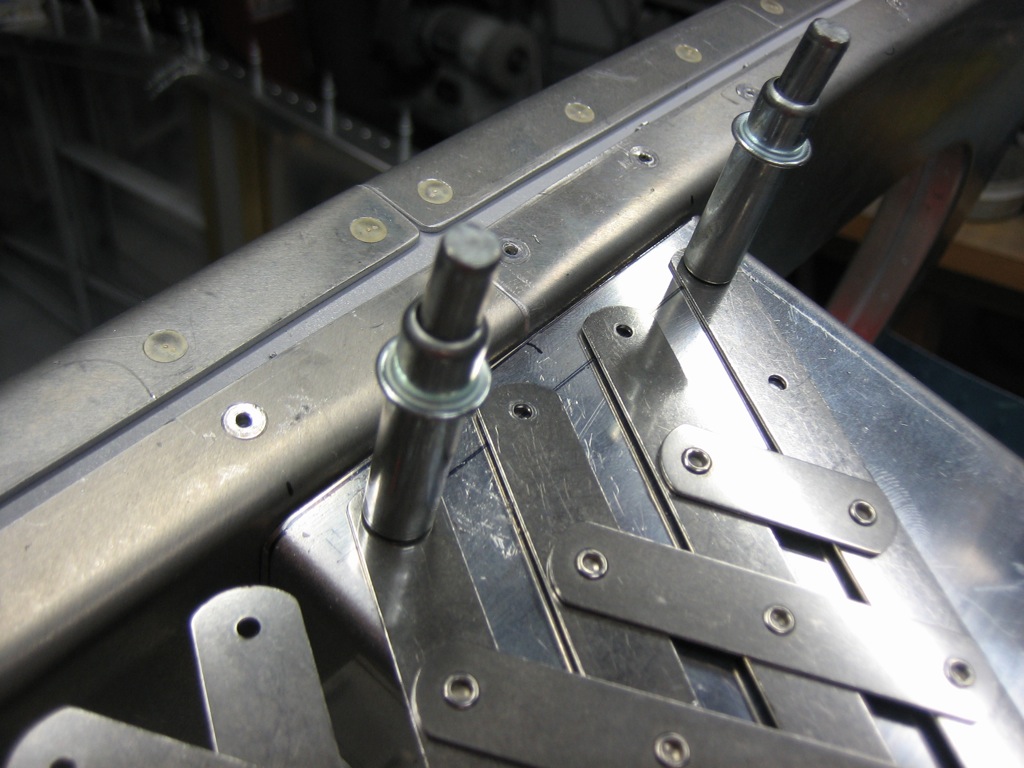

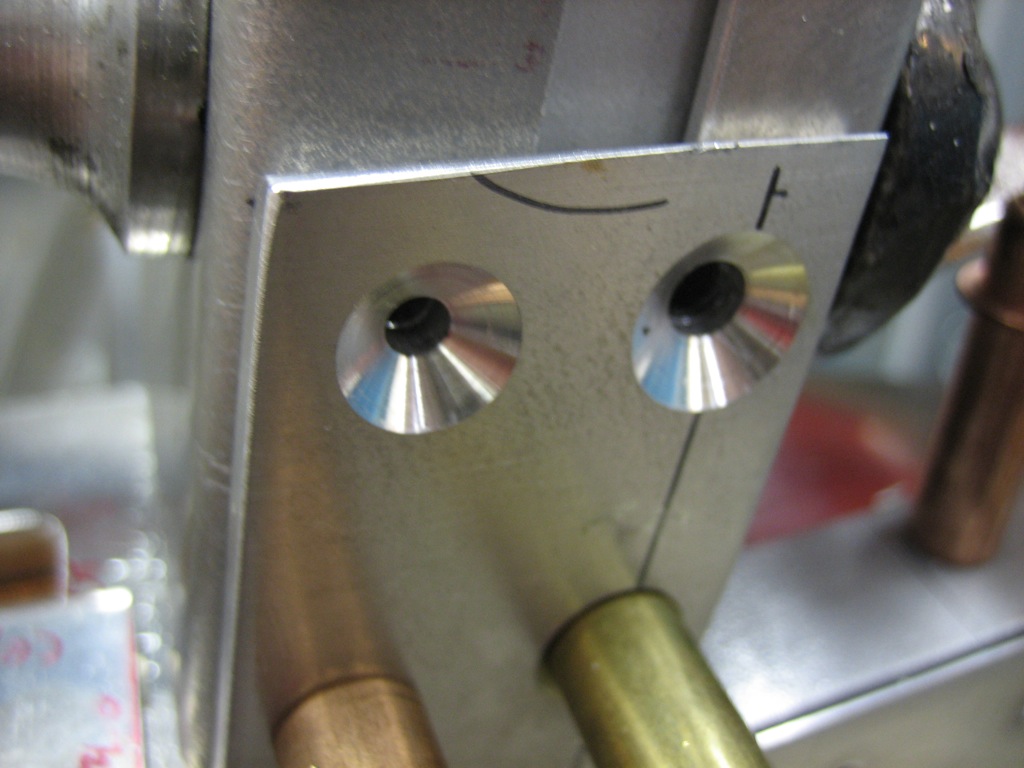

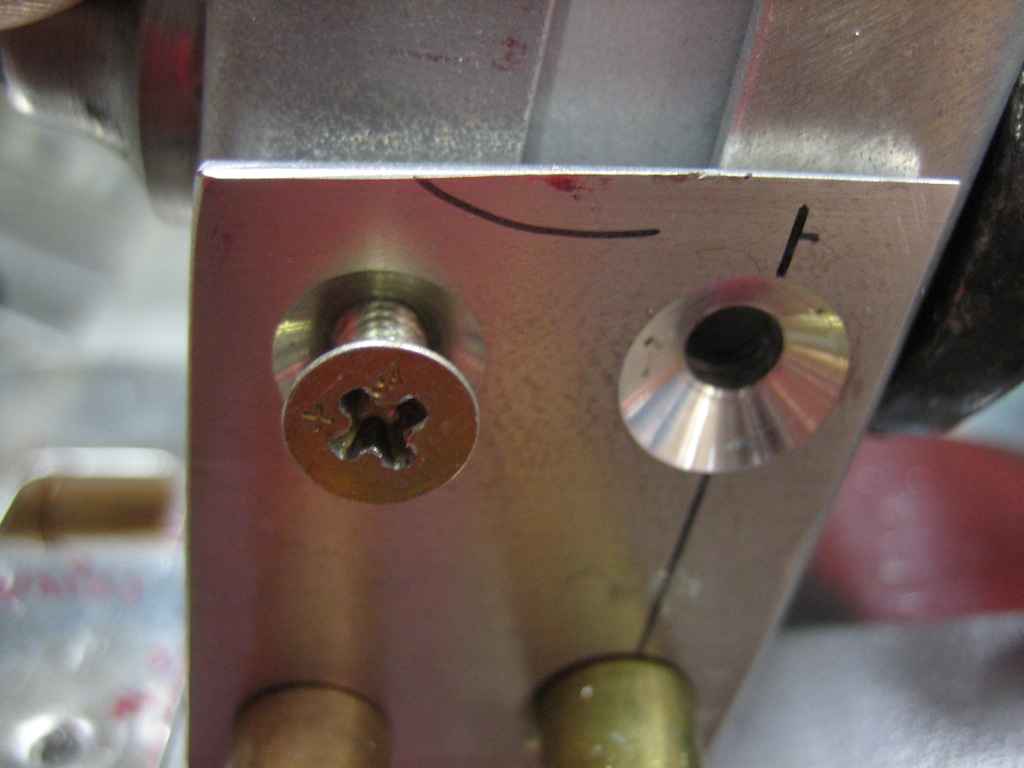

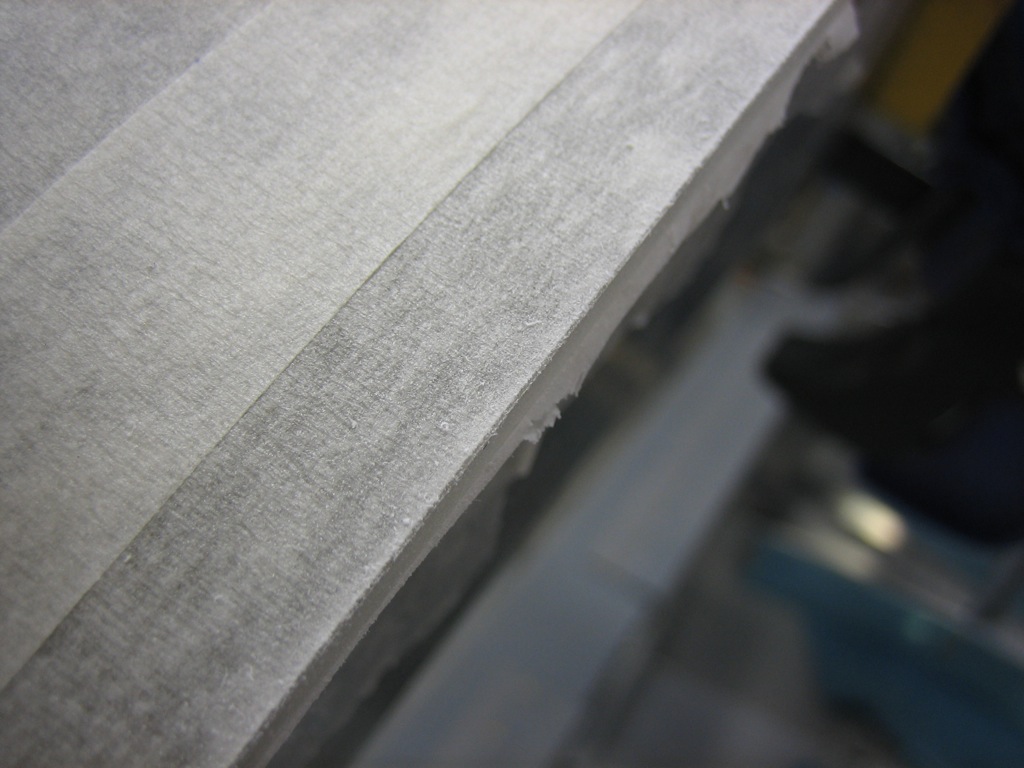

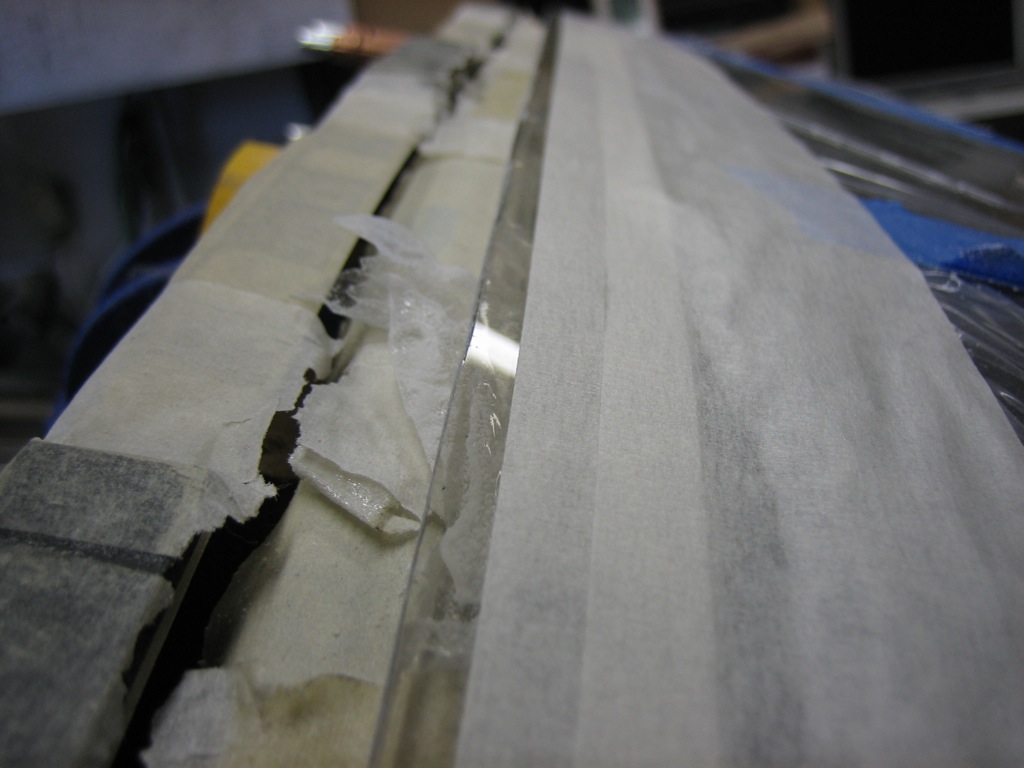

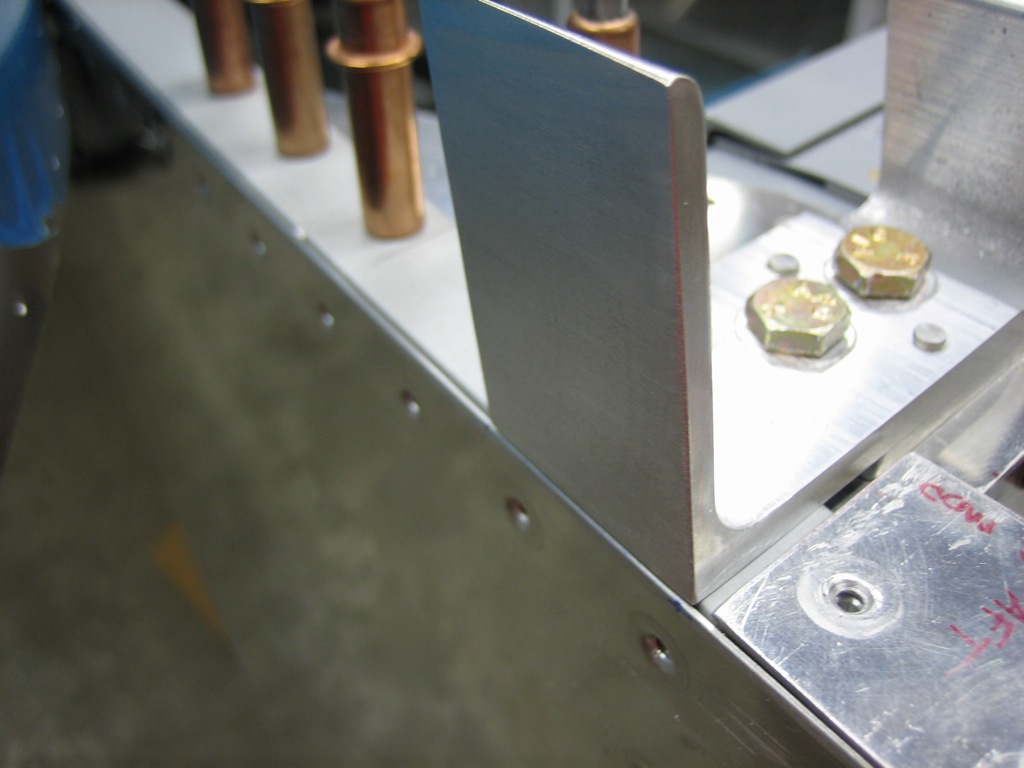

