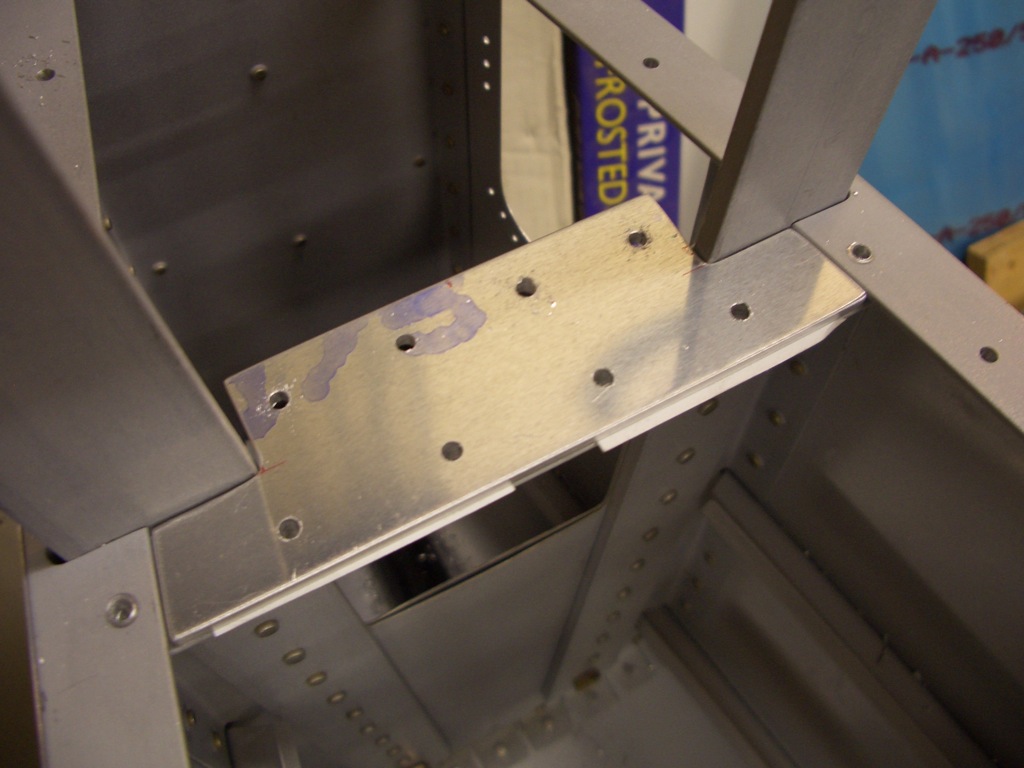

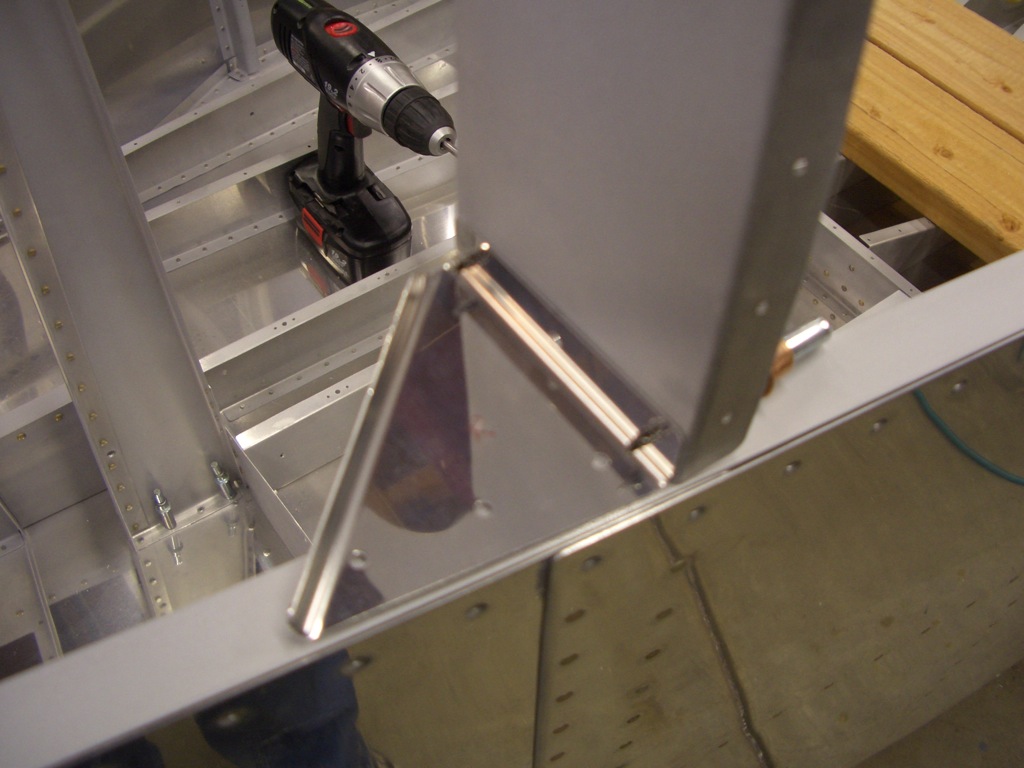

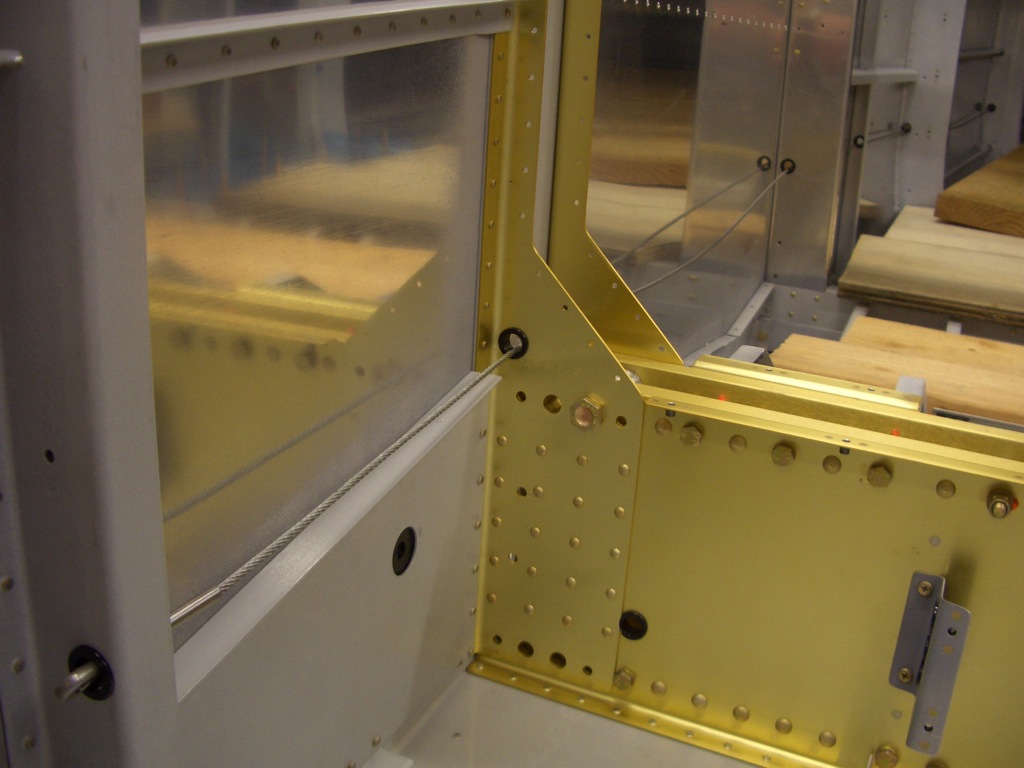

