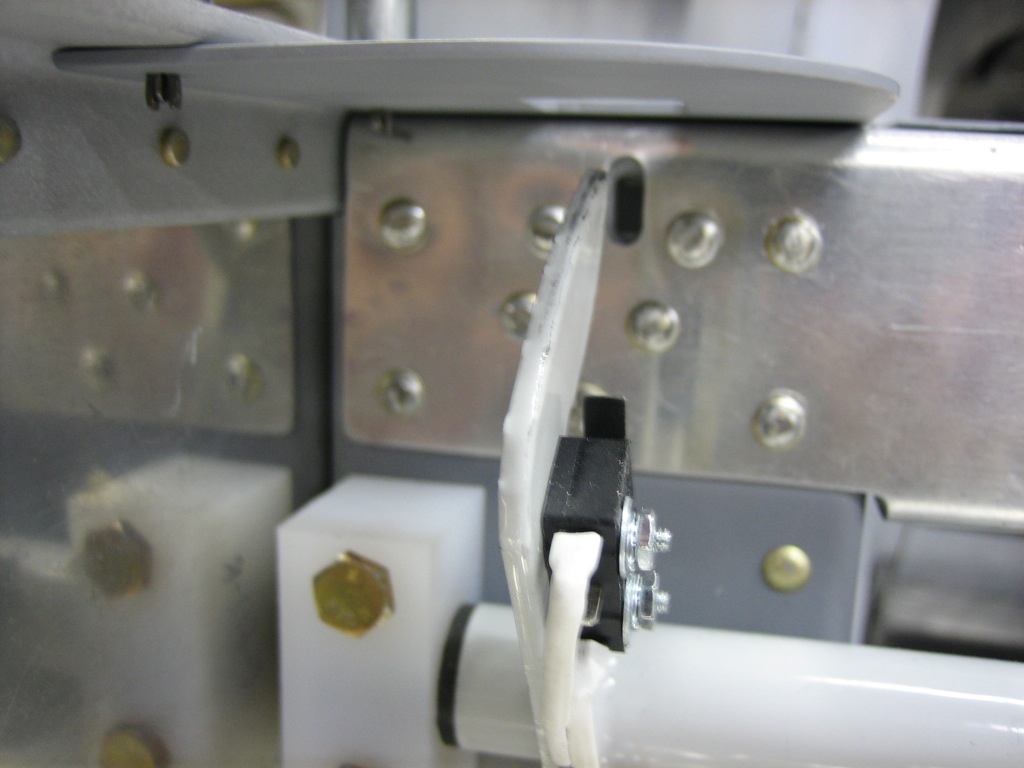

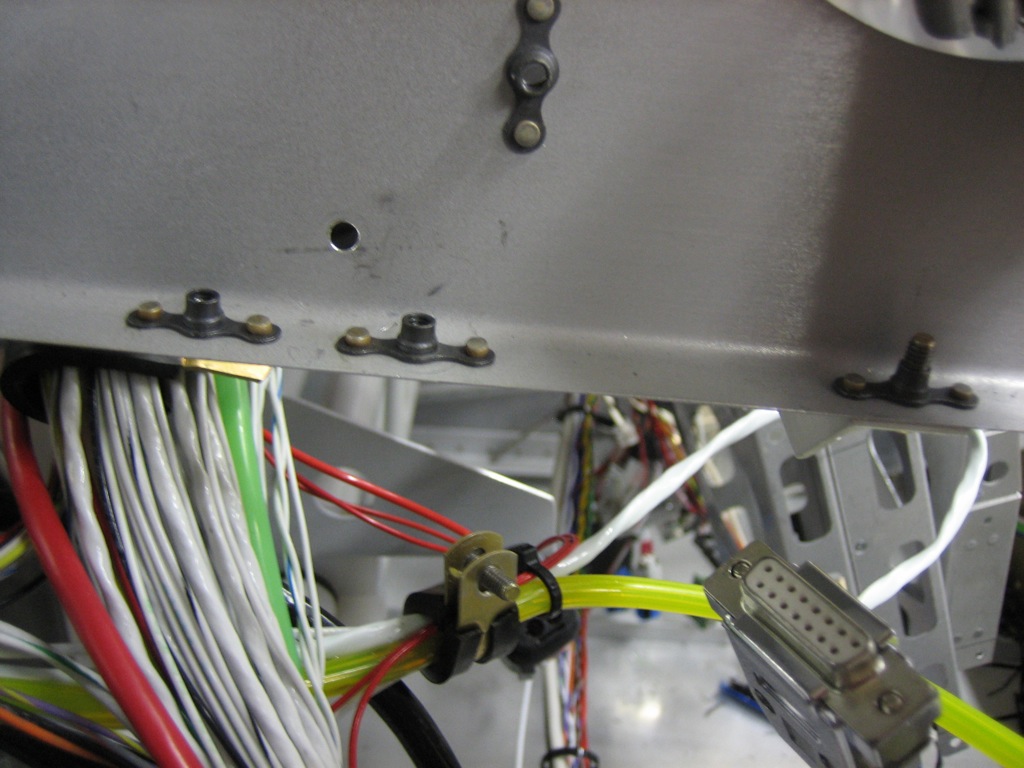

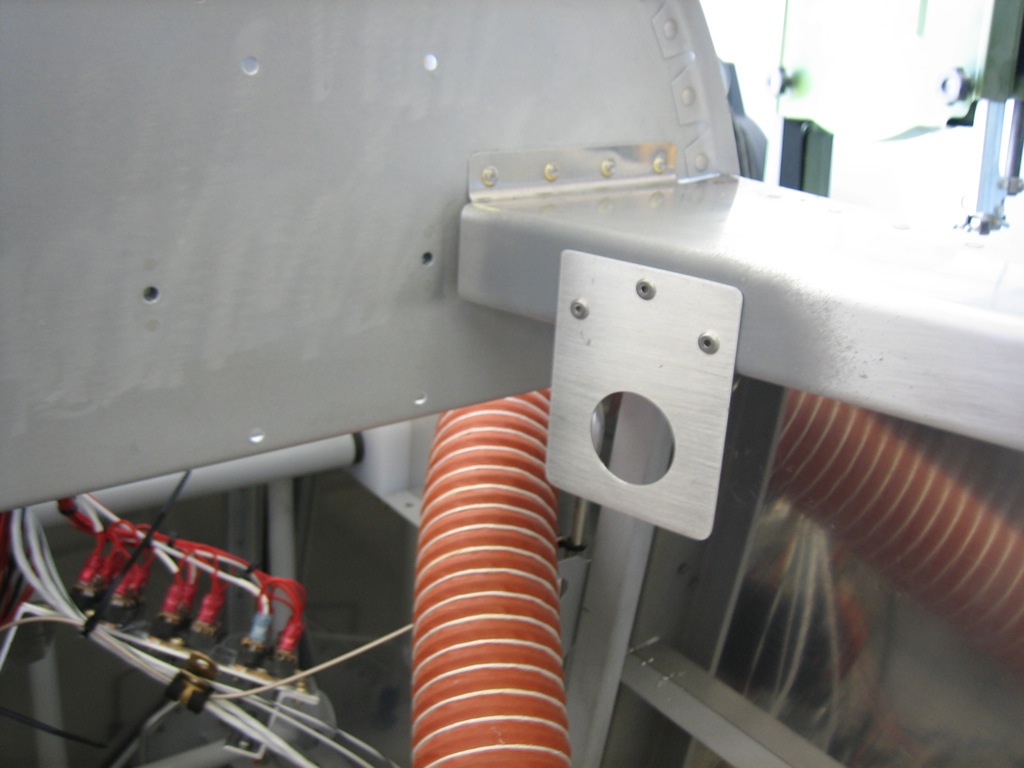

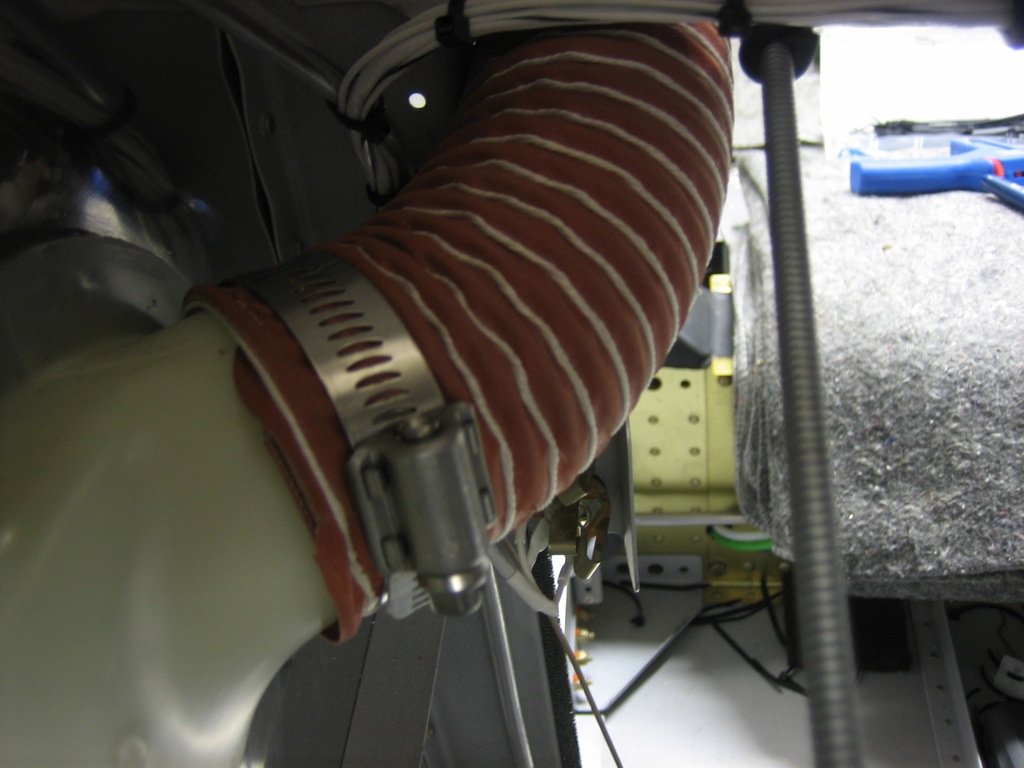

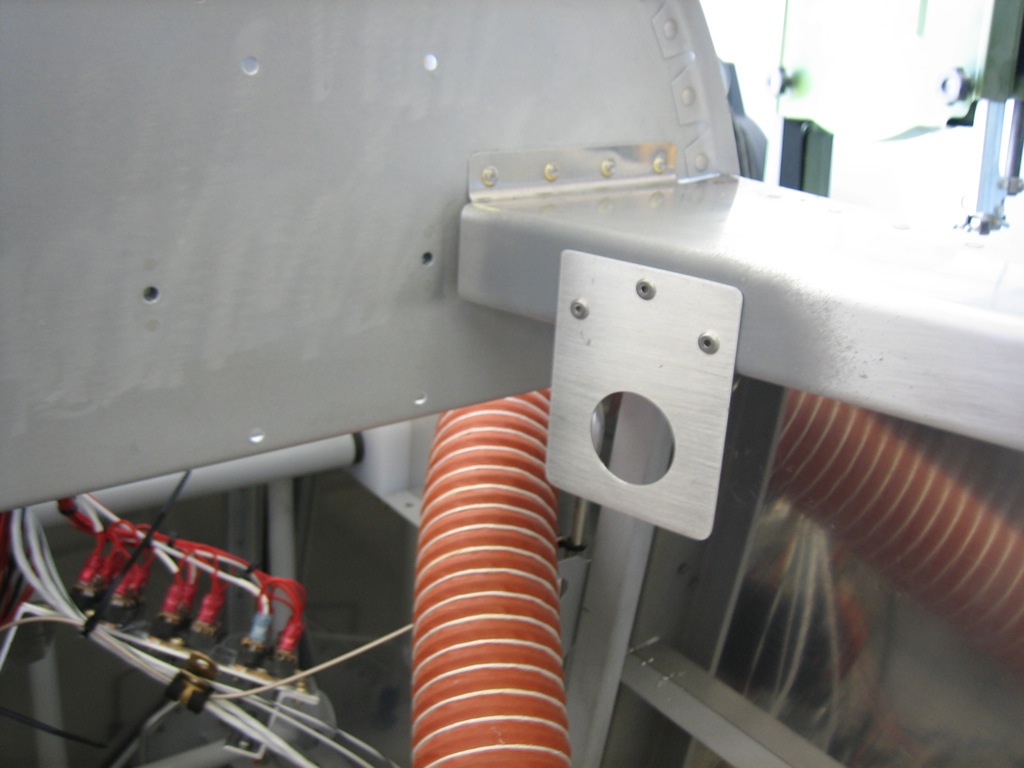

I added a small bracket to the right canopy deck between the panel and subpanel. This will hold a cigarette lighter socket that can be used to charge devices. I picked up a dual USB plug that I’ll likely leave in this most of the time. This was really the only place I could find behind the panel that isn’t blocked by something.