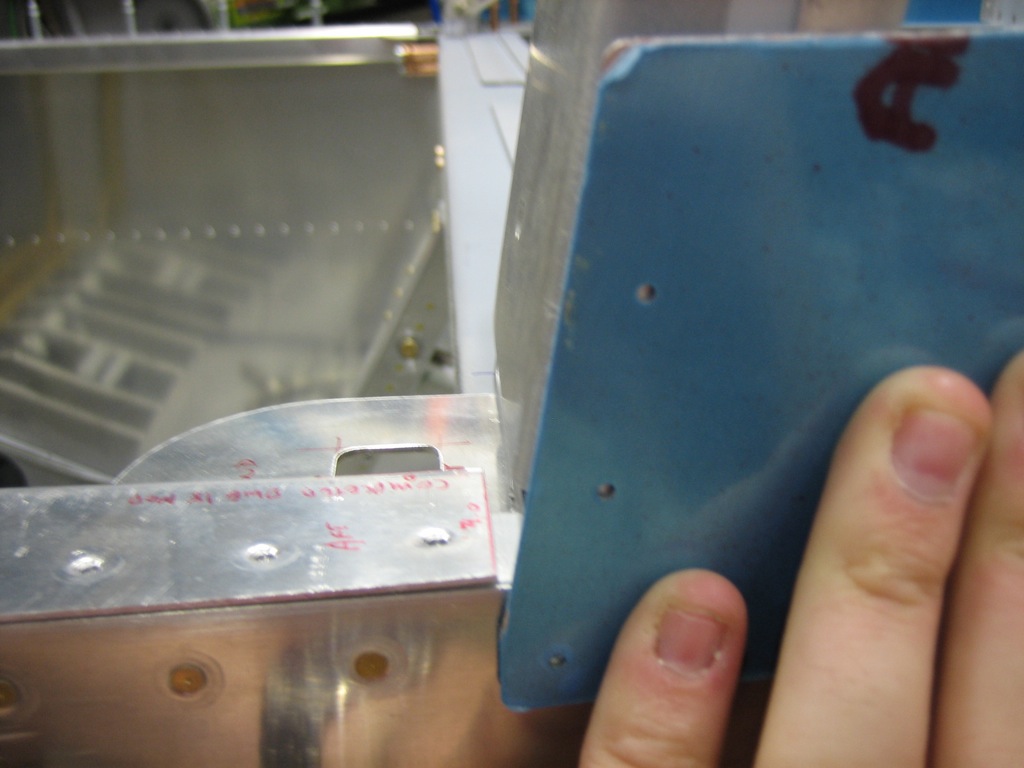

I finished trimming the cabin frame attach angles so that they’re flush with the sides of the fuselage. I alternated between using the vixen file and the disc sander, then finished up with the scotchbrite wheel.