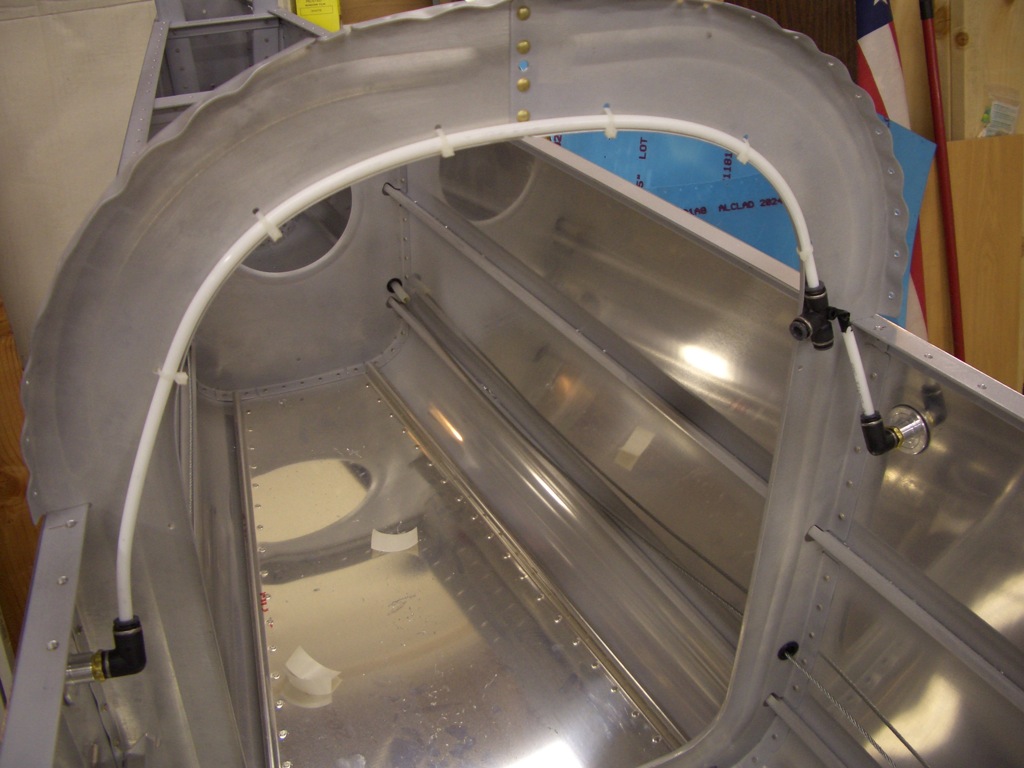

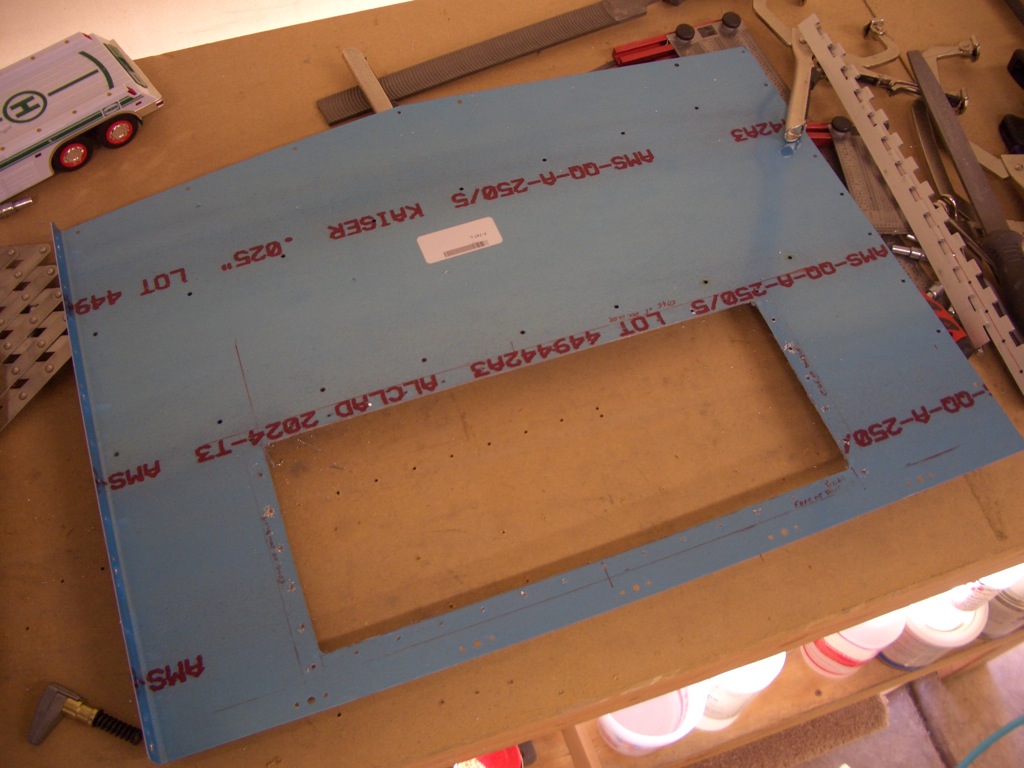

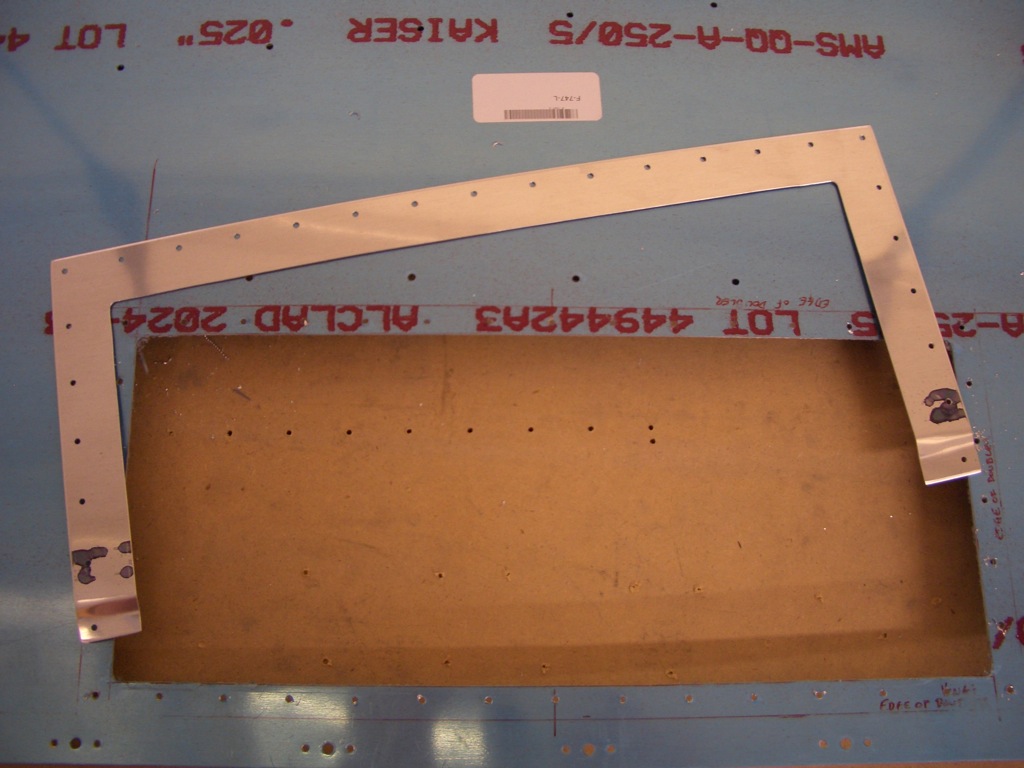