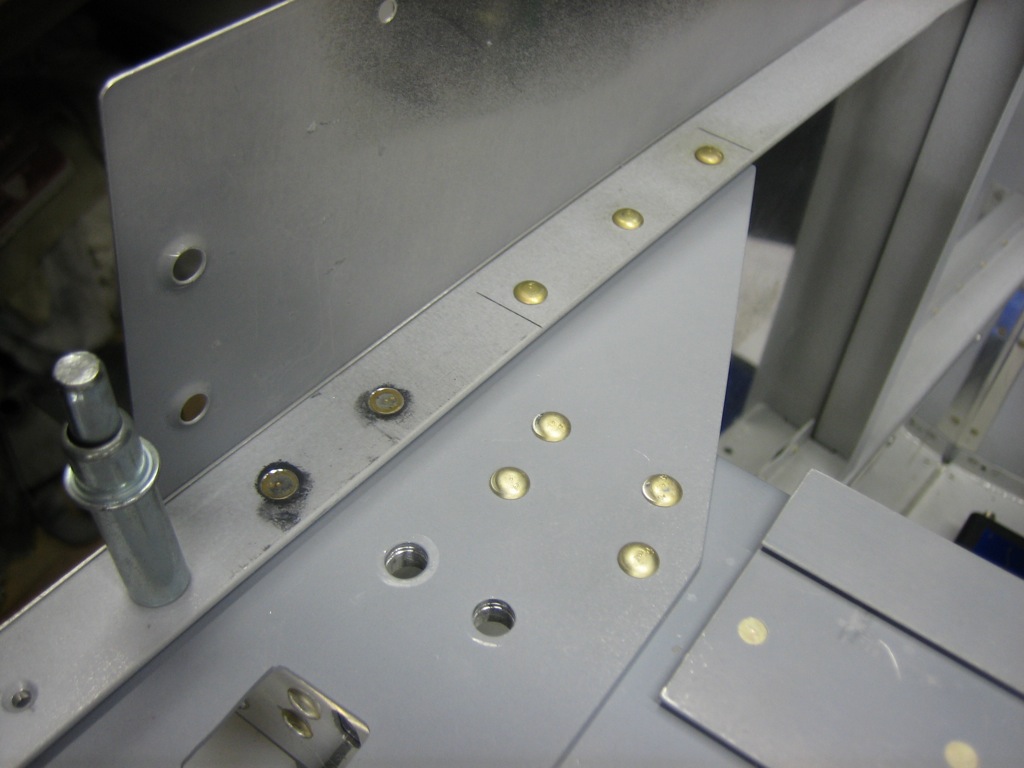

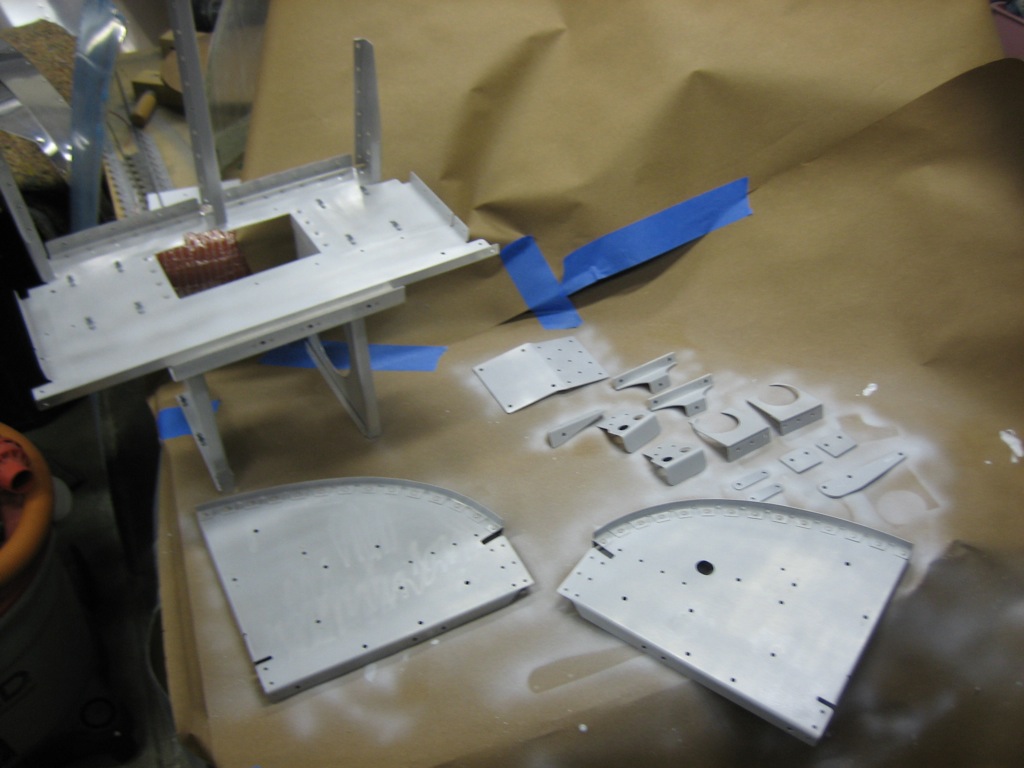

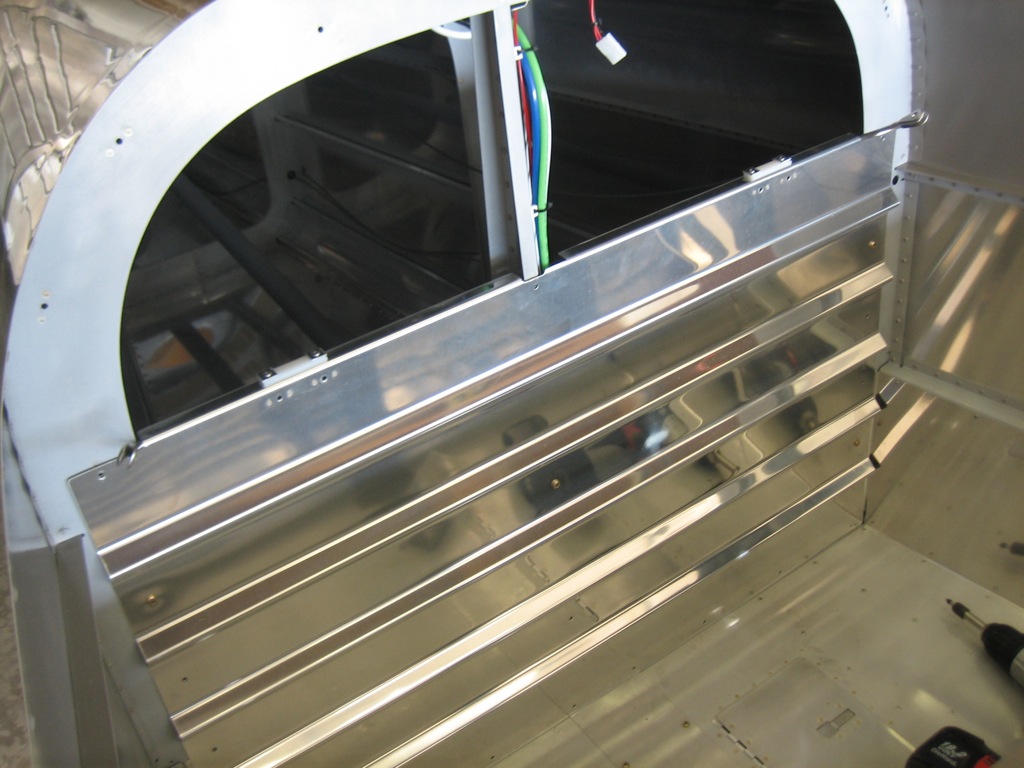

I primed all of the flap cover pieces. On the right is the flap motor wrapped up with paper towels. I primed the head of the bolt that will be visible on the outside of the flap motor support. On the far right is a piece of cardboard with a couple of #6 screws that are used to attach the flap position sensor. I’m painting them as well so they blend in.