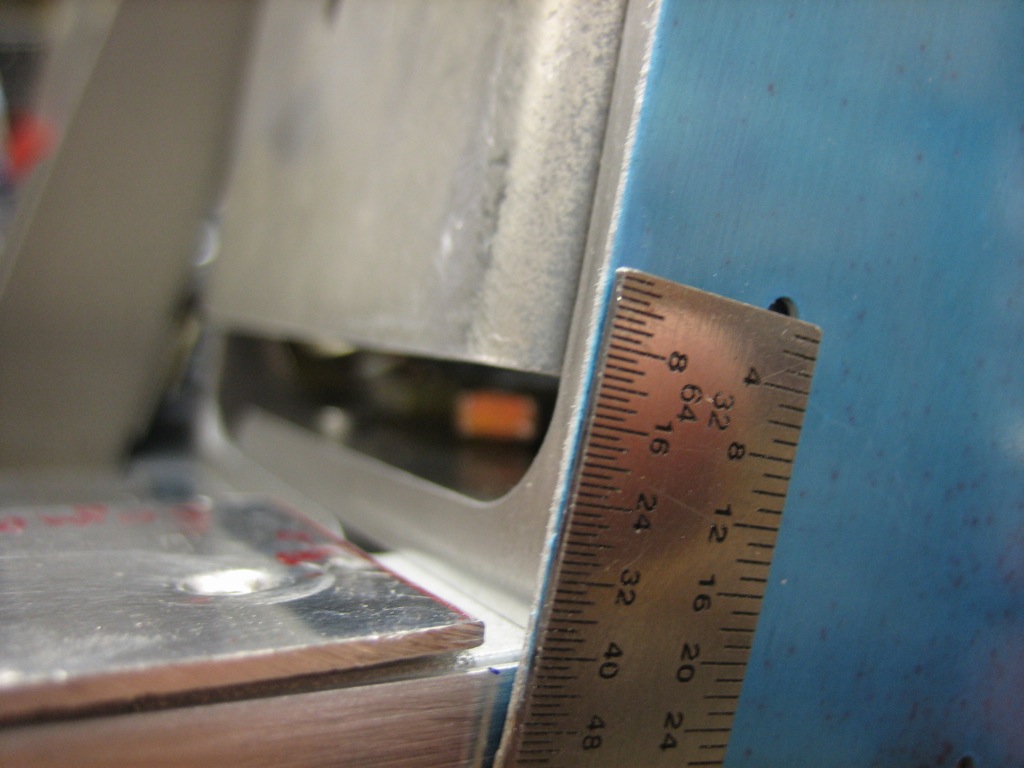

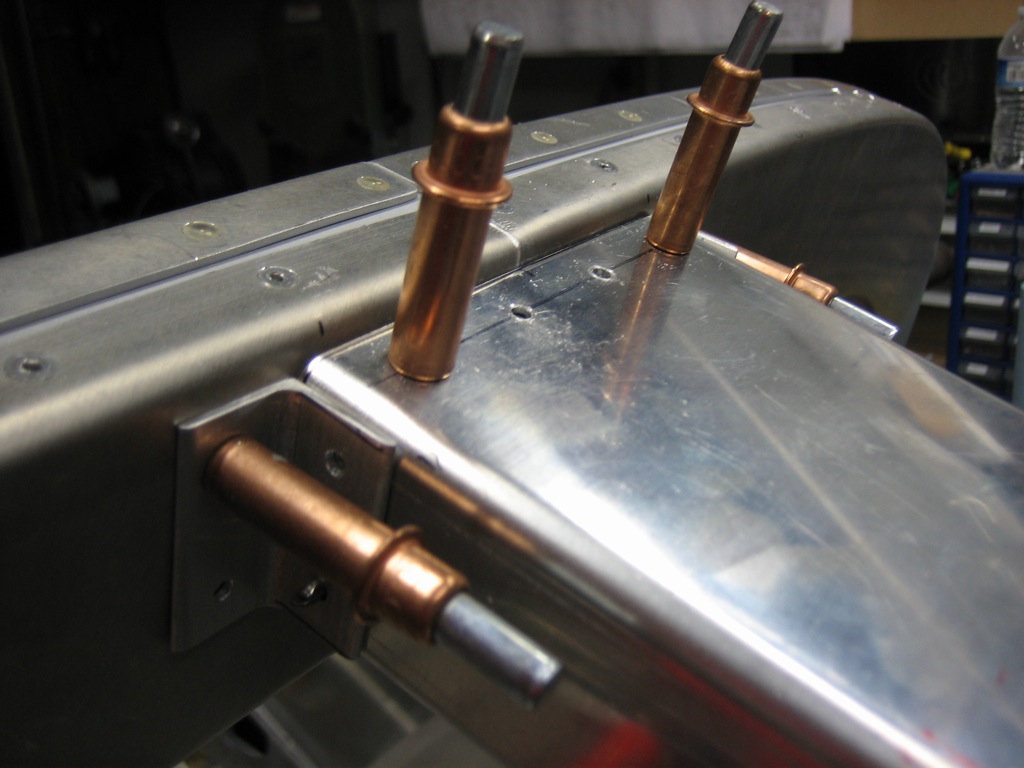

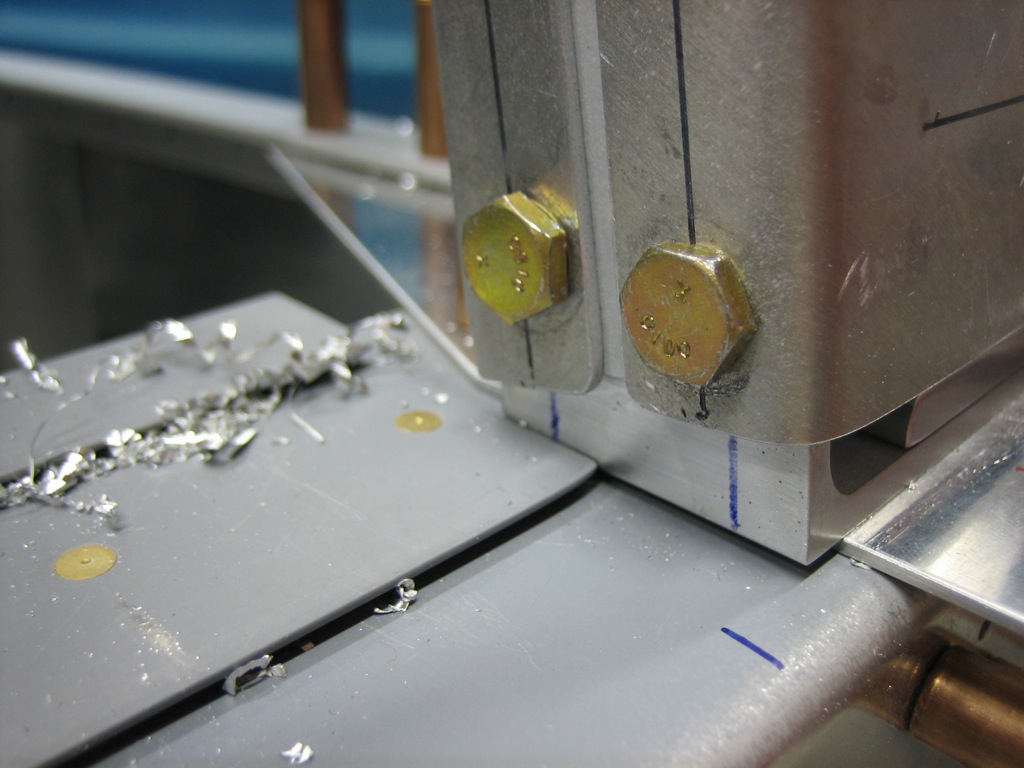