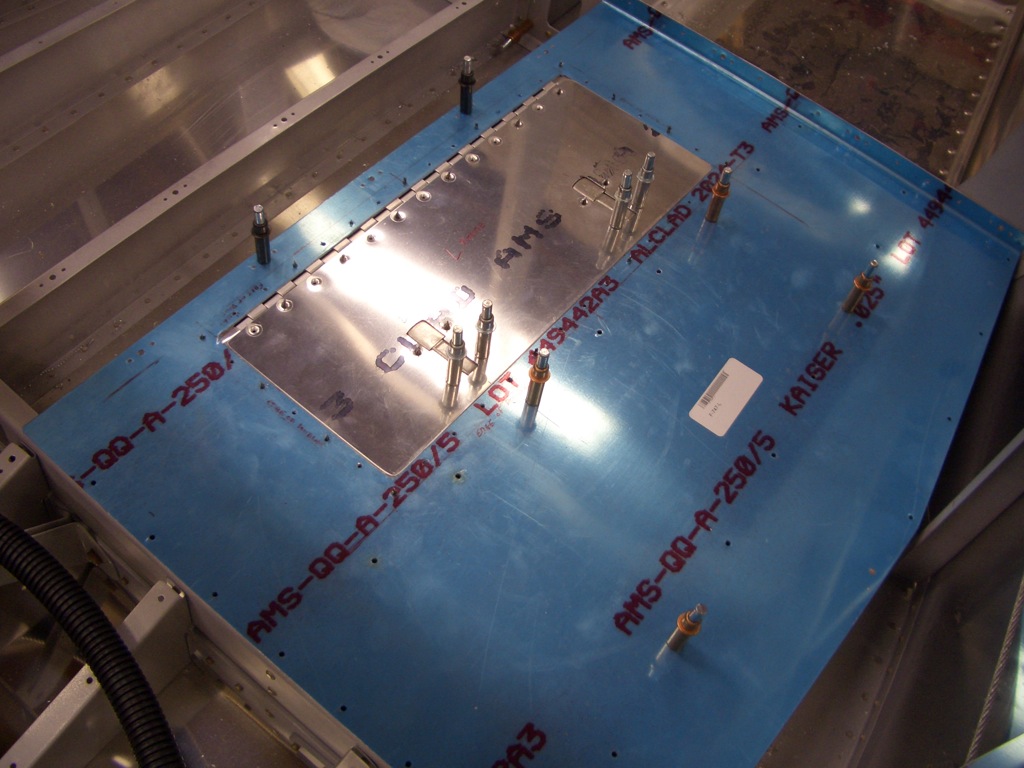

I finished the left F-757 plate and drilled it to the F-705 channel and longeron.