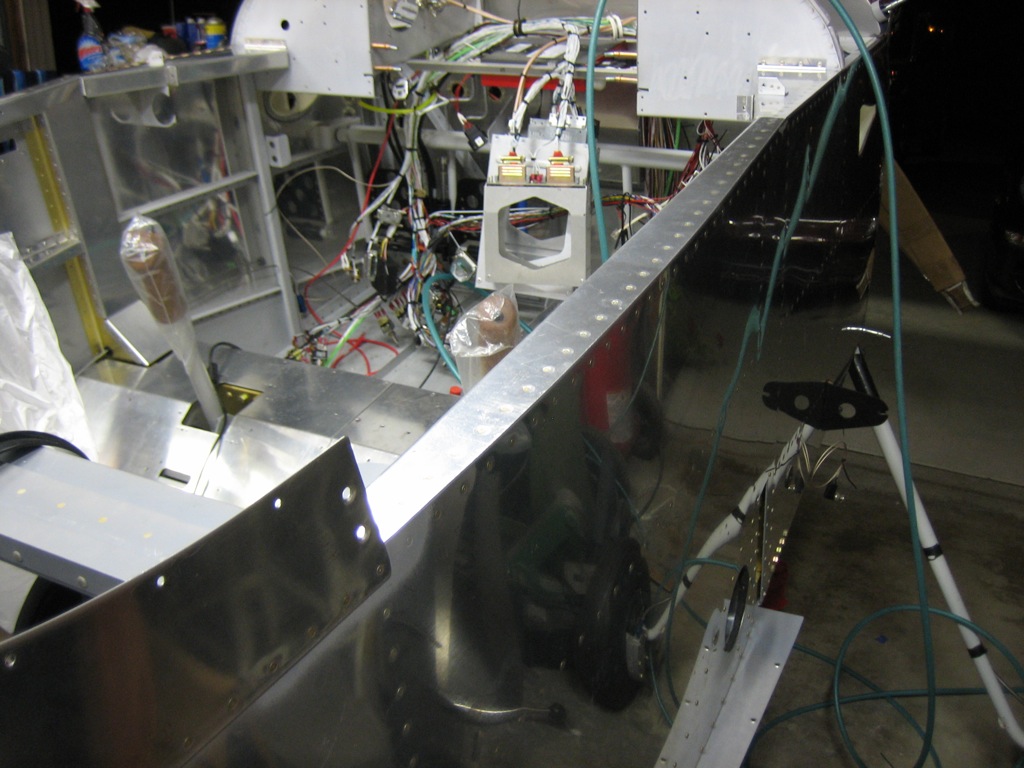

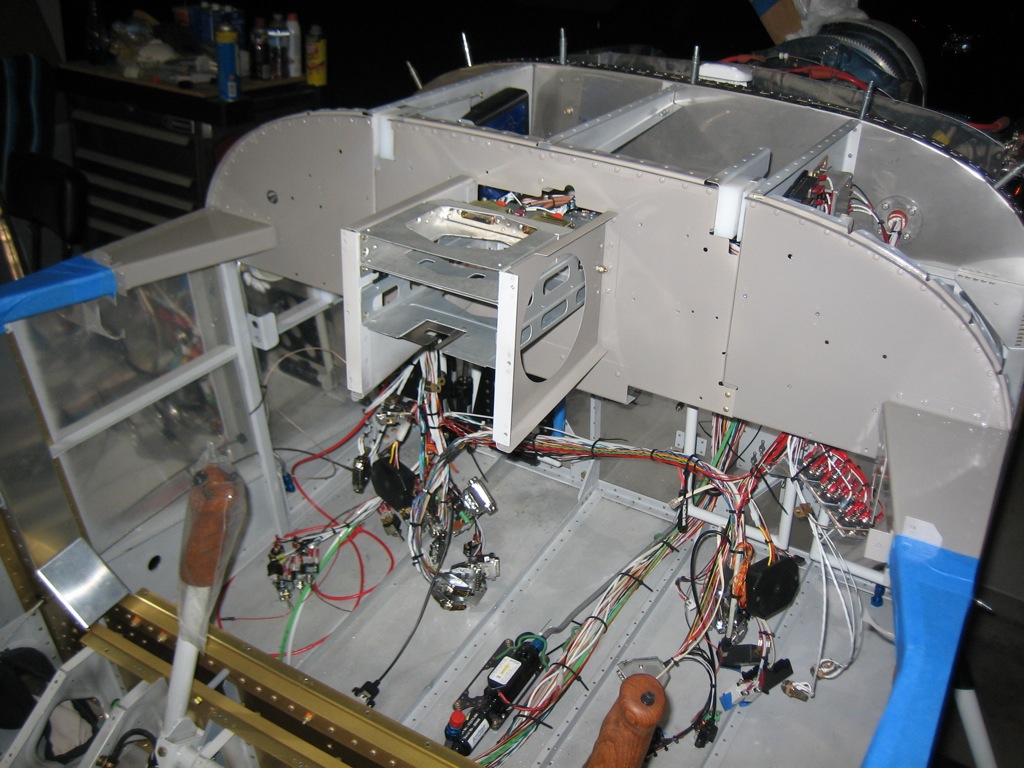

I masked off the interior and primed everything that will be painted. I’m only painting the parts that won’t be covered by the Classic Aero Designs interior.