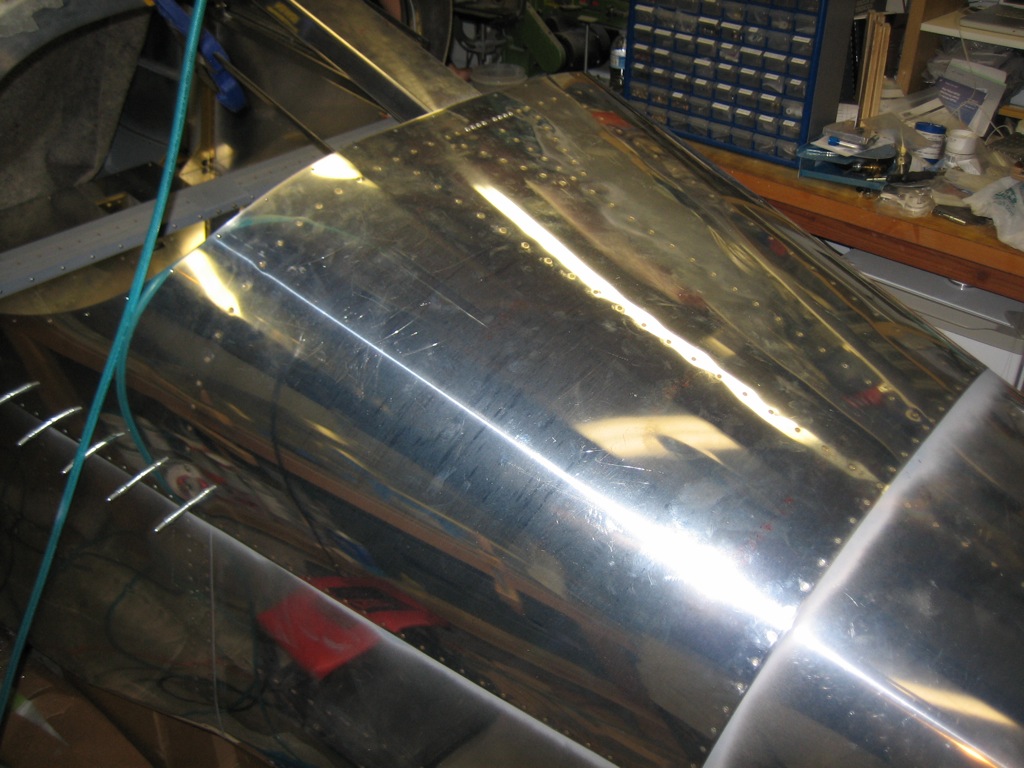

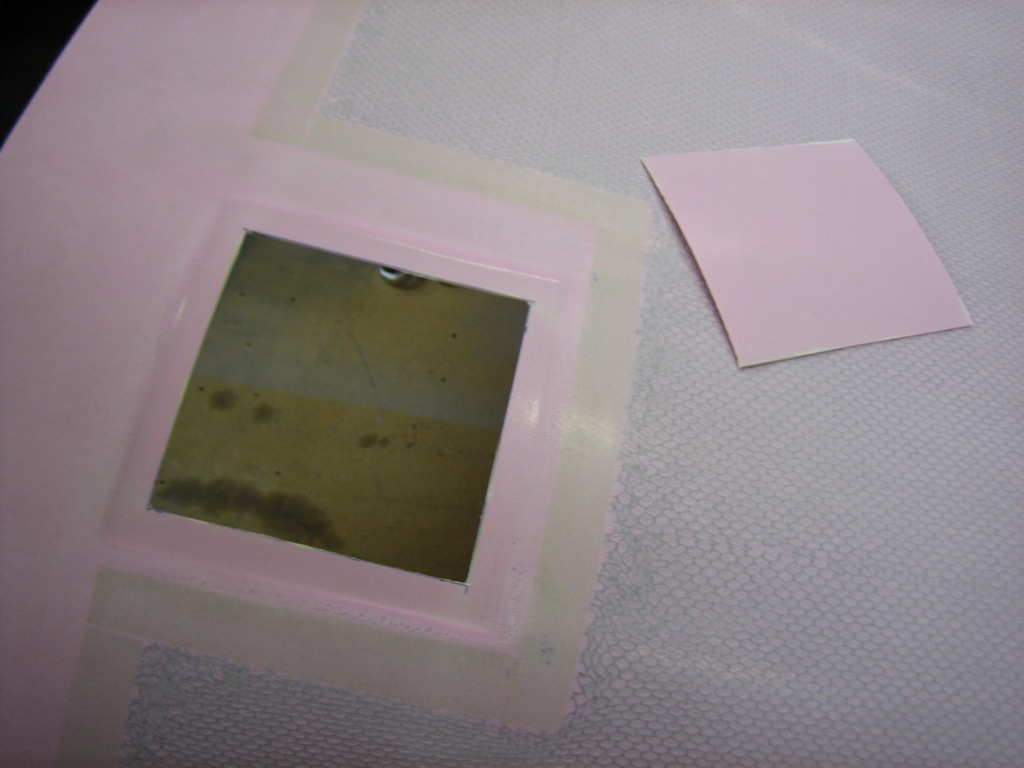

Here you can see how the aft top skin lays flush against the side of the angle.