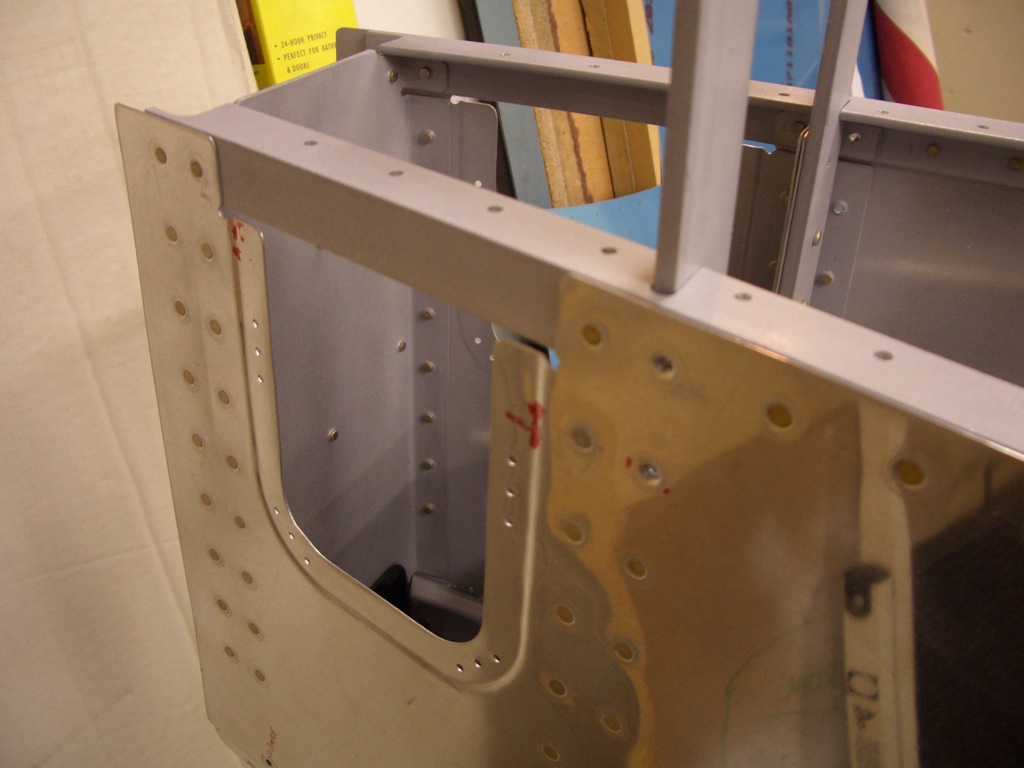

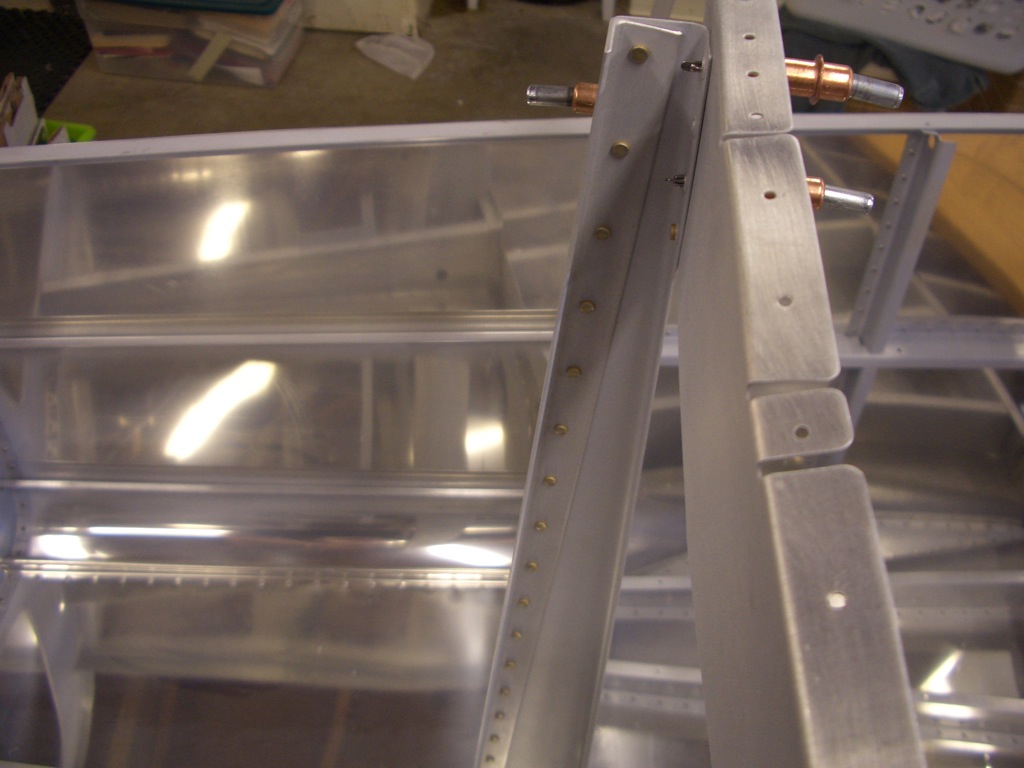

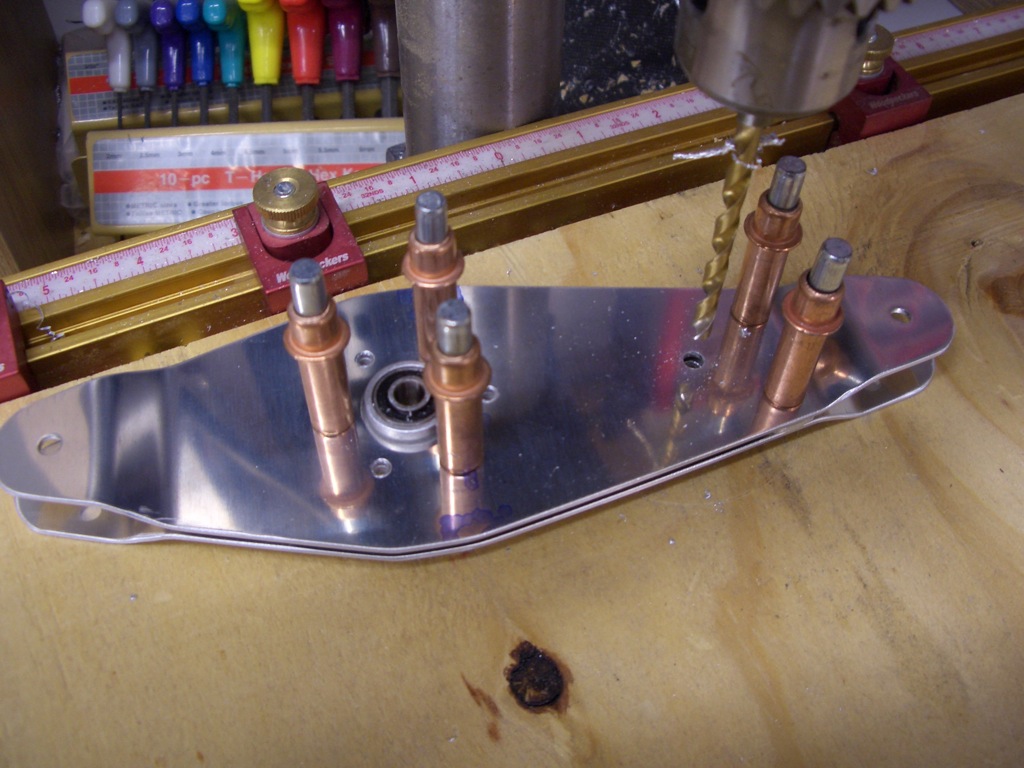

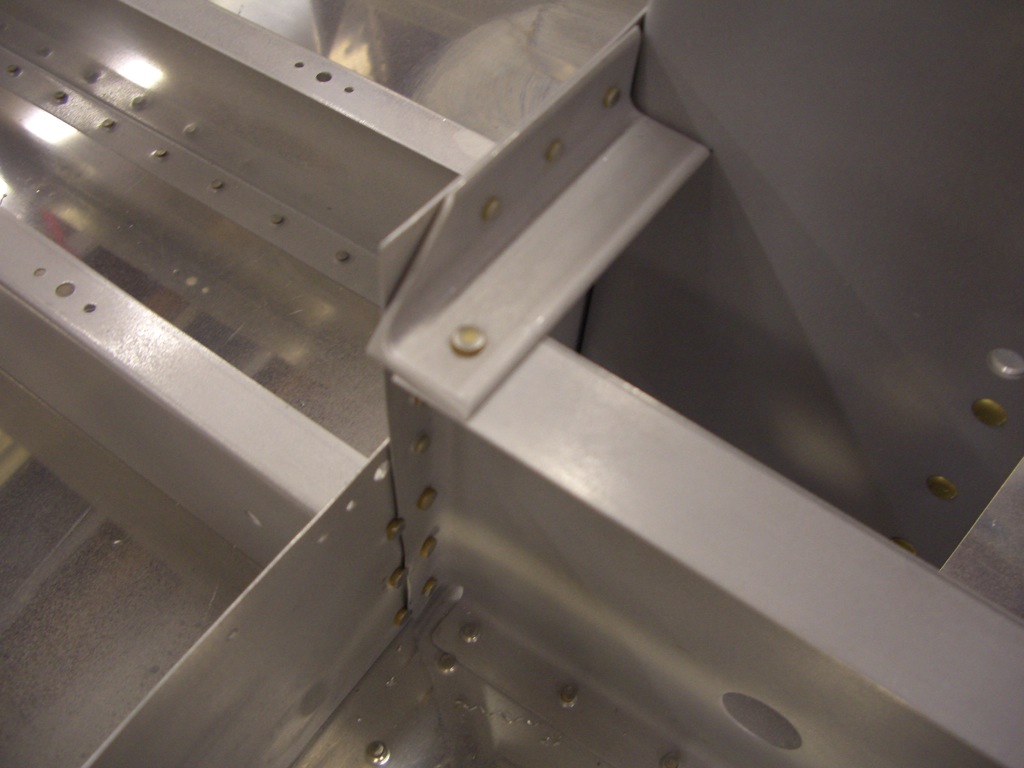

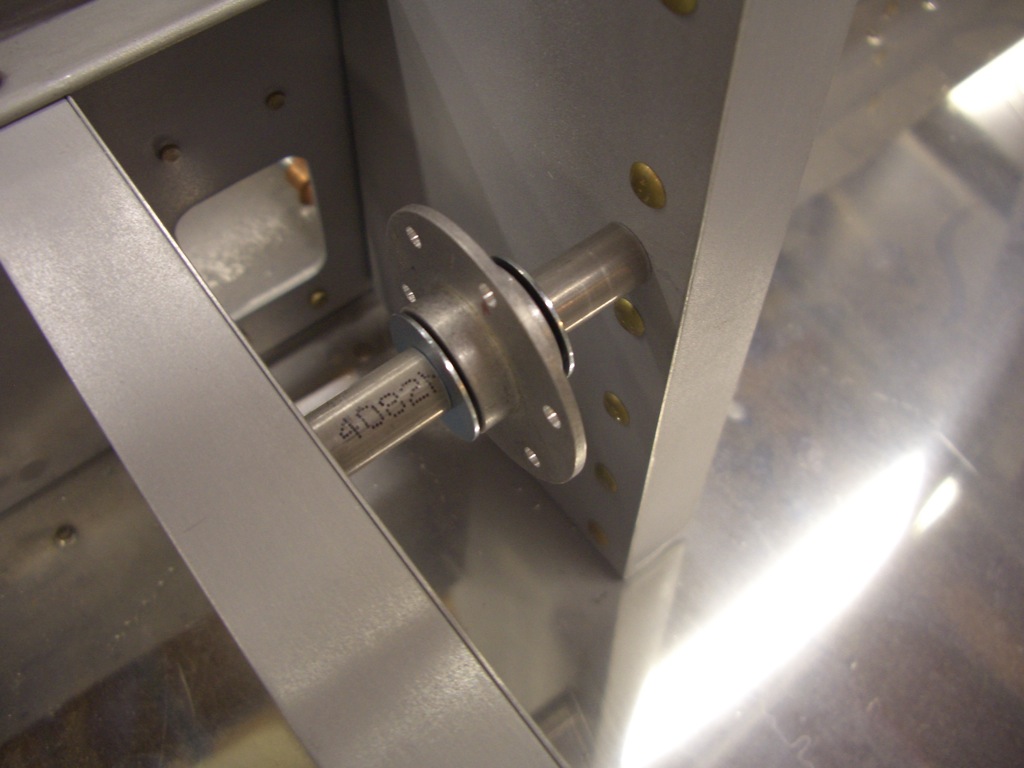

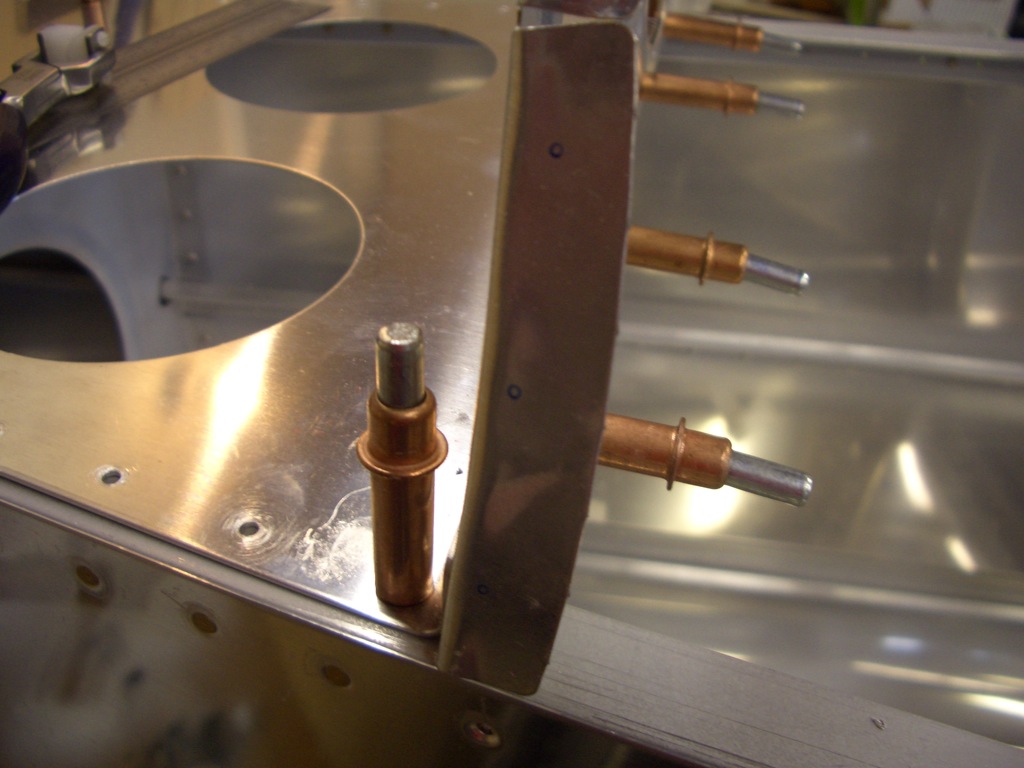