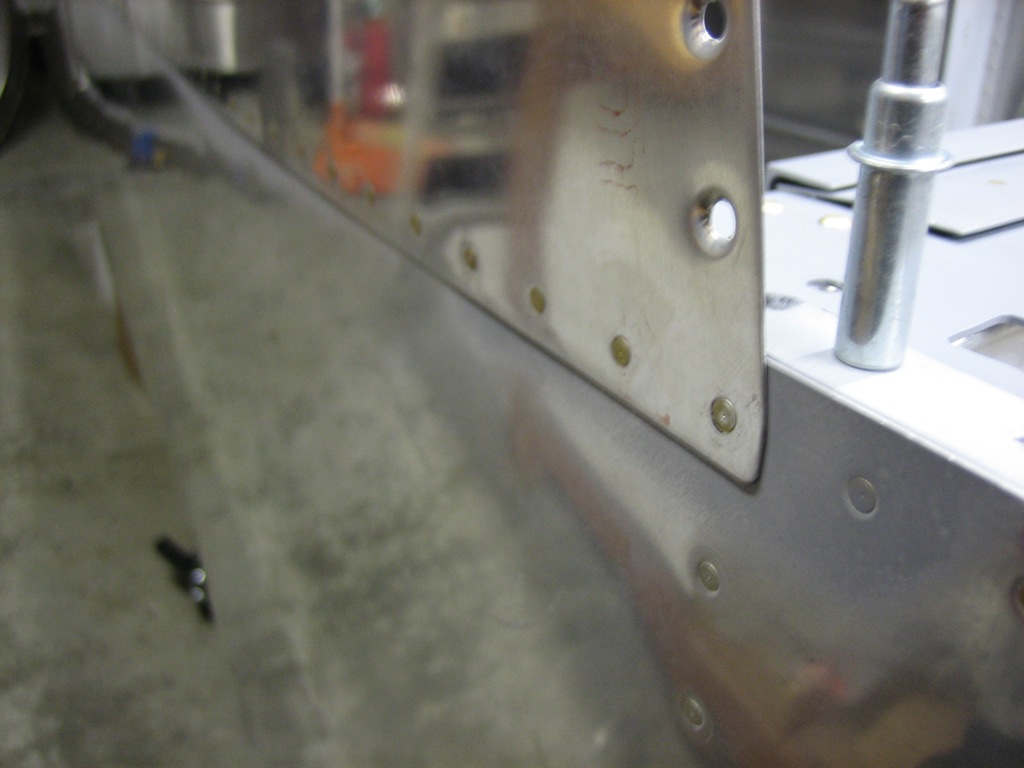

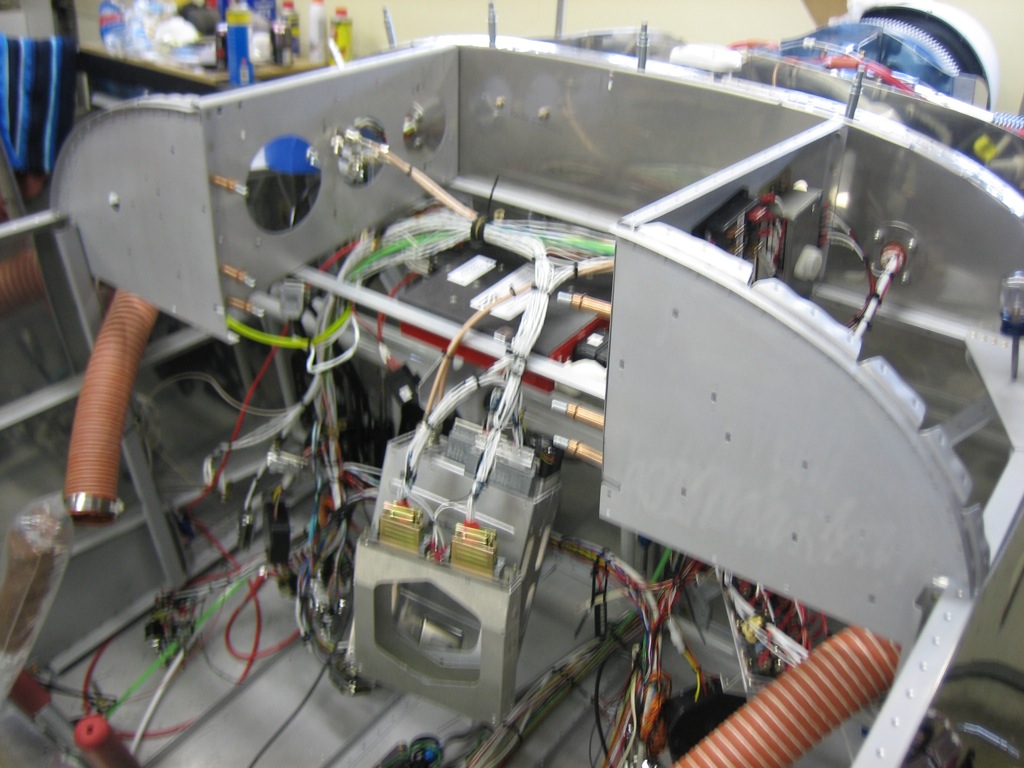

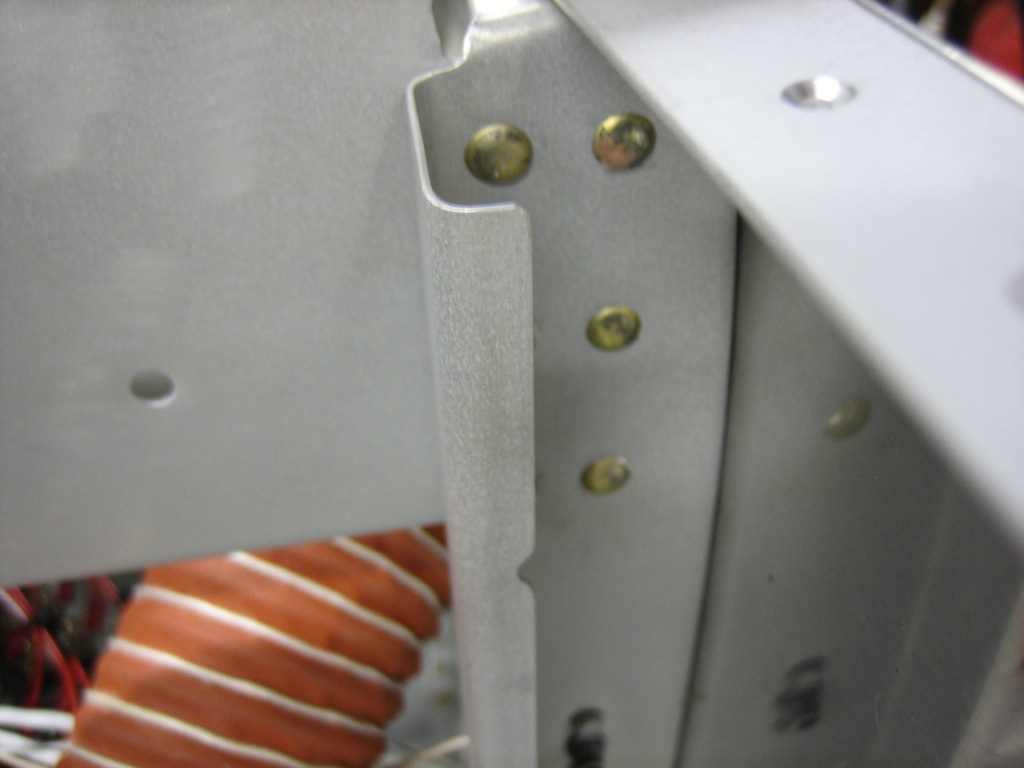

The canopy decks were primed up to the subpanel.