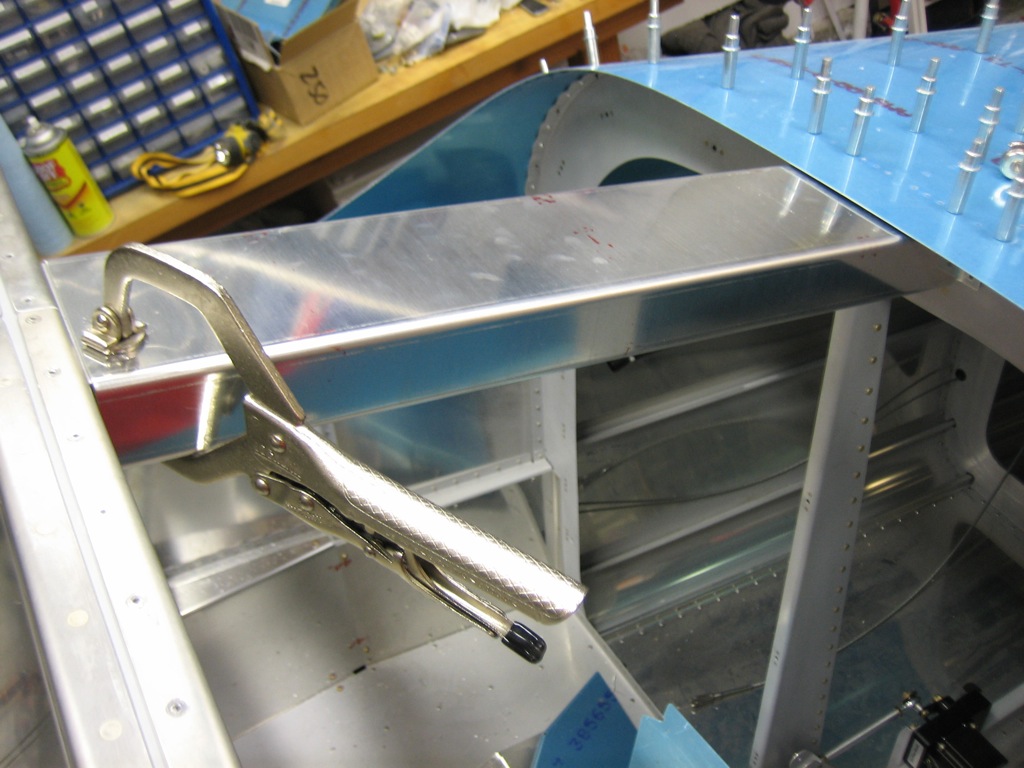

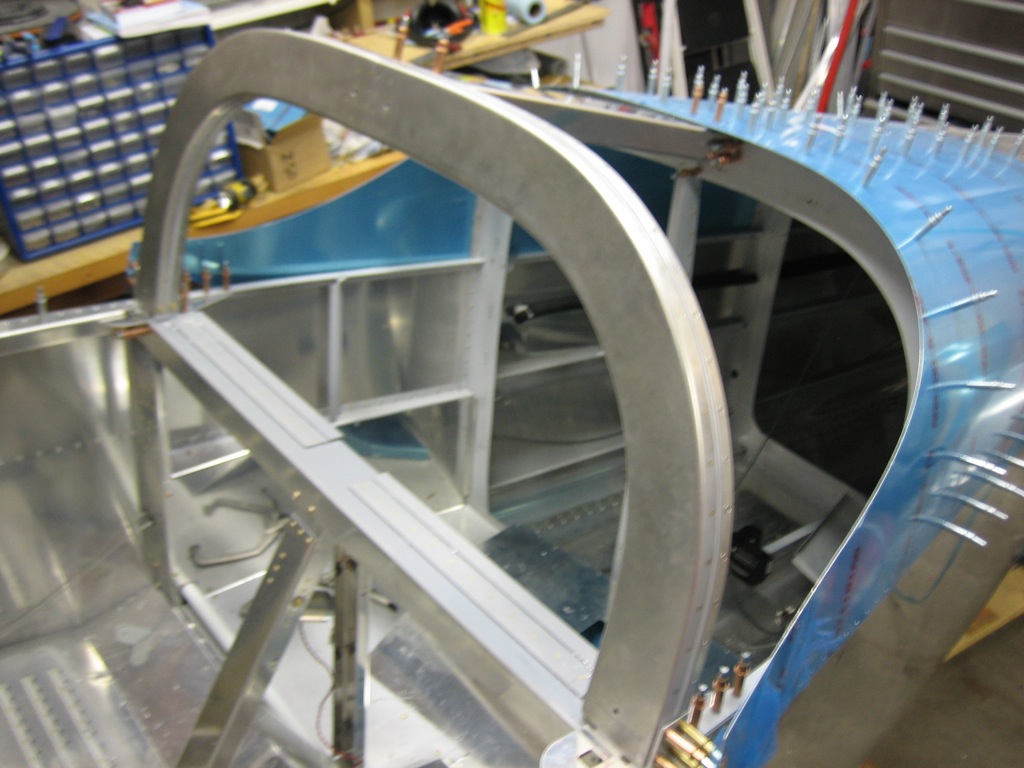

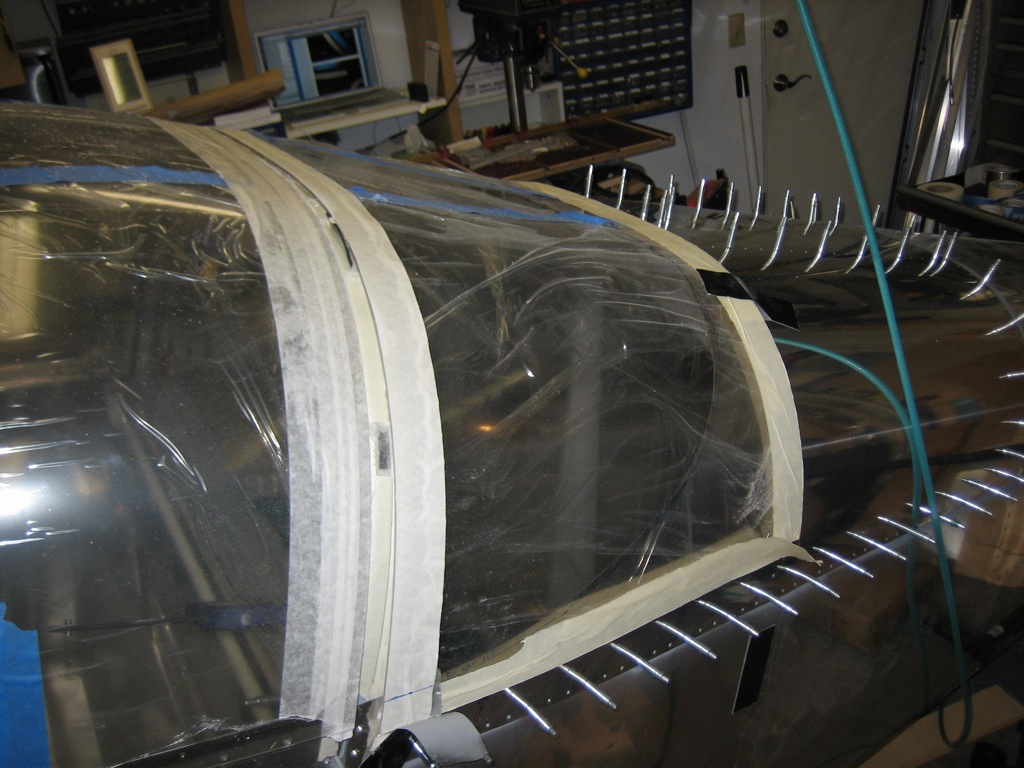

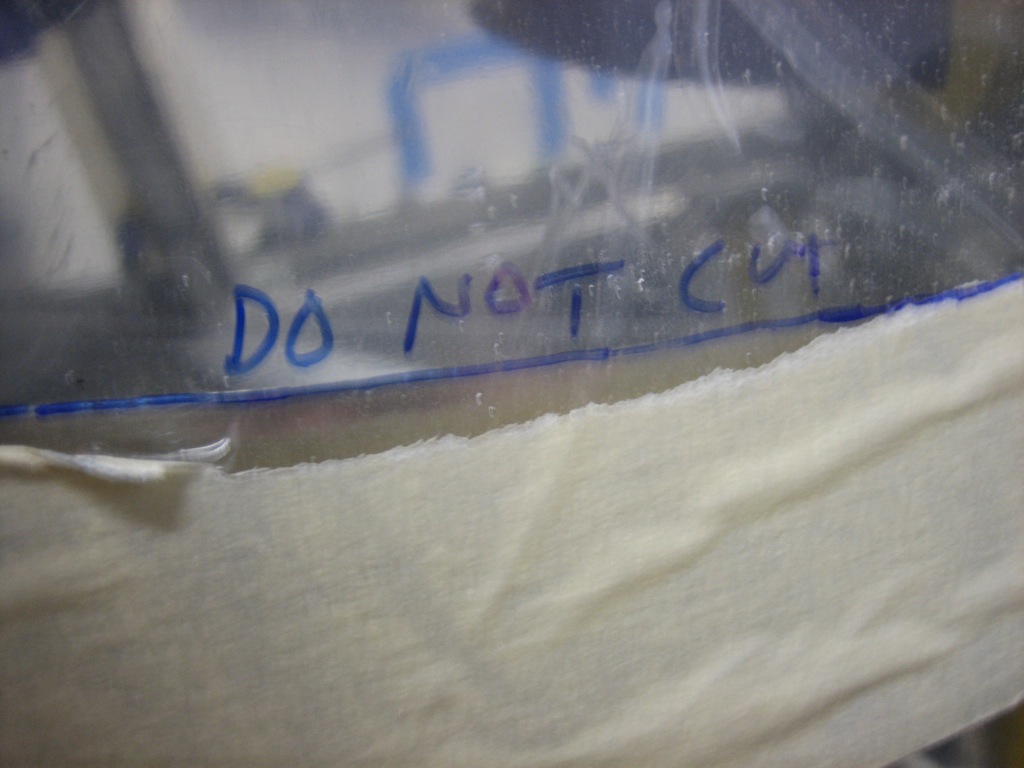

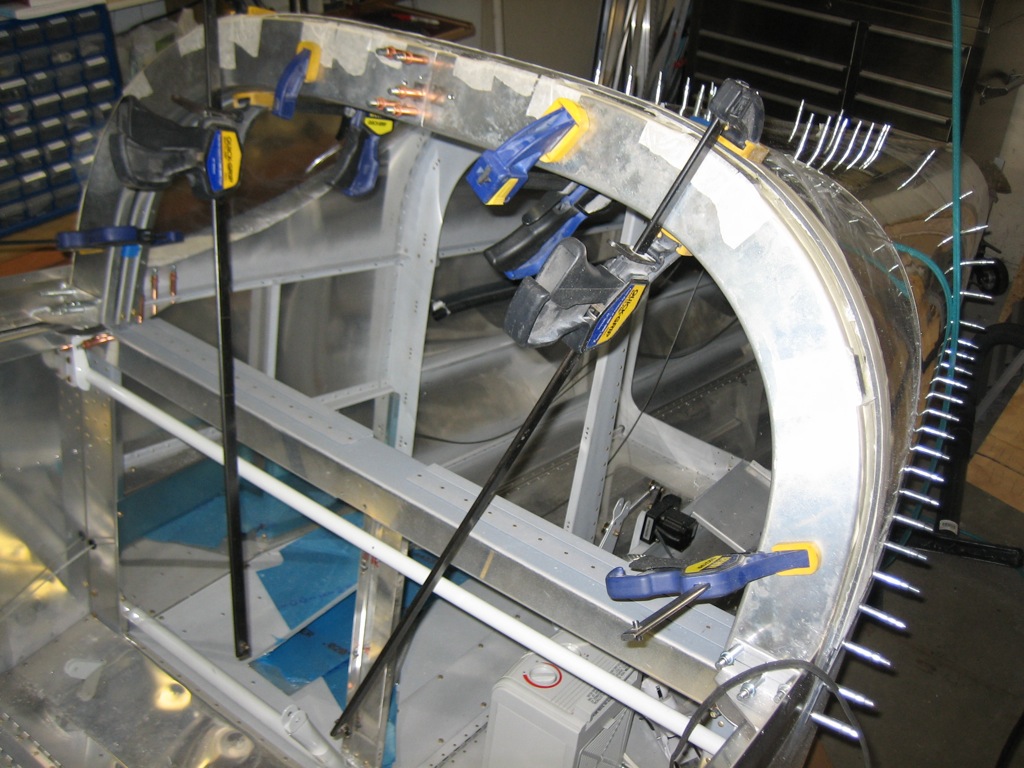

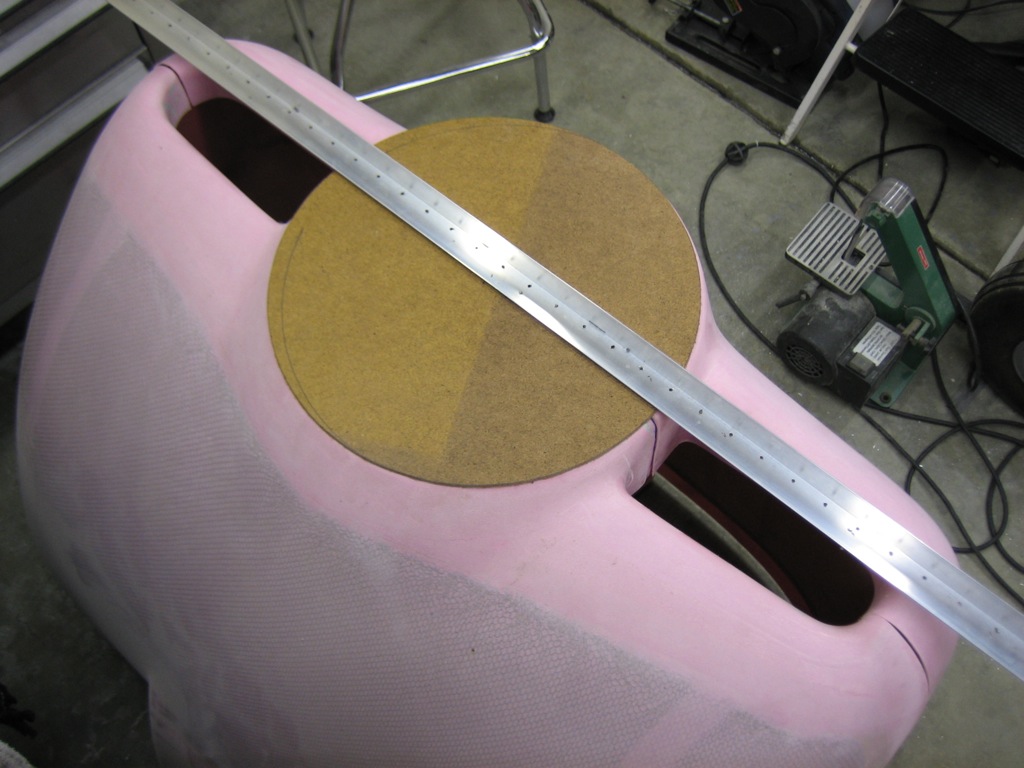

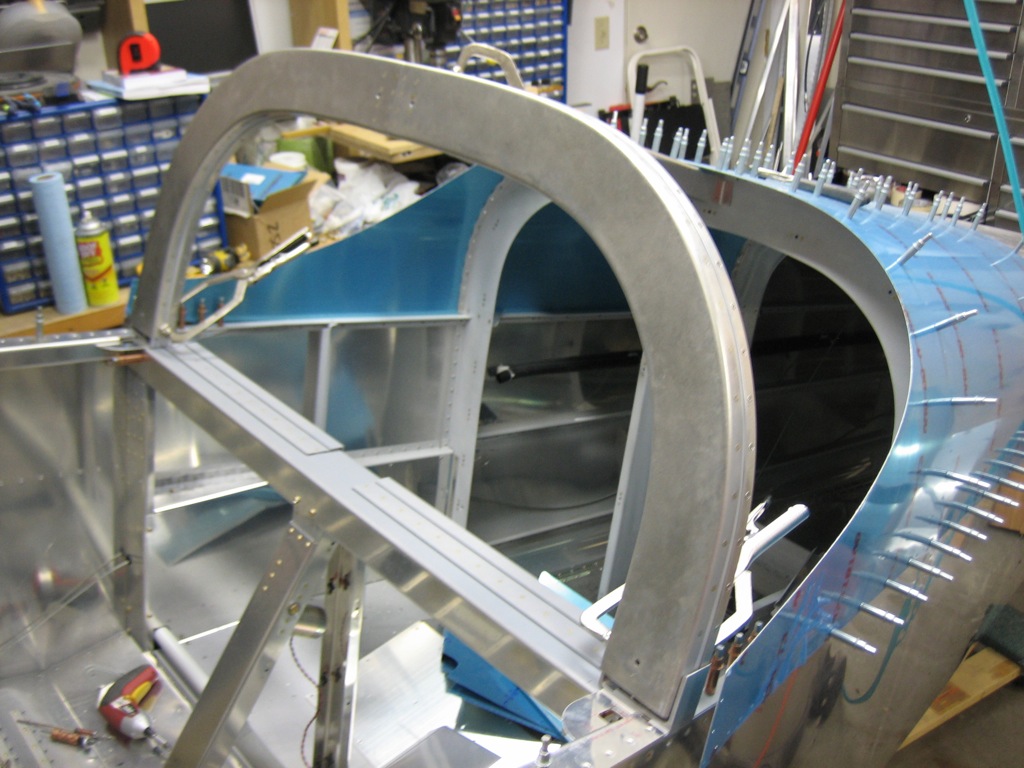

Here’s the cabin frame clamped as low as it can currently go. It’s still about 3/16″ of an inch high right now, but I actually want it to end up a little high so I can get more headroom. One of the engineers at Van’s said the cabin frame could be moved up at least 1/4″ without any problems. I want to double check this before permanently mounting the cabin frame though.