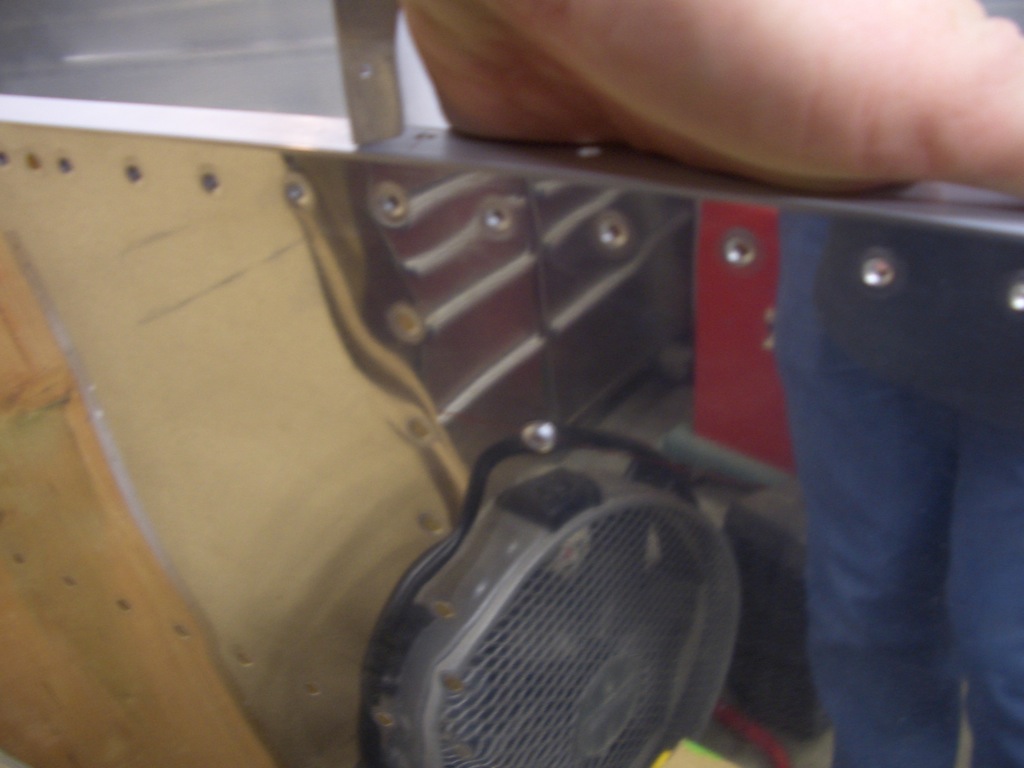

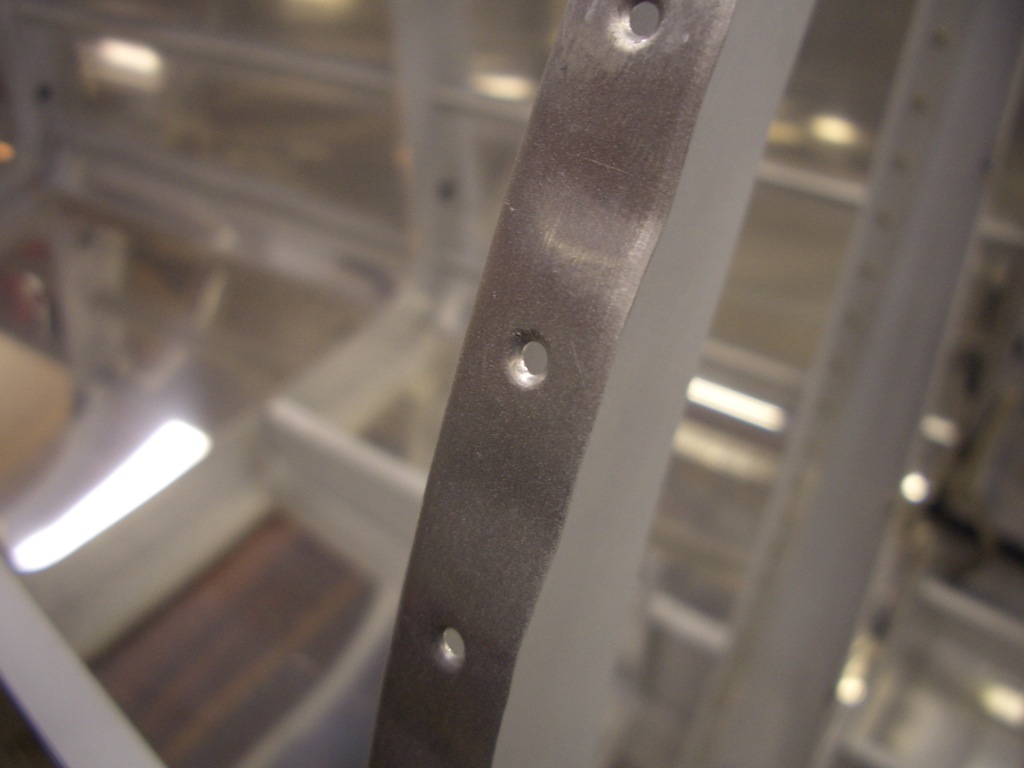

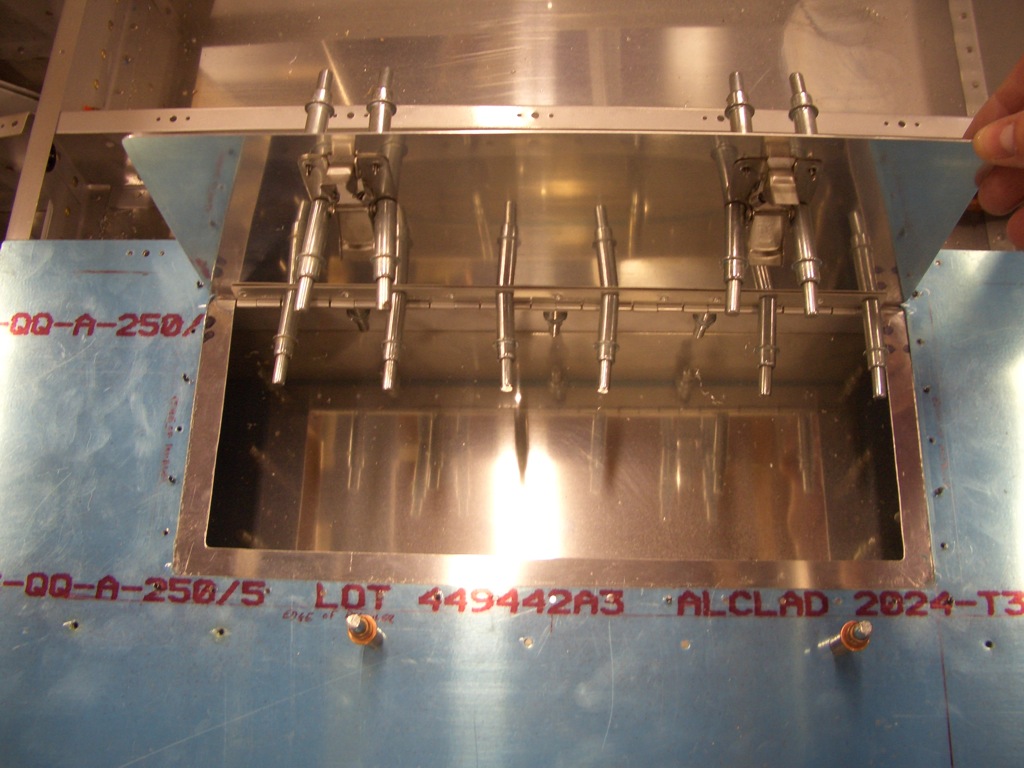

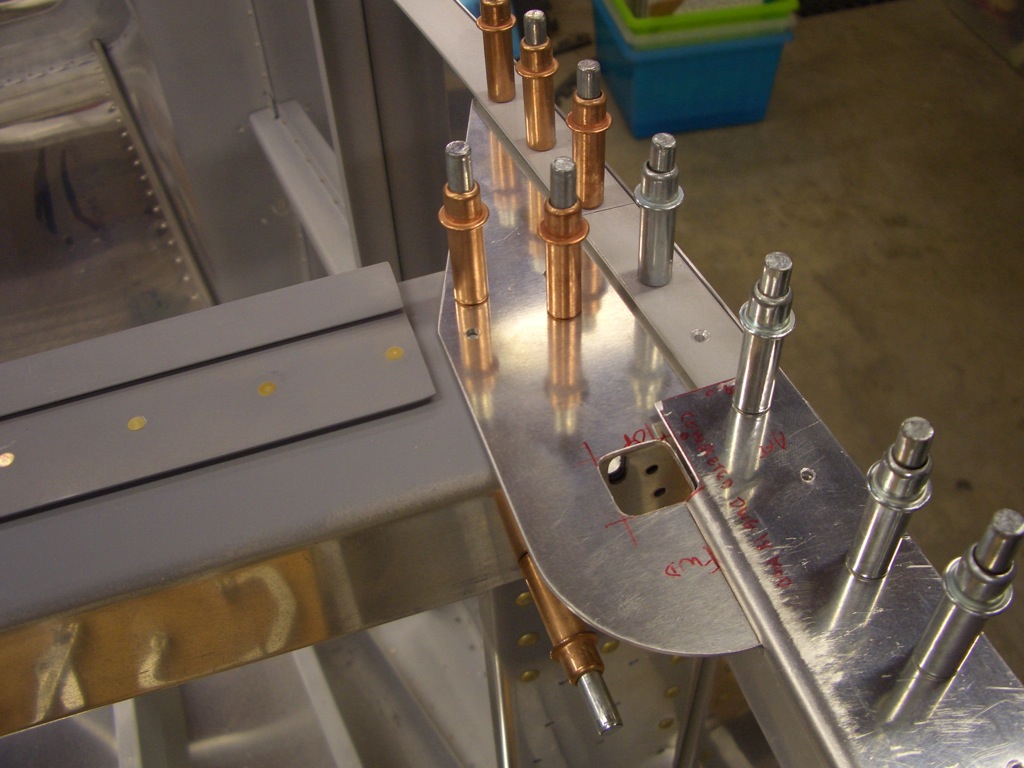

There were two holes in the aft fuselage that I couldn’t dimple earlier because