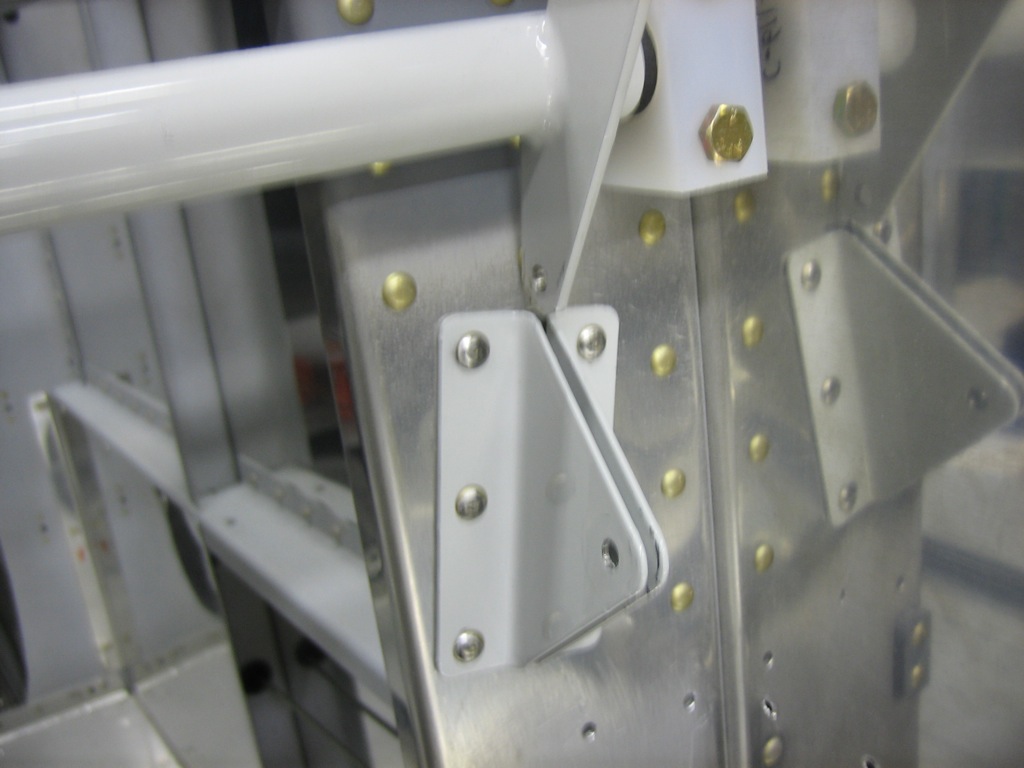

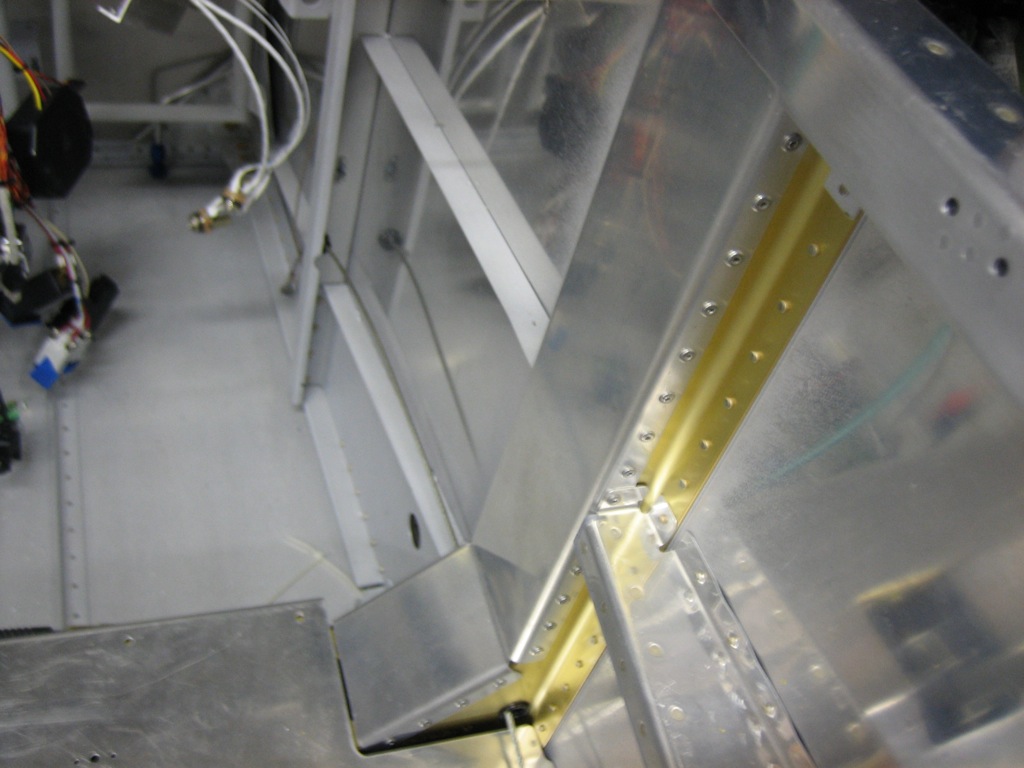

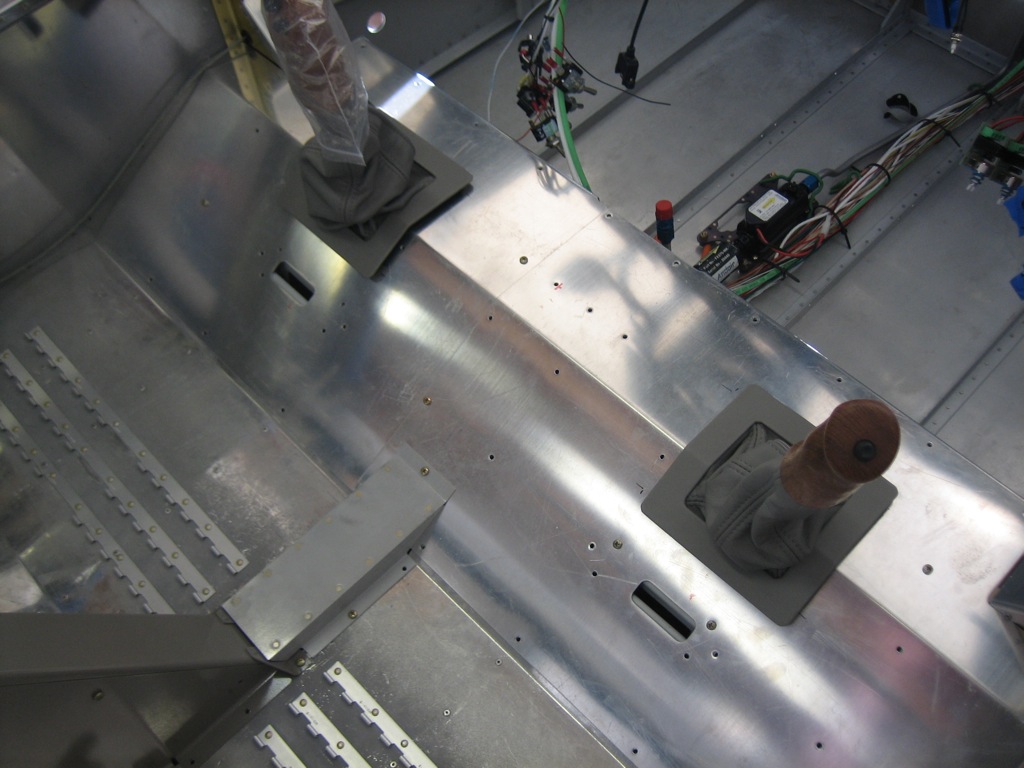

After that dried for a few hours, I painted everything with some paint that I had color matched to the leather used in the upholstery.

You can see here that I also painted the canopy latch torque tube since it’s visible between the seats and when the seat backs are pulled forward.

I put four coats of paint on (as specified by Stewart Systems). This seems like a lot, but the first coat is a translucent tack coat with two more fairly light coats before the final heavier coat. This greatly reduces runs since the early coats are very sticky.