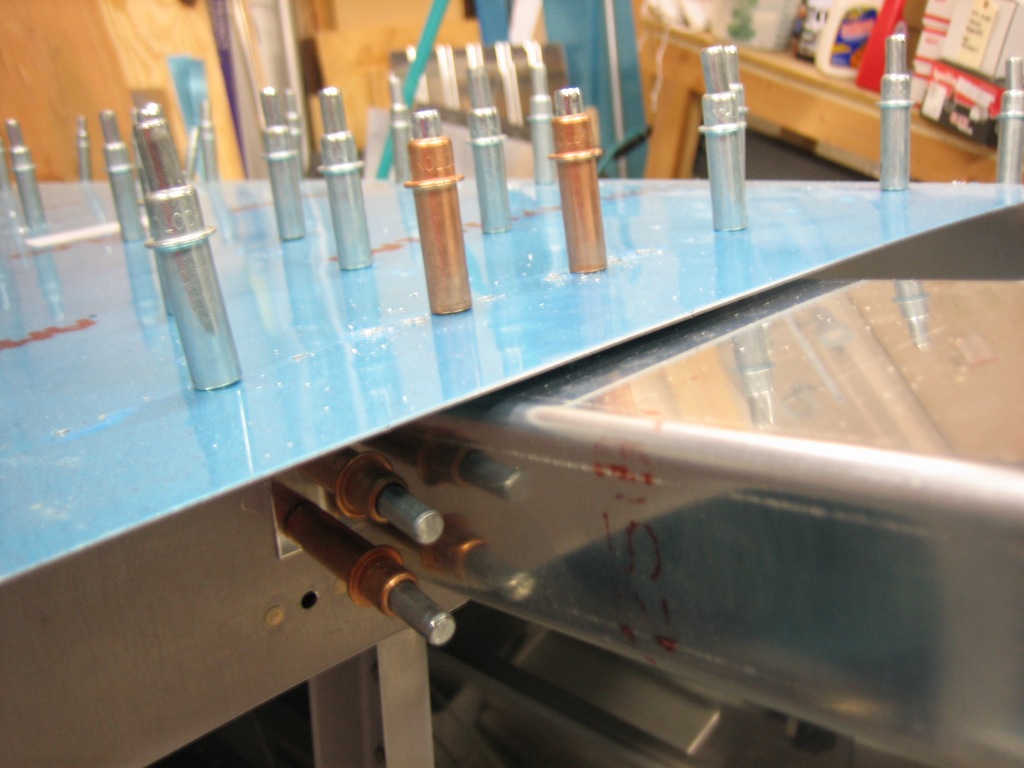

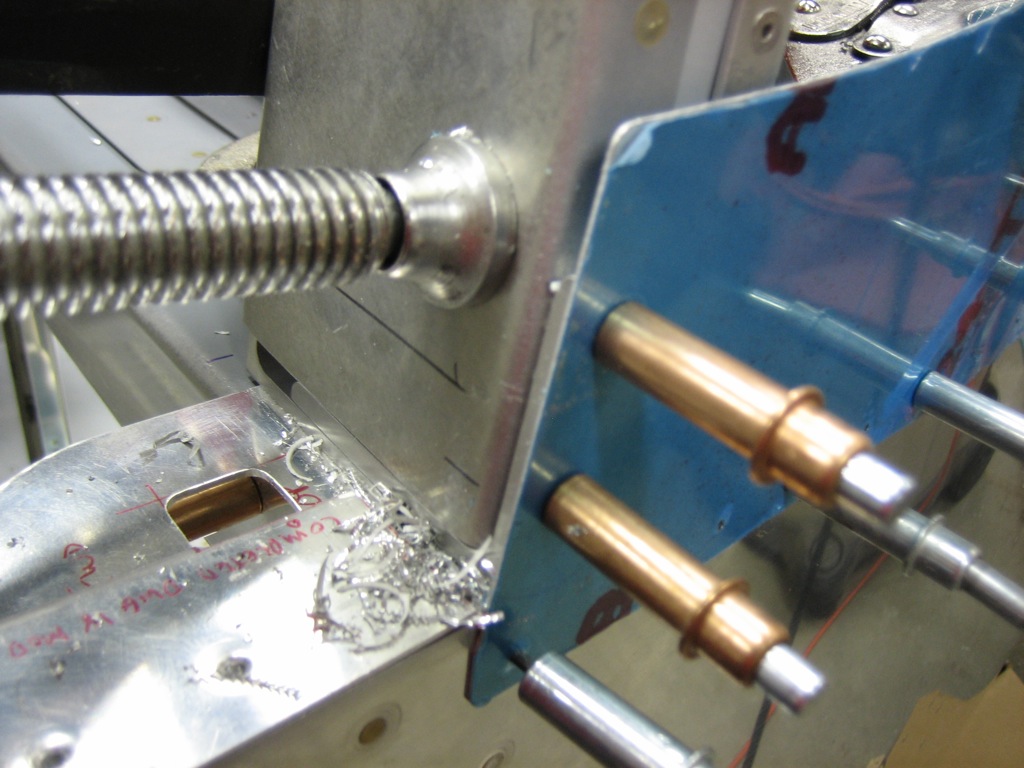

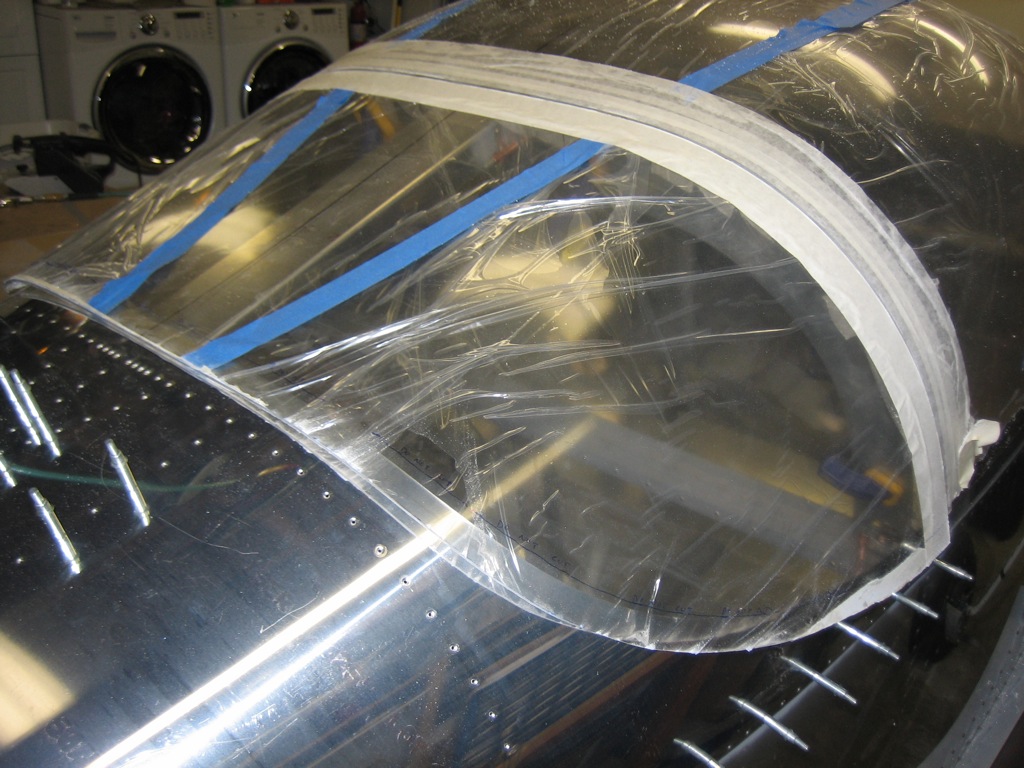

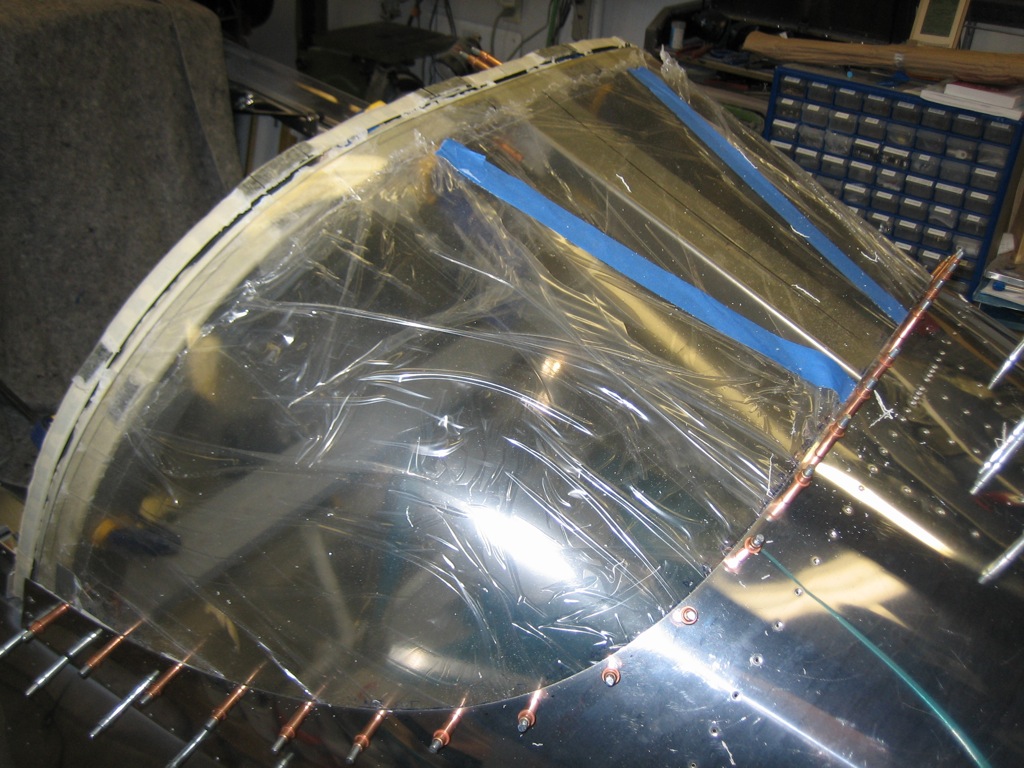

Here you can see that the side skin is perfectly aligned with the cabin frame (both angle and longitudinal position).