I inadvertently riveted too far up F-711. The vertical bars prevent getting a squeezer aligned with these holes, so I needed to get creative. Since the longeron is already dimpled and thick enough not to flex, I could just use the male portion of the die to form the dimple. Since the vertical bars prevent clamping directly, I used a scrap piece of angle and some clamps to either side to drive the male dimple die flush with the skin. This worked perfectly, and a rivet sits completely flush in the hole.

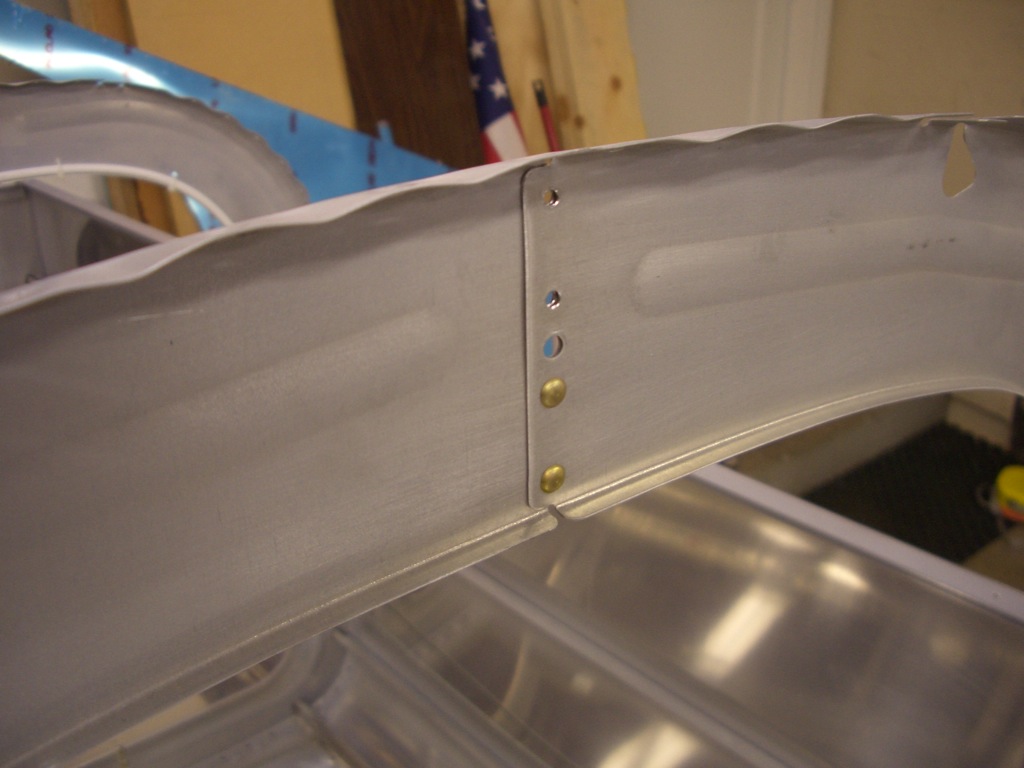

I managed to squeeze all of the remaining holes with the exception of the upper two holes in the forward flange of F-711. I’ll have to shoot these, but it’s too late to run the rivet gun tonight.