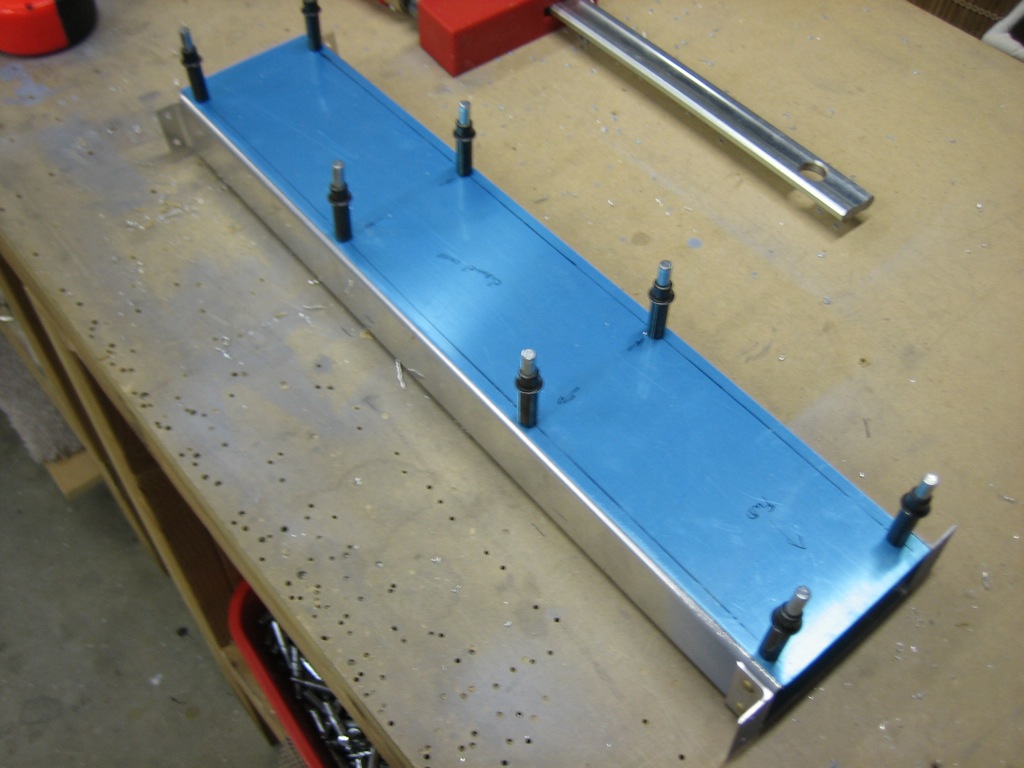

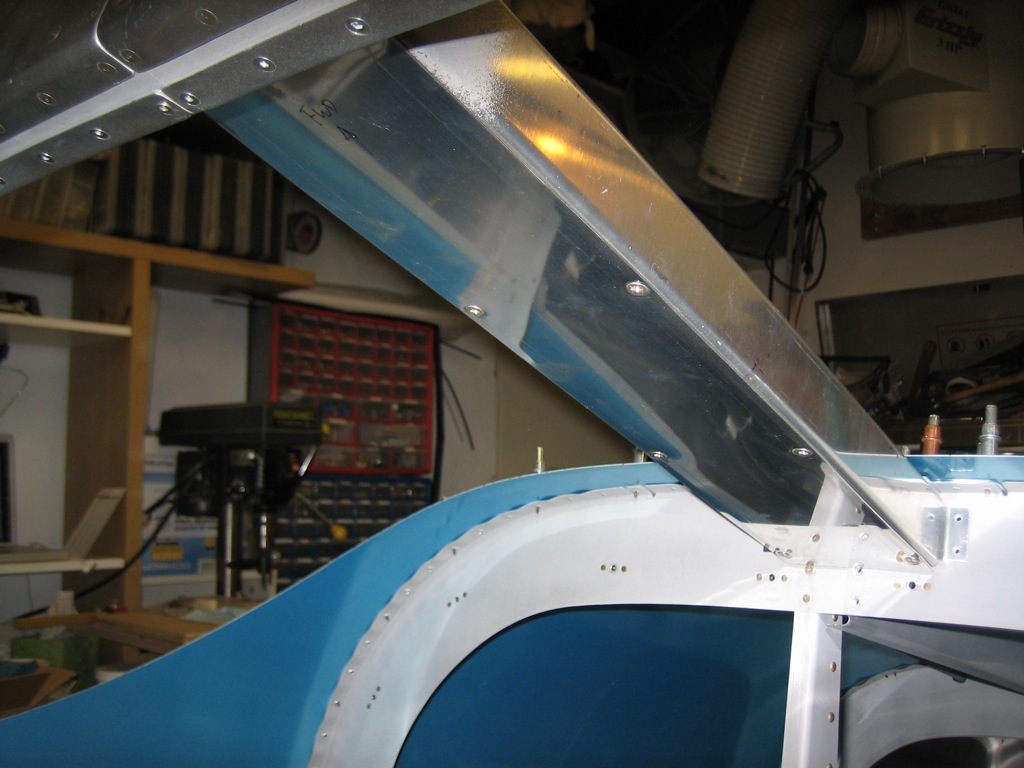

I also installed the cabin frame brace to correctly position the cabin frame. It’s clecoed in the back, but only clamped in the front. I don’t want to drill this until I’m sure of the position.